Abstract

Artificial Intelligence (AI) and Big Data Analytics (BDA) have the potential to significantly improve resilience of supply chains and to facilitate more effective management of supply chain resources. Despite such potential benefits and the increase in popularity of AI and BDA in the context of supply chains, research to date is dispersed into research streams that is largely based on the publication outlet. We curate and synthesise this dispersed knowledge by conducting a systematic literature review of AI and BDA research in supply chain resilience that have been published in the Chartered Association of Business School (CABS) ranked journals between 2011 and 2021. The search strategy resulted in 522 studies, of which 23 were identified as primary papers relevant to this research. The findings advance knowledge by (i) assessing the current state of AI and BDA in supply chain literature, (ii) identifying the phases of supply chain resilience (readiness, response, recovery, adaptability) that AI and BDA have been reported to improve, and (iii) synthesising the reported benefits of AI and BDA in the context of supply chain resilience.

Similar content being viewed by others

1 Introduction

Exogenous shocks transcend our previous experiences and have significant impacts, altering the competitive landscape within which businesses operate (Zamani et al., 2022). The Covid-19 pandemic has been characterised as such a shock (Wenzel et al., 2021) and since its outbreak, it has resulted in significant loss of life. Within the world of business, we have been witnessing a number of negative impacts and business failures, such as layoffs, closures and bankruptcies (Amankwah-Amoah et al., 2020). To a large extent, these outcomes were the result of adopting required social distancing measures to minimise the spread of the virus, which negatively impacted the sustainability and profitability of several businesses.

Within the context of operations and supply chains in particular, an important implication of this exogenous shock relates to great uncertainties. In many cases, the latter have been observed due to the pervasive dissemination of false news that has caused further disruption for businesses and everyday life (Verma & Gustafsson, 2020), to the tune of leading to what has been termed as an ‘infodemic’, spreading through online and mainstream media (Zarocostas, 2020). This infodemic has impacted consumer behaviour, whereby consumers turned to panic buying and hoarding of medical, cleaning and non-perishable supplies, motivated by fear of potential product unavailability (Zwanka & Buff, 2021). Not unexpectedly, this abrupt change in consumer behaviour has resulted in turn in supply chain disruptions, too (Kirk & Rifkin, 2020), with businesses trying to cope with and forecast demand so as to adjust their supply chain and operations.

From an operations perspective, such disruptions are often considered through the lens of risk management, because ultimately, disruptions are seen as potential risks that need to be anticipated and mitigated against. More precisely, as far as the impacts stemming from such misinformation and media hype are concerned, supply chain professionals are required to manage the risk of potential stock-outs versus stock holding stocks (Jüttner et al., 2003). Indeed, recent research has shown that the bullwhip effect created by Covid-19 misinformation resulted quite quickly to inventory excess, stockpiling and critical issues with managing stocks (Kapoor et al., 2021).

To address such challenges, businesses traditionally develop business continuity plans alongside risk management strategies to mitigate against disruptions (Azadegan et al., 2020). Some typical tangible strategies that safeguard against such risks are the implementation of vendor-managed inventory contractual agreements (Lee, 2016) and the configuration of leagile supply chains that increase the performance of the firm in light of uncertainties (Fadaki et al., 2020). However, studies have shown that emerging technologies, such as Artificial Intelligence (AI)and Business Data Analytics (BDA) among others, are indispensable towards providing business continuity, especially during exogenous shocks (Papadopoulos et al., 2020). Supply chains are today enhanced by sensors and actuators, such as RFIDs, GPS and POS, tags and other smart devices, all of which (continuously) send and receive data (Fosso Wamba et al., 2018), thus making the Internet of Things (IoT) a potential avenue for accurate predictions. However, it is technologies like BDA and AI that make such data streams useful and actionable for risk mitigation and for overcoming the challenges of misinformation: insights, for example, from BDA can support the incremental improvement and transformation of the operation model, through accurate and on-time insights regarding the supply network (Roden et al., 2017), while AI can be leveraged for developing proactive strategies for predicting the likelihood of risks occurring and their impact (Baryannis et al., 2019). As such, emerging technologies like BDA and AI can play a pivotal role in mitigating the negative impacts and support decision-makers in forming appropriate decisions and actions to tackle challenging situations.

To date, there is an ever growing interest with regards to the use and application of AI and BDA for risk management and developing and maintaining resilience in supply chains (e.g., Baryannis et al., 2019; Modgil, Singh, et al., 2021; Sanders 2016). Despite this interest, however, there are still areas less understood. A recent major review of supply chain resilience focused on research conducted over the past 20 years, detailing the types of disruptions along with their impact on the supply chain and recovery strategies for mitigating these, while technology has been examined at a rather abstract level (Katsaliaki et al., 2021). Other studies have focused on identifying and classifying the different AI techniques used for risk management (Baryannis et al., 2019; Hamdi et al., 2018), and on evaluating different such techniques as part of supply chain resilience (Belhadi, Kamble, Fosso Wamba, et al., 2021). In both cases, scholars seem less focused on how AI contributes towards resilience and along the different phases of risk management (readiness, response, recovery, adaptability). Others have found that AI supports the development of dynamic capabilities, which can in turn facilitate resilience within the firm as far as its supply chain is concerned (Modgil, Singh, et al., 2021). However, such a perspective does not necessarily explain what the exact role of AI and BDA is in supporting resilience beyond supporting organisational dynamic capabilities. Therefore, further research is needed to explore the contribution of technologies such as AI and BDA for building and maintaining resilience in the supply chain. We posit that there is still scope for consolidating existing findings regarding the benefits of BDA and AI in the supply chain resilience (SCR) literature and further exploring the phases of SCR that these technologies can improve in light of significant misinformation and disruption.

The overarching research question that drives this research is: “How do BDA and AI contribute towards supply chain resilience?” To address this question, we specifically examine: “what is the current state of AI and BDA in the SC literature on resilience”, “what phases of SCR (readiness, response, recovery, adaptability) has BDA and AI been shown to improve” and finally, “what are the claimed benefits of BDA and AI in SCR literature”. We adopt a systematic literature review approach that first helps us explore uses and applications of BDA and AI over the last ten years to provide a holistic understanding of the field. Second, this approach helps us explore in more detail what are the claimed benefits of BDA and AI in SCR. By synthesising the findings of prior studies, we identify the exact functions of these technologies that contribute towards resilience in supply chains. In doing so, the paper then focuses on the current challenges that either prohibit or inhibit (externally or internally, respectively) the application and exploitation of BDA and AI for overcoming risks and the misinformation impacts.

2 Resilience in supply chains

Supply chains today operate within an increasingly uncertain and competitive environment, where disruptions can have a significant impact on business performance (Azadegan et al., 2020). Such disruptions can be the result of accidents (Stecke & Kumar, 2009), natural but also man-made disasters (Elluru et al., 2019), including events as for example the 2008 global financial crisis, the UK’s withdrawal from the European Union (Brexit) (Belhadi, Kamble, Fosso Wamba, et al., 2021), loss of critical suppliers (Ponomarov & Holcomb, 2009), and many others.

Supply chain systems during the Covid-19 pandemic have been particularly susceptible to disruptions because of the volatile demand, stemming from incomplete and often misleading information circulated, that resulted in misinformation with regards to “procurement, capacity allocation, contracting, scheduling, postponement and demand forecasting” (Gunessee & Subramanian, 2020, p. 1202). Such misinformation has resulted to negative implications regarding consumer behaviour, and triggered in turn substantial and often difficult to handle fluctuations in demand (Ivanov, 2020), thus resulting in increased uncertainty.

To address such disruptions, the literature has highlighted the need to consider resilience of supply chains and to further delve on this concept, rather than restricting the discourse to solely risks (Gunessee & Subramanian, 2020). Resilience in general reflects a company’s ability to return to a business-as-usual state with regards to production and services following a major disruption (Rezapour et al., 2017). Specifically for supply chains, resilience describes the readiness of an organisation or business to address risks, uncertainty, and generally disruptions that may originate from customers, suppliers or other business processes and supply chain integration mechanisms used (Purvis et al., 2016).

Because disruptions can have significant repercussions for both revenues and costs (Ponomarov & Holcomb, 2009) and may lead to reputational damages(Elluru et al., 2019), to date, the literature has highlighted that overcoming disruptions is of critical importance for businesses. As such, within the operations and supply chain literatures, the concept of resilience is well integrated, as part of preparedness strategies, adopted by businesses for addressing disruptions (Pettit et al., 2019). Resilience can be defined as a system’s ability to return to its normal operating capacity within some identified bounds (Ioannidis et al., 2019), or to be more specific to supply chain systems, as the supply chain’s adaptive capacity to deal with disruption and quickly resume its previous performance (Belhadi, Kamble, Fosso Wamba, et al., 2021). Ponomarov and Holcomb have formally defined supply chain resilience as “the adaptive capability of the supply chain to prepare for unexpected events, respond to disruption and recover from them by maintaining continuity of operations at the desired level of connectedness and control over structures and function” (Ponomarov & Holcomb, 2009, p. 131).

Maintaining supply chain resilience allows businesses to ensure a continuous supply for their products (or services) to customers, despite turbulence in the environment. There are different approaches to ensuring supply chain resilience and these can be proactive, reactive or a combination of both, with the view to mitigate potential risks emerging in the environment (Lohmer et al., 2020). Existing scholarship suggests that, irrespective of the exact strategy adopted, disruptions in supply chain systems necessitate monitoring and controlling the environment on the one hand, and on the other hand being responsive and flexible in resource orchestration and reconfiguration as and when needed (Ralston & Blackhurst, 2020). To achieve this, scholars indicate that what is needed is superior information processing capabilities (Belhadi, Kamble, Fosso Wamba, et al., 2021), particularly because knowledge and information exchange among supply chain partners is considered conducive to risk reduction (Brandon-Jones et al., 2014). Indeed, information sharing can minimise ambiguities along the supply chain and increase visibility and performance (Wong et al., 2021), especially at times when these are put to the test. Wong et al., (2021) indicate that having access to accurate information before, during and after disruptions is of paramount importance, and that this can be achieved via real-time information exchange amongst supply chain partners. Such information exchange can support timely decision making and enhance the efficiency of the supply chain system (Li & Lin, 2006).

Belhadi et al., (2021a, b, c) note that there has been an increasing interest in building supply chain resilience via technological means, such as the exploitation of advanced technologies, like BDA and AI. Indeed, such emerging technologies can significantly support building supply chain resilience through the lens of accurate and timely data, information, and knowledge exchange among partners. For example, predictive analytics can support the design of disaster-resilient supply chains because it facilitates forecasting, decision making and speedier return to business-as-usual states (Hazen et al., 2018). Similarly, AI can be deployed, often as part of an overall Industry 4.0 approach, for supporting adaptation and evolution of smart information systems along the supply chain and as part of operations management (Ralston & Blackhurst, 2020).

To date, the literature on the use of AI and BDA for developing supply chain resilience seems to be somewhat fragmented and largely focused on the available computational techniques for supporting different mitigation strategies. However, the rapid evolution of these technologies and the ongoing misinformation-driven disruption of supply chain systems present an opportunity to focus in more detail on what are the exact benefits that these technologies have to offer and what role they can play at the different phases of supply chain resilience efforts, while considering the observed and anticipated challenges regarding their implementation and use. Motivated by the above, the present study adopts a systematic literature review to synthesise prior research on AI, BDA, and supply chain resilience to consolidate existing findings, to inform scholars and practitioners with regards the benefits and challenges of these technologies along each distinct phase of establishing supply chain resilience, and to propose a future research agenda that will shape future work in this field.

3 Method

The section outlines the systematic literature review (SLR)process adopted in this study. We follow the established guidelines proposed by Tranfield et al., (2003) which have been used in other SLR studies in varying contexts (e.g., Ahmad et al., 2018; Patyal et al., 2021; Spanaki et al., 2021; Tandon et al., 2020). By conducting an evidence-based review, an SLR “identifies key scientific contributions to a field or question, meta-analysis offers a statistical procedure for synthesizing findings in order to obtain overall reliability unavailable from any single study alone” (Tranfield et al., 2003, p. 209). It is widely accepted that conducting a SLR is a “fundamental scientific activity” (Mulrow, 1994, p. 597).

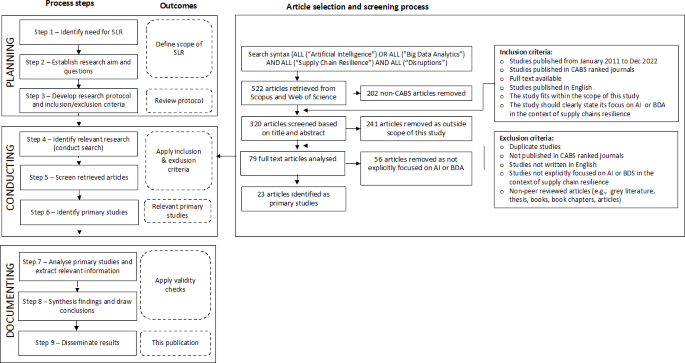

The SLR process is illustrated in Fig.1 and consists of 9 steps across three phases, namely, planning (3 steps), conducting (3 steps), and documenting (3 steps). Each of these three phases and 9 steps are discussed in detail in the remainder of this section.

3.1 Planning the SLR study

This section presents steps 1, 2 and 3 that are related to the planning of this SLR study. The motivation of this study is to classify and synthesise extant literature on supply chain resilience, through thematic analysis of the primary studies. The main objectives of this study (Step 1), as previously stated, are to (i) establish the body of knowledge of supply chain resilience by identifying and categorising extant research on the topic, (ii) identify the most relevant supply chain resilience articles, (iii) synthesise the reported benefits and challenges of AI and BDA in the context of supply chain resilience and (v) identify the opportunities for future research. To achieve these objectives, the research questions (Step 2) listed in Table1 will be answered.

As RQ1 is a broad research question, three sub questions (RQ1.1 - RQ1.4) have been identified to answer this question, while RQ2 and RQ3 will provide a synthesis of the reported challenges and benefits of AI and BDA in the context of supply chain resilience and disruptions.

We focus specifically on AI and BDA because these two technologies leverage and create opportunities for exploiting the numerous data streams that typically flow through and within a supply chain system. Namely, they can take advantage of the data that currently exist and flow through information systems such as Enterprise Resource Planning (ERP) ones, and which presently “track more data than we can digest”. ERPs can monitor and alert supply chain and operations management for shipping updates, stock levels, demand and supply (Pettit et al., 2019). While currently these systems can inform managers about the past and the present, if enhanced with BDA and AI capabilities, they can also inform them about potential future states and thus incorporate resilience-oriented concepts. At this point, it is also important to define how we interpret AI and BDA, as currently there are numerous definitions in the literature (Collins et al., 2021). We understand AI as “the ability of a system to identify, interpret, make inferences, and learn from data to achieve predetermined organizational and societal goals” (Mikalef & Gupta, 2021). Similarly, we approach BDA as the portfolio of technologies, techniques, and organisational resources that allow a company to analyse large-scale and complex datasets, so as to improve their performance and develop actionable insights from big data (Mikalef et al., 2018).

3.2 Conducting the SLR study

This section presents steps 4, 5 and 6 that are related to conducting this SLR study. The search string (Step 4) was developed based on the scope of this study. Keyword combinations (e.g., Artificial intelligence, big data analytics, supply chain resilience) that were used in previous SLR studies (i.e., Baryannis et al., 2019; Hosseini & Ivanov, 2019; Ngai et al., 2014; Sharma et al., 2020) in this field were used for searching the databases. Forward and backward citation review was also conducted to ensure we accumulated a relatively complete census of relevant literature (Webster & Watson, 2002). A search of the Scopus database retrieved 522 articles. We choose the Scopus database as it is the most extensive database for engineering and management focused academic journal articles. Further, it provides various fields on which the user can search for research papers (Grover & Kar, 2017).

Screening of the retrieved publications (Step 5) was achieved by following the best practices proposed by Tranfield et al., (2003) and Watson and Webster (2002). We focused exclusively on studies published in CABS ranked journals as it a common practice within the broader field of Business and Management (Hiebl, 2021). In addition, most typically, studies published in CABS ranked journals undergo a more rigorous review process. One author screened the articles to identify non-CABS ranked journals. The process resulted in 202 articles being excluded. Two authors then independently screened the articles to remove (i) duplicates (ii) non-English articles, (iii) non-peer reviewed scientific papers, and (iv) full articles not available. The process resulted in 241 articles being excluded. Next, two authors independently reviewed articles and excluded articles not explicitly focused on AI or BDA in the context of supply chain resilience. This process resulted in 56 articles being excluded as they refer to AI and BDA in the article but do not explicitly study these technologies. At the end of the process, 23 primary studies were identified (Step 6). The primary studies are listed in Appendix A.

3.3 Documenting the SLR study

This section presents steps 7, 8 and 9 that are related to the planning of this SLR study. Once the primary studies were identified, they were subject to in-depth analysis (Step 7) by three authors to mitigate validity threats due to researcher bias. Further, to mitigate this threat, data and researcher triangulation was established. The primary studies were analysed based on the research questions of this SLR study. The findings were then synthesised (Step 8) and written up as per the aims of this SLR study. Finally,the first author reviewed each activity (Step 7 and 8) to ensure consistency in the analysis of data, consolidation of the findings, and an evidence-based review SLR was written up.

4 Synthesis of results

This section presents the results from the analysis of the 23 primary studies, which is based on the research questions previously mentioned. The results represent the current state of AI and BDA research in the context of supply chain resilience between 2011 and 2021. We address our first research question: ‘What is the current state of AI and BDA in SC literature between 2011–2021?, by examining the following: (i) publication by year, (ii) publication outlets, (iii) research methodology adopted, (v) data collection techniques, and reported benefits, and (ix) reported challenges.

4.1 RQ 1.1 What number of academic studies on AI and BDA for SCR have been published between 2011 and 2021?

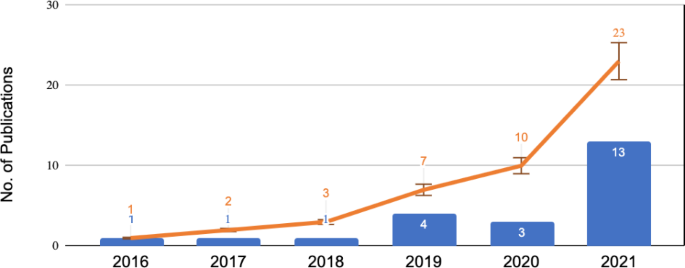

The aim of this research question is to establish the annual number of academic studies on AI and BDA within the context of supply chain resilience between 2011 and 2021. Figure2 shows the number of publications by year of the primary studies over the 10-year period. This timeline is valuable as it indicates that academic studies on AI and BDA in the context of supply chain resilience were not published in CABS ranked journals between 2011 and 2015. Since 2016 there is an accumulative increase (see amber scale) in publications. In this context there is a significant number of publications (13) in 2021. The 23 primary studies were published between 2016 and 2021 which are based on the inclusion and exclusion criteria used in this study.

4.2 RQ 1.2 What SC industries has AI and BDA research been applied to?

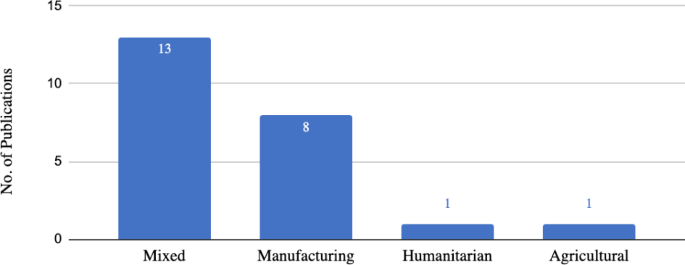

The aim of this research question is to identify the supply chain industries in which AI and BDA research have been applied to. Figure3 shows that most primary studies (13) applied AI and BDA to a mix of supply chain industries, followed by 8 primary studies that applied these technologies to manufacturing. By mix, we refer to supply chain industries whereby studies did not focus on a particular industry (e.g., automotive sector, following a case study approach or purposeful sampling of companies from the sector) but rather investigated these technologies across industries (e.g., automotive, manufacturing, agricultural and others). One study applied these technologies to humanitarian aid supply chains, and one to agricultural supply chains.

4.3 RQ 1.3 What journals are publishing AI and BDA related research in the context of the SC resilience & interruptions?

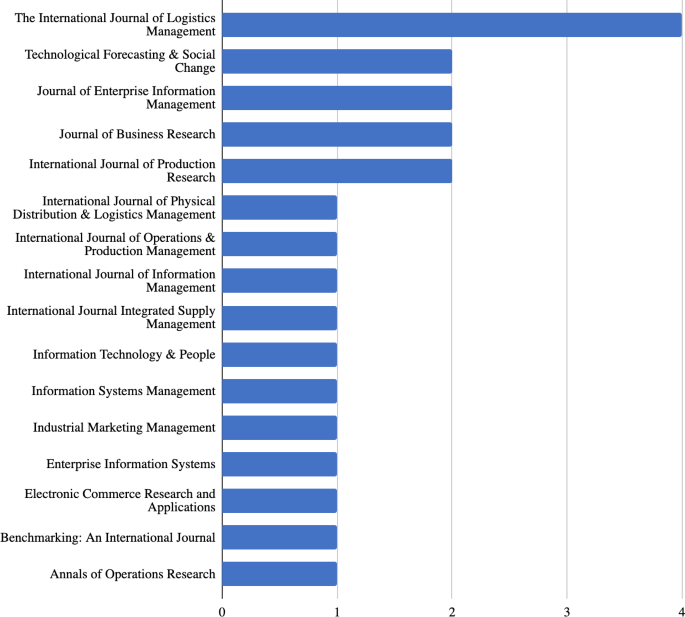

The aim of this research question is to identify what CABS ranked journals are publishing AI and BDA studies in the context of supply chain resilience and interruptions. Figure4 shows that The International Journal of Logistics Management published 4 such primary studies, followed by four journals that each published 2 primary studies, and the eleven other journals each published one primary study.

4.4 RQ 1.4 What research methods and data collection techniques have been used in AI and BDA studies that focus on SCR?

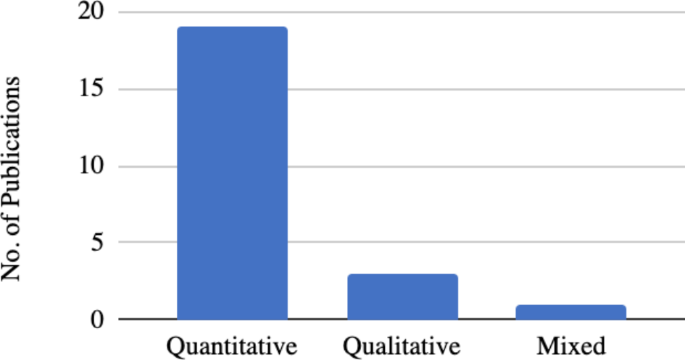

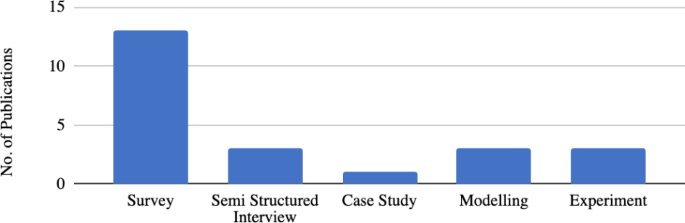

The aim of this research question is to categorize the research method and data collection techniques that have been used to study AI and BDA in the context of supply chain resilience. Figure5 shows that quantitative methods (19) are the most popular, followed by qualitative (3) and mixed methods (1).

A deeper analysis of the methods used in the 23 primary studies was conducted to establish the data collection techniques used in the respective studies. Figure6 shows that surveys (13) are the most popular techniques, where the data collection instrument is typically a questionnaire. Other data research designs have been used, but to a much lesser degree, namely semi structured interviews with experts (3), case studies (1), experiments (3), and modelling (3). We note that modelling and experiments often refer to simulation-based studies.

4.5 RQ 2 What phases of SCR (readiness, response, recovery, adaptability) has AI and BDA been shown to improve?

Our systematic review revealed several benefits of BDA and AI towards supply chain resilience, which, in this section, we present them by organising them across the phases of supply chain resilience. Existing studies indicate that supply chain resilience draws from four separate phases: readiness, response, recovery and adaptability strategies (Chowdhury & Quaddus, 2016; Ponomarov & Holcomb, 2009). The readiness phase reflects a business’ anticipation of and preparedness for disruptive events (Fahimnia & Jabbarzadeh, 2016). Readiness involves identifying and observing any changes happening within the micro- and macro-environment of the business (Maitlis & Sonenshein, 2010). Responsiveness indicates how a business enacts its preconceived mitigation strategies when experiencing disruptions (Stone & Rahimifard, 2018). The recovery phase entails repairing losses and returning to business-as-usual (Brandon-Jones et al., 2014) or moving to a future desired state as soon as possible (Fahimnia & Jabbarzadeh, 2016). Further extending the scope of supply chain resilience, Hohenstein et al., (2015) propose that there is an additional phase, that of growth, whereby businesses proceed with adapting and adjusting their operations and strategies on the basis of their experience during disruptions in order to prepare for future potential disruptions. We refer to this as the adaptation phase, following the approach espoused by Dennehy et al., (2021).

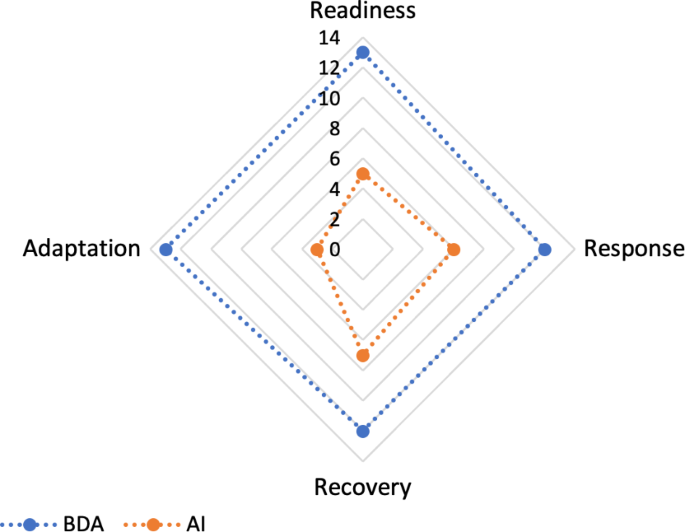

BDA and AI have proven to support and shape all supply chain resilience phases. Table2 provides a classification of existing studies across the four resilience phases. As shown, BDA and AI are emerging technologies that contribute towards all the phases of supply chain resilience, including the adaptation phase. Equally, it is shown that BDA is far more explored for its ability to support supply chain resilience comparatively to AI, and that AI for shaping adaptive strategies is somewhat underexplored.

With regards to the readiness phase, Dubey et al., (2021a, b) consider BDA as part of the dynamic capabilities of a business, which can minimise disruptions and particularly under volatile conditions, such as the Covid-19 pandemic. Extending these findings, Dennehy et al., (2021) highlight that the use of BDA as part of supply chain resilience supports the business to anticipate disruptions, specifically because this technology allows decision makers to sense and forecast such events, as well with tracking and monitoring activities within the context of their operations. Such findings directly explain why BDA and AI can help businesses mitigate misinformation along the supply chain within the context of the readiness phase. These technologies are in position to support businesses in anticipating disruptions, rather than remaining idle until these happen, by directly enabling the monitoring of any deviations from the business-as-usual state in the environment, and the recognition of early warning signals (Zouari et al., 2020) by leveraging accurate and real-time big data (Belhadi, Kamble, Jabbour, et al., 2021). With regards to this and for AI in particular, supervised machine learning techniques allow the removal of generalisations and noise and the analysis of historical data so as to arrive to better outcomes, grounded on the data (Cavalcante et al., 2019). In addition, as shown by Bag et al., (2021), descriptive, predictive and prescriptive analytics can support tracing suppliers’ performance in real time, which effectively contributes towards supply chain resilience as managers can sense disruptive events earlier on. The existing literature indicates similar benefits using AI with regards to readiness. Namely, Modgil et al., (2021a, b) have found that the use of AI supports sensing multidimensional and multi-layered risks in the environment, and that, especially during Covid-19, AI is being used as part of the daily routine to analyse and sense risks.

A critical phase for supply chain resilience is that of the response phase. As Modgil et al., (2021a, b) find, for a supply chain to be capable to respond in light of disruptive events, the business needs to exhibit the appropriate information processing capabilities, that will help align suppliers, retailers and distributors. The authors also found that, despite the misinformation and fake news that resulted in great fluctuations in demand during Covid-19, AI can be employed to cluster consumer behaviour and therefore address such demands more effectively. Despite delays and the shortages in materials, AI has been able to align stakeholders by enriching their information processing capabilities and supporting the rearrangement of distribution channels in a smart and effective way (Modgil, Gupta, Modgil et al., 2021a, b). Similar findings have been reported by Dennehy et al., (2021), with BDA facilitating resource reconfiguration in light of environmental changes and, most importantly, doing so in a timely fashion. In other words, emerging technologies such as AI and BDA can support the development of response mechanisms that can mitigate disruptions. This is because these technologies directly contribute towards developing dynamic capabilities that progressively become institutionalised, and then shift into risk resilience capabilities, that enable firms to restructure and reconfigure their resources, if and when needed (Singh & Singh, 2019).

As far as the recovery phase is concerned, several studies indicate the value of AI (e.g., Belhadi, Mani, Kamble, et al., 2021; Modgil, Singh, et al., 2021, 2021) and BDA (e.g., Dennehy et al., 2021; Ivanov, 2017; Khan et al., 2021; Sheng & Saide, 2021). Work in this area illustrates how these technologies facilitate recovery during and after disruptions by enabling firms to rebuild their supply chain operations, reconnect potentially fragmented supply chain components and coordinate recovery plans (Ivanov et al., 2019). For example, BDA and AI, coupled with other digital technologies, can speed up the execution of recovery plans to allow the timely mitigation of misinformation and disruption impacts, thus halting further propagation of the negative effects (Ivanov et al., 2019). In more detail, some of the benefits of AI and BDA for the recovery phase relate to the last mile delivery, whereby predictive analytics can help with managing disruptions in the workforce, and adopting paperless working patterns to create efficiencies across the supply chain (Modgil, Singh, et al., 2021). However, Rajesh (2016) has further found that it is not sufficient to use big data or more data for decision making during the recovery phase, but that instead what is needed is the use of the right data indicators, which will ensure accuracy and exactness in executing the recovery. Similarly, Cavalcante et al., (2019) have further emphasised the need for accurate data as well as the use of AI techniques that reduce potential abstractions from the datasets, and evaluated this approach through simulation and machine learning models, whereby their results indicate that decision making that is based on these approaches can enhance supplier selection when attempting to restore operations to the business-as-usual state, because managers can predict supplier performance following the disruption (Cavalcante et al., 2019) and achieve stabilisation and supply continuity (Dolgui et al., 2018).

The adaptive phase represents the firm’s efforts towards developing capabilities for dealing with current but also future disruptions: knowledge and experience are extracted from the firm’s current response and then become institutionalised within the business, thus informing future responses (Singh & Singh, 2019). Along these lines, using AI techniques has a significant positive impact on the firm’s adaptive capabilities because these techniques allow the firm to learn from the external environment and to reduce the complexity of highly complex systems, and thus facilitate resilience (Belhadi, Mani, Kamble, et al., 2021). In addition, AI can contribute and inform the firm’s restorative capacity, directly influencing the supply chain’s recovery (Cavalcante et al., 2019; Modgil, Singh, et al., 2021). Specifically, like in earlier phases, BDA and AI indicate ways for optimised resource allocation, especially when resources are scant (Ivanov et al., 2019), which is essential and part of the business’ core capabilities for resilient supply chains (Dennehy et al., 2021).Dennehy et al. (2021) in particular have found that BDA supports supply chains, not only to become flexible and adaptable following the recovery phase, but also that this technology can support moving even to a more desirable stage after the disruption. Modgil et al., (2021a, b) argue that, AI can equally support the adaptation of the supply chain following disruption, because it facilitates design thinking when human and non-human entities are involved in highly complex systems, and supporting managers and decision makers to learn directly from AI insights. Such insights may refer to identifying whether there is a gap between the existing information processing capabilities and the information that needs to be processed in the future to respond to disruptions, and how such a gap can be bridged. Further, BDA and AI, can support the adaptive phase by identifying the more vulnerable parts of the supply chain, recognising the required stock levels of (strategic) resources, and developing pathways for responding to future events, building on advance techniques such as simulations and gaming (Zouari et al., 2020).

As shown in Table2, several of the analysed studies exhibit an overlap with regards to the benefits stemming from AI and BDA. Specifically, in their majority, studies identify and discuss the benefits of AI and BDA for most if not all of the SCR phases. For example, Dennehy et al., (2021) indicate that BDA can support SCR with regards to all four phases (readiness, response, recovery and adaptation). With regards to AI, the examined studies show a similar pattern; yet, in most cases scholars identify benefits for three out of the four phases. For instance, Dubey et al., (2021a, b) indicate that AI may contribute towards readiness, response and adaptation, but do not discuss the recovery phase, whereas Cavalcante et al., (2019) explore benefits during the phases of response, recovery and adaptation but not readiness. The chart in Fig.7 visualises the aforementioned overlap of benefits across SCR phases for the two technologies. It also clearly illustrates that to date, far more studies focus on BDA, and that AI focused studies in their majority explore and consider benefits for recovery.

4.6 RQ 3 What are the claimed benefits of AI & BDA in SCR literature?

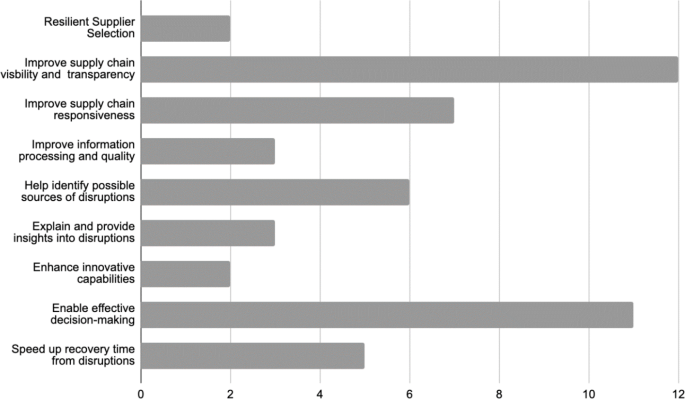

Across the collected studies, the main benefits identified with regards to supply chain resilience are shown in Fig.8. In Table3, we summarise the identified benefits of AI and BDA for SCR. Our analysis revealed that most of the studies identify BDA and AI as supportive of improving visibility and transparency across the supply chain and enabling effective decision-making.

With regards to improving visibility and transparency, Zouari et al., (2020) have found that the digitalisation of the supply chain, as facilitated by the use of BDA and AI, supports visibility along the supply chain because these technologies contribute towards gathering critical knowledge with respect to environment and the status of operating assets. Similarly, Belhadi et al., (2021a, b, c) have shown that BDA in particular, enhance transparency, which in turn supports supply chain resilience, because visibility combined with transparency enable quick buy-in and commitment of those involved in tackling disruptions, and in turn make recovery speedier and better. Such commitment and buy-in essentially relates to effective decision-making, i.e., the second most frequently cited benefit of BDA and AI. Indeed, the study by Dennehy et al., (2021) revealed that during crises, BDA, as a technological capability, supports supply chain professionals generate insights and intelligence, which can then empower top management to make decisions informed by data, rather than solely on the basis of experience and/or intuition. Examples of such decision-making include choices regarding the ideal location of facilities and specifically for times of crisis, regarding optimal prediction, distribution and inventory levels, when such decisions are modelled on the basis of big data (Mishra & Singh, 2020).

Another major benefit of BDA and AI lies with improving supply chain responsiveness. Responsiveness denotes how the supply chain responds to the demand, for example by adjusting production, modifying operations for both exploiting opportunities and addressing challenges, as well as at the human resource level, by organising and coordinating key personnel to do so (Zouari et al., 2020). Focusing on BDA specifically, Rajesh (2016) approach such responsiveness as corresponding to the speed with which a business addresses customer needs during disruptions and which can be measured as a function of on-time delivery ratio, the contract issue time, the contract approval time and the put-away ratio. The role of BDA in this respect relates to facilitating information sharing among supply chain partners and which results in managing and reducing risks. Considering BDA in combination to AI, studies have shown that responsiveness during crises can only be supported if these technologies are well integrated and interoperable (Frederico et al., 2021; Nayal et al., 2021). This highlights the importance of the quality, as well as the nature and form of the data used, that will enable such interoperability, and therefore real time information sharing, and thus extracting and responding to generated insights within highly complex environments (Nayal et al., 2021).

We found fewer studies investigating the use of BDA and AI for identifying the possible sources of disruption which are however quite illustrative regarding the role of these technologies for identifying risks ahead of and during disruptive events. Dubey et al., (2021a, b), for example, showcase the role of BDA for supporting managers to identify the possible threats, by making visible the vulnerabilities in the supply chain, thereby developing more accurate and relevant business continuity plans. Namely, BDA can be used for identifying risks stemming from the suppliers, but also as a medium for assessing their probability and their impact for operations. In addition, they can be used for identifying bottlenecks and insights for rescheduling tasks and events if and when needed (Cavalcante et al., 2019). Others have indicated ways for leveraging information stemming from social media in order to identify emerging risks. For example, Janjua et al., (2021) have developed a framework that draws information from social media (pertaining to e.g., natural disasters and labour disputes), which they then analyse using AI techniques to analyse threats, capture approximate location of said threats and their timing.

As a result, leveraging AI and BDA for identifying the source of disruption can also speed up the recovery of operations (Singh, 2020). Analytics and big data generally facilitate shorter order-to-delivery cycle times and the crafting of demand-driven operations. (Rajesh, 2016). In more detail, it is argued that BDA informs the planning, coordination, and control activities of firms during disruptive events, as part of their preparedness, alertness and agility. On the basis of these, firms can develop IT infrastructure capabilities that enable them to support quicker reactions during disruptions (Singh, 2020) because this technology, applied in the aforementioned ways, facilitates reduced lead times and the acquiring and processing of reliable information (Dubey, Gunasekaran, et al., 2021). In addition, the above approach is applicable even when extending the above methods to incorporate the suppliers’ side, because firms are then able to identify disruptive events impacting their suppliers, and quickly adapt to unpredictable changes within the greater supply chain environment (Sheng & Saide, 2021).

How and why BDA and AI help identify the source of disruptions and speed up recovery is addressed by few studies, whereby it is suggested that they provide superior insights regarding threats and improve information processing and quality. For example, it has been found that insights stemming from the processing of large datasets using BDA techniques can improve operation performance especially when such data come from multiple sources (Dubey, Gunasekaran, et al., 2021). For instance, BDA insights can inform resource orchestration and allocation, and thus facilitate grounded-on-the-data decision making (Dennehy et al., 2021). It is also argued that research and practice need to go beyond than simply leveraging BDA to develop ‘hard to imitate’ capabilities, but instead that other resources are also required, whereby firms exploit BDA in order to improve the quality of information flowing through their supply chain and operations (Singh & Singh, 2019). Indeed, BDA may influence supply chain resilience because it improves the quality of information (Bahrami & Shokouhyar, 2021) and empowers a strong IT infrastructure (e.g., cyberphysical systems, RFID technology, Industry 4.0 sensors), which in turn enables the collection of precise information with regards to operations and processes, which is more accurate and visually more legible, as data is captured automatically at the source and communicated in real time via graphs and charts (Ivanov et al., 2019). These then directly support quicker decision-making because they positively impact the organisation’s information capabilities and, by extension, supply chain resilience, because information planning, coordination and control are its core enablers (Belhadi, Mani, Kamble, et al., 2021).

Among the least explored benefits are those of the enhancement of innovative capabilities. The way that BDA and AI influence innovative capabilities is particularly important and interesting because such capabilities relate to improved information processing and quality (Bahrami & Shokouhyar, 2021; Belhadi, Mani, Kamble, Belhadi et al., 2021a, b, c), supply chain visibility and transparency (Belhadi, Mani, Kamble, Belhadi et al., 2021a, b, c), thereby enabling the development and the actioning of recovery strategies. Under the umbrella of innovative capabilities, scholars identify the firm’s abilities to generate and implement new ideas and insights, processes and products, whereby analytical capabilities are part of these, too (Bahrami & Shokouhyar, 2021). Lastly, we identified two studies whereby scholars link BDA and AI to superior and resilient supplier selection. These technologies enable firms to identify and manage suppliers on the basis of insights deriving from spending patterns, service level and penalty data, thereby developing a supply chain ecosystem that can respond to disruptions (Mandal, 2018). In addition, machine learning approaches can be particularly useful for supplier selection when combined with simulation techniques to practically examine how decisions regarding suppliers may influence the reliability of the supply chain, thus influencing its performance and overall resilience (Cavalcante et al., 2019).

5 Current challenges

Big data analytics and AI can be seen as emerging technologies with the potential to ‘equalise’ the impacts of uncertainty and enable organisations to predict supply and demand despite misinformation (Belhadi, Mani, Kamble, et al., 2021; Verma & Gustafsson, 2020). For example, Big Data Analytics can be applied for internal and external process sensing (e.g., inefficiencies), for forecasting, scheduling, real-time resource allocation, and for transforming operational inefficiencies, including real-time process reconfiguration (e.g., automated alerts when there is a high risk of failure) (Conboy et al., 2020). Other application areas are the inventory, capacity and labour scheduling, and sourcing. Sourcing, in particular, is potentially one of the areas of most concern during disruptions, and Big Data Analytics can support decision makers to measure risks and negotiate with suppliers “by providing factual leverage” (Sanders, 2016, p. 32). In addition, other benefits include coordination and knowledge sharing across the entire supply chain (Chen et al., 2015) as shown from several of the identified studies (e.g., Belhadi, Kamble, Jabbour, et al., 2021; Mandal, 2018; Rajesh, 2016; Singh & Singh, 2019). Despite the benefits from AI and BDA in SCR, most companies are facing difficulties owing to the large investments and challenges related to their deployment and integration (Cadden et al., 2021), privacy and security issues, lack of appropriate business cases (Dennehy, 2020), in-house capabilities (Rajesh, 2016), and sustainability (Patyal et al., 2021).

5.1 The challenge of identifying appropriate use cases

While AI and BDA can directly influence and impact positively on a company’s supply chain resilience, it is important for the company to identify relevant application areas in order to benefit from these technologies. This can help the company avoid potential issues arising from bandwagon effects due to the adoption of emerging technologies. Since there is a pressure from other organisations that have already adopted those technologies (Abrahamson & Bartner, 1990), organisations need to primarily make an assessment of the usefulness of the technological innovations for building SCR in accordance to their requirements (Abrahamson, 1991). We consider that the use of BDA can be useful in this respect by helping identify such use cases. Recent studies have shown that BDA can be employed to: support organizations to prioritise and coordinate activities on specific projects (Dennehy et al., 2021; Zamani et al., 2021), sense and respond to changes in the business environment (Barlette & Baillette, 2022; Zamani et al., 2022), and create business value (Oesterreich et al., 2022; Papadopoulos et al., 2022). We thus posit that BDA can be both the instrument that helps identify a problem and be part of the solution that addresses that problem in the context of supply chain resilience.

5.2 The challenge of scarce resources and investments

The funding practices adopted by businesses for the development of BDA contradict the traditional funding model (Dennehy et al., 2021). With new ideas and capabilities emerging from the use of BDA and AI, the business models have evolved which in turn demands for new management skills along with the technical competencies (Bahrami & Shokouhyar, 2021). The feasibility of adopting BDA by understanding the time to acquire and develop SCR and expected return on investment is a critical component. In fact, there are claims that many organisations have failed in realising the feasibility of BDA to meet supply chain resilience (Mikalef et al., 2020; Ross et al., 2013). The exploitative capabilities of the organisation (in terms of what, how and when) to harness the potential of BDA is crucial considering the huge investments made to build SCR. Organisations face enormous challenges in extracting and translating the information into decision making in relation to managing supply chain networks and there are many instances where the organisations have failed to yield positive return on investment (Dubey, Bryde, et al., 2021).

Further, the use of AI and BDA helps in the integration of key areas like managing supply chain networks and knowledge resources. However, for the effective use of these technologies a robust collaboration with the supply chain networks, knowledge resource capabilities and infrastructure is required (Sheng & Saide, 2021). Moreover, if there is a lack of knowledge about the use of real time big data for generating insights and if there are knowledge gaps in the adoption of the AI-based platforms, survivability of SCR may be impacted (Pinto et al., 2019). As such, a major challenge is that of the skill sets and expertise required in handling data analytics to address supply chain disruption (Ergun et al., 2009).

5.3 The challenge of organisational culture and change

There is a need to understand the importance of the organisational cultural change that is critical to harness the value of big data analytics (Vidgen et al., 2017). For instance, digital maturity helps in the adoption of digital supply chains and has a stronger impact on SCR. Developing digital maturities implies improving information sharing and data architectures, formalising processes, training and engaging all employees towards a digital mindset (Zouari et al., 2020). However, many companies make plans to implement digitalisation without considering the need to develop and enhance their degree of digital maturity. Additionally, a data-driven culture in firms may give rise to makeshift supplier-customer relationships thus affecting the bargaining power of firms represented by supplier selection predictive models based smart contracts (Cavalcante et al., 2019).

5.4 Challenges in relation to the wider ecosystem

The mere development of AI and BDA capabilities is not sufficient to prevent or solve the undefined impacts of exogenous shocks (Lawson et al., 2019; Sohrabi et al., 2020). Prior to considering AI and BDA for building up SCR, practitioners need to analyse the level of stress the supply chain can absorb and evaluate the degree of reconfiguration for the supply chains to withstand a disruption as well as their capability of analysing changing dynamics. It is essential for all the supply chain partners of a firm, including its lower tier suppliers, to implement a data-driven supply chain (Khan et al., 2021) when the firm develops AI and BDA capabilities for building SCR. The supply chain operations in risk management are also benefitted by supply chain resilience arising due to the collaboration among supply chain partners (Yen & Zeng, 2011). However, lower tier suppliers may not posses the required technological sophistication and be exposed to incompatible interface standards, legacy systems etc, nor have access to skilled resources required for developing AI and BDA capabilities. Moreover, poor decision-making and unreliable contingencies may arise due to inaccuracy of information and data shared that feed AI algorithms amidst uncertainty in supply chain.

6 Conclusions and future research

This study performed a systematic literature review on the contributions of artificial intelligence and big data analytics in supply chain resilience. We note that our study is not the first systematic literature in the domain of supply chain management with the focus on the use of technologies for addressing disruptions and enabling resilience. For example, Katsaliaki et al., (2021) conducted a similar investigation and identified some of the most popular modelling techniques and IT tools used for enhancing resilience. However, in our study, we focus specifically on AI and BDA. This allows us to provide a more nuanced understanding specifically with regards to these two technologies’ role towards supply chain resilience, and in turn, delineating the challenges for adopting them as part of supply chain management.

When investigating the thematic area of supply chain disruptions and resilience, this study can serve as a normative reference for the operations and supply chain disciplines. To this end, three broad-based research questions were identified. The first research question explored the current state of AI and BDA in the supply chain literature during the last decade. This research question investigated to which supply chain industries has AI and BDA been applied, which journals are publishing research on AI and BDA with a specific focus on SC resilience and disruptions, and what data collection techniques and research methods have been used in these studies. This research question has been addressed by providing a detailed summary in Sect.4.1 to 4.4 using Figs.2, 3, 4, 5 and 6. The second research question was aimed at understanding the phases of supply chain resilience that AI and BDA have improved. This question was addressed by integrating insights derived from the posited advantages of AI and BDA across the readiness, response, recovery, and adaptation phases of supply chain resilience in Sect.4.5 and summarizing them in Table2. The third research question sought to reveal the benefits of AI and BDA in supply chain resilience. This research question was answered by delineating and summarizing key themes pertaining to benefits of AI and BDA in SCR in Sect.4.6 using Fig.8; Table3.

The findings of this systematic literature review should be considered in light of its methodological limitations. First this review focussed only on articles in CABS ranked journals available in Scopus database. Other databases such as ACM and IEEE could have been included for an exhaustive search of papers. Second, the review considered “artificial intelligence”, “big data analytics” and “Supply chain resilience” as the keywords for querying the database and didn’t consider other related and interchangeably used terms such as “machine learning”, “business intelligence” or “natural language processing” as keywords. These limitations may be addressed in future research to mitigate the shortcomings of relying on a single database and a set of few umbrella keywords. Moreover, future research may inform the security and privacy related aspects of AI and BDA adoption in supply chain, thus aiding in authenticated use of supply chain systems and avoid data breaches.

This study is an endeavour to encapsulate the research conducted by leading researchers and published in top publication outlets in the field of business. The study has several implications including a need for broader coverage of data collection and methodological approaches such as case-study approach, simulation, and mixed methods. For instance, research based on case-study and mixed method approaches can supplement the understanding of barriers in adoption of AI and BDA for improving supply chain resilience. Moreover, amidst an era of unprecedented exogenous shocks to businesses, there is a growing interest in the use of AI and BDA for supporting supply chain resilience by speeding up recovery times, supplier selection, improving supply chain visibility, transparency, responsiveness. We believe that the structured insights of this review will aid academics and practitioners in the field of supply chain management to develop AI and BDA based interventions for supply chain resilience.

Concluding, we underline that the majority of the studies investigated relate to the use of BDA and AI to superior decision making (e.g., Bag et al., 2021; Nayal et al., 2021; Singh, 2020). However, insights from these technologies may not be sufficient. Supply chain disruptions are often characterised by an impetus to make accurate but quick decisions, under complex and difficult conditions. While BDA and AI can help clarify uncertainties and reduce risks by filling in informational gaps, whether, when and how an organisation will move from insights to actions rests with its decision makers, who need to make sense of such insights but often feel more comfortable turning to their intuitive judgement and prior experience to decide on next steps (Constantiou et al., 2019; Zamani et al., 2021). We would thus like to invite future research in this area, that will delve deeper into the behavioural perspective and decision-making to explore supply chain and operations decision makers’ behaviours towards the use of emerging technologies during disruptions.

Data availability

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

References

Abrahamson, E. (1991). Managerial Fads and Fashions: The Diffusion and Rejection of Innovations. Academy of Management Review, 16(3), 586–612. https://doi.org/10.5465/amr.1991.4279484

Abrahamson, E., Bartner, L. R., & DO BANDWAGON DIFFUSIONS ROLL? HOW FAR DO THEY GO? AND WHEN DO THEY ROLL BACKWARDS?. (1990). WHEN : A COMPUTER SIMULATION. Academy of Management Proceedings, 1990(1), 155–159. https://doi.org/10.5465/ambpp.1990.4978478

Ahmad, M. O., Dennehy, D., Conboy, K., & Oivo, M. (2018). Kanban in software engineering: A systematic mapping study. Journal of Systems and Software, 137, 96–113. https://doi.org/10.1016/j.jss.2017.11.045

Amankwah-Amoah, J., Khan, Z., & Wood, G. (2020). COVID-19 and business failures: The paradoxes of experience, scale, and scope for theory and practice. European Management Journal, Article in Press, 1–6. Scopus. https://doi.org/10.1016/j.emj.2020.09.002

Azadegan, A., Syed, T. A., Blome, C., & Tajeddini, K. (2020). Supply chain involvement in business continuity management: Effects on reputational and operational damage containment from supply chain disruptions. Supply Chain Management: An International Journal, 25(6), 747–772. https://doi.org/10.1108/SCM-08-2019-0304

Bag, S., Dhamija, P., Luthra, S., & Huisingh, D. (2021). How big data analytics can help manufacturing companies strengthen supply chain resilience in the context of the COVID-19 pandemic. The International Journal of Logistics Management, ahead-of i>-print(ahead-of-print). https://doi.org/10.1108/IJLM-02-2021-0095

Bahrami, M., & Shokouhyar, S. (2021). The role of big data analytics capabilities in bolstering supply chain resilience and firm performance: A dynamic capability view. Information Technology & People, ahead-of i>-print(ahead-of-print). https://doi.org/10.1108/ITP-01-2021-0048

Barlette, Y., & Baillette, P. (2022). Big data analytics in turbulent contexts: Towards organizational change for enhanced agility. Production Planning & Control, 33(2–3), 105–122. https://doi.org/10.1080/09537287.2020.1810755

Baryannis, G., Validi, S., Dani, S., & Antoniou, G. (2019). Supply chain risk management and artificial intelligence: State of the art and future research directions. International Journal of Production Research, 57(7), 2179–2202. https://doi.org/10.1080/00207543.2018.1530476

Belhadi, A., Kamble, S., Wamba, F., S., & Queiroz, M. M. (2021a). Building supply-chain resilience: An artificial intelligence-based technique and decision-making framework. International Journal of Production Research, 0(0), 1–21. https://doi.org/10.1080/00207543.2021a.1950935

Belhadi, A., Kamble, S., Jabbour, C. J. C., Gunasekaran, A., Ndubisi, N. O., & Venkatesh, M. (2021b). Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological Forecasting and Social Change, 163, 120447. https://doi.org/10.1016/j.techfore.2020.120447

Belhadi, A., Mani, V., Kamble, S. S., Khan, S. A. R., & Verma, S. (2021c). Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: An empirical investigation. Annals of Operations Research. https://doi.org/10.1007/s10479-021-03956-x

Brandon-Jones, E., Squire, B., Autry, C. W., & Petersen, K. J. (2014). A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. Journal of Supply Chain Management, 50(3), 55–73. https://doi.org/10.1111/jscm.12050

Cadden, T., Dennehy, D., Mantymaki, M., & Treacy, R. (2021). Understanding the influential and mediating role of cultural enablers of AI integration to supply chain. International Journal of Production Research, 1–29. https://doi.org/10.1080/00207543.2021.1946614

Cavalcante, I. M., Frazzon, E. M., Forcellini, F. A., & Ivanov, D. (2019). A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. International Journal of Information Management, 49, 86–97. https://doi.org/10.1016/j.ijinfomgt.2019.03.004

Chen, D. Q., Preston, D. S., & Swink, M. (2015). How the Use of Big Data Analytics Affects Value Creation in Supply Chain Management. Journal of Management Information Systems, 32(4), 4–39. https://doi.org/10.1080/07421222.2015.1138364

Chowdhury, M. M. H., & Quaddus, M. (2016). Supply chain readiness, response and recovery for resilience. Supply Chain Management: An International Journal, 21(6), 709–731. https://doi.org/10.1108/SCM-12-2015-0463

Collins, C., Dennehy, D., Conboy, K., & Mikalef, P. (2021). Artificial intelligence in information systems research: A systematic literature review and research agenda. International Journal of Information Management, 60, 102383. https://doi.org/10.1016/j.ijinfomgt.2021.102383

Conboy, K., Mikalef, P., Dennehy, D., & Krogstie, J. (2020). Using business analytics to enhance dynamic capabilities in operations research: A case analysis and research agenda. European Journal of Operational Research, 281(3), 656–672. https://doi.org/10.1016/j.ejor.2019.06.051

Constantiou, I., Shollo, A., & Vendelø, M. T. (2019). Mobilizing intuitive judgement during organizational decision making: When business intelligence is not the only thing that matters. Decision Support Systems, 121, 51–61. https://doi.org/10.1016/j.dss.2019.04.004

Dennehy, D. (2020). Ireland Post-Pandemic: Utilizing AI to Kick-Start Economic Recovery. Cutter Business Technology Journal, 33(11), 22–27

Dennehy, D., Oredo, J., Spanaki, K., Despoudi, S., & Fitzgibbon, M. (2021). Supply chain resilience in mindful humanitarian aid organizations: The role of big data analytics. International Journal of Operations & Production Management, 41(9), 1417–1441. https://doi.org/10.1108/IJOPM-12-2020-0871

Dolgui, A., Ivanov, D., & Sokolov, B. (2018). Ripple effect in the supply chain: An analysis and recent literature. International Journal of Production Research, 56(1–2), 414–430. https://doi.org/10.1080/00207543.2017.1387680

Dubey, R., Bryde, D. J., Blome, C., Roubaud, D., & Giannakis, M. (2021a). Facilitating artificial intelligence powered supply chain analytics through alliance management during the pandemic crises in the B2B context. Industrial Marketing Management, 96, 135–146. https://doi.org/10.1016/j.indmarman.2021a.05.003

Dubey, R., Gunasekaran, A., Childe, S. J., Fosso Wamba, S., Roubaud, D., & Foropon, C. (2021b). Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. International Journal of Production Research, 59(1), 110–128. https://doi.org/10.1080/00207543.2019.1582820

Elluru, S., Gupta, H., Kaur, H., & Singh, S. P. (2019). Proactive and reactive models for disaster resilient supply chain. Annals of Operations Research, 283(1), 199–224. https://doi.org/10.1007/s10479-017-2681-2

Ergun, O., Karakus, G., Keskinocak, P., Swann, J., & Villarreal, M. (2009). Humanitarian Supply Chain Management—An Overview. In C. Barnhart, U. Clausen, U. Lauther, & R. H. Möhring (Eds.), Models and Algorithms for Optimization in Logistics (09261Issue vol.). Germany: Schloss Dagstuhl - Leibniz-Zentrum fuer Informatik. http://drops.dagstuhl.de/opus/volltexte/2009/2181

Fadaki, M., Rahman, S., & Chan, C. (2020). Leagile supply chain: Design drivers and business performance implications. International Journal of Production Research, 58(18), 5601–5623. https://doi.org/10.1080/00207543.2019.1693660

Fahimnia, B., & Jabbarzadeh, A. (2016). Marrying supply chain sustainability and resilience: A match made in heaven. Transportation Research Part E: Logistics and Transportation Review, 91, 306–324. https://doi.org/10.1016/j.tre.2016.02.007

Fosso Wamba, S., Gunasekaran, A., Dubey, R., & Ngai, E. W. T. (2018). Big data analytics in operations and supply chain management. Annals of Operations Research, 270(1–2), 1–4. https://doi.org/10.1007/s10479-018-3024-7

Frederico, G. F., Kumar, V., Garza-Reyes, J. A., Kumar, A., & Agrawal, R. (2021). Impact of I4.0 technologies and their interoperability on performance: Future pathways for supply chain resilience post-COVID-19. The International Journal of Logistics Management, ahead-of i>-print(ahead-of-print). https://doi.org/10.1108/IJLM-03-2021-0181

Grover, P., & Kar, A. K. (2017). Big Data Analytics: A Review on Theoretical Contributions and Tools Used in Literature. Global Journal of Flexible Systems Management, 18(3), 203–229. https://doi.org/10.1007/s40171-017-0159-3

Gunessee, S., & Subramanian, N. (2020). Ambiguity and its coping mechanisms in supply chains lessons from the Covid-19 pandemic and natural disasters. International Journal of Operations & Production Management, 40(7/8), 1201–1223. https://doi.org/10.1108/IJOPM-07-2019-0530

Hamdi, F., Ghorbel, A., Masmoudi, F., & Dupont, L. (2018). Optimization of a supply portfolio in the context of supply chain risk management: Literature review. Journal of Intelligent Manufacturing, 29(4), 763–788. https://doi.org/10.1007/s10845-015-1128-3

Hazen, B. T., Skipper, J. B., Boone, C. A., & Hill, R. R. (2018). Back in business: Operations research in support of big data analytics for operations and supply chain management. Annals of Operations Research, 270(1–2), 201–211. https://doi.org/10.1007/s10479-016-2226-0

Hiebl, M. R. W. (2021). Sample Selection in Systematic Literature Reviews of Management Research. Organizational Research Methods, 1094428120986851. https://doi.org/10.1177/1094428120986851

Hohenstein, N. O., Feisel, E., Hartmann, E., & Giunipero, L. (2015). Research on the phenomenon of supply chain resilience: A systematic review and paths for further investigation. International Journal of Physical Distribution & Logistics Management, 45(1/2), 90–117. https://doi.org/10.1108/IJPDLM-05-2013-0128

Hosseini, S., & Ivanov, D. (2019). A New Resilience Measure for Supply Networks With the Ripple Effect Considerations: A Bayesian Network Approach.Annals of Operation Research. https://aquila.usm.edu/fac_pubs/16506

Ioannidis, C., Pym, D., Williams, J., & Gheyas, I. (2019). Resilience in information stewardship. European Journal of Operational Research, 274(2), 638–653. https://doi.org/10.1016/j.ejor.2018.10.020

Ivanov, D. (2017). Simulation-based single vs. Dual sourcing analysis in the supply chain with consideration of capacity disruptions, big data and demand patterns. International Journal of Integrated Supply Management, 11(1), 24–43. https://doi.org/10.1504/IJISM.2017.083005

Ivanov, D. (2020). Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review, 136, 101922. https://doi.org/10.1016/j.tre.2020.101922

Ivanov, D., Dolgui, A., & Sokolov, B. (2019). The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research, 57(3), 829–846. https://doi.org/10.1080/00207543.2018.1488086

Janjua, N. K., Nawaz, F., & Prior, D. D. (2021). A fuzzy supply chain risk assessment approach using real-time disruption event data from Twitter. Enterprise Information Systems, 0(0), 1–22. https://doi.org/10.1080/17517575.2021.1959652

Jüttner, U., Peck, H., & Christopher, M. (2003). Supply chain risk management: Outlining an agenda for future research. International Journal of Logistics Research and Applications, 6(4), 197–210. https://doi.org/10.1080/13675560310001627016

Kapoor, K., Bigdeli, A. Z., Dwivedi, Y. K., & Raman, R. (2021). How is COVID-19 altering the manufacturing landscape? A literature review of imminent challenges and management interventions. Annals of Operations Research. https://doi.org/10.1007/s10479-021-04397-2

Katsaliaki, K., Galetsi, P., & Kumar, S. (2021). Supply chain disruptions and resilience: A major review and future research agenda. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03912-1

Khan, S. A. R., Yu, Z., Umar, M., Lopes de Sousa Jabbour, A. B., & Mor, R. S. (2021). Tackling post-pandemic challenges with digital technologies: An empirical study. Journal of Enterprise Information Management, ahead-of i>-print(ahead-of-print). https://doi.org/10.1108/JEIM-01-2021-0040

Kirk, C. P., & Rifkin, L. S. (2020). I’ll trade you diamonds for toilet paper: Consumer reacting, coping and adapting behaviors in the COVID-19 pandemic. Journal of Business Research, 117, 124–131. https://doi.org/10.1016/j.jbusres.2020.05.028

Lawson, B., Potter, A., Pil, F. K., & Holweg, M. (2019). Supply chain disruptions: The influence of industry and geography on firm reaction speed. International Journal of Operations & Production Management, 39(9/10), 1076–1098. https://doi.org/10.1108/IJOPM-04-2018-0225

Lee, L. (2016). New Kids on the Blockchain: How Bitcoin’s Technology Could Reinvent the Stock Market. Hastings Business Law Journal, University of Utah College of Law, 12(2). https://ssrn.com/abstract=2656501 or https://doi.org/10.2139/ssrn.2656501

Li, S., & Lin, B. (2006). Accessing information sharing and information quality in supply chain management. Decision Support Systems, 42(3), 1641–1656. https://doi.org/10.1016/j.dss.2006.02.011

Lohmer, J., Bugert, N., & Lasch, R. (2020). Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. International Journal of Production Economics, 228, 107882. https://doi.org/10.1016/j.ijpe.2020.107882

Maitlis, S., & Sonenshein, S. (2010). Sensemaking in Crisis and Change: Inspiration and Insights From Weick (1988). Journal of Management Studies, 47(3), 551–580

Mandal, S. (2018). The influence of big data analytics management capabilities on supply chain preparedness, alertness and agility: An empirical investigation. Information Technology & People, 32(2), 297–318. https://doi.org/10.1108/ITP-11-2017-0386

Mikalef, P., & Gupta, M. (2021). Artificial intelligence capability: Conceptualization, measurement calibration, and empirical study on its impact on organizational creativity and firm performance. Information & Management, 58(3), 103434. https://doi.org/10.1016/j.im.2021.103434

Mikalef, P., Pappas, I. O., Krogstie, J., & Giannakos, M. (2018). Big data analytics capabilities: A systematic literature review and research agenda. Information Systems and E-Business Management, 16(3), 547–578. https://doi.org/10.1007/s10257-017-0362-y

Mikalef, P., Pappas, I. O., Krogstie, J., & Pavlou, P. A. (2020). Big data and business analytics: A research agenda for realizing business value. Information & Management, 57(1), 103237. https://doi.org/10.1016/j.im.2019.103237

Mishra, S., & Singh, S. P. (2020). A stochastic disaster-resilient and sustainable reverse logistics model in big data environment. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03573-0

Modgil, S., Gupta, S., Stekelorum, R., & Laguir, I. (2021a). AI technologies and their impact on supply chain resilience during COVID-19. International Journal of Physical Distribution & Logistics Management, ahead-ofi>-print(ahead-of-print). https://doi.org/10.1108/IJPDLM-12-2020-0434

Modgil, S., Singh, R. K., & Hannibal, C. (2021b). Artificial intelligence for supply chain resilience: Learning from Covid-19. The International Journal of Logistics Management, ahead-ofi>-print(ahead-of-print). https://doi.org/10.1108/IJLM-02-2021b-0094

Mulrow, C. D. (1994). Systematic Reviews: Rationale for systematic reviews. Bmj, 309(6954), 597–599. https://doi.org/10.1136/bmj.309.6954.597

Nayal, K., Raut, R., Priyadarshinee, P., Narkhede, B. E., Kazancoglu, Y., & Narwane, V. (2021). Exploring the role of artificial intelligence in managing agricultural supply chain risk to counter the impacts of the COVID-19 pandemic. The International Journal of Logistics Management, ahead-of i>-print(ahead-of-print). https://doi.org/10.1108/IJLM-12-2020-0493

Ngai, E. W. T., Peng, S., Alexander, P., & Moon, K. K. L. (2014). Decision support and intelligent systems in the textile and apparel supply chain: An academic review of research articles. Expert Systems with Applications, 41(1), 81–91. https://doi.org/10.1016/j.eswa.2013.07.013

Oesterreich, T. D., Anton, E., Teuteberg, F., & Dwivedi, Y. K. (2022). The role of the social and technical factors in creating business value from big data analytics: A meta-analysis. Journal of Business Research, 153, 128–149. https://doi.org/10.1016/j.jbusres.2022.08.028

Papadopoulos, T., Baltas, K. N., & Balta, M. E. (2020). The use of digital technologies by small and medium enterprises during COVID-19: Implications for theory and practice. International Journal of Information Management, 55, 102192. https://doi.org/10.1016/j.ijinfomgt.2020.102192

Papadopoulos, T., Singh, S. P., Spanaki, K., Gunasekaran, A., & Dubey, R. (2022). Towards the next generation of manufacturing: Implications of big data and digitalization in the context of industry 4.0. Production Planning & Control, 33(2–3), 101–104. https://doi.org/10.1080/09537287.2020.1810767

Patyal, V., Sarma, P., Modgil, S., Nag, T., & Dennehy, D. (2021). Mapping the links between Industry 4.0, Circular Economy and Sustainability: A Systematic Literature Review.Journal of Enterprise Information Management

Pettit, T. J., Croxton, K. L., & Fiksel, J. (2019). The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. Journal of Business Logistics, 40(1), 56–65. https://doi.org/10.1111/jbl.12202

Pinto, M. M. A., Kovaleski, J. L., Yoshino, R. T., & Pagani, R. N. (2019). Knowledge and Technology Transfer Influencing the Process of Innovation in Green Supply Chain Management: A Multicriteria Model Based on the DEMATEL Method. Sustainability, 11(12), 3485. https://doi.org/10.3390/su11123485

Ponomarov, S. Y., & Holcomb, M. C. (2009). Understanding the concept of supply chain resilience. The International Journal of Logistics Management, 20(1), 124–143. https://doi.org/10.1108/09574090910954873

Purvis, L., Spall, S., Naim, M., & Spiegler, V. (2016). Developing a resilient supply chain strategy during ‘boom’ and ‘bust.’. Production Planning & Control, 0–0. https://doi.org/10.1080/09537287.2016.1165306

Rajesh, R. (2016). Forecasting supply chain resilience performance using grey prediction. Electronic Commerce Research and Applications, 20, 42–58. https://doi.org/10.1016/j.elerap.2016.09.006

Ralston, P., & Blackhurst, J. (2020). Industry 4.0 and resilience in the supply chain: A driver of capability enhancement or capability loss? International Journal of Production Research, 58(16), 5006–5019. https://doi.org/10.1080/00207543.2020.1736724

Rezapour, S., Farahani, R. Z., & Pourakbar, M. (2017). Resilient supply chain network design under competition: A case study. European Journal of Operational Research, 259(3), 1017–1035. https://doi.org/10.1016/j.ejor.2016.11.041

Roden, S., Nucciarelli, A., Li, F., & Graham, G. (2017). Big data and the transformation of operations models: A framework and a new research agenda. Production Planning & Control, 28(11–12), 929–944. https://doi.org/10.1080/09537287.2017.1336792

Ross, J. W., Beath, C. M., & Quaadgras, A. (2013). December 1). You May Not Need Big Data After All.Harvard Business Review. https://hbr.org/2013/12/you-may-not-need-big-data-after-all

Sanders, N. R. (2016). How to Use Big Data to Drive Your Supply Chain. California Management Review, 58(3), 26–48. https://doi.org/10.1525/cmr.2016.58.3.26

Sharma, R., Kamble, S. S., Gunasekaran, A., Kumar, V., & Kumar, A. (2020). A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Computers & Operations Research, 119, 104926. https://doi.org/10.1016/j.cor.2020.104926

Sheng, M. L., & Saide, S. (2021). Supply chain survivability in crisis times through a viable system perspective: Big data, knowledge ambidexterity, and the mediating role of virtual enterprise. Journal of Business Research, 137, 567–578. https://doi.org/10.1016/j.jbusres.2021.08.041

Singh, N. (2020). Developing Business Risk Resilience through Risk Management Infrastructure: The Moderating Role of Big Data Analytics. Information Systems Management, 0(0), 1–19. https://doi.org/10.1080/10580530.2020.1833386

Singh, N. P., & Singh, S. (2019). Building supply chain risk resilience: Role of big data analytics in supply chain disruption mitigation. Benchmarking: An International Journal, 26(7), 2318–2342. https://doi.org/10.1108/BIJ-10-2018-0346

Sohrabi, C., Alsafi, Z., O’Neill, N., Khan, M., Kerwan, A., Al-Jabir, A., Iosifidis, C., & Agha, R. (2020). World Health Organization declares global emergency: A review of the 2019 novel coronavirus (COVID-19). International Journal of Surgery, 76, 71–76. https://doi.org/10.1016/j.ijsu.2020.02.034

Spanaki, K., Sivarajah, U., Fakhimi, M., Despoudi, S., & Irani, Z. (2021). Disruptive technologies in agricultural operations: A systematic review of AI-driven AgriTech research. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03922-z

Stecke, K. E., & Kumar, S. (2009). Sources of Supply Chain Disruptions, Factors That Breed Vulnerability, and Mitigating Strategies. Journal of Marketing Channels, 16(3), 193–226. https://doi.org/10.1080/10466690902932551

Stone, J., & Rahimifard, S. (2018). Resilience in agri-food supply chains: A critical analysis of the literature and synthesis of a novel framework. Supply Chain Management: An International Journal, 23(3), 207–238. https://doi.org/10.1108/SCM-06-2017-0201