Abstract

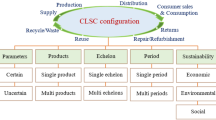

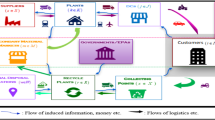

Fluctuations in supply chains’ input, such as demand, purchasing, transportation, and production costs, could negatively affect the supply chain’s efficiency and responsiveness. Several fluctuations lead to several types of shorter time intervals per period, resulting in high complexity in supply chain planning. This paper defines each time interval with the stable value of a parameter as a Season and considers different numbers of seasons from different lengths for each parameter per period. It proposes a multi-period multi-season multi-objective mixed-integer mathematical model to formulate several viability strategies under fluctuations in a closed-loop supply chain (CLSC) planning. In addition, a framework of viable healthcare supplier selection is proposed, involving several criteria, such as sustainability, resiliency, and Industry 4.0 adaptation, and using the fuzzy analytical hierarchy process. The proposed model is solved in a healthcare case study of face mask production using the optimality grade method and CPLEX solver. The results showed the need for forty-eight seasonal suppliers’ layoffs, seven production lines’ seasonal layoffs, several seasonal capacity regulations, and different levels of seasonal storage to reach a viable CLSC. In addition, the seasonal price and production cost forecasting should be as accurate as possible due to their significant share in the total costs. Also, sensitivity analysis showed the considerable role of seasonal demand variation on the layoff strategy of viability.

Similar content being viewed by others

References

Alizadeh, M., Ma, J., Marufuzzaman, M., & Yu, F. (2019). Sustainable olefin supply chain network design under seasonal feedstock supplies and uncertain carbon tax rate. Journal of Cleaner Production, 222, 280–299.

Alizadeh, M., Makui, A., & Paydar, M. M. (2020). Forward and reverse supply chain network design for consumer medical supplies considering biological risk. Computers and Industrial Engineering, 140, 106229.

Amindoust, A. (2018). A resilient-sustainable based supplier selection model using a hybrid intelligent method. Computers and Industrial Engineering, 126, 122–135.

Aryee, R., & Adaku, E. (2023). A review of current trends and future directions in reverse logistics research. Flexible Services and Manufacturing Journal, 1–30.

Bala, B., Bhuiyan, M., Alam, M., Arshad, F. M., Sidique, S. F., & Alias, E. (2017). Modelling of supply chain of rice in Bangladesh. International Journal of Systems Science: Operations and Logistics, 4(2), 181–197.

Bekkering, J., Hengeveld, E. J., van Gemert, W., & Broekhuis, A. (2015). Designing a green gas supply to meet regional seasonal demand: An operations research case study. Applied Energy, 143, 348–358.

Borgonovo, E. (2017). Sensitivity analysis. An introduction for the management scientist. International series in operations research and management science. Springer.

Bottani, E., & Rizzi, A. (2005). A fuzzy multi-attribute framework for supplier selection in an e-procurement environment. International Journal of Logistics: Research and Applications, 8(3), 249–266.

Braglia, M., & Petroni, A. (2000). A quality assurance‐oriented methodology for handling trade‐offs in supplier selection. International Journal of Physical Distribution and Logistics Management.

Canizes, B., Soares, J., Lezama, F., Silva, C., Vale, Z., & Corchado, J. M. (2019). Optimal expansion planning considering storage investment and seasonal effect of demand and renewable generation. Renewable Energy, 138, 937–954.

Chan, Y.-W.D., Wong, M.-L., Au, K.-W., & Chuang, S.-K. (2019). Seasonal influenza vaccine effectiveness at primary care level, Hong Kong SAR, 2017/2018 winter. Human Vaccines and Immunotherapeutics, 15(1), 97–101.

Chang, C. T., & Chou, H. C. (2013). A coordination system for seasonal demand problems in the supply chain. Applied mathematical modelling, 37(6), 3674–3686.

Cho, D. W., & Lee, Y. H. (2013). The value of information sharing in a supply chain with a seasonal demand process. Computers and Industrial Engineering, 65(1), 97–108.

Costantino, F., Di Gravio, G., Shaban, A., & Tronci, M. (2016). Smoothing inventory decision rules in seasonal supply chains. Expert Systems with Applications, 44, 304–319.

Derhy, M.-F. (2010). Linear programming, sensitivity analysis & related topics. Pearson.

Ehrenthal, J., Honhon, D., & Van Woensel, T. (2014). Demand seasonality in retail inventory management. European Journal of Operational Research, 238(2), 527–539.

Fallahi, A., Mokhtari, H., & Niaki, S. T. A. (2021). Designing a closed-loop blood supply chain network considering transportation flow and quality aspects. Sustainable Operations and Computers, 2, 170–189.

Ghamari, R., Mahdavi-Mazdeh, M., & Ghannadpour, S. F. (2021). Resilient and sustainable supplier selection via a new framework: a case study from the steel industry. Environment, Development and Sustainability, 1–39.

Gören, H. G. (2018). A decision framework for sustainable supplier selection and order allocation with lost sales. Journal of Cleaner Production, 183, 1156–1169.

Hasani, A., Zegordi, S. H., & Nikbakhsh, E. (2015). Robust closed-loop global supply chain network design under uncertainty: The case of the medical device industry. International Journal of Production Research, 53(5), 1596–1624.

Hosseini, S., & Barker, K. (2016). A Bayesian network model for resilience-based supplier selection. International Journal of Production Economics, 180, 68–87.

Hosseini, S., Morshedlou, N., Ivanov, D., Sarder, M., Barker, K., & Al Khaled, A. (2019). Resilient supplier selection and optimal order allocation under disruption risks. International Journal of Production Economics, 213, 124–137.

Huang, Y., Fan, Y., & Chen, C.-W. (2014). An integrated biofuel supply chain to cope with feedstock seasonality and uncertainty. Transportation Science, 48(4), 540–554.

Ishizaka, A., Khan, S. A., Kheybari, S., & Zaman, S. I. (2023). Supplier selection in closed loop pharma supply chain: A novel BWM–GAIA framework. Annals of Operations Research, 324(1–2), 13–36.

Ivanov, D. (2020). Viable supply chain model: integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Annals of operations research, 1–21.

Ivanov, D., & Dolgui, A. (2021). Stress testing supply chains and creating viable ecosystems. Operations Management Research, 1–12.

Ivanov, D., Dolgui, A., Blackhurst, J. V., & Choi, T.-M. (2023). Toward supply chain viability theory: from lessons learned through COVID-19 pandemic to viable ecosystems. In (Vol. 61, pp. 2402–2415): Taylor & Francis.

Ivanov, D. (2021a). Introduction to supply chain resilience: Management, modelling, technology. Springer.

Ivanov, D. (2021b). Supply chain viability and the COVID-19 pandemic: A conceptual and formal generalisation of four major adaptation strategies. International Journal of Production Research, 59(12), 3535–3552.

Ivanov, D. (2023). The Industry 5.0 framework: Viability-based integration of the resilience, sustainability, and human-centricity perspectives. International Journal of Production Research, 61(5), 1683–1695.

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915.

Ivanov, D., & Keskin, B. B. (2023). Post-pandemic adaptation and development of supply chain viability theory. Omega, 116, 102806.

Kapoor, K., Bigdeli, A. Z., Dwivedi, Y. K., & Raman, R. (2021). How is COVID-19 altering the manufacturing landscape? A literature review of imminent challenges and management interventions. Annals of Operations Research, 1–33.

Kapukaya, E. N., Bal, A., & Satoglu, S. I. (2019). A bi-objective model for sustainable logistics and operations planning of WEEE recovery. An International Journal of Optimization and Control: Theories and Applications (IJOCTA), 9(2), 89–99.

Khan, M. M., Bashar, I., Minhaj, G. M., Wasi, A. I., & Hossain, N. U. I. (2023). Resilient and sustainable supplier selection: an integration of SCOR 4.0 and machine learning approach. Sustainable and Resilient Infrastructure, 1–17.

Lotfi, R., Nazarpour, H., Gharehbaghi, A., Sarkhosh, S. M. H., & Khanbaba, A. (2022). Viable closed-loop supply chain network by considering robustness and risk as a circular economy. Environmental Science and Pollution Research, 1–20.

Luthra, S., Govindan, K., Kannan, D., Mangla, S. K., & Garg, C. P. (2017). An integrated framework for sustainable supplier selection and evaluation in supply chains. Journal of Cleaner Production, 140, 1686–1698.

Mehregan, M. R., Hashemi, S. H., Karimi, A., & Merikhi, B. (2014). Analysis of interactions among sustainability supplier selection criteria using ISM and fuzzy DEMATEL. International Journal of Applied Decision Sciences, 7(3), 270–294.

Moadab, A., Kordi, G., Paydar, M. M., Divsalar, A., & Hajiaghaei-Keshteli, M. (2023). Designing a sustainable-resilient-responsive supply chain network considering uncertainty in the COVID-19 era. Expert Systems with Applications, 227, 120334.

El Mokadem, M. (2017). The classification of supplier selection criteria with respect to lean or agile manufacturing strategies. Journal of Manufacturing Technology Management.

Moslemi, S., Zavvar Sabegh, M. H., Mirzazadeh, A., Ozturkoglu, Y., & Maass, E. (2017). A multi-objective model for multi-production and multi-echelon closed-loop pharmaceutical supply chain considering quality concepts: NSGAII approach. International Journal of System Assurance Engineering and Management, 8(2), 1717–1733.

Nagaraja, C. H., Thavaneswaran, A., & Appadoo, S. (2015). Measuring the bullwhip effect for supply chains with seasonal demand components. European Journal of Operational Research, 242(2), 445–454.

Nasr, A. K., Tavana, M., Alavi, B., & Mina, H. (2021). A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. Journal of Cleaner Production, 287, 124994.

Ni, Z., Chan, H. K., & Tan, Z. (2023). Systematic literature review of reverse logistics for e-waste: Overview, analysis, and future research agenda. International Journal of Logistics Research and Applications, 26(7), 843–871.

Parkouhi, S. V., & Ghadikolaei, A. S. (2017). A resilience approach for supplier selection: Using Fuzzy Analytic Network Process and grey VIKOR techniques. Journal of Cleaner Production, 161, 431–451.

Parkouhi, S. V., Ghadikolaei, A. S., & Lajimi, H. F. (2019). Resilient supplier selection and segmentation in grey environment. Journal of Cleaner Production, 207, 1123–1137.

Paul, S. K., Chowdhury, P., Chakrabortty, R. K., Ivanov, D., & Sallam, K. (2022). A mathematical model for managing the multi-dimensional impacts of the COVID-19 pandemic in supply chain of a high-demand item. Annals of Operations Research, 1–46.

Pramanik, D., Mondal, S. C., & Haldar, A. (2020). Resilient supplier selection to mitigate uncertainty: Soft-computing approach. Journal of Modelling in Management.

Rajesh, R., & Ravi, V. (2015). Supplier selection in resilient supply chains: A grey relational analysis approach. Journal of Cleaner Production, 86, 343–359.

Razmi, J., Kazerooni, M. P., & Sangari, M. S. (2016). Designing an integrated multi-echelon, multi-product and multi-period supply chain network with seasonal raw materials. Economic Computation & Economic Cybernetics Studies & Research, 50(1).

Resende, C. H., Geraldes, C. A., & Junior, F. R. L. (2021). Decision models for supplier selection in industry 4.0 Era: A systematic literature review. Procedia Manufacturing, 55, 492–499.

Rostami, O., Tavakoli, M., Tajally, A., & GhanavatiNejad, M. (2023). A goal programming-based fuzzy best–worst method for the viable supplier selection problem: A case study. Soft Computing, 27(6), 2827–2852.

Ruel, S., El Baz, J., Ivanov, D., & Das, A. (2021). Supply chain viability: conceptualization, measurement, and nomological validation. Annals of Operations Research, 1–30.

Sarkar, B., & Bhuniya, S. (2022). A sustainable flexible manufacturing–remanufacturing model with improved service and green investment under variable demand. Expert Systems with Applications, 202, 117154.

Sazvar, Z., Zokaee, M., Tavakkoli-Moghaddam, R., Salari, S. A.-S., & Nayeri, S. (2021). Designing a sustainable closed-loop pharmaceutical supply chain in a competitive market considering demand uncertainty, manufacturer’s brand and waste management. Annals of Operations Research, 1–32.

Shafiee, M., Zare Mehrjerdi, Y., & Keshavarz, M. (2021). Integrating lean, resilient, and sustainable practices in supply chain network: mathematical modelling and the AUGMECON2 approach. International Journal of Systems Science: Operations & Logistics, 1–21.

Sharma, M., & Joshi, S. (2020). Digital supplier selection reinforcing supply chain quality management systems to enhance firm's performance. The TQM Journal.

Sharma, S. K., Srivastava, P. R., Kumar, A., Jindal, A., & Gupta, S. (2023). Supply chain vulnerability assessment for manufacturing industry. Annals of Operations Research, 326(2), 653–683.

Tavana, M., Shaabani, A., Di Caprio, D., & Amiri, M. (2021). An integrated and comprehensive fuzzy multicriteria model for supplier selection in digital supply chains. Sustainable Operations and Computers, 2, 149–169.

Tayyab, M., & Sarkar, B. (2021). An interactive fuzzy programming approach for a sustainable supplier selection under textile supply chain management. Computers and Industrial Engineering, 155, 107164.

Tirkolaee, E. B., Goli, A., Ghasemi, P., & Goodarzian, F. (2022). Designing a sustainable closed-loop supply chain network of face masks during the COVID-19 pandemic: Pareto-based algorithms. Journal of Cleaner Production, 333, 130056.

Tseng, M.-L., Ha, H. M., Lim, M. K., Wu, K.-J., & Iranmanesh, M. (2022). Sustainable supply chain management in stakeholders: Supporting from sustainable supply and process management in the healthcare industry in Vietnam. International Journal of Logistics Research and Applications, 25(4–5), 364–383.

Tzeng, G.-H., & Huang, J.-J. (2013). Fuzzy multiple objective decision making. CRC Press.

Wolff, M., Becker, T., & Walther, G. (2023). Long-term design and analysis of renewable fuel supply chains–An integrated approach considering seasonal resource availability. European Journal of Operational Research, 304(2), 745–762.

Wu, C., Lin, Y., & Barnes, D. (2021a). An integrated decision-making approach for sustainable supplier selection in the chemical industry. Expert Systems with Applications, 184, 115553.

Wu, X., Cao, W., Wang, D., Ding, M., Yu, L., & Nakanishi, Y. (2021b). Demand response model based on improved Pareto optimum considering seasonal electricity prices for Dongfushan Island. Renewable Energy, 164, 926–936.

Xie, C., Deng, X., Zhang, J., Wang, Y., Zheng, L., Ding, X., Li, X., & Wu, L. (2023). Multi-period design and optimization of classified municipal solid waste supply chain integrating seasonal fluctuations in waste generation. Sustainable Cities and Society, 93, 104522.

Young-Jou, L., & Ching-Lai, H. (1992). Fuzzy mathematical programming: Methods and applications. Springer-Verlag.

Zare Mehrjerdi, Y., & Lotfi, R. (2019). Development of a mathematical model for sustainable closed-loop supply chain with efficiency and resilience systematic framework. International Journal of Supply and Operations Management, 6(4), 360–388.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hussaini, Z., Nemati, A. & Paydar, M.M. A multi-period multi-season multi-objective mathematical model for guaranteeing the viability of supply chains under fluctuations: a healthcare closed-loop supply chain application. Ann Oper Res (2023). https://doi.org/10.1007/s10479-023-05783-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10479-023-05783-8