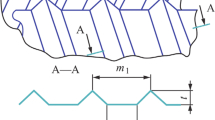

Results are presented for study and analysis of column equipment structure, loaded with MICHM-X mini ring packing. It is shown that the packing exhibits self-orientation properties during loading mini ring packing elements into the equipment. Predominantly horizontal orientation of mini ring packing elements within column equipment provides an almost homogeneous layup structure. A two-zone structure is proposed for model column equipment with random packing that may be used for predicting the hydrodynamic situation in column equipment. Appropriate calculation relationships are provided.

Similar content being viewed by others

References

R. Billet, Packed Towers in Processing and Environmental Technology, VCH, N.Y. (1995).

A. G. Laptev (ed.), M. I. Farakhov, M. M. Basharov, et al., Energy and Resource-Saving Technology and Equipment for Liquid Cleaning in Petrochemistry and Power Generation, Otechestvo, Kazan (2012).

A. Pushnov and A. Kagan, Structure and Gas Distribution in Column Equipment with Packing, LAPLAMBERT Academic Publishing GmbH & Co. KG, Saarbrücken (2012).

A. M. Kagan, K. V. Chizh, A. S. Pushkov, et al., “Mini ring packing aerodynamics,” Energosber. Vodopodg., No. 6(68), 42–45 (2010).

W. Fei, L. Sun, and Q. Guo, “Studies on a new packing-plum flower mini ring,” Chin. J. Chem. Eng., 10 No. 6, 631–634 (2002).

B. A. Sokol, A. K. Chernyshev, D. A. Baranov (ed.), et al., Mass Transfer Column Packing, Infokhim, Moscow (2009).

A. S. Pushnov and K. V. Chizh, “Geometric properties of mini ring packing for accomplishing heat- and mass-transfer processes,” Khim. Tekhnika, No. 7, 12–13 (2010).

A. S. Pushnov, K. V. Chizh, and M. G. Berengarten, “x-Radiographic study of bulk packing layer structure bounded by a cylindrical surface,” Poverkhn. Rentgen. Sinkhrotr. Neur. Issled., No. 11, 1–5 (2013).

M. Salehi and A. Salem, “Influence of sintering temperature on microstructural changes of ceramic Raschig ring,” Korean J. Chem. Eng., 26, No. 2, 500–505 (2009).

O. Florea and O. Smigel’skii, Calculations for Chemical Technology Processes and Equipment [Russian translation], Khimiya, Moscow (1971).

A. S. Pushnov, E. N. Petrashova, and M. G. Lagutkin, Patent 2440843 RF, IPC BO1J 19/32, “New regular ring packing layup,” No. 2010108213/05, subm. 03.09.2010, publ. 01.27.2012.

A. S. Pushnov, A. N. Filippov, Yu. A. Goz, and E. Yu. Baranova, “Liquid flow in column equipment with bulk packing,” Khim. Prom., 89, No. 2, 90–96 (2012).

G. Sonntag, “Einfluss des Lückenvolümen auf den Druckverlust in gasdurchdtrömen Füllkörpersäule,” Chem.-Ingen.-Techn., 32, No. 5, 317–319 (1960).

M. E. Aerov, O. M. Todes, and D. A. Narinskii, Equipment with Stationary Granular Layer. Hydraulic and Thermal Bases of Operation, Khimiya, Leningrad (1979).

Yu. B. Naumov, I. I. Felperin, A. S. Pushnov, et al., “Two-zone model of equipment with stationary granular layer,” Khim. Prom., No. 8, 463–465 (1986).

S. O. Ryzhov, Intensification of Carbon Dioxide Desorption from Aqueous Solutions on Highly Effective Regular Packing: Auth. Abstr. Diss. Cand. Techn. Sci., TPU, Tomsk (2013).

A. Pushnov, E. Mitrofanova, and E. Baranova, Hydrodynamics of Mini Ring Packing, Lithuanian District Heating Association, Kaunas (2013), pp. 52–54.

K. V. Chizh, O. L. Sofronova, A. S. Pushnov, and E. Yu. Baranova, “Layer method of charging packing in column equipment,” Khim. Prom., 88, No. 3, 154–158 (2011).

A. G. Laptev, N. A. Nikolaev, and M. M. Basharov, Methods for Intensifying and Modeling Heat Exchange Processes: Textbook, Teplotekhnik, Moscow (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 4, pp. 23–26, April, 2014.

Rights and permissions

About this article

Cite this article

Chizh, K.V., Pushnov, A.S. & Berengarten, M.G. Structure of Mini Ring Packing Layup in Column Equipment. Chem Petrol Eng 50, 244–250 (2014). https://doi.org/10.1007/s10556-014-9889-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-014-9889-7