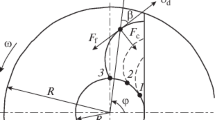

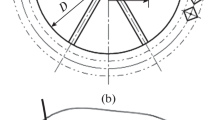

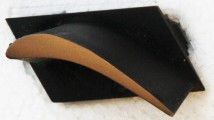

Ways to improve the efficiency with which materials are pulverized in impact centrifugal mills as well as ways of preventing wear of the blades are proposed. The problem is solved using equations that describe the motion of particles on the surface of the rotor in a polar coordinate system. It is discovered that the rate of impact of the particles against a blade increases linearly with increasing angular velocity. The angle of attack and radius of contact of a particle with the blade are independent of this velocity, though they are substantially affected by the initial position of the particles. The nature of the variation of the rate of impact and the angle of attack is determined, based on which possible wear of the blades may be predicted and measures taken to reduce wear.

Similar content being viewed by others

References

I. R. Kleis and Kh. Kh. Uuémyis, Wear Resistance of the Elements of Impact-Type Pulverizers, Mashinostroenie, Moscow (1986).

V. V. Tovarov and G. N. Oskalenko, “Investigation of the flight of particles from the blade rotors of centrifugal pulverizing machines,” in: Proc. Institute Giprotsement, Gosstroiizdat (1962), Iss. XXIV.C, pp. 64–91.

A. V. Tabolich, E. N. Ivanov, and S. N. Bondarenko, “Methods of increasing the wear resistance of the construction of the accelerator of centrifugal percussion mills of NPO Tsentr,” Processing of Mineral Ore. Innovative Technologies and Equipment: Proc. 6th MNTK, Oct. 4–5, 2016, NPO Tsentr, Minsk (2016), pp. 20–22.

P. E. Vaitekhovich, Intensification and Simulation of Processes of Dispersion in a Field of Inertial Forces, Belarus State Technological Univ., Minsk (2008).

P. E. Vaitekhovich, V. S. Frantskevich, and G. M. Khves’ko, “Determination of the most important parameters of centrifugal ball mills,” Khim. Neftegaz. Mashinostr., No. 10, 3–5 (2007).

D. N. Borovskii, P. E. Vaitekhovich, and D. V. Semenenko, “Mathematical simulation of the motion of grinding bodies in the rotor of a vertical centrifugal mill,” in: Tr. Belarus State Technological Univ. Ser. III, Khim. Tekhnol. Neorg. Vesh. (2009), Iss. XVII.C, pp. 163–166.

V. G. Barsukov and B. S. Krupich, Tribomechanics of Dispersed Materials (production applications), Grodno State Univ., Grodno (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 3, pp. 12–15, March, 2018.

Rights and permissions

About this article

Cite this article

Vaitekhovich, P.E., Borovskii, D.N., Grebenchuk, P.S. et al. Determination of the Basic Parameters of Impact Interaction of Abrasive Particles Against the Blades of the Rotor Accelerator of a Centrifugal Mill. Chem Petrol Eng 54, 156–160 (2018). https://doi.org/10.1007/s10556-018-0455-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-018-0455-6