Abstract

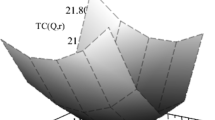

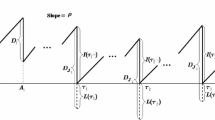

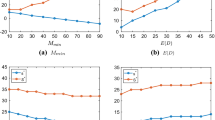

This paper addresses a multi-period production/inventory problem with two suppliers, where demand sizes and supplier lead time are stochastic and correlated. A discrete time, single item inventory system is considered, where inventory levels are reviewed periodically and managed using a base-stock policy. At the end of each period, a replenishment order is placed, which enters a queue at the buffer stage and is consequently forwarded to the first available supplier. We present a mathematical model of this inventory system and determine optimal safety stock levels for it, in closed form, using matrix analytic techniques and the properties of phase type distributions. To account for the effect of order crossovers, which occur whenever replenishment orders do not arrive in the sequence in which they were placed, the inventory shortfall distribution is analyzed. Finally, a set of numerical experiments with a system with two suppliers is presented, where the proposed model is compared to other existing models.

Similar content being viewed by others

References

Bell, C. E. (1980). Optimal operation of an M/M/2 queue with removable servers. Operations Research, 28(5), 1189–1204.

Betts, J. M. (2014). Calculating target inventory levels for constrained production: A fast simulation-based approximation. Computers and Operations Research, 49, 18–27.

Bobbio, A., Horváth, A., Scarpa, M., & Telek, M. (2003). Acyclic discrete phase type distributions: Properties and a parameter estimation algorithm. Performance evaluation, 54(1), 1–32.

Boute, R. N., Lambrecht, M. R., & Van Houdt, B. (2007). Performance evaluation of a production/inventory system with periodic review and endogenous lead times. Naval Research Logistics (NRL), 54(4), 462–473.

Boute, R. N., Colen, P. J., Creemers, S., Noblesse, A., Van Houdt, B., et al. (2012). Matrix-analytic methods in supply chain management: Recent developments. Review of Business and Economic Literature, 57(3), 283–302.

Boute, R. N., Disney, S. M., Lambrecht, M. R., & Houdt, B. V. (2014). Coordinating lead times and safety stocks under autocorrelated demand. European Journal of Operational Research, 232(1), 52–63.

Bradley, J. R., & Robinson, L. W. (2003) Improved base-stock policies under order crossover. Tech. rep., Working Paper. Cornell University.

Brill, P. H., & Posner, M. J. M. (1981). A two server queue with nonwaiting customers receiving specialized service. Management Science, 27(8), 914–925. https://doi.org/10.1287/mnsc.27.8.914.

Chakravarthy, S. R., & Agnihothri, S. R. (2008). A server backup model with Markovian arrivals and phase type services. European Journal of Operational Research, 184(2), 584–609. https://doi.org/10.1016/j.ejor.2006.12.016.

Chakravarthy, S. R., & Karatza, H. D. (2013). Two-server parallel system with pure space sharing and Markovian arrivals. Computers and Operations Research, 40(1), 510–519. https://doi.org/10.1016/j.cor.2012.08.002.

Chopra, S., Reinhardt, G., & Dada, M. (2004). The effect of lead time uncertainty on safety stocks. Decision Sciences, 35(1), 1–24.

Clark, A. J., & Scarf, H. (1960). Optimal policies for a multi-echelon inventory problem. Management science, 6(4), 475–490.

Dabbene, F., Gay, P., & Tortia, C. (2014). Traceability issues in food supply chain management: A review. Biosystems Engineering, 120, 65–80. https://doi.org/10.1016/j.biosystemseng.2013.09.006.

De Toni, A. (1999). Buyer–supplier operational practices, sourcing policies and plant performances: Results of an empirical research. International Journal of Production Research, 37(3), 597–619.

Dolgui, A., Ammar, O. B., Hnaien, F., & Louly, M. A. (2013). A state of the art on supply planning and inventory control under lead time uncertainty. Studies in Informatics and Control, 22(3), 255–268.

Federgruen, A., & Zipkin, P. (1986). An inventory model with limited production capacity and uncertain demands I. The average-cost criterion. Mathematics of Operations Research, 11(2), 193–207.

Filippopoulos, D., & Karatza, H. (2007). An M/M/2 parallel system model with pure space sharing among rigid jobs. Mathematical and Computer Modelling, 45(5), 491–530. https://doi.org/10.1016/j.mcm.2006.06.007.

Froehle, C. M., & White, D. L. (2014). Interruption and forgetting in knowledge-intensive service environments. Production and Operations Management, 23(4), 704–722. https://doi.org/10.1111/poms.12089.

Glasserman, P., & Tayur, S. (1996). A simple approximation for a multistage capacitated production–inventory system. Naval Research Logistics (NRL), 43(1), 41–58.

Goffin, K., Szwejczewski, M., & New, C. (1997). Managing suppliers: When fewer can mean more. International Journal of Physical Distribution & Logistics Management, 27(7), 422–436.

Hopp, W. J., & Spearman, M. L. (2000). Factory physics (2nd ed.). Long Grove: Waveland Press.

Johnson, P. F., Leenders, M. R., & Fearon, H. E. (1998). Evolving roles and responsibilities of purchasing organizations. International Journal of Purchasing and Materials Management, 34(4), 2–11.

Katehakis, M. N., Melamed, B., & Shi, J. J. (2015). Optimal replenishment rate for inventory systems with compound Poisson demands and lost sales: A direct treatment of time-average cost. Annals of Operations Research,. https://doi.org/10.1007/s10479-015-1998-y.

Kendall, D. G. (1953). Stochastic processes occurring in the theory of queues and their analysis by the method of the imbedded Markov chain. The Annals of Mathematical Statistics, 24, 338–354.

Kim, J. G., Chatfield, D., Harrison, T. P., & Hayya, J. C. (2006). Quantifying the bullwhip effect in a supply chain with stochastic lead time. European Journal of operational research, 173(2), 617–636.

Larsen, R. L., & Agrawala, A. K. (1983). Control of a heterogeneous two-server exponential queueing system. IEEE Transactions on Software Engineering, 9(4), 522–526. https://doi.org/10.1109/TSE.1983.234960.

Lee, Y. J., & Zipkin, P. (1992). Tandem queues with planned inventories. Operations Research, 40(5), 936–947.

Lu, Y., Song, J. S., & Yao, D. D. (2003). Order fill rate, leadtime variability, and advance demand information in an assemble-to-order system. Operations Research, 51(2), 292–308.

Noblesse, A. M., Boute, R. N., Lambrecht, M. R., & Van Houdt, B. (2014). Lot sizing and lead time decisions in production/inventory systems. International Journal of Production Economics, 155, 351–360.

Porter, M. E., & Millar, V. E. (1985, July-August). How information gives you competitive advantage. Harvard Business Review, pp. 149–160.

Revathy, P. H., & Subramanian, M. G. (2013). Two server (s, S) inventory system with positive service time, positive lead time, retrial customers and negative arrivals. International Journal of Computer Applications, 62(10), 9–13.

Robinson, L. W., Bradley, J. R., & Thomas, L. J. (2001). Consequences of order crossover under order-up-to inventory policies. Manufacturing & Service Operations Management, 3(3), 175–188.

Roundy, R. O., & Muckstadt, J. A. (2000). Heuristic computation of periodic-review base stock inventory policies. Management Science, 46(1), 104–109.

Shi, J., Katehakis, M. N., & Melamed, B. (2013). Martingale methods for pricing inventory penalties under continuous replenishment and compound renewal demands. Annals of Operations Research, 208(1), 593–612. https://doi.org/10.1007/s10479-012-1130-5.

Shin, H., Collier, D. A., & Wilson, D. D. (2000). Supply management orientation and supplier/buyer performance. Journal of Operations Management, 18(3), 317–333.

Song, J. S., & Yao, D. D. (2002). Performance analysis and optimization of assemble-to-order systems with random lead times. Operations Research, 50(5), 889–903.

Song, J. S., & Zipkin, P. H. (1996). The joint effect of leadtime variance and lot size in a parallel processing environment. Management Science, 42(9), 1352–1363.

Song, J. S., Xu, S. H., & Liu, B. (1999). Order-fulfillment performance measures in an assemble-to-order system with stochastic leadtimes. Operations Research, 47(1), 131–149.

Tayur, S. R. (1993). Computing the optimal policy for capacitated inventory models. Stochastic Models, 9(4), 585–598.

Van Nyen, P., Bertrand, J., Van Ooijen, H., & Vandaele, N. (2005). A heuristic to control integrated multi-product multi-machine production-inventory systems with job shop routings and stochastic arrival, set-up and processing times. OR Spectrum, 27(2–3), 399–434.

Veatch, M. H., & Wein, L. M. (1994). Optimal control of a two-station tandem production/inventory system. Operations Research, 42(2), 337–350.

Veinott, A. F, Jr. (1966). The status of mathematical inventory theory. Management Science, 12(11), 745–777.

Wang, P., Zinn, W., & Croxton, K. L. (2010). Sizing inventory when lead time and demand are correlated. Production and Operations Management, 19(4), 480–484.

Zipkin, P. H. (2000). Foundations of inventory management (Vol. 2). New York: McGraw-Hill.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Caceres, H., Yu, D. & Nikolaev, A. Evaluating shortfall distributions in periodic inventory systems with stochastic endogenous demands and lead-times. Ann Oper Res 271, 405–427 (2018). https://doi.org/10.1007/s10479-018-2764-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-018-2764-8