Abstract

After decades of outsourcing to low-cost countries, companies are restructuring their production footprint globally. Especially having experienced supply chain disruption caused by the unprecedented Covid-19 pandemic for the past several years, many multinational companies are considering bringing their operations back home (i.e., reshoring). At the same time, the U.S. government proposes using tax penalties to motivate companies to reshore. In this paper, we study how a global supply chain adjusts its offshoring and reshoring production decisions under two different circumstances: (1) under traditional corporate tax regulations; (2) under the proposed tax penalty regulations. We analyze cost variants, tax structures, market access and production risks to identify conditions where global companies decide to bring manufacturing back to their domestic countries. Our results show that multinational companies would be more likely to relocate the production from the main foreign country to an alternative country that enjoys even lower production costs under the proposed tax penalty. As identified by our analysis and as well as numerical simulations, reshoring can only occur in rare situations such as when the production costs in the foreign countries are close to that in the domestic country. Besides potential national tax reform, we also discuss the impact of the Global Minimum Tax Rate proposed by the G7 on global companies’ offshoring/reshoring decisions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Three decades ago, U.S. manufacturers shifted their supply chain from local to global. Globalization has offered companies tremendous opportunities to grow revenues and decrease costs. Starting one decade ago, the rising wages in those foreign countries, especially in China, and increasing transportation costs, duties, industrial real estate and other costs (Srai & Ané 2016) have reduced the cost advantage of offshoring. Therefore, companies are restructuring their production footprint globally, such as increasing the production volume in the region where the business unit’s headquarters is located. We define this phenomenon as reshoring following Brush et al. (1999) and Cohen et al. (2018). Recently, more U.S. and European manufacturers began to consider reshoring their productions driven by political campaigns to bring jobs back home (Tate & Bals, 2017). Overall, companies have been re-investigating their manufacturing activities, and the manufacturing reshoring has gained momentum in business practice and policymakers (Ciabuschi et al., 2019).

Companies need to evaluate their offshoring and reshoring strategies due to a variety of reasons. For instance, modern operational processes, manufacturers’ scalability, the rise of lean production, and many more have made it challenging to see global supply chain relocation or reshoring within a short time (Shih, 2020). Jung (2020) studied offshore and onshore sourcing strategies under supply and demand uncertainty and found offshore sourcing strategy is still appealing even if offshore sourcing has no cost advantage. Moretto et al. (2020) summarized the drivers of reshoring decisions related to cost, operation, organization, brand reputation, risk reduction, and government policies. Additionally, the supply chain disruptions caused by the Covid-19 pandemic have exposed the vulnerabilities of long global supply chains, and thus prompted companies to consider reshoring (Kearney, 2021). These decisions can be further complicated by regulatory changes, such as the tax forms advocated by the US government, which have provided incentives for companies to bring their operations back to the U.S. (Veneziani, 2020). Multinational manufacturing always dynamically balances offshoring and re-shoring strategies based on these factors.

Despite many companies claiming to bring their production back home, actual large-scale reshoring has not been observed. For example, Apple heavily relied on its China-centric supply chain. Recently given the tax incentive from the U.S. government, instead of bringing manufacturing back home as it promised, Apple moved a portion of its AirPod production to Vietnam and iPhone production to India, though the relatively unsatisfactory productivity and quality issues may bring a global company’s attention (Carr & Gurman, 2021). It is interesting to notice that global supply chain relocation did occur in some circumstances; however, those companies moved some of their production from wage-rising countries (e.g., China) to other countries with lower costs, not back to the United States. For example, textile mill production was reduced by around 38% in China while increasing by 26% in other Asian lower-cost countries (Kearney, 2021).

The hope is that with government incentives and policies, such as tax reforms, large-scale manufacturing reshoring could be made possible and sustainable. From the border adjustment tax (BAT) proposed by the Trump administration to the Offshoring tax penalty proposed by the Biden administration, the U.S. government has been considering diverse tax reforms. Although those tax proposals differ in many respects, they have a common thread—tax penalty for companies setting up operations overseas. For instance, with the proposed border adjustment tax, the cost of imported goods and services would no longer be deductible for tax purposes (Gaertner et al., 2018). And an additional 10% “offshoring penalty surtax” on profits for oversea-manufactured goods would be charged under the tax reform proposed by the Biden Administration (Miller et al., 2022). In light of what has been observed on global supply chains and what policies have been made by policymakers, it is important to address the following key research questions:

-

(1)

How would multinational companies respond to the tax reforms proposed by the home country?

-

(2)

Would the tax reforms motivate multinational companies to move production back home, given the presence of the lower production costs offered by a third country?

-

(3)

Under what circumstances, would multinational companies consider reshoring?

As noted by Cohen and Lee (2020), the potential impact of disruptions owing to government policy change is largely unknown. Therefore, we aim to fill this gap by investigating companies’ re-shore decisions in response to potential tax regulations. To achieve this, we investigate companies’ operations decisions under two different tax circumstances—traditional corporate tax policy and a proposed tax penalty policy. Without loss of generality, the proposed tax penalty policy here is assumed to share the same key component discussed above, i.e., tax penalty to companies offshoring. To be more specific, the cost of goods produced oversea wouldn’t be deductible for tax purposes and the corporate income tax rate in the home country could be varied or increased. In addition to the traditional corporate tax policy and the proposed tax penalty policy, we will also study the new international tax reform (Pillar One and Pillar Two) proposed by the G7 in 2021. These tax policies could significantly impact reshoring decisions. Besides tax, we also incorporate market access to the foreign country and transfer price considerations, which are crucial factors that influence companies’ manufacturing location decisions (Cohen & Lee, 2020; Xu et al., 2018). Market access refers to the degree to which a company can enter and sell its products in a foreign market, and it can greatly impact the profitability and sustainability of a company's global supply chain. For example, Pierre Beaudoin, chief executive of Bombardier, a Canadian maker of airplanes and trains, says the firm focused on cost savings made by sending jobs to China; now Bombardier is in China for the sake of China (The Economist, 2013).

As China becomes the largest market globally, reducing the production volume in or near China to increase domestic (e.g., U.S.) production might lead to potential interruptions in serving China and the neighboring countries, which would not be the optimal response from the companies. Hence, it is natural for multinational companies to consider alternative countries as supply sources, even though they may not be as attractive before the policy change. According to the survey of manufacturing sourcing decisions (Cohen et al., 2018), as labor cost is constantly rising in China, supply chain executives have started to move production to lower-cost locations close to China, such as Vietnam. We include this alternative option in our models under both tax regulation circumstances to make our results and conclusions pragmatic and informative.

Transfer price also plays a crucial role in offshoring and reshoring decision. When offshoring is present, transfer price is used to shift income from foreign countries to the home country (Abdallah, 1989). For example, a multinational company experiences a low unit production cost of $1 in her subsidiary in China and a retail price of $10 in the American market. Assuming a corporate tax rate of 20% in China and 40% in America (ignoring tariffs and other related taxes such as VAT), if the multinational company sets a transfer price at $2, her total after-tax profit is ($2–$1)*0.8 + ($10–$2)*0.6 = $5.6; however, if she sets the transfer price to be $9, her total after-tax profit increases to $7 leading to a 25% improvement. Therefore, a higher transfer price enables profit maximization when offshoring strategy dominates, though the multinational company is unable to set up an arbitrarily high transfer price as she has to follow the intra-firm transfer pricing regulations and principles (Ernst & Young, 2012 Halperin & Srinidhi, 1987; OECD, 1979, 1995, 1996, 1997).

Overall, we find that when the lower-cost alternative country is absent, the proposed tax penalty model will reduce the likelihood of offshoring all production to the foreign country, especially when the transfer priceis high. However, the reduced production volume might not be back to the domestic country when the alternative is available. We expect that portion of production to be relocated to the lower-cost alternative country once some conditions are satisfied. Our numerical estimations further confirm that instead of minimizing offshoring and returning production to the domestic country, the proposed tax penalty model can lead to suboptimal outcomes due to ineffective production in the alternative country and ultimately result in a reduction of consumer welfare in the domestic market. Therefore, instead of re-shore, relocated-offshore is more likely to happen despite the fact that quality issues and product risk may occur more frequently in the alternative country than in the foreign country.

Our paper contributes to the supply chain literature in several aspects. First, the paper provides insights into the cost variants and tax conditions that motivate global companies to move their manufacturing back under the tax penalty model. Second, we shed light on the complex conditions where global companies desire to move production to another foreign country with lower production costs instead of reshoring under the tax penalty model. This suggests that the tax penalty policy alone may not be sufficient to incentivize re-shoring in certain circumstances. Thirdly, we demonstrate how tax reforms and transfer pricing policies can impact the reshoring decisions. Finally, we highlight the impact of production risks on global supply chains and present a tradeoff between the cost-effectiveness and global supply chain sustainability. In summary, our model captures the interactions and tradeoffs involved in the reshoring problem, taking into account market access, transfer price, cost variants, and potential tax regulations at national and international levels. Our study provides a comprehensive picture of the dynamic business environment, consistent with the current global manufacturing landscape, and is informative for the ongoing policy debate.

The remainder of this paper is organized as follows: In Sect. 2, we review the related literature. In Sect. 3, we establish the model settings for further analysis. Section 4 analyzes the base model with traditional tax policy and the proposed tax penalty model to find companies’ offshoring vs. reshoring decisions and compare the difference under these models. In Sect. 5, we provide managerial insights and suggestions on what can drive the global company to make decisions in alignment with the government’s expectations and the directions of further research.

2 Literature review

There is a rich literature on the global supply chain network design with the existence of both production facilities and markets in multiple countries (Cohen & Huchzermeier, 1999; Cohen & Mallik, 1997; Hsu & Zhu, 2011; Kouvelis & Gutierrez, 1997; Meixell & Gargeya, 2005). However, very little research has been done on the impacts of tariffs and taxes as government incentives on the global supply chain network design. In this section, we mainly review the relevant literature on the impacts of recent new tariffs and taxes on the global supply chain network.

Empirical research in accounting attributes offshoring decisions partly to tax savings that occur from the difference of tax rates (Mutti, 2003). De Mooij and Ederveen (2003) performed a summary study of empirical research on foreign direct investment responsiveness to tax rates and found that on average 1% reduction in a country's tax rate leads to 3.3% increase in the country's foreign direct investment. This evidence suggests that low tax rate countries do attract more foreign companies. In operations management literature, however, the importance of taxation for offshoring has not been studied extensively. Usually, the tax rates are fixed parameters in global supply chain models as we describe in review of transfer pricing literature. A couple of new works address the taxation strategy in global supply chains to pursue profit maximization or cost minimization. For example, Balaji and Viswanadham (2008) studied how a multinational company integrated tax to make its decision on choices of foreign direct investment (FDI) or outsourcing at the different stages of a global supply chain to minimize total supply chain cost. Bogataj and Bogataj (2011) consider free economic zones as a tool to hedge the fluctuation of logistics and skilled human resources. Their paper examines the level of tax burden reduction in the free economic zones of accession countries. Hsu and Zhu (2011) examined the impacts of exported-oriented tax and tariffs on the optimal supply chain design when a multiple-national firm produces its product in China, and then sell the products both domestically and oversea. They compared four supply chain structures under different business environment and evaluated which structure outperform the other taking the tax and tariffs into consideration. This research tactically addresses the role of taxation without involving transfer price, which represents the price that one division in a multinational company charges another division for goods and service provided (Fernandes et al., 2015). Different transfer prices have a significant impact on the volume of taxation, thus on companies’ response to tax incentives.

On the other hand, Fernandes et al. (2015) developed a modeling framework to study how various transfer pricing schemes for a multinational company have an influence on distribution network strategy in terms of profit maximization under different countries tax policies. Specifically, they adopted a real option approach to investigate how the distribution network has an impact on the total profit of a supply chain under different tax rate differentials and how transfer price methods influence the total profits for various distribution network configurations when demand is uncertain. Spinowitz (2018) warned multinational corporations must “reevaluate their supply chains in light of the generally changed tax landscape and in light of the radically revised international tax regime”. Chae et al. (2019) then developed a conceptual model to study how the expected tariffs make companies act and adapt their supply base to reduce sourcing costs. They identified the severity of expected tariff change, timing uncertainty of tariff increase and geographical scope of the tariff as important attributes and analyze their impacts on supply base complexity. Because government plays a significant role in multination companies’ sourcing strategy by adjusting tariff and tax regulations, Niu et al. (2019) assumed a multinational firm and a domestic manufacturer engage in domestic competition and studied how government’s tariff regulations influence companies’ sourcing strategy if product quality and social welfare are considered.

Cohen and Lee (2020) found many companies were adopting new global supply chain strategies and optimizing their supply chain structure in response to dynamic changing factors such as tariffs, government tax incentive. They then identified opportunities for research in smart tax and incentive-based supply chain design with the advent of new trade tariffs, tax rates in different countries and trade agreement. Dong and Kouvelis (2020) first reviewed existing newsvendor models in the current literature to gain an understanding of the implications of tariffs for companies’ global facility network design decision. They then extended the model to the responsive pricing newsvendor network model and discussed the important dimensions that help further understand the impacts of tariffs on the interconnected supply chain. Faced with different customs duties and free-trade agreements, Prataviera et al. (2020) proposed a conceptual framework to take into account factors such as differential tax rates, transfer pricing schemes and exchange rate fluctuations in designing postponement strategy for global downstream supply chains. Other literature also studies the impacts of environmental tax policies on the sustainable supply chain network design. For example, Yu et al. (2019) investigated the impacts of emission tax policies on competing companies. They compared different tax policies on product demands, prices, total emissions and overall profits. Our work tries to fill the gap and attempts to combine the taxation and transfer pricing strategy and investigate how the tax rates under different circumstance affect the decision of transfer prices and then the optimal decision making in global supply chains.

3 Model settings

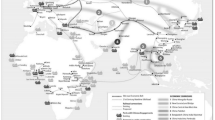

Considering the significant role China plays in the global supply chain, without loss of generality, we present the United States as the domestic country (with the subscript 1), while China as the main foreign country (with the subscript 2) and an alternative foreign country such as Vietnam (with the subscript 3) with relatively lower labor costs. We assume a global company produces a unique product sold to the domestic market in the United States, and to the Chinese market as well. Thus, there exist two markets, and three undefined production sites in the domestic country (e.g., USA), the main foreign country (e.g., China), and the alternative foreign country with lower production cost (e.g., Vietnam), respectively (Fig. 1).

We assume market demand in both countries is price-sensitive but uncorrelated. The retail prices both in the domestic market and foreign market are exogenous. Regarding the transfer price, the multinational company has to comply with the government’s regulations. When the foreign tax benefit exists, the global company has the incentive to set up a transfer price as high as possible, to avoid the high tax in the domestic country. In our model, according to the arm's length principle, we assume an upper limit for transfer prices, i.e., the transfer price cannot exceed such a limit (Tang, 2002; Wittendorff, 2010). On the other hand, a reasonable transfer price should not be lower than the foreign production cost. In the end, the transfer price must satisfy \(c\le T\le {T}_{U}\), where c denotes the production cost and \({T}_{U}\) is the upper limit of the transfer price (justified by the Comparable Uncontrolled Price (CUP) method, Halperin & Srinidhi, 1987). Based on the assumption of exogenous retail price p, we assume \({T}_{U}\ge p\) in the normal market. When a transfer exists, transportation costs cannot be neglected, as well as the cost of tariffs.

The main notations to be used in the models are listed as follows.\({d}_{i}\): Demand in Country \(i=1 \mathrm{or} 2\);\({c}_{i}\): Unit production cost in Country \(i=1, 2, \mathrm{or} 3\);\({t}_{i}\): Tax rate in Country \(i=1, 2, \mathrm{or} 3\);\({p}_{i}\): Retail price in Market \(i=1 \mathrm{or} 2\);\({T}_{iU}\): The upper limit of the transfer price for the product exported to Country \(i=1 \mathrm{or} 2\);\(T_{ij}^\Delta\) : Transfer price for the product exported from Country \(i (i=1, 2, \mathrm{or} 3)\) to Country \(j (j=1, \mathrm{or} 2)\), where Δ \(=Null, wo, or w\) which reflects Scenario 1, 2 or 3, respectively.\({TT}_{ij}\): Transportation cost and tariffs related if products shipped from Country \(i (i=1, 2, \mathrm{or} 3)\) to Country \(j (j=1 \mathrm{or} 2)\);\(Q_{ij}^\Delta\): The amount produced in Country \(i (i=1, 2 \mathrm{or} 3)\) and then consumed in Country \(j \left(j=1, \mathrm{or} 2\right)\), where Δ \(=Null, wo, or w\) which reflects Scenario 1, 2 or 3, respectively.\(\alpha \): a universal risk factor in the alternative foreign country 3.

4 Model analysis

We will study how a global supply chain adjusts itself under two different circumstances: (1) under traditional corporate tax policy; (2) under the tax penalty policy.

Under the traditional corporate tax policy, the after-tax profit of a company is \(\left(1-t\right){(pd-cQ)}^{+}\) versus \(\left(1-t\right)pd-cQ\) under the proposed tax penalty policy that is considered as a penalty for outsourcing, thus with a hope of bringing manufacturing home. Based on the observation from practical cases that tax rates in developing countries are usually lower than in developed counties (e.g., Johannesen et al., 2019), we will assume \({t}_{1}>{t}_{2}\) and analyze the global company’s strategic behavior accordingly. The analysis of the case \({t}_{2}\ge {t}_{1}\) is identical to what we are going to discuss in this section. Thus, such ignorance will not affect the intactness of the model analysis.

4.1 Base model: Scenario 1 (under traditional tax policy)

We start the analysis with the base model where only the domestic optional site and the main foreign operational site are considered. Such structure largely existed (and is still existing to some extent) in various global industries before the operational, environmental, and governing elements changed in the recent decade (Fig. 2).

The multinational company's objective is to maximize its global after-tax profits with respect to the decision variables including offshoring decision, production quantity, distribution, transfer prices and retail prices. Assuming the demand \({d}_{i} (i=1, 2)\) is sensitive to the retail price \({p}_{i} (i=1, 2)\), we have the demand function in the domestic market (\({d}_{1}\)) and the main foreign market (\({d}_{2}\)), respectively,

and

As discussed before, the demand in the domestic country is independent of the market in the main foreign country. Let \({Q}_{ij}\) denote the amount produced in the country \(i (i=1, 2)\) and then consumed in the country \(j (j=1, \mathrm{or} 2)\), we have

and

Following the transfer price policies discussed in Sect. 3, we have

Where \({T}_{ij}\) is the transfer price for the product exported from the country \(i (i=1 or 2)\) to the country \(j (j=1 or 2)\) and \({T}_{iU}\) represents the upper limit of the transfer price for the product exported to the country \(i=1, or 2\).

Thus, the total after-tax profit of the multinational company is

where \({TT}_{ij}\) denotes the transportation cost and tariffs related if products shipped from the country \(i (i=1, 2)\) to the country \(j (j=1, 2)\).

The multinational company’s strategic sourcing decision can be summarized in the following Theorem by investigating the optimal solution for Eq. (1).

Theorem 1

If \({t}_{1}>{t}_{2}\) , the optimal solutions to the model (Eq. 1) are as follows:

(1a) If \({c}_{2}<\left\{{c}_{1}+{TT}_{12}, {\widetilde{c}}_{{2}_{\_threshold}} \right\}\) , \({{Q}_{11}^{*}=Q}_{12}^{*}=0\) . All productions are made in the foreign country.

(1b) If \({c}_{2}\ge \left\{{c}_{1}+{TT}_{12}, {\widetilde{c}}_{{2}_{\_threshold}} \right\}\) , \({{Q}_{21}^{*}=Q}_{22}^{*}=0\) . All productions are made in the domestic country.

(1c) If \({c}_{1}+{TT}_{12}\ge {\widetilde{c}}_{{2\_}_{threshold}}\) and \({\widetilde{c}}_{{2\_}_{threshold}}<{c}_{2}< {c}_{1}+{TT}_{12}\) , \({{Q}_{12}^{*}=Q}_{21}^{*}=0\) , no transfer occurs on either side.

(1d) If \({c}_{1}+{TT}_{12}< {\widetilde{c}}_{{2}_{\_threshold}}\) and \({c}_{1}+{TT}_{12}<{c}_{2}<{\widetilde{c}}_{{2\_}_{threshold}}\) , \({Q}_{21}^{*}={d}_{1}\) and \({Q}_{12}^{*}={d}_{2}\) . Cross production occurs.where \({\widetilde{c}}_{{2\_}_{threshold}}=\frac{\left(1-{t}_{1}\right)\left({c}_{1}-{TT}_{21}\right)+\left({t}_{1}-{t}_{2}\right){T}_{1U}}{1-{t}_{2}}\)

Proof

See Appendix. #

Remark 1

The optimal retail prices (\({p}_{1}^{*}\) and \({p}_{2}^{*}\)) are not explicitly expressed in the analysis above, but they can be easily obtained based on the optional sourcing decision and the profit functions. The choice of retail prices does not impact the multinational company’s sourcing decision.

Theorem 1 summarizes the multinational company's optimal decisions, given that the foreign country holds a lower tax rate, which is common in many developing countries, such as China, and Thailand; those countries offer a low tax rate to attract foreign investments. Provided the tax benefit in the foreign country, the multinational company has the incentive to offshore their production as long as the foreign production costs are relatively low and international transportation costs and tariffs are affordable. Theorem 1 provides a threshold of the opportunity offshoring cost incorporated with tax rates, transportation cost, tariffs, and the allowable region of the transfer price (Fig. 3). As long as the foreign production cost \({c}_{2}\) is higher than such a threshold, the multinational company has no incentive to offshore the production for domestic market. A further look at the formula of the threshold \({\widetilde{c}}_{{2\_}_{threshold}}\) leads to the following corollary.

Corollary 1

If \({t}_{1}>{t}_{2}\) , the multinational company is more likely to benefit from offshoring the domestic production when

-

(1)

The upper limit of the transfer price \({T}_{1U}\) becomes larger; or

-

(2)

The domestic production \({c}_{1}\) becomes higher; or

-

(3)

The difference between the two tax rates becomes larger.

Proof

See Appendix. #

Theoretically, if there is no limit on the transfer price, offshoring always is a better choice. To restrict the multinational company from avoiding normal taxation, the domestic government, such as the United States, establishes transfer price policies indicated in the introduction section. A high domestic production cost certainly increases the chance of offshoring. The threshold \({\widetilde{c}}_{{2\_}_{threshold}}\) not only provides the multinational company a useful insight into offshoring decisions, but also helps the government with the policies of taxation. Nowadays, the voice of "bringing manufacturing home" is rising in some developed countries. \({\widetilde{c}}_{{2\_}_{threshold}}\) provides an important guideline for government regulation.

Furthermore, \({c}_{1}+{TT}_{12}\) can be considered as the adjusted unit production cost in the domestic country and then the unit is shipped to satisfy the foreign market. When the foreign production cost is smaller than the domestic production cost, it's better to manufacture in the foreign country and then directly sell to the foreign market.

Part (1c) in Theorem 1 indicates a situation where the multinational company offshores part of the production to the foreign country and then completely uses them to supply the foreign market. Meanwhile, the firm produces the remaining part in the domestic country and then sells them in the domestic market. This looks like two companies acting independently if we ignore the effect of the transfer price.

Part (1d) in Theorem 1 describes an interesting phenomenon stated before. To be specific, when the cost parameters satisfy \({c}_{1}+{TT}_{12} <{c}_{2}< {\widetilde{c}}_{{2\_}_{threshold}}\), import is better off than independent production for both companies. That is to say, the production in the domestic country will be entirely transferred to the foreign country, while what is produced in the foreign country will be completely shipped back to the domestic country. That's the cross-production case. This situation ensures the domestic company to take advantage of the low foreign tax rate and the foreign company utilizes the low domestic production cost, though it is not the common case.

Cross-production could be somehow paradoxical at first glance due to the transportation cost and tariffs are incurred whenever there is an export or import. As such, it would not be wise to let such an unavoidable cost happen twice. However, if we take the transfer price \({T}_{1}\) and \({T}_{2}\) into consideration, a cross-production becomes possible in some ways. By satisfying the transfer price policy, one company might utilize a proper transfer price to take the low production cost advantage or low tax rate advantage from the other country. As long as any corresponding transportation cost and tariffs exceed the improved profit, cross production is not a good choice. This is why cross production is not popular in real business.

Corollary 2

According to the current tax rates, it is reasonable to assume \({t}_{1}>15\%\) and \({t}_{2}<15\%\) . If the global minimum effective rate of “at least 15%” proposed by the G7 is approved, i.e., \({t}_{2}\) will be 15% or even higher, the multinational company is less likely to offshore.

Proof

See Appendix. #

4.2 Tax penalty model

In this section, we are going to study the multinational company’s sourcing decision under the proposed tax penalty model. Will reshoring be more likely to occur under the new tax regulation? Or will global companies be pushed to move their production to other foreign countries with lower production costs? To facilitate the model analysis in this tax penalty setting, we start the discussion in Sect. 4.2.1 with two potential operational sites (same as in the base model) and then extend the analysis in Sect. 4.2.2 to include the alternative foreign operational site with even lower production costs. We only consider the case \({t}_{1}>{t}_{2}\) in this section as before.

4.2.1 Tax penalty model without an alternative foreign country: Scenario 2

Given the government’s tax penalty on outsourcing, the company earns the following profit in general,

Thus, the total profit of the multinational company is

Similar to the base model, we can derive the strategic behavior of the multinational company by investigating Eq. (2). The aggregated optimal solutions are summarized in the following Theorem.

Theorem 2

If \({t}_{1}>{t}_{2}\) , the optimal solutions to the model (Eq. 2) are as follows:

(2a) If \({c}_{2}<({1-t}_{1}){c}_{1}-{TT}_{21}\) , \({Q}_{11}^{wo*}=0={Q}_{12}^{wo*}\) . All foreign production.

(2b) If \(\left({1-t}_{1}\right){c}_{1}-{TT}_{21}\le {c}_{2}\le {c}_{1}+{TT}_{12}\) , \({Q}_{21}^{wo*}=0={Q}_{12}^{wo*}\) . Separate production.

(2c) If \({c}_{2}>{c}_{1}+{TT}_{12}\) , \({Q}_{22}^{wo*}=0={Q}_{21}^{wo*}\) . All domestic production.

Proof

See Appendix. #

Remark 2

In the base model, \({\widetilde{c}}_{{2}_{threshold}}=\frac{\left(1-{t}_{1}\right)\left({c}_{1}-{TT}_{21}\right)+\left({t}_{1}-{t}_{2}\right){T}_{1U}}{1-{t}_{2}}\), obviously, \({\widetilde{c}}_{{2}_{threshold}}=\frac{\left(1-{t}_{1}\right)\left({c}_{1}-{TT}_{21}\right)+\left({t}_{1}-{t}_{2}\right){T}_{1U}}{1-{t}_{2}}>({1-t}_{1}){c}_{1}-{TT}_{21}\); thus, it is less likely to make “all foreign production” happen under the tax penalty policy. Does this mean that there is a higher chance of domestic production or reshoring? Or is it just wishful thinking? In fact, we will see the production might be relocated to another foreign country with lower production costs once certain conditions are satisfied.

Remark 3

The cross-production case is not possible under the tax penalty policy. In addition, the condition in (2c) is hard to be met, thus it is rare to see that both market demands are satisfied by domestic production.

Similar to the extended discussion on the global minimum effective rate by the G7 before, we can study the effect of the global minimum effective rate on offshoring under the tax penalty model.

Corollary 3

The global minimum effective rate of “at least 15%” proposed by the G7 will not impact the outsourcing decision of the multinational company under the tax penalty policy.

Proof

See Appendix. #

The explanation of Corollary 3 lies in the setting of the transfer price (see Eq. A4 in the Appendix) not impacted by the tax rate in the foreign country under the tax penalty policy. Therefore, the increase in \({t}_{2}\) will certainly decrease the global after-tax profit of the firm but won’t affect its sourcing decision.

4.2.2 Tax penalty model with an alternative foreign country: Scenario 3

Manufacturing will move back to the domestic country if \({c}_{2}>({1-t}_{1}){c}_{1}-{TT}_{21}\). Given the increasing labor cost in China, such a condition might not be hard to meet. But there has not been a clear sign that global companies are moving their production back; instead, many are relocating their production to another foreign site with even lower production costs, such as Vietnam. We use Fig. 4 to illustrate such a situation. In this subsection, we will investigate the multinational company’s strategic sourcing behavior and study why and when it is profitable to outsource to another foreign country with lower production costs.

In this scenario, there are three potential operational sites still with two markets. Continuing with the findings in the previous model, we focus on the case \({Q}_{21}=0\), i.e., no outsourcing to the main foreign country 2. That is, the condition in (2b) or (2c) is met with the cost parameters.

Extending the findings in Theorem 2, it will be reasonable to assume if \({Q}_{11}=0\), there will be \({Q}_{21}=0\). In other words, if the demand in market 1 is satisfied by the alternative foreign operational site 3 (with lower production costs), the domestic production will be zero, and the demand in market 2 will either be met by its own production 2 or the lower-cost production 3, depending on the cost parameters.

We introduced a variable \(\alpha (\alpha \in (\mathrm{0,1}])\) in the alternative foreign production to reflect a universal risk effect that could be quality, defective production, natural disaster, pandemic, or any combination of them. As discussed in the Introduction, the alternative foreign countries with lower production costs, i.e., Vietnam, are generally considered to experience higher risks due to the inherent social and economic factors of developing countries. The higher the chance of any risk, the lower the value of \(\alpha \).

Following the similar profit structure in Eq. (2), we have the profit function of the multinational company if another foreign country with lower production costs exists.

The analysis of the strategic behavior of the multinational company in Scenario 3 is much more complicated than in the previous scenarios. We will summarize all the proofs in the Appendix. But to present the following theorems, we first list several important inequalities and equalities.

Let (\(\overline{5 }\)) represents the contrary of inequality (5), i.e.,

Let’s present the following theorems.

Theorem 3.1

If \({t}_{1}>{t}_{2}\) , both market demands are satisfied by the lower-cost production when any of the conditions (3.1a) through (3.1c) is satisfied.

(3.1a) Ieqs. (7) and (8) hold simultaneously.

(3.1b) Ieqs. (7), (5) and (6) hold simultaneously.

(3.1c) Ieqs. (8), ( \(\overline{5 }\) ), and (9) hold simultaneously.

Proof

See Appendix. #

Notice that if Ieq. (4) doesn’t hold, \({Q}_{32}\) will have a value of 0, then \({\xi }^{+}\) reduces to 0. Thus, when Ieq. (8) holds but Ieq. (9) is not satisfied (i.e., (\(\overline{9 }\)) holds), we will have \({Q}_{31}^{w*}={d}_{1}/\alpha \) and \({Q}_{32}^{w*}=0\).

Theorem 3.2

If \({t}_{1}>{t}_{2}\) , the domestic market demand will be satisfied by the alternative foreign country with lower production costs while the main foreign country ensures its demand is covered by its own production, if the following condition is satisfied,

(3.2a) Ieqs. (8) and ( \(\overline{9 }\) ) hold simultaneously.

Another possible scenario is the alternative foreign country 3 with lower production costs only exports to the main foreign country 2; that is \({Q}_{31}^{w*}=0\) and \({Q}_{32}^{w*}={d}_{2}/\alpha \), when the inequality (6) doesn’t hold while Ieq. (7) is satisfied.

Theorem 3.3

If \({t}_{1}>{t}_{2}\) , the alternative foreign country 3 with lower production costs only exports to the main foreign market demand 2 if the following condition is satisfied.

(3.3a) Ieqs. (7) and ( \(\overline{6 }\) ) hold simultaneously.

Remark 3

Iequation (\(\overline{9 }\)) is stronger than Ieq. (\(\underline{7}\)), but Ieqs. (8) and (\(\overline{7 }\)) doesn’t lead to Theorem 3.2. Similarly, Ieqs. (7) and (\(\overline{8 }\)) doesn’t lead to Theorem 3.3.

Theorem 3.4

When \({t}_{1}>{t}_{2}\) and none of the conditions listed in Theorems (3.1)–(3.3) is satisfied, the scenario reduces to the model setting discussed in Sect. 4.2.1 where the alternative foreign country 3 with lower production costs is not an option.

Remark 4

Theorems 3.1 and 3.2 have shown that as long as \({(1-{t}_{1})c}_{1}>\frac{{c}_{3}}{\alpha }+{TT}_{31}\) (Ieq. (8)), there will be a great chance for domestic country 1 to outsource to the alternative foreign country 3 with lower production costs. In fact, if the inequality (8) holds, only the situation where Ieqs. (5), (9) and (7) are satisfied simultaneously will impede such outsourcing.

Recall Theorem 2, when \(\left({1-t}_{1}\right){c}_{1}\le {c}_{2}+{TT}_{21}\), there is no exporting from the main foreign country 2 to the domestic market 1. As stated at the beginning of Sect. 4.2.2, all findings in Theorem (3.1) through (3.4) are based on such assumption of no outsourcing to the foreign country 2. That being said, as long as \(\frac{{c}_{3}}{\alpha }+{TT}_{31}<\left({1-t}_{1}\right){c}_{1}\le {c}_{2}+{TT}_{21}\), the multinational company is more willing to move manufacturing to an alternative foreign country 3 with lower production costs.

Looking at Ieq. (8), if the chance of risk is relatively low (or acceptable) in the alternative foreign country 3 of lower production, the value of \(\alpha \) would be high or even close to 1. Given the fact of the lower-cost production in the foreign country 3 (\({c}_{3}\ll {c}_{2}\)), when there is not a significant deviation among the shipping costs (\({TT}_{21}\) vs \({TT}_{31}\)), there is a high chance to make \(\frac{{c}_{3}}{\alpha }+{TT}_{31}<\left({1-t}_{1}\right){c}_{1}\le {c}_{2}+{TT}_{21}\) happen. As such, moving production to the alternative foreign country 3 with lower production costs is simply beneficial than reshoring. That is, moving manufacturing won’t happen as wished by the government.

Corollary 4

If \({t}_{1}>{t}_{2}\) , the multinational company is more likely to benefit from moving production to another foreign country with lower production costs when

-

(1)

The alternative foreign production cost \({c}_{3}\) becomes smaller; or

-

(2)

The risk effect is getting smaller ( \(\alpha \) is getting larger); or

-

(3)

The upper limit of the transfer price \({T}_{3U}\) becomes larger when \({t}_{3}\le {t}_{2}\) ; or

-

(4)

The upper limit of the transfer price \({T}_{3U}\) becomes smaller when \({t}_{3}>{t}_{2}\) .

Similar to the extended discussion on the global minimum effective rate by G-7 before, we can study the effect of the global minimum effective rate on offshoring under the tax penalty model.

Corollary 5

According to the current tax rates, it is reasonable to assume \({t}_{1}>15\%\) and \({t}_{3}<15\%\) . If the global minimum effective rate of “at least 15%” proposed by the G7 is approved, i.e., \({t}_{3}\) will be 15% or even higher, the multinational company holds a higher chance to offshore to the alternative foreign country with lower production costs.

Proof

See Appendix. #

Remark 5

The finding in Corollary 5 is interesting. But it might only happen when alternative foreign country with lower production costs already exports to the main foreign market. Under that circumstance, the increase in \({t}_{3}\) leads to an additional loss from the production risk or defective production.

To illustrate the analytical findings presented in Theorem 3.1 through 3.4, a few numerical experiments were conducted. The estimation of parameters (e.g., risk factor \(\alpha \), Transportation cost and tariffs \({TT}_{ij}\), tax rate \({t}_{i}\), unit production cost \({c}_{i}\), etc.) is based on the published data set, reports, and articles (Damodaran, 2022; Kennemer, 2021; U.S. Trade Representative, 2021; Burkhart, 2019; Statista, 2020, 2021). The unit production cost in the U.S., \({c}_{1}\), is used as a reference, and the value is set to be 1. All other production costs, tariff and transportation costs, and transfer prices are presented in the percentage of \({c}_{1}\). For instance, if \({c}_{2}=0.25\), it means \(\frac{{c}_{2}}{{c}_{1}}=25\%\). \(TT=0.1\) means the tariff and transportation costs between the two countries are assumed to be 10% of the production cost in the U.S. \({T}_{U}=2\) means the upper limit of the transfer price is assumed to be twice the production cost in the U.S.

In Figs. 5, 6, and 7, the red region represents the conditions where Theorem 3.1 is met, i.e., both market demands are satisfied by the lower-cost production; the green region represents the conditions where Theorem 3.3 is guaranteed, i.e., there is only transfer from the alternative foreign country with lower production costs to the main foreign market demand; the black region represents the conditions where Theorem 1a (in the base model) is guaranteed, i.e., there is no production in the alternative foreign country with lower production costs, but transfers from the main foreign market exports to the domestic market; the cyan region represents the conditions where Theorem 1c (in the base model) is guaranteed, i.e., no transfer occurs between any countries.

Surprisingly, there is a small chance that no transfer occurs. In other words, the domestic market is served by its domestic production (The cyan region in Fig. 5). This could possibly happen only when the production costs in the main foreign country and the alternative foreign country with lower production costs are very close to the production cost in the domestic country. We all know it is rare under the current circumstance. It is more likely to see either the transfer from the alternative foreign country with lower production costs to both markets (the red regions) or the transfer from the main foreign country to the domestic (the black regions). It is interesting to see the tax rate in the domestic country does not affect the offshoring decision significantly (Fig. 6). In other words, the tax reduction in the United States might not serve the purpose of bringing production back. The tariff and transportation costs and the production risk factor have a great impact on the global supply chain (Fig. 7). The tariff and transportation costs between any two countries are simply assumed to be the same. When the tariff and transportation costs go up, the chance of producing in the alternative foreign country with lower production costs reduces since the cost advantage becomes smaller. As \(\alpha \) gets larger (i.e., the production in the alternative foreign country with lower production costs is more reliable), production is more likely to be located in the alternative foreign country with lower production costs.

One impressive example of how \(\alpha \) affects the sourcing allocation is the COVID pandemic. The report (Reuters, 2022) has shown “China’s exports shrank 8.7% while imports declined 10.6% in November due to weakened external demand”. During the past three years, the pandemic lockdowns in China have socially and economically imposed trading risks on China, which makes investors and multinational companies see the alternative foreign country (e.g., Vietnam) as a relatively more reliable site to trade. In such circumstance, \(\alpha \) gets larger and more production moves to alternative foreign countries.

5 Managerial insights and conclusions

In this paper, we examine how a multinational company evaluates its operational decisions in terms of offshoring and reshoring under two different tax regulations. Our results provide a few managerial implications for both global companies and national governments. First, the comparison between the base model and the tax penalty model without the existence of the alternative foreign country with lower production costs shows that it is less likely to make “all foreign production” under the tax penalty policy. Does this mean that there is a higher chance of domestic production or reshoring? Or is it just wishful thinking? In fact, we may expect that the production might be relocated to the alternative foreign country with lower production costs instead of reshoring back to the domestic country once certain conditions are satisfied. However, the tax penalty model might bring production back to its domestic countries when supply chain disruptions frequently occur, a scenario close to the current environment due to the pandemic and increasing number of natural disasters.

Second, we find the transfer price would greatly impact the sourcing decision of the multinational company in the base model, but it plays no critical role in the tax penalty model without the alternative foreign country with lower production costs. Thus, the tax penalty model might be effective when the transfer price regulations are not solid in some countries. Third, the analysis of the tax penalty model with a lower-cost foreign country is much more complex. However, we are able to reveal the multinational company has a desire to offshore to the alternative foreign country with lower production costs under different circumstances even if the production risks prevail. Thus, the adoption of the proposed tax penalty policy “motivating” global companies to re-shore might be only wishful thinking. More so, it imposes additional risks considering the insufficient production capacity in the alternative foreign country with lower production costs. This issue is even challenging for sophisticated manufacturing since the workforce in the foreign country with lower production costs is relatively inexperienced regarding products requiring high levels of technical precision. The relocation of the long-term “know-how” can be expensive and time-consuming. This may explain why the companies still rely on their production in China as the main foreign country during the pandemic. As for products of low technical precision, such as clothing, global fashion brands experienced local pollution fights. For instance, the severe water pollution in Hai Duong, 30 miles east of Hanoi, leads to local blockage by the villagers (Nguyen, 2017). To effectively motivate global companies to bring manufacturing back, instead of a penalty, we would recommend a governmental incentive scheme, i.e., subside global companies in a pre-determined period if they re-shore.

There are a number of ways to extend this research. Our model currently assumes two overlapping markets with a short selling season. One possible extension is to study the effect of transfer pricing in non-overlapping markets (e.g., a primary market and a secondary market) or multiple markets over different selling seasons. In these cases, the inventory issues should be carefully addressed due to a longer time range. Another possible extension would be to consider the mixed supply modes, i.e., the demand could be satisfied from local/foreign production and/or third-party sources. The fee charged by the third-party source with prompt replenishment could be higher than the local/foreign production cost. This issue is very important, especially for seasonal products. Last but not least, global supply chain integration can be investigated by incorporating multiple markets' selling efforts and creating supply chain contracts and schemes.

References

Abdallah, W. M. (1989). International transfer pricing policies: Decision making guidelines for multinational companies. Quorum Books.

Balaji, K., & Viswanadham, N. (2008). A tax integrated approach for Global Supply Chain Network Planning. IEEE Transactions on Automation Science & Engineering, 5(4), 587–596.

Bogataj, D., & Bogataj, M. (2011). The role of free economic zones in global supply chains - a case of reverse logistics. International Journal of Production Economics, 131, 365–371.

Brush, T. H., Marutan, C. A., & Karnani, A. (1999). The plant location decision in multinational manufacturing firms: An empirical analysis of international business and manufacturing strategy perspectives. Production and Operations Management, 8(2), 109–132.

Burkhart, M. (2019, October 16). Manufacturing In Vietnam: 5 Key Factors For Moving From China. https://www.intouch-quality.com/blog/3-key-factors-for-sourcing-in-vietnam

Carr, A., & Gurman, M. (2021). Tim Cook’s $2.3 Trillion Fortress. Bloomberg Businessweek, 4689, 40–45.

Chae, S., Mena, C., Polyviou, M., Rogers, Z. S., & Wiedmer, R. (2019). The effects of tariff increases on supply base complexity: A conceptual framework. Journal of Purchasing & Supply Management, 25(4), 100556.

Ciabuschi, F., Lindahl, O., Barbieri, P., & Fratocchi, L. (2019). Manufacturing reshoring. European Business Review, 31(1), 139–159.

Cohen, M. A., Cui, S., Ernst, R., Huchzermeier, A., Kouvelis, P., Lee, H. L., Matsuo, H., Steuber, M., & Tsay, A. A. (2018). OM Forum—Benchmarking global production sourcing decisions: Where and why firms offshore and reshore. Manufacturing & Service Operations Management, 20(3), 389–402.

Cohen, M. A., & Huchzermeier, A. (1999). Global supply chain management: A survey of research and applications. In A. Tayur, R. Ganeshan, & M. Magazine (Eds.), Quantitative models for supply chain management (pp. 669–702). Kluwer Academic Press.

Cohen, M. A., & Lee, H. L. (2020). Designing the right global supply chain network. Manufacturing & Service Operations Management, 22(1), 15–24.

Cohen, M. A., & Mallik, S. (1997). Global supply chains: Research and applications. Production and Operations Management, 6(3), 193–210.

Damodaran, A. (2022). Company Financial Data Sources. http://people.stern.nyu.edu/adamodar/New_Home_Page/data.html

De Mooij, R. A., & Ederveen, S. (2003). Taxation and foreign direct investment: A synthesis of empirical research. International Tax and Public Finance, 10, 673–693.

Dong, L., & Kouvelis, P. (2020). Impact of tariffs on global supply chain network configuration: Models, predictions, and future research. Manufacturing & Service Operations Management, 22(1), 25–35.

Ernst & Young. (2012). Transfer Pricing Global Reference Guide. https://assets.ey.com/content/dam/ey-sites/ey-com/en_gl/topics/tax/guides/worldwide-transfer-pricing-reference-guide-2012.pdf

Fernandes, R., Pinho, C., & Gouveia, B. (2015). Supply chain networks design and transfer-pricing. The International Journal of Logistics Management, 26(1), 128–146.

Gaertner, F. B., Hoopes, J. L., & Maydew, E. L. (2018). Shareholder wealth effects of border adjustment taxation. https://ssrn.com/abstract=2956740

Halperin, R., & Srinidhi, B. (1987). The effect of the U.S. income tax regulations’ transfer pricing rules on allocative efficiency. The Accounting Review, 62(4), 686–706.

Hsu, V., & Zhu, K. (2011). Tax-effective supply chain decisions under China’s export-oriented tax policies. Manufacturing & Service Operations Management, 13(2), 163–179.

Johannesen, N., Tørsløv, T., & Wier, L. (2019). Are less developed countries more exposed to multinational tax avoidance? Method and evidence from micro-data. The World Bank Economic Review, 34(3), 790–809.

Jung, S. H. (2020). Offshore versus onshore sourcing: Quick response, random yield, and competition. Production & Operations Management, 29(3), 750–766.

Kearney. (2021). The Tides Are Turning: 2021 Reshoring Index. https://www.kearney.com/operations-performance-transformation/us-reshoring-index

Kennemer, J. (2021). How to Export from Vietnam to the United States. https://www.cosmosourcing.com/blog/how-to-export-from-vietnam-to-the-united-states-regulations-and-tariffs-when-importing-to-the-us

Kouvelis, P., & Gutierrez, G. (1997). The newsvendor problem in a global market: Optimal centralized and decentralized control policies for a two-market stochastic inventory system. Management Science, 43(5), 571–585.

Meixell, M., & Gargeya, V. B. (2005). Global supply chain design: A literature review and critique. Transportation Research Part E, 41(6), 531–550.

Miller, D. S., Nussbaum, A. H., Rosow, S., Corn, R. M., Friedman, R. A., Hamilton, M. T., & May, A. P. (2022). Summary of the Biden Administration’s Fiscal Year 2023 Green Book Tax Proposals. https://www.proskauertaxtalks.com/2022/07/summary-of-the-biden-administrations-fiscal-year-2023-green-book-tax-proposals/

Moretto, A., Patrucco, A. S., & Harland, C. M. (2020). The dynamics of reshoring decisions and the role of purchasing. International Journal of Production Research, 58(19), 5929–5944.

Mutti, J. (2003). Foreign direct investment and tax competition. IIE Press.

Nguyen, M. (2017). Vietnam pollution fight hits supplier to global fashion brands. Reuters. https://www.reuters.com/article/us-vietnam-pollution-idUSKBN1A60GO

Niu, B., Liu, Y., Luo, H., & Feng, B. (2019). Domestic sourcing vs. cross-border sourcing: Impact of the quality of the scrap metal and Government’s tariff policies. Journal of Cleaner Production, 208, 1281–1293.

OECD. (1979). Transfer pricing guidelines for multinational enterprises and tax administrations. OECD.

OECD. (1995). Transfer pricing guidelines for multinational enterprises and tax administrations. OECD.

OECD. (1996). Transfer pricing guidelines for multinational enterprises and tax administrations. OECD.

OECD. (1997). Transfer pricing guidelines for multinational enterprises and tax administrations. OECD.

Prataviera, L. B., Perotti, S., Melacini, M., & Moretti, E. (2020). Postponement strategies for global downstream supply chains: A conceptual framework. Journal of Business Logistics, 41(2), 94–110.

Reuters. (2022). China’s Trade Suffers Worst Slump in 2–1/2 yrs as COVID WOES, Feeble Demand Take Toll. https://www.reuters.com/markets/asia/chinas-exports-imports-dive-nov-feeble-demand-domestic-covid-woes-2022-12-07/

Shih, W. C. (2020). Bringing Manufacturing Back to the U.S. Is Easier Said Than Done. https://hbr.org/2020/04/bringing-manufacturing-back-to-the-u-s-is-easier-said-than-done

Spinowitz, M. (2018). Tax-efficient supply chain in shadow of tax reform. Tax Executive, 70(2), 20–25.

Srai, J. S., & Ané, C. (2016). Institutional and strategic operations perspectives on manufacturing reshoring. International Journal of Production Research, 54(23), 7193–7211.

Statista. (2020). Manufacturing labor costs per hour: China, Vietnam, Mexico 2016–2020. Statista. https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/

Statista. (2021). Hourly earnings in U.S. manufacturing 2006–2021. Statista. https://www.statista.com/statistics/187380/hourly-earnings-in-us-manufacturing-since-1965/

Tang, R. Y. (2002). Current Trends and Corporate Cases in Transfer Pricing. All Books and Monographs by WMU Authors. 468.

Tate, W. L., & Bals, L. (2017). Outsourcing/offshoring insights: Going beyond reshoring to rightshoring. International Journal of Physical Distribution & Logistics Management, 47(2), 106–113.

The Economist. (2013). Here, there and everywhere. The Economist. https://www.economist.com/special-report/2013/01/17/here-there-and-everywhere

U.S. Trade Representative. (2021). 2021 National Trade Estimate Report on Foreign Trade Barriers. Office Of the United States Trade Representative. https://ustr.gov/sites/default/files/files/reports/2021/2021NTE.pdf

Veneziani, V. (2020). How to bring back manufacturing jobs: Cut the corporate tax and invest in infrastructure. https://www.businessinsider.com/nam-and-milken-institute-tax-and-policy-changes-are-needed-for-job-creation-2010-1

Wittendorff, J. (2010). Transfer pricing and the arm’s length principle in international tax law. Kluwer Law International.

Xu, J., Hsu, V. N., & Niu, B. (2018). The impacts of markets and tax on a multinational firm’s procurement strategy in China. Production & Operations Management, 27(2), 251–264.

Yu, M., Cruz, J. M., & Li, D. (2019). The sustainable supply chain network competition with environmental tax policies. International Journal of Production Economics, 217, 218–231.

Funding

Ziping Wang has received funding from National Science Foundation (Award number: 2200506). Jingxian Chen has received funding from the National Natural Science Foundation of China (Grant Numbers. 71771127 and 72171073).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Proof of Theorem 1 To solve the optimal solution for Eq. (1), we investigate the profit in each market according to the independence of the demand in separate markets. Let \({\pi }_{1}\) be the profit gained from the consumption in Market 1.

Since \({\pi }_{1}\) is increasing in the transfer price \({T}_{21}\) following \(\frac{\partial {\pi }_{1}}{\partial {T}_{21}}=({t}_{1}-{t}_{2}){Q}_{21}\), the optimal transfer price can be expressed as \({T}_{21}^{*}={T}_{1U}\) given \({t}_{1}>{t}_{2}\).

Furthermore, \({Q}_{11}+{Q}_{21}={d}_{1}={a}_{1}-{b}_{1}{p}_{1}\), thus \({Q}_{21}={a}_{1}-{b}_{1}{p}_{1}-{Q}_{11}\)

Obviously, if \(\frac{\partial {\pi }_{1}}{\partial {Q}_{11}}<0\), the domestic demand will be covered by the foreign production, i.e., \({Q}_{11}^{*}=0\). Therefore, if the production cost in the main foreign market \({c}_{2}\) satisfies

\({Q}_{11}^{*}=0\) and \({Q}_{21}^{*}={a}_{1}-{b}_{1}{p}_{1}\). Otherwise, \({Q}_{11}^{*}={a}_{1}-{b}_{1}{p}_{1}\) and \({Q}_{21}^{*}=0\).

On the other hand, \({\pi }_{2}\) can represent the profit gained from the consumption in Market 2.

Noticing that\(\frac{\partial {\pi }_{1}}{\partial {T}_{12}}=\left({t}_{2}-{t}_{1}\right){Q}_{12}<0\), when\({t}_{1}>{t}_{2}\), we have the optimal transfer price\({T}_{12}^{*}={c}_{1}\). Similar to the analysis as before, we have\(\frac{\partial {\pi }_{1}}{\partial {Q}_{22}}=\left(1-{t}_{2}\right)\left({{c}_{1}+TT}_{21}-{c}_{2}\right)\). Thus, when \({c}_{2}>{c}_{1}+{TT}_{12}\), \({Q}_{22}^{*}=0\) and\({Q}_{12}^{*}={a}_{2}-{b}_{2}{p}_{2}\); Otherwise \({Q}_{22}^{*}={a}_{2}-{b}_{2}{p}_{2}\) and\({Q}_{12}^{*}=0\). #

Proof of Corollary 1

All results can be simply derived from the equation of

where \({T}_{1U}\) is the upper limit of the transfer price \({T}_{1}\). #

Proof of Corollary 2

\({\widetilde{c}}_{{2\_}_{threshold}}=\frac{\left(1-{t}_{1}\right)\left({c}_{1}-{TT}_{21}\right)+\left({t}_{1}-{t}_{2}\right){T}_{1U}}{1-{t}_{2}}\) is decreasing in \({t}_{2}\), thus the condition (1a) in Theorem 1 is less likely to be satisfied and then the multinational company has lower chance to offshore. #

Proof of Theorem 2

Based on the profit function of the multinational company in Eq. (2), the optimal transfer price \({T}_{21}^{wo*}\) can be derived as follows,

Thus

Given \({t}_{1}>{t}_{2}\), \(\frac{\partial {\pi }^{wo}}{\partial {T}_{12}}=(1-{{t}_{1})Q}_{12}-\left(1-{t}_{2}\right){Q}_{12}=({t}_{2}-{t}_{1)}{Q}_{12}<0\).

Thus,

Next, let’s take a look at \({Q}_{11}^{wo}\) and \({Q}_{21}^{wo}\). Similar to the base model, we can express the profit of the company in a combination of the profit achieved from the domestic market and the profit achieved from the foreign market. That is

where,

Given \({Q}_{11}+{Q}_{21}=\) \({a}_{1}-{{b}_{1}p}_{1}={d}_{1}\), we have the following optimum conditions,

If\( {c}_{1}>\frac{{c}_{2}+{TT}_{21}}{1-{t}_{1}}\), or\({c}_{2}<({1-t}_{1}){c}_{1}-{TT}_{21}\), then \({Q}_{11}^{wo*}=0\), and\({Q}_{21}^{wo*}={d}_{1}\).

If\( {c}_{1}\le \frac{{c}_{2}+{TT}_{21}}{1-{t}_{1}}\), or\({c}_{2}\ge ({1-t}_{1}){c}_{1}-{TT}_{21}\), then \({Q}_{21}^{wo*}=0\), and\({Q}_{11}^{wo*}={d}_{1}\).

We can analyze \({\pi }_{2}^{wo}\) in a similar way.

Given \({Q}_{12}+{Q}_{22}=\) \({a}_{2}-{{b}_{2}p}_{2}={d}_{2}\), we have the following optimum conditions,

If\({c}_{2}>{c}_{1}+{TT}_{12}\), then \({Q}_{22}^{wo*}=0\), and\({Q}_{12}^{wo*}={d}_{2}\).

If\({c}_{2}\le {c}_{1}+{TT}_{12}\), then \({Q}_{12}^{wo*}=0\), and\({Q}_{22}^{wo*}={d}_{2}\).

Obviously, \({c}_{1}+{TT}_{12}>({1-t}_{1}){c}_{1}-{TT}_{21}\), thus we have the aggregated optimal solutions in Theorem 2. #

Proof of Corollary 3

All conditions in Theorem 2 are indifferent in \({t}_{2}\). #

Proof of Theorem 3.1 –3.4

Obviously, if \({t}_{2}\ge {t}_{3}\), \({T}_{32}^{w*}={T}_{3U}\). When \({t}_{2}<{t}_{3}\) and \({\gamma }^{+}=0\), \({T}_{32}^{w*}={T}_{3U}\).

Let’s check the condition of \({t}_{2}<{t}_{3}\) but \({\gamma }^{+}=1\). Under this situation, it seems \({T}_{32}^{w*}={c}_{3}\); however, after we substitute \({c}_{3}\) into \({T}_{32}\), (\(\alpha {{T}_{32}-{c}_{3})Q}_{32}-{c}_{3}\left(1-\alpha \right){Q}_{31}\) turns out to be negative, thus \({\gamma }^{+}=0\), which contradicts the presumed condition \({\gamma }^{+}=1\). Thus, no matter what relationship exists between \({t}_{2}\) and \({t}_{3}\), we have

Similar to the model analysis in the previous sections, we still have

where

and \({\xi }^{+}=1\), if (\(\alpha {{T}_{3U}-{c}_{3})Q}_{32}-{c}_{3}\left(1-\alpha \right){Q}_{31}>0\); 0 otherwise.

Thus

If \((1-{t}_{1}){c}_{1}\le \left(\frac{{c}_{3}}{\alpha }+{TT}_{31}\right)-{t}_{3}\frac{1-\alpha }{\alpha }{c}_{3}\bullet {\xi }^{+}\), \({Q}_{11}^{w*}={d}_{1}\), \({Q}_{31}^{w*}=0\)

If \({(1-{t}_{1})c}_{1}>\left(\frac{{c}_{3}}{\alpha }+{TT}_{31}\right)-{t}_{3}\frac{1-\alpha }{\alpha }{c}_{3}\bullet {\xi }^{+}\), \({Q}_{11}^{w*}=0\), \({Q}_{31}^{w*}={d}_{1}/\alpha \)

Given that the value of \({\xi }^{+}\) depends on the sign of (\(\alpha {{T}_{3U}-{c}_{3})Q}_{32}-{c}_{3}\left(1-\alpha \right){Q}_{31}\), we need to discuss the optimality of \({Q}_{32}\) and figure out the aggregated optimal production solutions.

To be specific, we compare the profits generated from \({d}_{2}\).

Thus,

Obviously, if

Therefore, if the following three inequalities (Ieq. (5–7), as presented in main context) hold together

We have \({Q}_{31}^{w*}={d}_{1}/\alpha \) and \({Q}_{32}^{w*}={d}_{2}/\alpha \). In other words, all production will occur in the lower-cost production country 3. Iequation (A12) ensures \({\xi }^{+}=1\), and the other two rewrites the optimal conditions generated for \({Q}_{31}\) and \({Q}_{32}\).

Let (\(\overline{5 }\)) represents the contrary of inequality (5), i.e., (\(\alpha {{T}_{3U}-{c}_{3})d}_{2}-{c}_{3}\left(1-\alpha \right){d}_{1}\le 0\), in a similar setting where \({\xi }^{+}=0\), we still have \({Q}_{31}^{w*}={d}_{1}/\alpha \) and\({Q}_{32}^{w*}={d}_{2}/\alpha \), if the following three inequalities are satisfied simultaneously,

It is worth noting that the inequality (7) guarantees inequality (9), and similarly, the inequality (8) guarantees inequality (6). Therefore, Theorem 3.1 is proved. #

Proof of Corollary 5

\(\left(\frac{{c}_{3}}{\alpha }+{TT}_{31}\right)-{t}_{3}\frac{1-\alpha }{\alpha }{c}_{3}\) is decreasing in \({t}_{3}\), thus Ieq. (6) is more likely to be satisfied and then the multinational company has higher chance to offshore according to Theorems 3.1 and 3.3. #

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Cheng, F., Chen, J. et al. Offshoring or reshoring: the impact of tax regulations on operations strategies. Ann Oper Res 326, 317–339 (2023). https://doi.org/10.1007/s10479-023-05346-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-023-05346-x