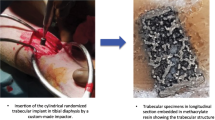

Diaphyseal defects of canine tibia bones were replaced with bioactive cylindrical mesh implants made of Ti–6Al–4V titanium alloy. Bone−implant units were cut with a precision cutter using abrasive cutting discs (thickness, 0.76 mm; rotational speed, 2000 rpm; feed rate, 12 mm/min for sample 1 and 5 mm/min for samples 2–4). Tissues were found to suffer thermal damage at a disc feed rate of 12 mm/min; 72.6% of tissues in the projection of the defect cavity were found to be unsuitable for histological examination. At a feed rate of 5 mm/min, thermal damage or significant mechanical damage to the tissues was not observed. Thus, at the stage of preparation of samples of titanium–containing bone−implant units for the assessment of osseointegration, the degree of tissue preservation, under otherwise identical conditions, depends on the cutting tool feed rate.

Similar content being viewed by others

References

Kotel’nikov, G. P., Kolsanov, A. V., Nikolaenko, A. N., Volova, L. T., Rossinskaya, V. V., Boltovskaya, V. V., Popov, N. V., Shcherbovskikh, A. E., and Prikhodko, S .A., “Testing additive materials on human fibroblast cell cultures,” Klin. Eksp. Khir. Zh. Akad. Petrovsk., 6, No. 2, 67–73 (2018).

Vishnevskiy, A. A., Kazbanov, V. V., and Batalov, M. S., “Prospects for the use of titanium implants with desired osteogenic properties,” Khir. Pozv., 13, No. 1, 50–58 (2016).

Koshuro, V. A., Fomina, M. A., Rodionov, I. V., and Fomin, A. A., “Nanoporous structure of coatings formed by thermal spraying of aluminum oxide with further microarc oxidation on titanium alloy VT6 implants,” Biomed. Eng., 50, No. 1, 54–57 (2016).

Kononovich, N. A., Popkov, A. V., Popkov, D. A., and Shastov, A. L., “X–Ray dynamics of bone formation during the replacement of diaphyseal defects of the leg bones with a bioactive cellular implant,” Uch. Zap. Kazan. Gos. Akad. Vet. Med. Baumana, 236, No. 4, 105–111 (2018).

Vasilyuk, V. P., Straube, G. I., and Chetvertnykh, V. A., “Optimization of surgical treatment of partial and complete defects of the jaw using cellular structures from titanium in the experiment,” Sovr. Probl. Nauki Obr., No. 3, 24 (2017).

Popkov, A. V., Popkov, D. A., Tverdokhlebov, S. I., and Kononovich, N. A., Cellular Cylindrical Bioactive Implant for Replacing Circular Defects of Tubular Bones, RF Patent No. 171823 (patent owner: Federal State Budgetary Institution “Russian Ilizarov Scientific Center ‘Restorative Traumatology and Orthopaedics’”, Ministry of Health of the Russian Federation) (2017).

Li, X., Zhu, W., Wang, J., and Deng, Y., “Optimization of bone drilling process based on finite element analysis,” Appl. Therm. Eng., 108, 211–220 (2016).

Hsiung, J. C., Kung, H. K., and Chen, H. S., “Application of cryogenic treatment to enhance the property of a bone saw blade,” Life Sci. J., 11, No. 10, 1160–1165 (2014).

Lee Ju Eun, Chavez, C. L., and Park, J., “Parameters affecting mechanical and thermal responses in bone drilling: A review,” J. Biomech., 71, No. 11, 4–21 (2018).

Wallace, R. J., Spadaccino, A., Leung, A., Pan, Z., Ganilova, O., Muir, A., Lucas, M., and Simpson, A. H. R. W., “A comparison of past, present and future bone surgery tools,” Int. J. Orthopaed., 2, No. 3, 266–269 (2015).

Malanin, A. D., Zhulikov, A. L., and Novochadov, V. V., “Morphological characteristics of regenerates after cold–plasma treatment of experimental non–full–layer lesions of hyaline cartilage,” Vestn. VolGU, Ser. 11, No. 2, 8–15 (2011).

Celarek, A., Kraus, T., Tschegg, E. K., Fischerauer, S. F., Stanzl–Tschegg, S., Uggowitzer, P. J., and Weinberg, A. M., “PHB, crystalline and amorphous magnesium alloys: Promising candidates for bioresorbable osteosynthesis implants?” Mater. Sci. Eng. C. Mater. Biol. Appl., 32, No. 6, 1503–1510 (2012).

Eshet, Y., Mann, R. R., Anaton, A., Yacoby, T., Gefen, A., and Jerby, E., “Microwave drilling of bones,” IEEE Trans. Biomed. Eng., 53, No. 6, 1174–1182 (2006).

Augustin, G., Davila, S., Udilljak, T., Staroveski, T., Brezak, D., and Babic, S., “Temperature changes during cortical bone drilling with a newly designed step drill and an internally cooled drill,” Int. Orthopaed., 36, No. 7, 1449–1456 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Meditsinskaya Tekhnika, Vol. 54, No. 2, Mar. –Apr., 2020, pp. 31–33.

Rights and permissions

About this article

Cite this article

Kononovich, N.A., Litvinov, Y.Y., Gorbach, E.N. et al. A Method for Preparation of Samples of Titanium–Containing Bone–Implant Units for Assessing Osseointegration. Biomed Eng 54, 121–124 (2020). https://doi.org/10.1007/s10527-020-09987-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10527-020-09987-1