Abstract

Dissolved oxygen (DO) concentration in water is one of the most important water quality parameters in rivers, lakes, and reservoirs. The most effective way to increase DO concentration in water is aeration. Conduits with high aeration performance are predicted to significantly increase aeration efficiency. Based on this prediction, the physical parameters affecting the aeration efficiency (E20) of the conduit aeration system were experimentally investigated. The effect of different jet plunge angles, flow rates, hydrostatic levels, Froude numbers, and gate opening rates was investigated to optimize the system for the best ventilation efficiency. As a result, the aeration efficiency (E20) improves with increasing air intake performance at low gate openings, high Froude numbers, and hydrostatic levels. The increase in jet plunge angles and hydrostatic level directly increases the aeration efficiency. The study showed that conduit systems can be an important alternative for pond aeration due to initial investment and operating costs, low energy cost, and high aeration efficiency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Global warming, the increasing scarcity of the world’s population, and the rapid depletion of food and water resources are among the primary concerns of humanity. Alongside global warming, the diminishing and disappearance of freshwater sources, the decrease in biodiversity in terrestrial and marine ecosystems, and the disruption of the food chain balance have become inevitable. In recent years, the adverse effects of global warming have been particularly observed in water resources and their quality. DO concentration in water is one of the most important water quality parameters in rivers, lakes, and reservoirs.

A few industries that rely on DO concentration as a crucial indication of water quality are aquaculture, food production, environmental monitoring, and industrial production (Wei et al. 2019). The unit of measurement for DO in water is usually milligrams per liter or mg/L. A 5–6 mg/L is the recommended DO level for high-quality water. When the DO level is less than 2 mg/L, the quality of the water declines and is not ideal (Wanja et al. 2020). The decrease or depletion of dissolved oxygen concentration in water can occur due to various factors, such as nutrient pollution from agricultural runoff, temperature changes, and increased biological oxygen demand (BOD) from organic matter. These conditions cause reversible or irreversible metabolic damage in fish, resulting in mass fish deaths and significant financial losses in aquaculture systems. Even if the stress caused by hypoxic waters is tolerated by the fish, the rate of feed intake and utilization decreases, limiting growth and development (Tuna Kelestemur 2012a, b; Qayyum et al. 2005). DO is one of the most important parameters controlling fish growth and survival and is the primary limiting factor. It has been proven that emergency aeration is the best technique to prevent fish deaths during dissolved oxygen crises (Subha et al. 2021).

To maintain ecological balance, the necessary DO concentration must be ensured in rivers. The only way to increase oxygen levels in water sources is through aeration, either by natural or artificial methods. Artificial aeration involves providing oxygen to a body of water typically through the use of systems such as compressors, hydraulic systems, or fountains (Cheng et al. 2019; Roy et al. 2017a). Studies on the air/water flow ratio and E20 in various hydraulic structures have been carried out recently (Khdhiri et al. 2014; Singh & Kumar 2022; Singh et al. 2021). Numerous studies have been conducted on pond aeration systems using different techniques (Kumar et al. 2013b; Suravut et al. 2017; Rathinakumar et al. 2017; Bahri et al. 2018). Yadav et al. (2022) reported that activities such as respiration, photosynthesis, and diffusion affect DO solubility, which is dynamic.

Theoretically, aeration is the process of increasing the contact area between water and air through natural or mechanical methods. Pond aeration systems have become very popular in the field of aquaculture during the past two decades (Boyd & McNevin 2020). In aeration with hydraulic structures, which are part of mechanical systems, to speed up the flow of oxygen into the water, a lot of air bubbles are added. The surface area that is available for mass transmission is increased by these air bubbles (Tuna et al. 2014). Aeration can be accomplished through the infusion of air into the water column (Roy et al. 2017b; Roy et al. 2021a, b, c). Aeration performed with hydraulic structures can be more economical compared to conventional aeration methods due to increased oxygen transport efficiency and decreased energy consumption (Aytac & Tuna 2023).

To improve aeration efficiency, several aerator types have been designed. The units developed with the help of mechanical and hydraulic structures can be counted as compressors, impeller systems, step drops, etc. The use of these systems in cultivation areas is completely determined by economic conditions. The aeration units with low installation cost and low energy consumption are preferred. Some scientists have carried out studies on cost. Kumar et al. 2013a, b(a-b) determined the economic analyses of different types of aerators according to the size of the pond. Boyd (1998) analyzed various aeration systems and evaluated their performance. Aytac et al. (2024) conducted a study demonstrating the performance and energy efficiency of a prototype conduit system developed for pond aeration. This analysis shows that the ideal design contributed more than three times the system’s average water volume running through it, at an energy cost of 0.10 kWh/m3 of air (Aytac et al. 2024). Alternative options for raising water quality include hydraulic structures like venturi, stepped spillways, nozzle orifices, or free overflow structures. Weirs, venturi aerators, stepped cascades, and stepped spillways can all increase the amount of dissolved oxygen in a river flow system. Recently, research has been conducted to study the air/water flow ratio (Qa/Qw) and E20 in different hydraulic structures (Yadav et al. 2020, 2021, 2022; Singh & Kumar 2022; Singh et al. 2021; Khdhiri et al. 2014).

The use of suitable aerators for the aeration process both in fish production areas and in the required areas provides both operational and economic benefits. Compressors, impeller, spiral, and dispersed are widely used. However, these aerators consume large amounts of energy and have high operating costs. This motivates engineers to produce an aerator that can be manufactured cheaply, has few components, and is easy to use with low maintenance costs.

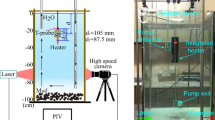

At this point, conduits can be used effectively in aeration units due to their high aeration performance and cheap and easy manufacturing features. In high-head conduits, a high-velocity flow occurs when the conduit gate is opened. The speed increases so much that the pressure becomes negative. In order to balance this negative pressure, the system starts to take air from the atmosphere (Fig. 1). Fine air bubbles that introduce oxygen solution into the flow are created when a duct is opened slightly upstream of the conduit cover. In addition, the high pressure inside the conduit makes it easier for the oxygen in the water to dissolve.

High-head gated conduit flow (Aytac & Tuna 2023)

Some research activities have been carried out to determine the aeration efficiency (E20) of conduits (Aydin et al. 2023; Baylar et al. 2022; Aydin et al. 2021; Ozkan et al. 2015; Tuna et al. 2014).

But no detailed research has been carried out to determine the physical parameters at the point of applicability of these systems in aquaculture facilities for the amount of DO these parameters will provide. In this experimental study, the aeration efficiency (E20) of a conduit-supported unit developed by us to solve the abovementioned problems is discussed. The research aims to determine the variation of aeration efficiency (E20) in a pond aeration system, the effect of different jet plunge angles, discharge rates, hydrostatic levels, Froude numbers, and gate opening rates on the aeration efficiency of the system, and the optimal physical parameters of the system required to achieve maximum aeration efficiency. As a result, it is aimed to evaluate the practical applicability and performance of the experimentally determined parameters in pool aeration applications.

This research will provide an option to investors with the motivation to establish an aeration unit with low initial investment cost, reduce energy costs, and consequently increase profitability in aquaculture facilities by using a method applicable to aquaculture facilities.

Oxygen transfer mechanism

Gas transfer in water is performed to introduce gases such as chlorine and DO or to remove gases like CO2 and H2S from water. The solubility of a gas in water depends on the type of gas, the temperature of the water, and the concentrations of pollutants in the water. When a liquid medium is in contact with a gas or gas mixture, gas molecules transfer from the gas phase to the liquid or vice versa. This process continues until an equilibrium state is reached between the gas and the liquid. At equilibrium, the concentration of gas in the liquid is saturated.

Aeration of liquids involves a mass transfer process between gas and liquid. The driving force here is generally the partial pressure difference in the gas phase and the concentration difference (Cs-C) in the liquid phase. The mass transfer process occurs within the film on both sides of the interface where gas and liquid come into contact.

In systems encountered in water aeration, generally, gases with low solubility in water are involved, and the rate of gas transfer is proportional to the difference between the concentration of the gas at equilibrium and the existing concentration. For such systems, the gas transfer rate is expressed by the following equation:

The oxygen transfer efficiency, as defined by Gulliver and Kawahara (1990), represents the structure’s ability to supply oxygen for water to reach saturation concentration, as expressed by Eq. 1:

where E represents the oxygen transfer efficiency.

-

E = 0 indicates that the hydraulic structure does not induce oxygen transfer in the downstream water.

-

E = 1 indicates that the downstream water has reached saturation.

-

E > 1 values indicate that the downstream water is excessively saturated through the hydraulic structure (Cd > Cs).

Since the saturation concentration of oxygen is a function of temperature, temperature affects the efficiency of oxygen transmission as well. In order to offer a consistent framework for contrasting various systems, the oxygen transfer efficiency needs to be standardized at a specific temperature. Gulliver and Kawahara (1990) expressed the variation of oxygen transfer efficiency with temperature using Eq. 2.

where E20 is the oxygen transfer efficiency at 20 °C water temperature and f is a coefficient expressed by the following equation (Eq. 3). T represents the water temperature (°C).

Gas transfer is defined as the process by which gas is transferred from the gas phase to the liquid phase. The rate of molecular diffusion of dissolved gas in a liquid is dependent on the characteristic of the gas and the liquid, the temperature, the concentration gradient, and the cross-sectional area across which diffusion occurs. One of the most widely used theories for gas–liquid mass transfer is the Lewis and Whitman (1924), two-film theory. This theory is based on a physical model in which two films exist at the gas–liquid interface. The two films, one gas and one liquid, provide resistance from the passage of gas molecules between the bulk liquid and the bulk gaseous phases. It is important to note that the bulk liquid and bulk gas phases are completely mixed. A definition sketch is shown in Fig. 2.

Materials and methods

The experimental investigation sought to determine how several physical characteristics affected the oxygen transfer efficiency of a pool aeration system. These parameters included hydrostatic water levels, water flow rates, and the air–water jet’s plunge angles injected into the pool. Since tap water was used in the trials, there was no chance of organic materials, suspended particles, or floating matter interfering with the results. All of the parts used in the experimental settings are shown in Fig. 3.

A water tank, mixer, water pump, flow gate, thermometer, anemometer, flowmeter, conduit, and DO meters made up the setup.

Three distinct entrance ports, positioned at a height of three-quarters of the pond’s depth (hydrostatic level), were part of the experimental setup. The angles at which these ports were attached to the pond were 30°, 45°, and 60°, enabling the jet of air and water to enter the pond to be adjusted in terms of penetration depth and plunge angle.

In order to examine the effects of hydrostatic water level in the circular cross-sectional experimental set with a diameter of 1.6 m and a volume of 3 m3, three different levels were determined by considering the center of the jet plunge angle, and water was present in the pond according to these levels. The initial level was deemed to be 0 cm submerged, followed by H1/2 submerged at 25 cm and H1/2 deeply submerged at 50 cm.

A galvanized metal pipe with a circular cross-section, with dimensions of 200 cm in length and 8.09 cm in diameter, was utilized to facilitate air intake into the system. The conduit cover opening rates were set at 40%, 30%, and 10%. In order to allow air from the outside to enter the pipe, a 14.00-mm diameter air pipe was opened downstream of the conduit cover. The air pushed into the pipe was measured at a velocity of 1.5% mv + % using a high-precision anemometer. To get the air flow rate, the area of the air input pipe was multiplied by the average air velocity that was observed there.

Three different gate opening ratios were utilized to assess the impact of the ratio on the air intake. The radial gate’s radius was chosen with consideration for the required gate height at the smallest gate opening ratio. The largest value of the gate height (h1) measurement was used to compute the gate radius, as illustrated in Fig. 4. The result was 74.9 mm. For every gate opening ratio, the curvature remained constant. Calculations were made to determine the water velocity beneath the gate by conducting experiments at different flow rates.

The range of Froude numbers (Fr) was 4.84 to 79.72. Equation 4 was used to determine the Froude number using the conduit’s effective depth (ye).

where ye, the effective depth, is the water cross-sectional flow area divided by the water surface width, g is the acceleration of gravity, and V is the water velocity at the gate site. The vena contracta portion has frequently been used as the foundation for the Froude number in literature.

Because high-head gated conduits require high-velocity air–water mixture flow, the Froude number in this study was based on the effective depth in the conduit, avoiding the need to compute flow depths and velocities at the vena contracta section. In general, the Reynolds number is used in pipe systems and the Froude number is used in channel flows. In our study, since the flow in the pipe flow is narrowed by the cover, the water cannot cover the entire pipe wall, so it flows in a certain percentage of the pipe spatially. Therefore, it would be incorrect to consider it as a flow covering the entire pipe wall and to use the Reynolds number. For this purpose, the area covered by the water in the constriction zone and the critical flow height were determined, and Froude number calculations were made accordingly.

Measurements were conducted in experimental groups corresponding to a 10% gate opening, where the aeration performance was optimal, to determine DO concentration values (E20).

To measure the water temperature and DO concentration, a HANNA Model HI 9142 oxygen meter was utilized. The oxygen meter was calibrated before each use. The oxygen transfer efficiency, denoted as (E), was calculated using Eq. 1. For the purpose of comparing the experimental results, the obtained oxygen transfer efficiencies were standardized to 20 °C using Eq. 2.

In the experiments, sodium sulfite (Na2SO3) and cobalt chloride (CoCl2) were employed to reduce the DO concentration of the water in the tank to approximately 0 mg/L. In theory, 1 g/m3 of dissolved oxygen (DO) must be removed with 7.9 g/m3 of sodium sulfite. The approximate sodium sulfite requirements were calculated using the DO of the test tap water (10–20% excess is used). The deoxygenation reaction is catalyzed by the addition of 3.3 g/m3 cobalt II chloride. As a result, the salt content was kept low and closely watched during the trials to avoid any accumulation of residues from the deoxidant chemicals that were added to the water. Therefore, the results are unaffected by the presence of chemicals.

The experiments were conducted using tap water with low salt content, and the salt levels were continuously monitored throughout the experiments to prevent any substantial accumulation of residues from the chemicals used to deoxygenate the water. Therefore, it is unlikely that the presence of chemicals or contaminants had a substantial impact on the outcomes.

Cobalt chloride and sodium sulfite were added to the water using a mixer until the DO level was 0 mg/L.

The altitude of the laboratory where the experiments were conducted is approximately 1100 m. DO saturation concentration (Cs) values at standard conditions (sea level) were converted to the laboratory conditions using the following Eq. 5:

Here, Cs1 represents DO saturation concentration (mg/L) at the laboratory conditions, Cs denotes DO saturation concentration (mg/L) at standard conditions (sea level), and EL is the elevation of the laboratory above sea level.

Statistical analysis

When F values are analyzed as a result of variance analysis, the fact that the significance is greater than the F value indicates that the results obtained depending on the change of independent variables are significant. When the p values are analyzed, the fact that all of them are small (p < 0.05) indicates that the independent variables are effective on the result. As can be seen from the p values and percentage effect ratios, the most effective variable was Fr (Table 1). In addition, when the correlation coefficient (R2) was calculated, it was found to be 0.92, which indicates the consistency in the results.

An empirical correlation predicting aeration efficiency (E20) was developed for the new pond aeration system based on the results of 135 experiments. The equation (Eq. 6) obtained from these experiments yielded a correlation coefficient R2 = 0.92 and is represented as follows:

where K is the ratio of gate opening, Qa/Qw is the air demand ratio, H denotes the hydrostatic level (m), α stands for the jet plunge angle, and E20 represents the aeration efficiency at 20 °C.

Results and discussion

The purpose of this study was to ascertain the impact of several experimental options on the pond air intake efficiency and to identify the systems that offered the highest efficiency of air intake. The determined optimal air intake efficiency was taken into consideration while evaluating the energy costs related to the new system. Sorting the options into groups was done in order to better comprehend the experimental outcomes. Subgroups were created for each group.

Gate opening’s impact on air demand ratio

The relationship between the Froude number (Fr) and the air demand ratio (Qa/Qw) for various conduit gate opening ratios is depicted in Fig. 5. It is evident that as the Fr value increases, the Qa/Qw ratio also rises for all gate opening ratios. This result suggests a clear correlation between water velocity and air intake efficiency. The potential energy, pressure, and velocity of a fluid are all redistributed as it moves from one location to another, according to the Bernoulli equation, a basic concept in fluid mechanics. In our experimental configuration, the gravitational height (z) stays constant given that the flow follows the same conduit axis. The flow’s velocity increases as the cross-section gets smaller, which causes the pressure to noticeably decrease. As a matter of fact, the gate outlet frequently produces negative pressure. The system’s air intake increases in response to this pressure differential, or negative pressure.

When the gate opening ratio of 10%, the air intake efficiency in the experimental investigation attained its maximum value. The air intake efficiency fell as the gate opening ratio rose. It is clear that the intake of air efficiency and gate opening ratio are inversely correlated. This is because the pressure difference between the gate outlet and the outlet reduces as the gate opening ratio increases. The air intake efficiency falls as a result of the decreased pressure difference.

In conclusion, the correlation between the Froude number (Fr) and the air demand ratio (Qa/Qw) for various conduit gate opening ratios has been elucidated further. It is now emphasized that the intake efficiency peaks at a gate opening ratio of 10%, highlighting a clear inverse relationship between air intake efficiency and gate opening ratio.

The impact of air–water jet plunge angle on air demand ratio

It is clear from examining the experimental groups in Fig. 6 that the alternatives with α = 45° exhibit the highest aeration performance. However, when the hydrostatic level and angle change together, the aeration performance is directly affected by this situation. Specifically, at low hydrostatic water levels, an angle of 60° demonstrates optimal performance, while as the hydrostatic level increases, the optimum angle shifts to 45°. While there is not much difference in the effectiveness of alternative options, a general pattern shows that aeration efficiency tends to decline with decreasing air–water jet plunge angle. From this, it can be concluded that aeration effectiveness and the water jet plunge angle are inversely related. Furthermore, jet plunge angle experiments indicate that choices with α = 60° exhibit the optimal distribution of air bubbles in the tank.

Hydrostatic level and air demand ratio

Examining each of the experimental groups shown in Fig. 7 makes it clear that the options with the hydrostatic level at H = 0 cm achieve the best air entrance performance. On the other hand, the aeration capacity decreases when the hydrostatic level rises in all of the groups involved in the experiment. Essentially, the hydrostatic level and aeration efficiency are inversely correlated.

A deeper look at Fig. 7 reveals that, in all cases when the α = 30°, aeration performance increases nearly linearly. Moreover, when all experimental groups are examined together, it is evident that cases of insufficient aeration are more common when there is a hydrostatic level of H = 50 cm and low water volumes.

The following phenomenon explains why aeration performance decreases as the hydrostatic level rises: The submerged air–water jet in the pond experiences pressure from the rising static water level above it. Consequently, this elevated pressure negatively impacts the aeration process, leading to a reduction in performance.

Graphs in three dimensions comparing combined parameters

It is evident from Fig. 8a that the air intake rate is maximized when both the gate opening ratio and angle decrease. In experiments with low gate openings, the air intake rate tends to decrease as the angle is raised while the gate opening remains constant. However, when there are large gate openings, the circumstances are the opposite.

The three-dimensional graph illustrates the relationship between the H and the volume of water pumped into the pond as well as the volume of air entering the system. Figure 8b shows that the intake of air performance drops with growing hydrostatic level. On the other hand, the air intake rate maximum as the amount of water injected into the pond grows. High hydrostatic levels and low water volumes limit the air intake performance. It follows that the submergence effect is lessened when more water is put into the system. Submergence loses its effectiveness, especially in trials when a large volume of injected water is used.

The link between the K and the amount of water injected into the pond with the air volume entering the system is shown in the three-dimensional graph in Fig. 8c. It is clear from looking at Fig. 8c that as gate opening and water volume increase, the air intake rate peaks. The air intake performance is greatly improved by increasing the volume of water fed into the system, especially in tests with narrow gate apertures. Experiments with huge gate apertures reveal no change in the air intake rate as the water volume increases. This graph clearly shows that one of the most important parameters affecting air intake performance is the gate opening.

The three-dimensional graph in Fig. 8d illustrates the relationship between the water jet’s angle of submergence and the volume of water injected into the pond when air enters the system. It can be shown from Fig. 8d that the air intake performance and the angle of submergence are inversely related. Increasing the amount of water pumped into the pond maximizes the air intake rates in studies conducted at low submergence angles. Nevertheless, the air intake performance remains constant when the water volume is increased in studies with high submergence angles.

Oxygen experiments

DO meters used for measuring DO should be placed at a minimum depth of 20 cm below the water surface. Three points were selected depths in the vertical column. The average of readings from all the DO meters was considered the DO concentration of the water.

DO experiments were conducted to understand how physical factors affect aeration efficiency (E20) in a newly developed pond aeration system. The following results were obtained by analyzing the data obtained.

Figure 9 depicts plots of the E20 (aeration efficiency) in relation to the air demand ratio (Qa/Qw) for the K, the α, and hydrostatic level (H). As shown in these figures, the aeration efficiency increased with the air demand ratio. This increase can be attributed to the increased Qa/Qw with an increasing Fr. The jet plunge angle did not have a significant effect on E20. Results indicated that for Qa/Qw > 2, there was a decreasing tendency in the aeration efficiency. As the hydrostatic level increased within the pond, the effect of the α decreased.

Analyzing the experimental data shown in Fig. 10, it can be seen that hydrostatic levels of H = 0 cm are often where the lowest oxygen transfer efficiency occurred. This is explained by the air–water jet’s incapacity to inject into the pond.

Upon overall examination of the experiments, it was noted that in some alternatives, despite the decrease in air intake efficiency (Qa/Qw), the oxygen transfer efficiency (E20) increased.

Dindorf (2012) looked into the energy efficiency evaluation of compressors that are frequently used for aquaculture aeration and calculated the compressors’ unit aeration costs. This analysis indicates that the unit cost of aeration is 1.30 kWh/m3 of air. Machines that have an energy consumption of less than 1.30 kWh/m3 of air are considered high-energy efficiency compressors. The figure in question, 0.10 kWh/m3 of air, was determined to be the most suitable test alternative for conduit design. It is clear from the comparison that this figure is much lower than compressors. Singh (2010) found the standard aeration efficiency (SAE) of a CSC aerator to be 2.16–2.70 kg O2/kWh in his experimental study. The geometrical parameters of the pooled circular stepped cascade (PCSC) aerator were determined by Kumar et al. (2013a). According to the results of the study, the SAE of the PCSC aerator (2.43–3.23 kg O2/kWh) was found to be higher than that of the CSC aerator. Additionally, in order to evaluate the aeration costs, various aerator types were chosen depending on how well they performed in terms of aeration when used with the suggested high-head conduit. Yadav et al. (2022) measured the energy consumption in kgO2/kWh of aerators like paddle wheels, venturi jets, and aspirating aerators in their experimental study. The corresponding figures are 3.48, 1.66, and 3.72. When compared to those of the head-gated conduit, 0.10 kWh of energy is required to move 3.20 m3 of air at the optimal value determined by the experiment (Aytac et al. 2024). One cubic meter of air contains around 1.355 kg of O2. As a result, the performance of the high-cover conduit is approximately 4.3 kgO2/kWh. Below are the ventilation efficiency results of studies conducted by some scientists (Table 2).

Study limitations

The findings of this study are based on experimental data obtained at a specific laboratory scale. The performance of the system in large-scale aquaculture ponds may vary. The study provides an insight into the oxygen efficiency of the aeration system. This will be an important alternative in decision-making for those interested in aquaculture. As a result, it is predicted that the use of these systems in aquaculture sites will reduce product cost and thus increase facility profitability. In the future, this system can be applied to real systems to eliminate the size effect, and factors such as initial investment, operating costs, and payback period can be calculated.

Conclusions

This study investigates the characteristics of a new aeration system through the optimization of the design characteristics of conduit systems that can be an alternative to existing aerators. A series of aeration experiments were conducted to investigate the aeration efficiency characteristics of the conduit system at different gate openings, jet plunge angles, hydrostatic levels, and Froude numbers. The results revealed that the gate opening, hydrostatic level, and Froude number significantly affect the aeration performance (Qa/Qw) and aeration efficiency (E20) parameters. The best air intake efficiency was obtained in the experimental setup with a 10% opening rate, α= 60° plunge angle, and a hydrostatic level of 0 cm. In this alternative, the aeration performance Qa/Qw value was 3.20, and the aeration efficiency E20 was 0.74. The obtained results indicate that the designed method facilitates an easy attainment and involves introducing a significant influx of air bubbles into the pond, which is necessary for the massive volume of air bubbles needed for pond aeration. High hydrostatic levels, Froude numbers, and low gate openings will greatly benefit aeration efficiency in systems. These benefits make the conduit a viable substitute for current pond aeration technologies.

Data availability

Datasets used and/or analysed during the present study are available from the corresponding author upon reasonable request.

Abbreviations

- α :

-

The angle of plunge of the air–water jet (°)

- Q a :

-

Airflow that is taken up by the conduit (m3/s)

- Q w :

-

Conduit flow rate (m3/s)

- K :

-

Gate opening ratio

- H :

-

Hydrostatic level (cm)

- E 20 :

-

Aeration efficiency

- Fr:

-

Froude number

- DO:

-

Dissolved oxygen

- BOD:

-

Biological oxygen demand

References

Adel M, Shaalan MR, Kamal RM, El Monayeri DS (2019) A comparative study of impeller aerators configurations. Alex Eng J 58(4):1431–1438

Aydin AB, Baylar A, Ozkan F, Tuna MC, Ozturk M (2021) Influence of cross-section geometry on air demand ratio in high-head conduits with a radial gate. Water Supply 21(8):4086–4097. https://doi.org/10.2166/ws.2021.162

Aydin, A. B., Baylar, A., Ozkan, F., Tuna, M. C., & Oztürk, M. 2023. Investigation of the geometry effect on air-demand ratio in conduits with a sluice gate. J Water Resour Res https://doi.org/10.1680/jwama.22.00048

Aytac, A., Kelestemur, G.T. & Tuna, M.C. 2024. An effective aeration system for high performance pond aeration at low energy cost. Aquacult Int. https://doi.org/10.1007/s10499-024-01492-6

Aytac A, Tuna MC (2023) Development of a new generation flotation cell and monitoring of air bubbles. Water Pract Technol 18(1):27–39. https://doi.org/10.2166/wpt.2022.170

Bahri S, Setiawan RPA, Hermawan W, Junior MZ (2018) The development of furrower model blade to paddlewheel aerator for improving aeration efficiency. IOP Conf Ser Mater Sci Eng 1:352

Baylar A, Ozkan F, Yildirim CB, Aydin AB, Tuna MC, Ozturk M (2022) The role of cross-sectional geometry of high-head gated conduit in oxygen transfer efficiency. Water Environ J 36(3):372–379. https://doi.org/10.1111/wej.12770

Boyd CE (1998) Pond water aeration systems. Aquacult Eng 18(1):9–40

Boyd CE, McNevin AA (2020) Aerator energy use in shrimp farming and means for improvement. J World Aquacult Soc 52(1):1–24. https://doi.org/10.1111/jwas.12753

Cheng X, Xie Y, Zhu D, Xie J (2019) Modeling re-oxygenation performance of fine-bubble–diffusing aeration system in aquaculture ponds. Aquacult Int 27(5):1353–1368. https://doi.org/10.1007/s10499-019-00390-6

Dayıoğlu MA (2022). Experimental study on design and operational performance of solar-powered venturi aeration system developed for aquaculture–A semi-floating prototype. Aquac Eng 98. https://doi.org/10.1016/j.aquaeng.2022.102255

Dindorf R (2012) Estimating potential energy savings in compressed air systems. Procedia Eng 39:204–211

Gulliver JS, Kawahara K (1990) Oxygen transfer in environmental engineering systems. Oxygen transfer from atmosphere to activated sludge. Springer, Tokyo, pp 1–10

Huang W, Wu C, Xia W (2009) Oxygen transfer in high-speed surface aeration tank for wastewater treatment: full-scale test and numerical modeling. J Environ Eng 135(8):684–691. https://doi.org/10.1061/(asce)ee.1943-7870.0000023

Khdhiri H, Potier O, Leclerc JP (2014) Aeration efficiency over stepped cascades: better predictions from flow regimes. Water Res 55:194–202. https://doi.org/10.1016/j.watres.2014.02.022

Kumar A, Moulick S, Mal BC (2010) Performance evaluation of propeller-aspirator pump aerator. Aquacult Eng 42(2):70–74

Kumar A, Moulick S, Singh BK, Mal BC (2013a) Design characteristics of pooled circular stepped cascade aeration system. Aquacult Eng 56:51–58

Kumar A, Moulick S, Mal BC (2013b) Selection of aerators for intensive aquacultural pond. Aquacult Eng 56:71–78. https://doi.org/10.1016/j.aquaeng.2013.05.003

Lewis WK, Whitman WG (1924) Principles of gas absorption. Ind Eng Chem Res 16(12):1215–1220. https://doi.org/10.1021/ie50180a002

Ozkan F, Demirel IH, Tuna MC, Baylar A (2015) The effect of length of free-surface gated circular conduit on air-demand ratio and aeration efficiency. Water Supply 15(6):1187–1192. https://doi.org/10.2166/ws.2015.081

Qayyum A, Ayub M, Tabinda AB (2005) Effect of aeration on water quality, fish growth and survival in aquaculture ponds. Pakistan J Zool 37(1):75–80

Rathinakumar V, Dhinakaran G, Suribabu CR (2017) Effect of hydraulic and geometrical properties on stepped cascade aeration system. J Eng Sci Technol 12(3):756–766

Roy SM, Moulick S, Mal BC (2017a) Design characteristics of spiral aerator. J World Aquacult Soc 48(6):898–908

Roy A, Sharma S, Bhattacharjee S (2017b) Aeration: an efficient method for oxygen infusion into water bodies. Environ Eng Res 22(3):251–257

Roy SM, Moulick S, Mukherjee CK (2020) Design characteristics of perforated pooled circular stepped cascade (PPCSC) aeration system. Water Supply 20(5):1692–1705. https://doi.org/10.2166/ws.2020.078

Roy A, Sharma S, Bhattacharjee S (2021a) Impact of aeration on water quality: a review. Water Res 135:343–355

Roy A, Sharma S, Bhattacharjee S (2021b) Aeration techniques for water treatment: a comprehensive review. J Environ Manage 295:113048

Roy A, Sharma S, Bhattacharjee S (2021c) Aeration strategies for improving water quality in aquatic ecosystems. Environ Sci Pollut Res Int 28(11):13478–13495

Singh D, Kumar M (2022) Study on aeration performance of different types of piano key weir. Water Supply 22(5):4810–4821. https://doi.org/10.2166/ws.2022.131

Singh A, Singh B, Sihag P (2021) Experimental investigation and modeling of aeration efficiency at labyrinth weirs. J Soft Comput. Civil Eng 5(3):15–31. https://doi.org/10.22115/scce.2021.284637.1311

Singh BK (2010) Design characteristics of circular stepped cascade pump aeration system. Ph.D Thesis, Department of Agricultural and Food Engineering, Indian Institute of Technology Kharagpur, India

Subha MR, Jayraj P, Rajendra M, Pareek CM, Mal BC (2021) Aquacult Int 29:1181–1217. https://doi.org/10.1007/s10499-021-00685-7

Suravut S, Hirunlabh J, Khedari J, Kiddee K (2017) Standalone water wheel low speed surface aerator Chaipattana RX-2-3, controller system. Energy Procedia 138:751–755

Tuna MC, Ozkan F, Baylar A (2014) Experimental investigations of aeration efficiency in high-head gated circular conduits. Water Sci Technol 69(6):1275–1281. https://doi.org/10.2166/wst.2014.021

Tuna Kelestemur G (2012a) Effects of hypoxic stress on electrolyte levels of blood in juvenile rainbow trout (Oncorhynchus mykiss). Iran J Fish Sci 11(4):930–937

Tuna Kelestemur G (2012b) Physiological effects created on fish of hypoxic waters. BİBAD, Turk J Sci Rev 5(1):75–78

Wanja DW, Mboera LEG, Yongo M, Ochanda H, Gachohi JM (2020) Fish husbandry practices and water quality in central Kenya: potential risk factors for fish mortality and infectious diseases. Vet Med Int 2020:6839354

Wei Y, Wei Q, Tan Z, Xu L, Yang J (2019) Review of dissolved oxygen detection technology: from laboratory analysis to online intelligent detection. Sensors 19(18):3995

Yadav A, Kumar A, Sarkar S (2020) An experimental study to evaluate the efficacy of air entrainment holes on the throat of a venturi aeration system. Aquacult Int 28:1057–1068. https://doi.org/10.1007/s10499-020-00511-6

Yadav A, Kumar A, Sarkar S (2021) Performance evaluation of venturi aeration system. Aquacult Eng 93:102156. https://doi.org/10.1016/j.aquaeng.2021.102156

Yadav A, Kumar A, Sarkar S (2022) Economic comparison of venturi aeration system. Aquacult Int 30:2751–2774. https://doi.org/10.1007/s10499-022-00931-6

Zhang C, Song B, Shan J, Ni Q, Wu F, Wang S (2020) Design and optimization of a new tube aeration device. Aquacult Int 28:985–999

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Ayca Aytac, Guluzar Tuna Kelestemur, and M. Cihat Tuna. The first draft of the manuscript was written by M. Cihat Tuna, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Handling Editor: Brian Austin

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Oxygen dissolution in water significantly increased after implementing a high-head conduit system

• Developed correlations predict aeration efficiency (E20) with conduit aeration systems for ponds, offering valuable guidance for optimizing aeration performance

• When the system has optimized parameters, it shows high aeration performance and promises economic benefits and environmental sustainability

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kelestemur, G.T., Aytac, A. & Tuna, M.C. Experimental investigation on oxygenation efficiency of an effective aeration system for ponds. Aquacult Int (2024). https://doi.org/10.1007/s10499-024-01583-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10499-024-01583-4