Abstract

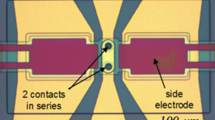

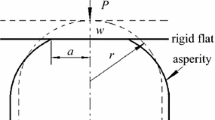

The main scope of this paper is to investigate the adhesion effect on the mechanical response of MEMS components for RF switch application by using an atomic force microscope (AFM). The occurrence and strength of adhesion effects in MEMS devices depend on a variety of environmental, geometrical and operational parameters. The temperature influence on adhesion is experimentally analyzed considering MEMS materials commonly used to fabricate RF switches. The adhesion force is the main factor with influence on stiction. In fact, stiction is the adhesion occurring between the contact surfaces due to surface forces including van der Waals, capillary forces, Casmir forces, and electrostatic forces. The adhesion between AFM tip and the materials under interest is investigated using the spectroscopy in point mode of an AFM. Different coated AFM tip is considered for tests. The AFM spectroscopy-in-point curve gives the direct measurement of tip-sample interaction force as a function of the gap between the tip and sample. The adhesion between tip and sample is characterized by so-called pull-off or pull-out force. The pull-off force is related in current continuum contact mechanics model to the work of adhesion. Using a thermal controller stage the temperature of investigated materials is changed. The mechanical properties variation of MEMS materials as a function of temperature is monitored and the temperature influence on adhesion is analyzed. The influence of the surface roughness on the adhesion forces between AFM tip and samples is determined. Different roughness (Ra) of investigated polysilicon samples is varied in the range of ∼5 to 15 nm. A high value of adhesion force is determined for the contact between gold AFM tip and gold sample comparatively with the contact between Si3N4 AFM tip and gold material. The contact areas between an AFM tip and substrate is an important parameter for analyzing the adhesion effect. The results from laboratory indicate that the adhesive force increases if the surface roughness decreases because the contact area increases. The adhesion between gold microcantilever and substrate obtained from experimental tests (the AFM spectroscopy-in-point mode) results is obtained. During tests, the AFM tip from Si3N4 coated with gold is applied at the beam free-end and deflects the sample to substrate.

Similar content being viewed by others

References

Achanta, S., & Celis, J.-P. (2006). Nanotribology of MEMS/NEMS. In E. Gnecco & E. Meyer (Eds.), Fundamentals of friction and wear on the nanoscale (pp. 521–547). Berlin: Springer. doi:10.1007/978-3-540-36807-6_23.

Bhushan, B. (1999). Handbook of micro/nanotribology (2nd ed.). New York: CRC, LLC. ISBN 0-8493-8402-8.

Bhushan, B. (2003). Adhesion and stiction: mechanisms, measurement techniques and methods for reduction. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 21(6), 2262–2296.

Birleanu, C., Pustan, M., Dudescu, C., Belcin, O., & Rymuza, Z. (2012). Nanotribological investigations on adesion effect applied to MEMS materials. Acta Technica Napocensis Journal Series: Applied Mathematics and Mechanics, 55(III), 671–676.

Cappella, B., & Dietler, G. (1999). Force-distance curves by atomic force microscopy. Surface Science Reports, 34, 1–104.

Chau, A., Régnier, S., Delchambre, A., & Lambert, P. (2010). Theoretical and experimental study of the influence of AFM tip geometry and orientation on capillary force. Journal of Adhesion Science and Technology, 24, 2499–2510.

Derjaguin, B. V., Muller, V. M., & Toporov, Y. P. T. (1975). Effect of contact deformations on the adhesion of particles. Journal of Colloid and Interface Science, 53(2), 314–326.

Drelich, J. (2006). Adhesion forces measured between particles and substrates with nano-roughness. Minerals & Metalurgical Processing, 23, 226–232.

Jacobs, T., Ryan, K., Keating, P., Grierson, D., Lefever, J., Turner, K., et al. (2013). The effect of atomic-scale roughness on the adhesion of nanoscale asperities: a combined simulation and experimental investigation. Tribology Letters, 50, 81–93.

Johnson, K. L., Kendall, K. & Roberts, A. D. (1971). Surface energy and the contact of elastic solids. Proceedings of the Royal Society A, 324, 301–313.

Kim, S. H., Dugger, M. T., & Mittal, K. L. (2011). Adhesion aspects in MEMS/NEMS (pp. 135–161). Boca Raton: CRC.

Naumann M. (2013). MEMS reliability in shock environments. PhD Thesis, Technical University from Chemnitz, Germany.

Stegemann, B., Backhau, H., Kloss, H., & Santner, E. (2007). “Spherical AFM Probes for Adhesion Force Measurements on Metal Single Crystals”, FORMATEX 2007. In A. Méndez-Vilas & J. Díaz (Eds.), Modern research and educational topics in microscopy (pp. 820–828).

Tormoen, G. W., Drelich, J., & Beach, E. R. (2004). Analysis of atomic force microscope pull-off forces for gold surfaces portraying nanoscale rough-ness and specific chemical functionality. Journal of Adhesion Science and Technology, 18, 1–18.

Wu, L., Noels, L., Rochus, V., Pustan, M., & Golinval, J.-C. (2011). A micro-macroapproach to predict stiction due to surface contact in microelectromechanical systems. Journal of Microelectromechanical Systems, 20, 976–990.

Santner, E., & Stegemann, B. Adhesion measurements by AFM—a gateway to the basics of friction. Federal Institute for Materials Research and Testing (BAM), Berlin.

van Zwol, P. J., Palasantzas, G., & De Hosson, J. Th. M. Influence of random roughness on the adhesion between metal surfaces due to capillary condensation. Department of Applied Physics, Netherlands Institute for Metals Research and Zernike Institute for Advanced Materials, University of Groningen, The Netherlands.

Zhao, Y.-P., Wang, L. S., & Yu, T. X. (2003). Mechanics of adhesion in MEMS—a review. Journal of Adhesion Science and Technology, 17(4), 519–546.

Acknowledgments

This work was supported by a STAR no. 97/2013 Grant from the Research Program for Space Technology Development and Innovation and Advanced Research – STAR, “Tribomechanical Characterization of MEMS Materials for Space Applications under harsh environments”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Birleanu, C., Pustan, M. Analysis of the adhesion effect in RF-MEMS switches using atomic force microscope. Analog Integr Circ Sig Process 82, 571–581 (2015). https://doi.org/10.1007/s10470-014-0481-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10470-014-0481-z