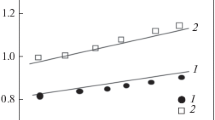

Two- and three-pass film evaporator designs were developed. High performance of the evaporators is achieved through the use of distribution devices. Diagrams were developed for connecting multipass film evaporators to the columns in rectification systems. A model to describe the distribution of the liquid phase in the rising film section of the evaporator tubes was designed, taking into account the differences in the liquid level near the most loaded and the least loaded tubes of this line. The designed model was investigated. In the model, the evaporation of a six-component mixture of rectification column residue from the production of commercial o-xylene was considered. The effect of the liquid level in the lower distribution chamber around the most loaded and least-loaded heat exchanger tubes on the specific flow rate and variability of fluid flow in the tubes with the rising liquid film, the flow resistance of the tubes, and the fraction of evaporated steam was determined.

Similar content being viewed by others

References

M. V. Klykov and G. S. Surkov, “Investigation of a distillation column with integrated heat exchange,” Young People in Science: New Arguments: Coll. Sci. Works from the 2nd Int. Youth Competition (Russia), Sci. Partnership Argument, Lipetsk (2015), pp. 171–179.

M. V. Klykov, T. V. Alushkina, and M. O. Abrosimova, “Thermal dehydration of fuel oil,” Neftegaz. Delo, No. 2, 266–280, UGNTU (USPTU), Ufa (2015).

M. V. Klykov, E. D. Alekseeva, A. V. Abdullin, and M. P. Savkin, “Utilization of oil sludge,” Integration of Science and Education in Oil and Gas-Specialized Universities-2016: Proc. Int. Sci.-Method. Conf. Dedicated to the 60th Anniv. of the UGNTU Branch in Salavat, Izd. UGNTU, Ufa (2016), pp. 382–383.

N. N. Istomin, M. V. Klykov, and E. F. Timergazin, Patent 2178324 RF, IPC2 B 01 D 1/22, “Film evaporator,” Byull., No. 2 (2002).

M. V. Klykov, “Distribution of liquid in film evaporators,” Khim. Tekhnol., No. 1 (163), 67–72 (1989).

V. N. Sokolov and I. V. Domanskii, Gas-Liquid Reactors, Mashinostroenie, Leningrad (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 9, pp. 13–16, September, 2017.

Rights and permissions

About this article

Cite this article

Klykov, M.V., Alushkina, T.V. Modeling of Liquid Distribution in Multipass Rising Film Evaporators. Chem Petrol Eng 53, 576–583 (2018). https://doi.org/10.1007/s10556-018-0384-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-018-0384-4