Abstract

The chemical production process is tedious due to the integration of different types of equipment and variables. Designing the controller is crucial in the chemical industry due to the interactive and non-linear system behaviour. An intelligent autonomous controller can improve the operating efficiency of the industry. Although several controllers have been developed, different system failures are frequently reported. Hence, controllers such as proportional integral derivative (PID), fuzzy logic controller (FLC), and hybrid fuzzy PID (F-PID) applied in the chemical industries are critically reviewed in the paper. Initially, the PID controller-based approaches are reviewed for different purposes in the chemical industry. After that, the FLC-based controllers-based papers are reviewed. In order to satisfy the issues in both controllers, the H-PID controllers have been reviewed. This review paper will provide an effective solution for operation control in the chemical industry under different operating conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The control system plays a major role in industrial processes regulating system performance at a particular set point. System components and parameters are adjusted within the range for better system performance (Yuvaraj et al. 2019). Among several industries, the chemical industry has a large proportion worldwide due to its importance in products such as food, medicine, and petroleum (Griffin et al. 2018). The chemical industry is non-linear in nature; therefore, efficient control measures are required to ensure satisfactory system performance. Controlling the system parameters is the most important task due to the non-linear variations in the manipulated parameters. The system conditions must be monitored continuously to control the non-linear behavior (Manisha et al. 2018). Programmable logic controllers (PLC) are considered a vital area of automation in the chemical industry (Alphonsus and Abdullah 2016). The heater is an important piece of equipment in the industrial process, especially in the chemical industry, to improve product quality and process efficiency. The Stirred Tank Heater (STH) is omnipresent in the chemical industry for producing new materials through batch reactions (Septiani et al. 2017). The STH is mainly used for varying the fluid temperature inside the tank.

Hence, temperature control is often required in the chemical industries. Several controllers have been used in the chemical industry to control the system temperature in a continuous stir tank reactor. Various controllers such as proportional-integral (PI), proportional integral derivative (PID), and fuzzy are designed in the existing works to cope with the varying system conditions such as temperature, pressure, and liquid flow (Deepa et al. 2015; Abd El-Hamid et al. 2015). Meanwhile, liquid level control approaches in the system must be adopted to regulate liquid flow. Despite its importance, liquid level control is complex due to its non-linear nature (Harivardhagini and Raghuram 2015). Several works have looked at the coordination between system control and safety considerations. PID controllers are often used for process control in the chemical industries because of their simple structure benefits. The requirement of PID controller performance is accomplished through different tuning rules (Saini et al. 2016).

However, the conventional PID controllers are suitable for controlling the linear system and therefore need to be upgraded to deal with non-linear chemical industry processes. On the other hand, the fuzzy logic controller (FLC) has been used in a system with a non-linear nature (Var et al. 2015). The fuzzy logic (FL) approach examines system operation using if-then rules with various matching degrees for given operating conditions. FLC can handle vague situations and generate a solution regarding linguistic variables (Roy et al. 2019; Mahalakshmi et al. 2015). In the case of the chemical industry, the lack of ability to control the occurrence of disruptions may lead to accidents under certain circumstances. Therefore, safety measures to prevent these issues are vital in ensuring the plant’s normal operation (Hosseinnia et al. 2018). Anyhow, the conventional PID and fuzzy controllers have difficulties reacting to the changes in operating conditions, which necessitates the development of better controller models (Liu et al. 2016). The hybridization of fuzzy and PID (F-PID) controllers will improve system performance under varying conditions (Kabila and Glan Devadhas 2015). The general objective of the chemical plant is to produce new materials through chemical or biological transformation. The food industry and pharmaceutical products are the major applications of the chemical industry. The chemical industry has provided multiple building blocks and raw materials for some industries as it plays a significant role in manufacturing.

Furthermore, the applicability of controllers in the chemical industry is considered a future research topic due to their role in daily life. However, the least exploration is conducted toward non-linear dynamic behaviour control of chemical plants. Hence, this paper is intended to examine the role of commonly used controllers such as PID, FLC, and hybrid fuzzy –PID (F-PID) for non-linear control of the chemical industries. This paper aims to provide an overview of PID, FLC, and F-PID controllers utilized in the literature from the initial phase to the present. The number of papers used in this review is shown in Fig. 1.

The prime objectives of this paper are listed as follows,

-

To examine the need for process control in the chemical industry for varying operating variables.

-

Investigate the PID controller-based approaches for pH level control and liquid flow control in the chemical industry.

-

Examine the performance of the chemical plant under FLC for various purposes in the chemical industries.

-

Analyze the operation of a chemical plant through a fuzzy-tuned PID controller along with its limitations.

-

Provide an effective solution to overcome the issues in the chemical industries under varying operating conditions such as varying temperatures.

The rest of this paper is organized as follows; Sect. 2 explains the chemical industry’s basic parameters and functioning and the need for controlling approaches. Section 3 elaborates on the detailed review of PID, FLC, and F-PID controllers in the chemical plant. Section 4 the process control challenges in the chemical industry and Sect. 5 concludes the overview with future work.

2 Review methodology

This section has explained how the articles are selected for conducting a literature survey on this review paper. The research methodology includes the following steps,

-

Planning.

-

Conducting.

-

Reporting.

2.1 Planning

The research planning is made for identifying the necessity of systematic review in the nonlinear process controlling of chemical industry. Existing reviews have been done of the nonlinear process control of chemical industries but there are no reviews, particularly for PID, FLC, and F-PID in nonlinear process control. Thus, this paper has provided an extensive review on this topic. Initially, the research questions are raised and this review should answer the following queries:

-

What is the need for process control in chemical industries?

-

What are the basic units in chemical industries and how does it work?

-

How are the PID controllers used in chemical industries?

-

What are the applications of fuzzy-based controllers in chemical industries?

-

What are the limitations of PID, FLC, and F-PID controllers in chemical industries?

2.2 Conducting

The literature must be selected in a way to answer the research queries. Appropriate research articles for this topic are identified based on the screening and mapping process. The paper screening is carried out through three strategies such as word word-based search, creeping-based search, and inclusion and exclusion of paper. In word based searching strategy, the important papers are searched through relevant words that are listed below:

-

Nonlinear process control in the chemical industry.

-

PID controllers for liquid level control in the chemical industry.

-

FLC controller for the chemical industry.

-

Hybrid F-PID for process control in the chemical industry.

2.2.1 Inclusion strategy

-

Include the paper with PID, FLC, and F-PID for the chemical industry.

-

Include the papers published between 2015 and 2023.

2.2.2 Exclusion strategy

-

Exclude the papers published before 2014.

-

Exclude the papers having unclear information about the publications.

2.3 Preliminary discussion on the process of the Chemical Industry

The main goal of the chemical industry is to create new materials by separating or integrating materials through chemical reactions. The final product from these plants, either lower or higher quality, depends on the production process or the control schemes of different operators (Souza et al. 2018; Mandal et al. 2019). In the chemical industry, the input variables are given to the plant to produce the required product. The controller is attached to the system to ensure the efficient operation of the plant by controlling different measures. The measured and the reference temperature are transferred to the controller if the controller is used for temperature control. The controller examines the deviation between these two values and then takes the control measures. As in the case of flow rate control, the valve is maintained at a particular set point to regulate the liquid flow. Finally, the process output is controlled within the desired level. The fundamental flow of processes in the chemical industry is shown in Fig. 2.

The process variables involved in the chemical industry are explained below:

-

Inputs: The input parameters to the chemical industries are raw materials that vary under the application.

-

Process: The parameters required to maintain the operation are called process parameters.

-

External parameters: The external parameters are referred to as the elements not present inside the process.

-

Output: The output parameters are measured in terms of several measures such as improved flow rate, pressure, temperature and composition of other parameters.

2.3.1 Necessity for process control in the Chemical Industry

Process control in the chemical industry is necessary for regulating operating variables such as pressure, temperature, fluid level, and humidity while manufacturing a product. The control of the system model deals with different purposes requiring continuous plant monitoring. Most chemical reactions are either endothermic or exothermic, depending on the nature of the production process. For example, the supply tank, material line and pumps must be heated in a range to maintain viscosity. On the other hand, chemical reactions often occur in the reactors under chemical reactions and temperature control is applied based on the material type (Noriyanto and Musyafa 2019). Moreover, temperature control relies on factors such as pressurization, heat exchange rate, and component efficiency. Thus, the temperature control system must be used in the chemical industry to react quickly under varying operating conditions.

On the other hand, the lack of liquid flow in highly sensitive environments can contribute to increased consequences in the liquid level control. Accurate flow rate control is an advancing field of the complex system, such as constant liquid flow requiring systems (Mishra et al. 2015). Liquid flow control is widely applied in the chemical process that needs to be compensated with varying pressure ranges. The fluid rate control can be applied by measuring the flow velocity, mass flow rate and volume. Due to the varying functions of the chemical plants, the flow control needs to compensate for the product requirement.

Furthermore, the pressure inside the plant must be measured and controlled within the limit for producing high-quality products. The necessity of chemical industry controllers escalates based on applications like gas separation, pH level control, etc. The efficient process control approach will enhance the following factors,

-

Operational efficiency.

-

Reduction in product variability.

-

Process safety.

-

Profit in material production.

Manual control of the chemical plant is not safe under certain circumstances. Thus, it has been replaced by the controllers. The controller-integrated chemical plant has increased system stability and flexibility (Dulău 2020). These benefits significantly improve production and economy of scale in the chemical industry. Thus, the chemical industrial process requires well-defined monitoring systems and controllers.

3 Different controllers for process control in the Chemical Industry

This section has reviewed several controllers to regulate the operation of the chemical industry under varying system conditions.

3.1 System Control with PID Controller

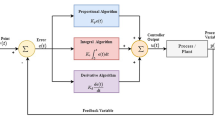

The PID controller is used in various industries to regulate system process parameters such as temperature, pressure, and liquid flow. The PID controller combines a proportional controller with an additional integral derivative that compensates for the system operation under system variations (Sharma et al. 2015). In this section, the PID controller in the chemical industries has been reviewed for various applications. The basic functioning of the PID controller is shown in Fig. 3.

Hydrogen Potential (pH) regulation has been of greater importance in chemical and biological industries. Controlling the pH has been challenging for designers due to unpredictable and non-linear processes. Despite these difficulties, a conventional proportional-integral-derivative (PID) controller commonly uses pH control in the industry.

pH neutralization was directly relevant to chemical reaction outcomes and environmental impact issues. The PID controller did not result in healthy performance in the neutralization process due to non-linearity. Therefore, Renato Aparecido Aguiar et al. (Aguiar et al. 2018) proposed a fractional-order PID controller (FOPID) to improve performance for pH neutralization in chemical plants. The work instructed that the reactor level is also controlled using the FOPID controller in addition to controlling pH. A continuous stirred tank reactor (CSTR) was adapted to carry out the chemical reactions in that paper. Three streams were mixed into the CSTR: acid, base, and buffer. The FOPID controller controlled the acid and base flow, whereas the buffer flow was manually controlled. Then the chemical reaction was done in the tank, and the pH and the reactor tank level values were measured. The system variables were related to the reaction invariants and the reactor level, representing the pH value that the base flow rate can regulate. The output variables pH and reactor level make closed-loop feedback with the FOPID controller.

Nowadays, most chemical industries allow microwave heating to perform chemical reactions with the shortest heating duration. In many chemical plants, microwave thermostatic reactors have replaced existing power-adjustable thermostatic reactors. Yongqiang Zhou et al. (Zhou et al. 2017) proposed processing liquid materials using microwave thermostatic chemical reactors by controlling the coolant velocity. The paper suggested that the reaction vessel contains liquid for the sample and that the microwave coolant flows through a spiral heat exchanger to control the temperature. Then, the microwave irradiated the sample liquid and processed the liquid materials by the control system of the PID controller at a constant temperature. Then the velocity of the coolant was controlled by the PID controller. The temperature control with different coolants like water, ethanol, and methanol was analyzed in the work.

Due to their popularity, cost-effective, and simplicity, PID controllers were adopted in chemical applications to control liquid flow. Poomani and Rameshwari (Poomani and Rameswari 2015) implemented non-linear control to maintain liquid flow levels using an enhanced PID (E-PID) mechanism. The spherical-shaped tank of maximum height and a radius of 0.5 m was utilized in the chemical process because simple to understand as a system. The performance analysis was calculated regarding settling time, overshoot, ISE, and IAE error values. The result of the E-PID controller was compared with the conventional Ziegler-Nichols PID (ZN-PID) controller. The Nyquist plot was designed to analyze the stability of the spherical tank system. The flow of liquid level in the tank with the E-PID controller was analyzed at minimum settling time and with less overshoot than the conventional ZN-PID controller.

Munna Kumar et al. (Kumar et al. 2019) suggested controlling the temperature in the reactor using an internal model control-based PID controller (IMC-PID). The temperature could be controlled in the fermentation process for ethanol production under unstable second-order time delay. The production of alcohol was considered in the fermentation process, and the continuous stirred tank reactor (CSTR) was considered. The comparing output of the temperature of the substrate and reactor was fed to the IMC-based PID controller, where the process transfer function and equivalent process control take place. The output of the PID controller is fed to the CSTR, where the cooling agent flows through the control valve. The reactor’s temperature was regulated by manipulating the jacket flow rate and controlling the temperature of reactor feedback with a PID controller to maintain the process. The process of temperature control in chemical plants is shown in Fig. 4.

The modelling of the heat exchanger with a perfect controlling process was risky due to the non-linearity. In order to suppress that, Firew D. Olana and Tadele A. Abose (Olana and Abose 2021) implemented a mathematical model of shell and tube heat exchangers by a PID controller. The laboratory heat exchanger was used for heat transfer. The cold and hot fluids were the inputs to the heat exchanger, which incorporated a bundle of parallel tubes, and the heat was transferred between the fluids. Different functions are performed due to the series of baffles in the tube, and finally, the cold fluid outcome from the heat exchanger is controlled by a PID controller. The controller function deals with Chein et al. tuning method, which was a large overshoot plus dead time process.

Sina Razvarz, and Cristobel Vargas-Jarillo (Razvarz et al. 2019) proposed controlling the flow rate of fluid oil in pipelines by motor pump vibration control. A torsional actuator placed in the motor can regulate the system vibrations. The fluid flow rate could be controlled by a PID controller based on the Lyapunov stability analysis method adopted in the paper. The minimum range of proportional and derivative gain made the system unstable, so to make it a stable system, the PID gain stability analysis method was applied for better efficiency. The flow model accepted the liquid flow through the pump, and the PID controller’s control signal was given to the torsional actuator to provide the necessary control forces.

Soniya Kocher and Kori (Kocher and Kori 2015) modelled the temperature control of the heat exchanger system in the plant with a PID controller. The proposed heat exchange system comprises the tube exchanger and the reactor in which the heated stream flows through the tubes. The resultant fluid was stored in the tank supplied to the heat exchange system. Here, the PID controller was used to regulate the heat flow. The measured temperature from the plant and set points were given as inputs to the PID.

Beza Negash Getu (Getu 2016) proposed the PID controller based on water level control in chemical industrial processes. The water level in the tank was regulated using motor pumps along with PID. In that proposed work, the water level and the reference height of the water were given to the controller that provides speed control to the motor, thereby controlling the water level. The motor speed was estimated using a speed measurement device then it was transformed to height transformation. The transformation of these variables provides a controlled output related to the flow rate and water level.

Vanavil et al. (Vanavil et al. 2015) proposed an improved PID controller with a lead-lag filter to control the open-loop unstable process. In that paper, the chemical models were represented through transfer functions. The PID was designed using a direct synthesis method that produces peak overshoot. Thus, the set point weights were introduced for the proposed controller, which ranged between 0 and 1. The controller parameter was estimated based on the sensitivity function. The performance efficacy of the suggested model was explained through different examples.

Giovani S et al. (Silva et al. 2017) proposed a PID controller with a model predictive algorithm (MPA) to reduce the operational cost of the controller in chemical applications. In that proposed model, the IMC tuning was applied for both the series and parallel PID controllers. Moreover, the performance was examined with positive and negative disturbances in the system. The system performance was examined through the density of fluid, energy and motion equations expressed in mathematical equations. The model was implemented in Computational Fluid Dynamics (CFD).

Mostafa A. Fellani et al. (Fellani and Gabaj 2015) proposed the PID controller-based liquid level control in a tank system. Here, the controller was used for regulating the water flow into the tanks, thereby examining the speed of the pump. In that paper, the system’s performance was examined with and without the controller. The analysis found that the pump continuously flowed the water until it overflowed while the controller was removed. Moreover, the flow into the tank was enhanced using the controller.

Vásquez et al. (Vásquez et al. 2023) developed the PID-based sliding mode controller for a nonlinear chemical plant. The suggested model design is a nonlinear system using the reaction curve identification method. The reduced order model was represented through the first order plus dead time and the nonlinear surface was used for the proposed controller design.

Kumar et al. (Kumar et al. 2016) developed the modified PID that consists of two PID blocks to control the nonlinear operation in the spherical tank. In that suggested model, the deviation between the reference and measured value of the liquid was considered an error. Hence, the controller gains were tuned in such a way as to minimize the errors.

Goud et al. (Goud et al. 2022) have introduced the tuned PID for controlling the nonlinear temperature in CSTR. In the suggested model, the temperature was controlled by the auto-tuned PID via a feedback loop. Bhookya et al. (Bhookya et al. 2022) developed the PID for controlling liquid levels in the process industry. Quiñόnez et al. (Quiñόnez et al. 2019) compared the different schemes of nonlinear PID controllers for regulating the temperature in the bioreactor process.

Several methods applied with the PID controller are illustrated in Table 1.

3.2 Control of chemical plant with FLC

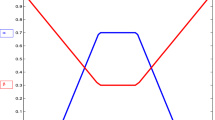

The traditional PID controller is adopted in several fields owing to its simple structure and adaptability benefits. However, its performance is not satisfactory in the non-linear operation of the system. In the case of the chemical industry process, the temperature, pressure, and other processing variables vary over time (Bhandare and Kulkarni 2015). Thus, the FLC is introduced to enhance the system performance simultaneously. The basic operation of the fuzzy controller is shown in Fig. 5.

Gas separation from the air played a major role in the chemical industry. The conventional gas separation process using a PID controller was a multi-loop and multi-variable control. It does not provide quality control and high delay when the system is unstable. In order to overcome those drawbacks, Koldaev et al. (Koldaev et al. 2020) proposed a fuzzy logic controller (FLC) based gas separation process that revealed the membrane process was adapted for separating nitrogen gas from the air. The membrane plant included air separation modules in the cylindrical tank and accepted the compressed air as input. The membrane module supplied air to the fibers connected inside the tank in parallel. The water, hydrogen, and helium molecules have been diffused into it due to the pore arrangement in the fibre walls and can be sent out easily. Oxygen and carbon dioxide were drilled through the walls; nitrogen and argon in the air were stored on the inner side of the membrane. The FLC was utilized to perform better accuracy and gas separation process speed based on fuzzy rules.

The manufacturing of fertilizer in the chemical industry was correlated with the production of foods. Most of the plants relied on fertilizer, so the demand was higher. Due to uncontrolled manufacture and poor quality, the industry suffers losses. In order to rectify that, Darius Andriukaitis et al. (Andriukaitis et al. 2019) introduced the fuzzy logic controller for pelletizing equipment. The paper analyzed the measurement of pellet data collected from fertilizer plants. The fertilizer could be pelletized by chemical reactions, which had a high melting point, and converted into a liquid to form pellets and pellet measurements could be calculated using an auxiliary system. The auxiliary system was an advanced system that operated under fuzzy logic rules. By collecting and measuring the data from plants, the industry manufactured the fertilizer in order to avoid losses.

In the chemical process, liquid level management and control was the most important plan. Hence, managing an industrial liquid filled in the tank was at a certain accuracy level. Wireless communication was a great process of passing information using electromagnetic cables, reducing cable costs, and repairing maintenance when differentiated from wired communication. Ismail Bayram et al. (Bayram et al. 2019) proposed a fuzzy controller in the wireless liquid level simulator, which analyzed data transmission between the system and computer using two antennas. The water fed to the system was kept in a tank, and a pump was opened by electricity, causing the system liquid to flow. A fuse was utilized, which closed the pump to restrict water overflow. The liquid level controller and pressure control valve were used to control the liquid flow and pressure, respectively. The output from those valves was connected with the modules, including the transmitted data between two antennas. The wireless liquid level process control measurements ISE and IAE values were calculated for various liquid level points based on fuzzy results.

The separation of a chemical mixture into individual components through such a chemical reaction is termed chromatography, which plays a crucial part in the chemical industries. The chromatographic separation should be accurate and effective. Therefore Chao-fan Xie and Yang-Jie Tang (Xie and Tang 2021) proposed using advanced simulated moving bed (SMB) technology for chromatography with the fuzzy controller. The separated compounds are first dissolved with the solvent and then fed into the column depending on the pressure. Each component is injected into the fixed phase in the column by the functioning mobile phase. The components with low absorption power with fixed phase were quickly excreted, and components with high power were released slowly. The chromatographic SMB separation encountered a few difficulties when changing environmental parameters and industrial equipment. So, SMB made some adjustments due to changing parameters and equipment. An automatic tuning fuzzy controller was utilized to control the purity in separation from the SMB device. The output force could be controlled under varying parameters to ensure the applied force is in even when the relative error is less.

The chemical process was applied in manufacturing to change the production of materials. In the chemical industry, the distillation column was more significant for splitting the liquid mixture into its pure components by applying or dismissing the heat. Due to vapour and liquid flow dynamics, the time delay rose in the distillation column and was an unfavorable issue in process control. Hamdy and Ramadan (Hamdy and Ramadan 2017) implemented a Smith predictor (SP) and fuzzy decoupling system for multiple-input multiple-output chemical processes. The author suggested that each output was caused by each input in the MIMO chemical process under varying time delays, which leads to poor system response. In order to balance that, SP was introduced in the paper to rectify the time delay problems. The fuzzy decoupling control was also employed in the paper to avoid interaction issues, especially for the purification process. The elements in the decoupling system have functioned as basic fuzzy rules, and SP recovered time delay problems.

A chemical reactor is an energy-consuming apparatus in a chemical process, and the entire effective production is based on the normal operation and performance of the reactor. To control the chemical reactor for optimal concentration value output, Isomiddin Sidikov et al. (Sidikov et al. 2020) designed a fuzzy synergetic controller to regulate non-linear systems’ problems. A chemical reactor was enabled with a mechanical stirrer and cooling jacket. The apparatus carried out an exothermic reaction, and the reactor jacket cooled the reaction with the coolant. After that, a fuzzy synergetic controller was utilized to control the non-linear systems. The concentration and temperature of the process were stabilized in a chemical reactor using control techniques.

In the chemical industry, ensuring safety was difficult due to various variables. In order to ensure safety in chemical processes or plants, the risk factor could be calculated by joining the frequency and magnitude of accidents. For that, Gonzalez Dan et al. (Dan et al. 2017) proposed estimating the frequency of an accident by a fuzzy logic control system. Frequency estimation was based on historical incident data, and accuracy was based on data quality. By adjusting the fuzzy frequency modifier, the frequency should be calculated for various accidents, which is more accurate and realistic. The frequency with high magnitude implies that more safety measures were needed to perform risk management in the chemical plant.

Mamdani’s fuzzy model exhibits many rules to deduce the rules, Ahmadi et al. (Eghbal Ahmadi et al. 2018) proposed a new fuzzy approach of fuzzy composition variables (FCV) for flash separation of crude oil. FCV was a new Mamdani fuzzy model that combined all molar fraction variables of material as one fuzzy variable. The number of components in the material was considered the number of fuzzy sets, whereas the membership function represented the molar fraction value. FCV also included a lumping mapping when the number of components in the material was large. The membership function of each lumped fuzzy set was the summation of the membership function of all fuzzy sets of lumped components. The flash vaporization of crude oil at any operating temperature and pressure was done by FCV rules to predict the outlet stream’s molar fraction and liquid fraction.

Controlling an exothermic process in the chemical industry was difficult due to the sudden heat excretion, resulting in some accidents. In order to rectify that, Wan Ying Chai et al. (Chai et al. 2020) suggested fuzzy logic control for an exothermic batch process. A batch reactor is a commonly used chemical apparatus performing higher output. Thermal runaway of the exothermic process in the batch reactor affected the quality of production and safety of the chemical plant. Predicting optimal temperature using a conventional PID controller needed a separate supervision control. So, the paper adopted the Mamdani type fuzzy logic model to perform an optimum temperature in an exothermic batch process. The technique used in the paper was capable of performing varying temperatures in different stages.

Chemical laboratories have faced many accidents due to liquid waste disposal, which poses an environmental protection and safety problem. Chao-Chung Ho and Ming-Shu Chen (Ho and Chen 2018) proposed a fuzzy theory-based failure mode effects analysis (FMEA) method to progress liquid waste disposal. Initially, liquid waste was collected in a container and stored in a laboratory liquid waste storage room. Then transported to the liquid waste storage field at the semester’s end and delivered to the waste disposal plant by the clearance company once the amount of waste reaches a certain level. In order to reduce the unexpected hazards due to human error and external factors, some safety measures were necessary to manage. So alarming and examining the alert mechanism was important in liquid waste management. The FMEA method was adopted to highlight laboratories’ waste management processes and reduce the risk. The FMEA adopts fuzzy rules to find the risk priority number, calculated by multiplying severity, detection, and occurrence. The liquid level control architecture is shown in Fig. 6.

Controlling the liquid level in the chemical industry plays an important role in providing good quality. The conventional PID controller’s liquid level control method was very difficult. In order to conquer that, Adnan Rafi AI Tahtawi et al. (Al Tahtawi et al. 2020) proposed an FL controller to maintain the liquid level in the tank. The module has two tanks, namely a reservoir and a controlled tank. The liquid was filled in by an electric pump that acts as an actuator and could be detected by an ultrasonic sensor. The Sugeno fuzzy mechanism was applied to the actuator to maintain the liquid level. Based on the input variable error value and change in error, the process of liquid control is maintained. The outcome was performed in the form of valve opening and pump speed. So, the results for liquid levels with or without disturbances were explained by calculating IAE and ITAE errors. Several methods applied with FLC are illustrated in Table 2.

3.3 Fuzzy-PID controller for chemical industry application

In order to overcome the shortcomings in traditional PID and fuzzy controllers, these controllers are combined. The hybrid F-PID controller inherits the advantages of both controllers. Here, the FLC is used for tuning the controller parameters in PID; thus, it improves computational efficiency (So and Jin 2018). The basic architecture of F-PID controllers in the chemical industry application is shown in Fig. 7.

In order to control the system by considering the delay time and the steady state error, Anitha et al. (Anitha et al. 2019) have proposed the hybrid fuzzy-PID (F-PID) controller. The proposed controller was implemented with the single input-single output model, where the piezoelectric transmitter’s signals from the pressure tanks were conveyed through the analog signals. The A-D converter converted the transmitted analog signal into the digital signal. The converter’s output was fed into the controller to take the control measures. The control valve in that arrangement provided the controlled pressure into the tank. That proposed hybrid F-PID controller measured the error and error variation in the system where the set of functions combines the fuzzy and PID controller. That proposed controller provided an optimum solution based on the priority of both the PID and fuzzy controllers.

Liquid level control is an important topic in the chemical industry application, whereas noise affects the system condition. Hence to address these issues, Trinh Luong Mien (Mien 2017) proposed the F-PID controller. That controller was designed for a coupled tank system. In that model, the initial parameters were examined through the linear model; meanwhile, the fuzzy rules were used for tuning the PID controller. In FL, level error and derivative of the error were given as inputs based on these parameters, and the fuzzy rules were generated. Accordingly, the control parameters for the PID controller were generated. At last, the control outputs were generated by combining maximum and minimum rules. The results analysis shows that the controlled model had better performance in terms of lower rise time and steady-state error.

The conventional PID controllers are suitable for controlling a linear process; hence it does not become effective for non-linear operation; Thus, Jhon Edisson et al. (Rodríguez-Castellanos et al. 2018) proposed a fuzzy PID controller. That proposed hybrid controller was tested on the CSTR model. The hybrid controller allows error and change in error as its input function. That control architecture was constructed based on the combinations of FLC-PD and FLC-PI controllers. Both controllers accept similar inputs, and then the control actions are generated by the FLC. The controller’s static gains were selected between the lower and the upper bounds. The gains of the PID controller were transferred to the F-PID controller through the conversion equation. The proposed controller was estimated under non-linear conditions, while performance was measured in terms of IATE and IAE under normal and disturbance conditions.

In order to improve the performance of the electric heating process in the chemical industry, Peng Jin et al. (Jin et al. 2018) proposed the F-PID controller. The two-point method identified the system, selecting the response curve’s coordinate values. Initially, the open loop control was carried out on the system, where three inputs’ time constant and lag time was examined. The adaptive F-PID controller in that model was designed based on a fuzzy control algorithm. The temperature deviation and temperature error were input to the FLC, while the fuzzy rules were used to generate the controller gains from PID. That proposed controller was evaluated on the electric heating plate under different temperature ranges.

In order to improve the performance of the controller under disturbance in liquid flow, Sofian Yahya et al. (Yahya et al. 2022) proposed an adaptive F-PID controller. That proposed controller provided an efficient solution during a disturbance. A simple fluid flow servomotor model was modeled based on actuator motion. The liquid flow model was designed based on the transfer functions of the servo motor. The heating tank system was designed, and its flow rate was examined by sensors sent to the feedback controller. The microcontroller unit decided the operation of the valve control. That adaptive F-PID controller re-tunes the control parameters based on the error-value variations. Additional values of the PID controller interfaced with the nominal PID controller while the disturbance was occurring. That controller was estimated under normal and disturbance conditions.

To deal with the issues of non-linear processes in the chemical industry due to the varied viscosity, Vinothkumar and Esakkiappan (Vinothkumar and Esakkiappan 2021) have proposed an F-PID controller in hopper liquid level control. The delay time process examined the mathematical model parameters such as delay time and time constant in the first order. The error in liquid level and rate of change of liquid level error were given to the FLC based on those values, and the rules were generated. The Hopper tank liquid controlling was modelled in the Simulink tool, and the results were verified regarding ITAE, IAE, and ISE. The performance of liquid level control in the hopper tank was also estimated with the fuzzy PI controller, and satisfactory results were found in the F-PID controller.

Quality and safety are important considerations in the chemical industry, and adopting controllers can achieve these goals. However, the excessive time consumption and the overshoot degraded the controller performance. In order to overcome these issues, Olatunji Hezekiah Adigun (Adigun 2018) proposed the decentralized F-PID controller. The tank models were designed based on the mass balance equation. The fuzzy logic was used for estimating the PID controller parameters. In that paper, the four-coupled tank system resembles a chemical plant. In the tank model, the liquid level was controlled by two pumps. The controlling valves controlled each pump.

Negar Moghadam et al. (Moghadam et al. 2017) proposed a type-2 F-PID controller to improve the precise flow of chlorine in the chloroacetic acid production industry. The system error and deviation in system error were inputs to the FLC. In the type-2 fuzzy model, the type-2 model was mapped into the type-1 fuzzy sets, converting the fuzzy sets into crisp output. In the type-2 fuzzy models, numerous numbers and types of membership functions were generated. Based on those factors, several fuzzy rules were generated for choosing the gain values of proportional, integral, and derivatives. Different types of membership functions, such as Gaussian, triangular, and trapezoidal, were generated, and their corresponding performance metrics were evaluated. Under normal and disturbance conditions, the system performance was evaluated with existing controller models.

Jafar Tavoosi et al. (Tavoosi et al. 2021) proposed a generalized type-2 F-PID (GT2FPID) controller to overcome the noise issues in conventional PID controllers. In that model, the rules generated by FLC were used for tuning the control parameters of PID. The generalized predictive controller was used for examining the controller parameters of PID, which was used as the observer controller. That suggested controller architecture minimizes the temperature in the CSTR system. The observer controller had to provide an optimum value for the controlling parameter under varied system conditions by minimizing the errors. That proposed model was implemented with the CSTR system, and the results were compared with existing models regarding temperature variation and controller tuning.

The tubular heat exchanger is one of the central tasks in the chemical industry and was achieved through the efficient modeling of the shell and heat exchanger. In order to improve the design of these models, Somasundar Reddy and Balaji (Reddy and Balaji 2021) proposed the F-PID controller. That proposed controller was used for controlling the heat in the shell and tube heat exchanger. The FPID controller provided an output by comparing the outputs from fuzzy and PID controllers through two logic functions. The arithmetic output from the proposed controller was given to the plant model in either multiplication or addition operation. That FPID controller had the benefits of dynamic and steady-state response. Moreover, the fuzzy rules were formulated using positive, negative, and zero values.

To deal with the issues in the non-linear operation of the chemical industry, Edison Benalcazar et al. (Benalcázar et al. 2021) proposed an F-PID reset-based controller. The FPID controller was formed through the designed PID controller. In the FLC, both the error and change in error were given as inputs then the FPID controller was modelled by mathematical equations. The operating ranges of the PID controller were decided based on fuzzy variables. The performance efficacy of the suggested controller was examined through ISE, ITAE, and control variations. The performance of the proposed F-PID controller was estimated in the radial graphs under different controllers.

Mohanty et al. (Mohanty and Mohanty 2020) proposed the fuzzy-based PID controller for heat exchangers in the chemical industry. This proposed model added the feed-forward and feed-backward control strategy in the PID controller. With the addition of an efficient controller, the load fluctuations and disturbances in the system have been reduced.

Haoran et al. (Liu et al. 2023) proposed the F-PID controller for the chemical industry’s polymerase chain reaction (PCR). The relay self-tuning algorithm has been proposed for the initial generation of fuzzy parameters. Then the feed-forward algorithm was used to pre-compensate variables in the F-PID controller.

To overcome the instabilities caused by the PID controller, Njoku et al. (Njoku 2021) used the F-PID controller to control pH between 0 and 14. To examine the pH curve, the general time delay transfer function was considered. The error and derivative of the PID gains were fed to fuzzy logic to produce optimal gains.

Jegatheesh et al. (Jegatheesh and Kumar 2020) proposed the hybrid model of fuzzy and fractional order PID controller for level control in spherical tanks. The proposed regulator was studied in the two-tank spherical system. The fuzzy rules chose the proportional and integral gains in the proposed control model. The liquid in the tank has been divided into four zones to control the flow rate. Several methods used with the hybrid H-PID controller are shown in Table 3.

3.4 MPC controllers for non-linear control of chemical plants

This section reviews some existing methods for MPC-based control strategies in chemical plants.

Pua et al. (Pua et al. 2022) proposed a robust MPC with the artificial neural network (ANN) for pH control. In this model, the data sets were created by multiple tests with a length of 1200 min on the MPC and trained by the ANN. The training data set in this model was validated with and without the presence of noise. The Levenberg-Marquardt algorithm was used to train the ANN.

Naregalkar et al. (Naregalkar and Durairaj 2021) suggested the least squares support vector machines (LSSVM) based MPC for CSTR regulatory control. In this model, the non-linearity was solved by the Hammerstein model. The linear dynamics were represented by the Laguerre filters and the non-linearities by the LSSVM.

Rúa et al. (Rúa et al. 2021) suggested the MPC for stabilizing the power plant with CO2 capture based on chemical absorption. The non-linear behaviour of the plant was predicted by the non-linear network model with the MPC strategy. The offset-free control was accomplished by the delta-input formulation.

Qianrong et al. (Li et al. 2021) suggested the MPC for controlling the CO2 chemical capture process. The absorber was added with the steady state model during the optimum working condition. The equilibrium model was selected to support the rate level model absorption and desorption.

Nogueira et al. (Nogueira et al. 2020) suggested the Infinite Horizon MPC (IHMPC) for controlling the polyethylene polymerization process control in the chemical industry. The CSTR was connected to the plug flow reactor (PFR) in that model. In the controller model, the set points and past values from experimentation were given.

Morales et al. (Morales et al. 2020) suggested a controller for the separation of ethanol-water mixture in the closed-loop system. Disturbances in the system were predicted through the nonlinear mathematical equations with distributed parameters. Hammerstein-Wiener structure of a nonlinear reduced control-oriented model was used for controller designing. Two controllers such as MPC and fuzzy PD + I was designed to validate the performance. Torres Cantero et al. (Cantero et al. 2017) compared three control structures for evaluating the performance of salt extractive distillation plants. Finally, the R/F single-end configuration was selected as the best for designing the pilot plant.

Rumbo et al. (Morales et al. 2022) developed two controller models with the Hammerstein-Wiener model for bio-ethanol dehydration. In order to compensate for the fault, the fault tolerant control (FTC) and fuzzy PID were evaluated on the system model. Sorcia-Vázquez et al. (Sorcia-Vázquez et al. 2020) developed the tube-based MPC for a tank system. The suggested controller was modelled in four tanks three three-valve systems. The suggested model was portioned into two subsystems. With the use of a centralized controller, the desired level of the tank was obtained.

Cruz-Rojas et al. (Cruz-Rojas et al. 2019) developed the MPC for controlling the excess ratio of oxygen in the electric motor. The difference pressure in between the anode and cathode was minimized by the PID controller. The suggested controllers were validated on the PEM fuel cell to minimize the temperature level. Martínez García et al. (García et al. 2022) developed state feedback control (SFC) for hydrogen production through the pressure swing adsorption process. In that paper, the suggested controller was designed through the Hammerstein–Wiener model. The suggested model was validated under different cases and the results were shown for SFC and discrete PID. Rumbo Morales et al. (Morales et al. 2019) presented the pressure oscillation adsorption process with predictive control. On the other hand, an FTC was developed in (Torres et al. 2023) to improve the production of biohydrogen.

Torres Cantero et al. (Cantero et al. 2022) developed an extractive distillation column for bioethanol production.

In advance of MPC, an adaptive controller was used (Sainz-García et al. 2022) to mitigate the disturbances for the CSTR system. The suggested control model has two parts as fixed design and an online output update section. Central control improved the stability through pole placement via a linearized model. The controller model enhanced the placement of the pole based on the sensitivity function. Anyhow the disturbance rejection models have been widely used in recent works (Rubio et al. 2012). MPC-based controllers are illustrated in Table 4.

4 Challenges in the chemical industry process

The chemical industry requires continuous system monitoring to take necessary control actions towards the non-linear process. Although the controller improves the system performance under various operating conditions, the long-term process of the plant is directly impacted by the control actions. The establishment of controller tuning methods greatly impacts controller operation. The controller with efficient tuning methods can be rewarding since the impact of variations made in the system will affect the process output. Moreover, the chemical industry process may face the following challenges,

-

The system must respond quickly to the variation in the input elements.

-

Continuous upgrading of controller models and software increases system complexity.

-

The integration of the PID controller must be adopted with proper tuning methods to overcome the system instability.

-

Higher computational cost is an important issue in the chemical industry process.

-

The predictive schemes are widely applied in system control, but their computational cost is higher than the PID controller.

-

On the other hand, the FLC effectively controls different parameters, but its performance depends on the parameters considered in fuzzy rules.

-

The interconnection between several units and control complexity has resulted in system state prediction and control complexities.

5 Conclusion and future scope

The global demand for the chemical industry faces several challenges, including process safety and product quality. The operation of modern chemical industries would be more difficult without using the controllers. The system’s safety and efficient operation require accurate control of the variables within specified limits. As the need for industrial automation increases significantly, the control system must be flexible, reliable, and robust under various operating conditions. The adoption of PID, FLC, and a combination of these controllers is omnipresent in industrial control. Thus, this paper has reviewed the PID, FLC, and F-PID controllers for various operations control such as temperature, pH level, and liquid level control in chemical industry applications. Moreover, this paper examines the performance efficacy of these controllers in various operating conditions. In addition, the disadvantages of all methods were analyzed and presented in tables. Finally, the challenges faced by the chemical industries are discussed, and efficient solutions to overcome these challenges. Major issues in the PID, FLC, and F-PID controllers are the lack of optimized tuning that results in poor performance under dynamic system conditions. At the same time, the tuning approach must adopt the rapid changes in the system. More detailed and accurate controller modelling for various process control in the chemical industry is the future aspect of this review. Furthermore, it is suggested to use the proper tuning approach for the controllers to achieve the desired functions in the WBS.

Data availability

Data sharing is not applicable to this article.

References

Abd El-Hamid AS, Eissa AH, Abouel-Fotouh AM, Abdel-Fatah MA (2015) Research Article Comparison Study of different structures of PID controllers. Res J Appl Sci Eng Technol 11(6):645–652

Adigun OH (2018) Decentralized Fuzzy-PID based Control Model for a Multivariable Liquid Level System. J Adv Comput Eng Technol 4(4):247–254

Aguiar RA, Franco IC, Leonardi F, Lima F (2018) Fractional PID controller applied to a chemical plant with level and pH control. Chem Prod Process Model 13(4)

Al Tahtawi AR, Yahya S, Setiadi B, Marsya C (2020) The implementation of embedded fuzzy Logic Controller on Liquid Level Control System. In International Seminar of Science and Applied Technology (ISSAT 2020). Atlantis Press 161–166

Alphonsus ER, Abdullah MO (2016) A review on the applications of programmable logic controllers (PLCs). Renew Sustain Energy Rev 60:1185–1205

Andriukaitis D, Laucka A, Valinevicius A, Zilys M, Markevicius V, Navikas D, Sotner R, Petrzela J, Jerabek J, Herencsar N, Klimenta D (2019) Research of the Operator’s Advisory System based on fuzzy logic for Pelletizing Equipment. Symmetry 11(11):1396

Anitha T, Gopu G, Nagarajapandian M, Arun Mozhi Devan P (2019) Hybrid fuzzy PID controller for pressure process control application. In 2019 IEEE Student Conference on Research and Development (SCOReD), IEEE 129–133

Bayram İ, Zeybek Z, Altinten A, Alpbaz M (2019) Application of fuzzy control in a wireless liquid level simulator. Wireless Pers Commun 109(1):211–222

Benalcázar E, Camacho O, Leiva H (2021) Linear and Nonlinear Fuzzy PID Reset-Based Controllers: An application for a Chemical Process with Variable Delay. In 2021 IEEE CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), IEEE 1–5

Bhandare DS, Kulkarni NR (2015) Performances evaluation and comparison of PID controller and fuzzy logic controller for process liquid level control. In 2015 15th International Conference on Control, Automation and Systems (ICCAS), IEEE 1347–1352

Bhookya J, Kumar MV, Kumar JR, Rao AS (2022) Implementation of PID controller for the liquid level system using mGWO and integration of IoT application. J Industrial Inform Integr 28:100368

Cantero CAT, Lopez GL, Alvarado VM, Jimenez RFE, Morales JYR, Coronado EMS (2017) Control structures evaluation for a salt extractive distillation pilot plant: application to bio-ethanol dehydration. Energies 10(9):1276

Cantero CAT, Zúñiga RP, García MM, Cabral SR, Calixto-Rodriguez M, Martínez JSV, Enriquez MGM et al (2022) Design and control applied to an extractive distillation column with salt for the production of bioethanol. Processes 10(9):1792

Chai WY, Tan MK, Teo KT, Tham HJ (2020) Fuzzy Logic Control of Exothermic Batch Process. In 2020 IEEE 2nd International Conference on Artificial Intelligence in Engineering and Technology (IICAIET), IEEE 1–6

Cruz-Rojas A, Rumbo-Morales JY, de la Cruz-Soto J, Brizuela-Mendoza JA, Sorcia-Vázquez FDJ, Martínez-García M (2019) Simulation and control of reactants supply and regulation of air temperature in a pem fuel cells system with capacity of 50 KW. Revista Mexicana De Ingeniería Química 18(1):349–360

Da Silva GC, Silva LF, de Souza MB Jr (2017) The performance of Classic and Advanced controllers on the output temperature control in a Heat Exchange process. Chem Eng Trans 57:1003–1008

Dan JG, Arnaldos J, Darbra RM (2017) Introduction of the human factor in the estimation of accident frequencies through fuzzy logic. Saf Sci 97:134–143

Deepa S, Anipriya N, Subbulakshmy R (2015) Design of controllers for continuous stirred tank reactor. Int J Power Electron Drive Syst 5(4):576

Dulău M (2020) Control Strategies for Thermal Processes in Chemical Industry. In Proceedings, MDPI 63(1): 34

Eghbal Ahmadi MH, Royaee SJ, Tayyebi S (2018) Mamdani fuzzy modeling of Flash Vaporization using a New Concept: fuzzy composition variable. J Petroleum Res 28:71–83 (97 – 3

Fellani MA, Gabaj AM (2015) PID controller design for two tanks liquid level control system using Matlab. Int J Electr Comput Eng 5(3):436

García MM, Morales JYR, Torres GO, Paredes SAR, Reyes SV, de Sorcia Vázquez J, Vidal F, Martínez AFP, Zúñiga JSV RP and, Vargas EMR (2022) Simulation and state feedback control of a pressure swing adsorption process to produce hydrogen. Mathematics 10(10):1762

Getu BN (2016) Water Level Controlling System using Pid Controller. Int J Appl Eng Res 11(23):11223–11227

Goud H, Sharma PC, Nisar K, Ibrahim AAA, Haque MR, Yadav NS, Swarnkar P, Gupta M, Chand L (2022) PSO Based Multi-Objective Approach for Controlling PID Controller. Computers, Materials & Continua 71(3)

Griffin PW, Hammond GP, Norman JB (2018) Industrial energy use and carbon emissions reduction in the chemicals sector: a UK perspective. Appl Energy 227:587–602

Hamdy M, Ramadan A (2017) Design of Smith predictor and fuzzy decoupling for MIMO chemical processes with time delays. Asian J Control 19(1):57–66

Harivardhagini S, Raghuram A (2015) LabVIEW Based Design and Analysis of Fuzzy Logic, sliding Mode and PID Controllers for Level Control in Split Range Plant. I-manager’s. J Instrum Control Eng 3(3):31

Ho CC, Chen MS (2018) Risk assessment and quality improvement of liquid waste management in Taiwan University chemical laboratories. Waste Manag 71:578–588

Hosseinnia B, Khakzad N, Reniers G (2018) Multi-plant emergency response for tackling major accidents in chemical industrial areas. Saf Sci 102:275–289

Jegatheesh A, Kumar CA (2020) Novel fuzzy fractional order PID controller for nonlinear interacting coupled spherical tank system for level process. Microprocess Microsyst 72:102948

Jin P, Zheng M, Qi B, Feng D Heating speed control method based on adaptive fuzzy PID algorithm. In 2018 13th IEEE Conference on Industrial, Electronics, Applications (2018) (ICIEA), IEEE 471–475

Kabila V, Glan Devadhas G (2015) Comparative analysis of PID and fuzzy PID controller performance for continuous stirred tank heater. Indian J Sci Technol 8(23):1–7

Kocher S, Kori AK (2015) PID Based Temperature Control of a Plant Heat Exchanger System. Int J Novel Res Electr Mech Eng 2(2):43–47

Koldaev AI, Koldaeva ZM, Evdokimov AA, Boldyrev DV, Kuzmenko IP (2020) Design of a fuzzy controller for a membrane gas separation process control system. In IOP Conference Series: Materials Science and Engineering, IOP Publishing 873(1): 012026

Kumar DD, Meenakshipriya B, Ram SS (2016) Design of PSO-based I-PD controller and PID controller for a spherical tank system. Indian J Sci Technol 9(12):1–5

Kumar M, Prasad D, Giri BS, Singh RS (2019) Temperature control of fermentation bioreactor for ethanol production using IMC-PID controller. Biotechnol Rep 22:e00319

Li Q, Zhang W, Qin Y, An A (2021) Model predictive control for the process of mea absorption of CO2 based on the data identification model. Processes 9(1):183

Liu J, Zhang PJ, Wu JG, Bu PF, Chen WF Research on the control of adding acid to circulating water based on expert fuzzy PID control. In 2016 Chinese Control and, Conference D (2016) (CCDC), IEEE 4853–4858

Liu H, Fang Y, Su X, Wang Y, Ji M, Xing H, Gao Y, Zhang Y, He N (2023) Temperature control algorithm for polymerase chain reaction (PCR) instrumentation based upon improved hybrid fuzzy proportional integral derivative (PID) control. Instrum Sci Technol 51(2):109–131

Mahalakshmi P, Poornapushpakala S Simulation of cascade control for a multiprocess station using fuzzy logic. In 2015 International Conference on Communications and, Processing S (2015) (ICCSP), IEEE 1768–1772

Mandal S, Dutta P, Kumar A (2019) Modeling of liquid flow control process using improved versions of elephant swarm water search algorithm. SN Appl Sci 1(8):1–16

Manisha G, Anitha T, Nagarajapandian M (2018) Model Based Controller for Non-linear Process. In 2018 7th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), IEEE 902–906

Mien TL (2017) Liquid level control of the coupled-tank system using the fuzzy-PID controller. Int J Eng Res Technol (IJERT) 6(11):459–464

Mishra P, Kumar V, Rana KP (2015) A fractional order fuzzy PID controller for binary distillation column control. Expert Syst Appl 42(22):8533–8549

Moghadam N, Shabaninia F, Abbasi H (2017) Superiority of using interval type-2 fuzzy pid controller over the conventional type-1 fuzzy controller in a chlorine flow control system. In 2017 5th Iranian Joint Congress on Fuzzy and Intelligent Systems (CFIS), IEEE 128–135

Mohanty MD, Mohanty MN (2020) Design of fuzzy logic-based PID controller for heat exchanger used in chemical industry. In New Paradigm in Decision Science and Management: Proceedings of ICDSM 2018 (pp. 371–379). Springer Singapore

Morales JYR, López GL, Alvarado VM, Cantero CAT, Rivera HRA (2019) Optimal predictive control for a pressure oscillation adsorption process for producing bioethanol. Computación Y Sistemas 23(4):1593–1617

Morales JYR, López GL, Martínez VMA, Vázquez FJS, Mendoza JAB, García MM (2020) Parametric study and control of a pressure swing adsorption process to separate the water-ethanol mixture under disturbances. Sep Purif Technol 236:116214

Morales JYR, Mendoza JAB, Torres GO, Vázquez FJS, Rojas AC, Vidal AFP (2022) Fault-tolerant control implemented to Hammerstein–Wiener model: application to bio-ethanol dehydration. Fuel 308:121836

Naregalkar A, Durairaj S (2021) A novel LSSVM-L Hammerstein model structure for system identification and nonlinear model predictive control of CSTR servo and regulatory control. Chem Prod Process Model 17(6):619–635

Njoku D (2021) A hybrid Intelligent Control Model for regulating pH in Industrial Chemical process. J Electr Eng Electron Control Comput Sci 8(3):1–8

Nogueira IB, Fontes RM, Ribeiro AM, Pontes KV, Embirucu M, Martins MA (2020) A robustly modeled predictive control strategy applied in the control of a simulated industrial polyethylene polymerization process. Comput Chem Eng 133:106664

Noriyanto RD, Musyafa A (2019) Reliability and safety study on heat exchanger control system: A case study in the ortho-xylene process-petrochemical industry. In AIP Conference Proceedings, AIP Publishing LLC 2088(1): 020047

Olana FD, Abose TA (2021) PID temperature Controller Design for Shell and Tube Heat Exchanger. Int J Eng Manuf 1:37–46

Poomani K, Rameswari R (2015) Enhanced PID Control Strategy: application to Spherical Tank System. Int J Res Appl Sci Eng Technol 3(3):138–141

Pua ZY, Hermansson AW, Lim CH (2022) ANN-based Multi-Model Predictive Control for pH-Control. InIOP Conference Series: Materials Science and Engineering (Vol. 1257, No. 1, p. 012035). IOP Publishing

Quiñόnez K, Camacho O, Chávez D (2019) Application of nonlinear pid controllers to bioreactor processes. In 2019 IEEE 4th Colombian Conference on Automatic Control (CCAC), 1–6

Razvarz S, Vargas-Jarillo C, Jafari R, Gegov A (2019) Flow control of fluid in pipelines using PID controller. IEEE Access 7:25673–25680

Reddy CS, Balaji KB (2021) A fuzzy-PID controller in shell and tube heat exchanger simulation modeled for temperature control. Indonesian J Electr Eng Comput Sci (IJEECS) 21(3):1364–1371

Rodríguez-Castellanos JE, Grisales-Palacio VH, Cote-Ballesteros JE (2018) A tuning proposal for direct fuzzy PID controllers oriented to industrial continuous processes. IFAC-PapersOnLine 51(4):657–662

Roy K, Mukherjee A, Jana DK (2019) Prediction of maximum oil yield from almond seed in the chemical industry: a novel type-2 fuzzy logic approach. S Afr J Chem Eng 29(1):1–9

Rúa J, Hillestad M, Nord LO (2021) Model predictive control for combined cycles integrated with CO2 capture plants. Comput Chem Eng 146:107217

Rubio J, Figueroa M, Cruz JHP, Rumbo JY (2012) Control para estabilizar y atenuar las perturbaciones en un péndulo invertido rotatorio. Revista mexicana de física E 58(2):107–112

Saini P, Kumar R, Rajput N (2016) Cascade-PID control of a non-linear chemical process. Non-linear Stud 23(4)

Sainz-García SH, López GL, Alvarado VM, Morales JYR, Sarmiento-Bustos E, Durán OAZ (2022) Adaptive Control for Narrow Bandwidth Input and output disturbance rejection for a non-isothermal CSTR System. Mathematics 10(18):3224

Septiani NI, Bayusari I, Haiyunnisa T, Suprapto BY Optimization of PID control parameters with genetic algorithm plus fuzzy logic in stirred tank heater temperature control process. In 2017 International Conference on Electrical Engineering and, Science C (2017) (ICECOS), IEEE 61–66

Sharma A, Fikar M, Bakosova M (2015) Comparative study of time optimal controller with pid controller for a continuous stirred tank reactor. Acta Chim Slovaca 8(1):27–33

Sidikov I, Yakubova N, Usmanov K, Kazakhbayev S (2020) Fuzzy synergetic control non-linear dynamic objects. Karakalpak Sci J 3(2):14–22

So GB, Jin GG (2018) Fuzzy-based non-linear PID controller and its application to CSTR. Korean J Chem Eng 35(4):819–825

Sorcia-Vázquez FDJ, Garcia-Beltran CD, Valencia-Palomo G, Brizuela-Mendoza JA, Rumbo-Morales JY (2020) Decentralized robust tube-based model predictive control: application to a four-tank-system. Revista Mexicana De Ingeniería Química 19(3):1135–1151

Souza ML, Ávila Filho S, Brito R, Cerqueira I, Avila J (2018) Discussion about Criteria for the Management of Alarms and Cognitive Limits for the Chemical Industry. In International Conference on Applied Human Factors and Ergonomics, Springer, Cham 330–342

Tavoosi J, Shirkhani M, Abdali A, Mohammadzadeh A, Nazari M, Mobayen S, Asad JH, Bartoszewicz A (2021) A new general type-2 fuzzy predictive scheme for PID tuning. Appl Sci 11(21):10392

Torres GO, Morales JYR, Martinez MR, Valdez-Martínez JS, Calixto-Rodriguez M, Sarmiento-Bustos E, Cantero CAT, Buenabad-Arias HM (2023) Active Fault-Tolerant Control Applied to a pressure swing adsorption process for the production of Bio-hydrogen. Mathematics 11(5):1129

Vanavil B, Chaitanya KK, Rao AS (2015) Improved PID controller design for unstable time delay processes based on direct synthesis method and maximum sensitivity. Int J Syst Sci 46(8):1349–1366

Var A, Kumbasar T, Yesil E (2015) An internal model control-based design method for single input fuzzy PID controllers. In 2015 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), 1–7

Vásquez M, Yanascual J, Herrera M, Prado A, Camacho O (2023) A hybrid sliding mode control based on a nonlinear PID surface for nonlinear chemical processes. Eng Sci Technol Int J 40:101361

Vinothkumar C, Esakkiappan C (2021) Fuzzy PI and Fuzzy PID Controller Based Hopper Tank Level Control System. In 2021 International Conference on Advances in Electrical, Computing, Communication and Sustainable Technologies (ICAECT), IEEE 1–5

Xie CF, Tang YJ (2021) An automatic advanced fuzzy controller for simulated moving bed. IEEE Access 9:61455–61465

Yahya S, Al Tahtawi AR, Wijayanto K, Faizah B (2022) Adaptive Fuzzy-PID Controller for Liquid Flow Control in the Heating Tank System. Int J Integr Eng 14(1):173–180

Yuvaraj D, George A, Karthikeyan M, Shanmugam SK, Suresh B, Samapth R (2019) Experimental Approach of various Controller tuning methods for integrating processes with Dead Time. J Inf Math Sci 11(3–4):281–299

Zhou Y, Zhang C, Xie T, Hong T, Zhu H, Yang Y, Liu C, Huang K (2017) A microwave thermostatic reactor for processing liquid materials based on a heat exchanger. Materials 10(10):1160

Funding

No funding is provided for the preparation of the manuscript.

Author information

Authors and Affiliations

Contributions

Pankaj Mohindru-Conceptualization,Methodology, Software, Formal analysis, Investigation, Resources, Validation, Data Curation, Writing - Original Draft, Writing - Review & Editing, Visualization, Supervision, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by authors.

Consent to participate

The author has agreed to participate in this submitted article.

Consent to publish

The single author involved in this manuscript gives full consent for publication of this submitted article.

Competing interests

The authors declare no competing interests.

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohindru, P. Review on PID, fuzzy and hybrid fuzzy PID controllers for controlling non-linear dynamic behaviour of chemical plants. Artif Intell Rev 57, 97 (2024). https://doi.org/10.1007/s10462-024-10743-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s10462-024-10743-0