Abstract

Identifying the root causes of part-to-part variation is a central problem in most six-sigma programs, especially of modern manufacturing processes. This is challenging as the sources and patterns of the variation are often unknown or previously unidentified. A small literature aims to address this problem by discovering unknown, previously unidentified variation sources, in a manner that helps understand their nature, from only a sample of measurement data. However, the common solution of this literature is unideal for this objective in terms of both methodology and metrology aspects. This paper proposes a convolutional generative modeling framework for optical scanning data to address this limitation. The proposed approach can correctly discover the true variation sources and visualize their individual patterns in two manufacturing examples, without any prior knowledge of the variation. The approach also outperforms state-of-the-art methods in these examples.

Similar content being viewed by others

References

Apley, D. W., & Shi, J. (2001). A factor-analysis method for diagnosing variability in mulitvariate manufacturing processes. Technometrics. https://doi.org/10.1198/00401700152404354

Apley, D. W., & Zhang, F. (2007). Identifying and visualizing nonlinear variation patterns in multivariate manufacturing data. IIE Transactions. https://doi.org/10.1080/07408170600899573

Baek, J., Jeong, M. K., & Elsayed, E. A. (2020). Residual-based surface segmentation for monitoring topographic variations. IEEE Transactions on Automation Science and Engineering. https://doi.org/10.1109/TASE.2020.3027810

Bastani, K., Kong, Z., Huang, W., & Zhou, Y. (2016). Compressive sensing–based optimal sensor placement and fault diagnosis for multi-station assembly processes. IIE Transactions, 48(5), 462–474. https://doi.org/10.1080/0740817X.2015.1096431

Brakel, P., & Bengio, Y. (2017). learning independent features with adversarial nets for non-linear ICA, arXiv:1710.05050 [stat]. [Online]. Available: http://arxiv.org/abs/1710.05050

Bui, A. T., & Apley, D. W. (2018). A monitoring and diagnostic approach for stochastic textured surfaces. Technometrics. https://doi.org/10.1080/00401706.2017.1302362

Bui, A. T., & Apley, D. W. (2019). An exploratory analysis approach for understanding variation in stochastic textured surfaces. Computational Statistics & Data Analysis, 137, 33–50. https://doi.org/10.1016/j.csda.2019.01.019

Bui, A. T., & Apley, D. W. (2022). Analyzing nonparametric part-to-part variation in surface point cloud data. Technometrics, 64(4), 457–474. https://doi.org/10.1080/00401706.2021.1883482

Colosimo, B. M., & Pacella, M. (2011). Analyzing the effect of process parameters on the shape of 3D profiles. Journal of Quality Technology, 43(3), 169–195. https://doi.org/10.1080/00224065.2011.11917856

Dumoulin, V., & Visin, F. (2016). A guide to convolution arithmetic for deep learning, arXiv:1603.07285 [cs, stat], [Online]. Available: http://arxiv.org/abs/1603.07285

Goodfellow, I. J. et al. (2014). Generative adversarial nets. In Proceedings of the 27th International Conference on Neural Information Processing Systems - Volume 2, Cambridge, MA, USA, Dec. 2014, pp. 2672–2680. [Online].

Goodfellow, I. J., Bengio, Y., & Courville, A. (2016). Deep learning. The MIT Press.

He, S., Jiang, W., & Deng, H. (2018). A distance-based control chart for monitoring multivariate processes using support vector machines. Annals of Operations Research, 263(1), 191–207. https://doi.org/10.1007/s10479-016-2186-4

Howard, P., Apley, D. W., & Runger, G. (2018). Distinct variation pattern discovery using alternating nonlinear principal component analysis. IEEE Transactions on Neural Networks and Learning Systems, 29(1), 156–166. https://doi.org/10.1109/TNNLS.2016.2616145

Howard, P., Apley, D. W., & Runger, G. (2018). Identifying nonlinear variation patterns with deep autoencoders. IISE Transactions, 50(12), 1089–1103. https://doi.org/10.1080/24725854.2018.1472407

Hyvärinen, A., & Oja, E. (2000). Independent component analysis: Algorithms and applications. Neural Networks, 13(4), 411–430. https://doi.org/10.1016/S0893-6080(00)00026-5

Khemakhem, I., Kingma, D., Monti, R., & Hyvarinen, A. (2020) Variational autoencoders and nonlinear ICA: A unifying framework. In International Conference on Artificial Intelligence and Statistics, Jun. 2020, pp. 2207–2217. [Online]. Available: http://proceedings.mlr.press/v108/khemakhem20a.html

Kim, S., & Turkoz, M. (2021). Bayesian sequential update for monitoring and control of high-dimensional processes. Annals of Operations Research. https://doi.org/10.1007/s10479-021-04188-9

Kingma, D. P., & Welling, M. (2014). Auto-encoding variational bayes, arXiv:1312.6114 [cs, stat]. [Online]. Available: http://arxiv.org/abs/1312.6114

LeCun, Y., et al. (1989). Handwritten digit recognition: Applications of neural network chips and automatic learning. IEEE Communications Magazine, 27(11), 41–46. https://doi.org/10.1109/35.41400

Lee, H. Y., & Apley, D. W. (2004). Diagnosing manufacturing variation using second-order and fourth-order statistics. International Journal of Flexible Manufacturing Systems. https://doi.org/10.1023/B:FLEX.0000039172.84756.39

Lee, J., Son, J., Zhou, S., & Chen, Y. (2020). Variation source identification in manufacturing processes using Bayesian approach with sparse variance components prior. IEEE Transactions on Automation Science and Engineering, 17(3), 1469–1485. https://doi.org/10.1109/TASE.2019.2959605

Locatello, F. et al. (2019). Challenging common assumptions in the unsupervised learning of disentangled representations. In International Conference on Machine Learning, pp. 4114–4124. [Online]. Available: http://proceedings.mlr.press/v97/locatello19a.html

Makhzani, A., Shlens, J., Jaitly, N., Goodfellow, I., & Frey, B. (2016). Adversarial autoencoders. arXiv:1511.05644 [cs]. [Online]. Available: http://arxiv.org/abs/1511.05644

McInnes, L., Healy, J., & Melville, J. (2020). UMAP: Uniform manifold approximation and projection for dimension reduction. arXiv:1802.03426 [cs, stat],. [Online]. Available: http://arxiv.org/abs/1802.03426

Nordhausen, K., & Oja, H. (2018). Independent component analysis: A statistical perspective. Wires Computational Statistics, 10(5), e1440. https://doi.org/10.1002/wics.1440

Shan, X., & Apley, D. W. (2008). Blind identification of manufacturing variation patterns by combining source separation criteria. Technometrics. https://doi.org/10.1198/004017008000000316

Shi, Z., Apley, D. W., & Runger, G. C. (2016). Discovering the nature of variation in nonlinear profile data. Technometrics. https://doi.org/10.1080/00401706.2015.1049751

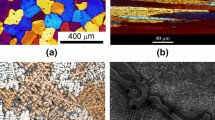

Shi, Z., Apley, D. W., & Runger, G. C. (2019). Identifying and visualizing part-to-part variation with spatially dense optical dimensional metrology data. Journal of Quality Technology, 51(1), 3–20. https://doi.org/10.1080/00224065.2018.1541380

Wang, C.-H., & Li, F.-C. (2020). Economic design under gamma shock model of the control chart for sustainable operations. Annals of Operations Research, 290(1), 169–190. https://doi.org/10.1007/s10479-018-2949-1

Zeiler, M. D., Krishnan, D., Taylor, G. W., & Fergus, R. (2010). Deconvolutional networks. In 2010 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, pp. 2528–2535, doi: https://doi.org/10.1109/CVPR.2010.5539957

Zou, C., Ning, X., & Tsung, F. (2012). LASSO-based multivariate linear profile monitoring. Annals of Operations Research. https://doi.org/10.1007/s10479-010-0797-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

10479_2022_5077_MOESM1_ESM.gif

In the online supplementary materials of this paper, the files “cylinder pattern 1.gif” and “cylinder pattern 2.gif” show animated visualizations of individual patterns of the two discovered variation sources in the cylindrical example in Section 4, along Visualization paths #1 and #2 in Fig. 4, respectively. Similarly, the files “gasket bead pattern 1.gif”, “gasket bead pattern 2.gif”, and “gasket bead pattern 3.gif” show animated visualizations of individual patterns of the three discovered variation sources in the gasket bead example in Section 5, along Visualization paths #1, #2, and #3 in Fig. 7, respectively. Supplementary file1 (GIF 461 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bui, A.T. Root cause analysis of manufacturing variation from optical scanning data. Ann Oper Res (2022). https://doi.org/10.1007/s10479-022-05077-5

Accepted:

Published:

DOI: https://doi.org/10.1007/s10479-022-05077-5