Abstract

In today’s complex and ever-changing world, Supply Chain Management (SCM) is increasingly becoming a cornerstone to any company to reckon with in this global era for all industries. The rapidly growing interest in the application of Deep Learning (a class of machine learning algorithms) in SCM, has urged the need for an up-to-date systematic review on the research development. The main purpose of this study is to provide a comprehensive vision by reviewing a set of 43 papers about applications of Deep Learning (DL) methods to the SCM, as well as the trends, perspectives, and potential research gaps. This review uses content analysis to answer three research questions namely: 1- What SCM problems have been solved by the use of DL techniques? 2- What DL algorithms have been used to solve these problems? 3- What alternative algorithms have been used to tackle the same problems? And do DL outperform these methods and through which evaluation metrics? This review also responds to this call by developing a conceptual framework in a value-adding perspective that provides a full picture of areas on where and how DL can be applied within the SCM context. This makes it easier to identify potential applications to corporations, in addition to potential future research areas to science. It might also provide businesses a competitive advantage over their competitors by allowing them to add value to their data by analyzing it quickly and precisely.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the current technological era with complex industrial developments, the agility and effectiveness of supply chains play a vital role in the improvement of their profits. The supply chain concept has a long history since Oliver and Weber (1982) proposed primary definition in their academic work. In the last decades of the twentieth century, the supply chain area has grown considerably into international locations which motivated both practitioner and academic interests. Shukla et al. (2011) highlighted that the supply chain in its classical form is a network of facilities that produce raw materials, transform them into intermediate goods or final products, and deliver them to customers by the distribution system. However, this definition has enlarged over time. Nowadays, different industries especially the automobile, computer, and high-tech companies witnessed that physical logistics are becoming more reliant on information technology, which may also be used to enable new cooperative arrangements (Meixell and Gargeya 2005). Having an advanced supply chain network for participating companies becomes a source of competitive advantage in the technology era (Louw and Pienaar 2011).

Data sets have grown in size and variety as a result of the increase in data volume and diversity. To maximize the total generated value, disruptive technologies stimulus using new techniques, principles, and models in the SCM (Dolgui 2018). By the 1990s, companies were adopting Electronic Data Interchange (EDI) and Enterprise Resource Planning (ERP) systems to connect and exchange information among supply chain partners (Demir 2020). These systems provided easier access to data for analysis, along with assisting businesses in their designing, planning and forecasting (Demir 2020). This collaboration would result to have quicker processes, greater technological improvements, reduced development costs, and enhanced customer satisfaction in today’s dynamic market conditions (Attaran and Attaran 2007). In the 2000s, businesses began turning to business intelligence and predictive analytic software solutions (Negash and Gray 2008). These solutions helped companies gain a more in-depth knowledge of how their supply chain networks were performing, how to make better decisions and how to optimize their networks (Barbosa-Povoa et al. 2018). The challenge today concerns how companies can best use the huge amounts of data generated in their supply chain networks. Many companies like Google, Amazon and Procter & Gamble not only have lots of data points in different systems or at suppliers to mine them but also unique techniques and methods to analyze it (Ariker 2015). The more accurate data analysis, giving the better chance to companies an edge by making sure alerts arrive on time, so they can make best decisions.

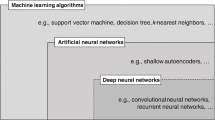

With the increasingly vast amount of data available today, companies should use Artificial Intelligence techniques to drive business growth through actionable insights generated from datasets (Piccialli et al. 2021). Although there is no common category among researchers to classify AI techniques, based on Wikipedia website, we can categorize AI techniques in 7 different sections: Search and optimization, Logic, Probabilistic methods for uncertain reasoning, Classifiers and statistical learning methods, Artificial neural networks, Deep learning, Specialized languages and hardware (Wikipedia 2022). One of these technological methods that are designed to impact growth is the automation of knowledge work known as DL. The DL is a new learning algorithm consisting of a multi-layer neural network which is a subset of machine learning for discovering multiple levels of distributed representations (Guo 2016). It has a huge impact on different fields, such as cancer diagnosis, precision medicine, self-driving cars, predictive forecasting, and speech recognition (Shrestha and Mahmood 2019). Many DL algorithms have been developed both by practitioners (software companies/departments) and academic interests such as Deep Neural Network (DNN), Convolutional Neural Network (CNN), Recurrent Neural Network (RNN), and their new variants.

Industrial enterprises have recently become keenly interested in the highly value-adding potential of DL (Addo-Tenkorang 2016). Supply chain Key factors including inventory planning, supplier quality evaluation, demand forecasting, procure-to-pay, order-to-cash, production planning, logistics management, and more are becoming worthy paradigms for companies (Skjott-Larsen et al. 2007). DL approaches may be used to equip supply chains with a self-aware mechanism that connects many operational items at the same time, while constantly learning in the process (Tirkolaee et al. 2021). This collaboration can result in improving supplier delivery performance, demand forecasting accuracy, supplier quality management and compliance, production planning and factory scheduling accuracy, forecasting demand for new products, as well as minimizing supplier risk, freight costs, inventory and operations costs, response times to customers, consequently leading to the improved SCM performance (Cachon 2001).

In order to provide a general picture of DL applications in the SCM and to bridge the gaps between them, this research intends to focus on not only overviewing DL applications in the SCM and their potential role in improving network efficiency but also providing a taxonomy with which to map and evaluate different supply chain research interconnected with DL. Even though there are other reviews on supply chain and machine learning, some areas remain unexploited. There are limited reviews especially focused on the intersection of DL algorithms and the SCM and in this research, we provide an overview of this area to lucubrate on illuminating the research trends through answering three critical research questions as mentioned in Sect 2.1.

We also determine the research gaps, propose directions for filling these gaps, and present a conceptual framework to highlight the potential supply chain areas that can be dealt with DL algorithms. This paper is organized as follows. We explain our review methodology in Sect. 2 where we also provide review questions, related work, and the material collection process. Section 3 contains a bibliometric analysis as well as a discussion of the reviewed literature to answer the research questions. In Sect. 4, we present a conceptual framework. Research gaps and opportunities for future research directions are also brought into Sect. 4. In Sect. 5, we propose a conceptual framework. In Sect. 6, we provide derived managerial insights. Finally, a summary and some conclusions we can draw from the work in terms of moving toward a disciplinary approach have been mentioned in Sect. 7.

2 Systematic review

This review aims at investigating the applications of DL techniques in supply chain operations and management. To do so, the review methodology proposed in Barbosa-Povoa et al. (2018) and used in many other review papers (Ribeiro and Barbosa-Povoa 2018; Portugal et al. 2018), is adopted. This methodology consists of the following steps: defining research questions, analyzing previous literature reviews, collecting material, descriptive analysis of the collected material, category selection, and evaluating the material. These steps are described in the following subsections of this section and the next section.

2.1 Research questions

In line with the purposes of this review, several research questions are defined to analyze the state of the art. These questions clear the research path. Meanwhile, answering these questions provide readers with keys to a comprehensive understanding of the topic. The present review explores the following three research questions:

- RQ1:

-

What kind of supply chain problems have been addressed using DL algorithms?

- RQ2:

-

What DL algorithms have been applied in the field of SCM?

- RQ3:

-

Which alternative techniques have been used, by other scholars, to tackle the same problems considered by the set of the 43 investigated papers? Is deep learning better than these alternative techniques and through which evaluation metrics?

To answer these questions, we carefully reviewed selected papers, categorized them based on several structural dimensions (Sect. 3.2), and elaborate on their studied supply chain problems, their employed DL techniques, and the results of their numerical analysis considering the comparison of their algorithms’ performance with the performance of the other methods.

2.2 Previous literature reviews

The literature review papers here analyzed are the output of a search performed on the Scopus database under the terms “deep learning”, “deep machine learning” or “deep neural network” in titles, abstracts, or keywords, and the term “supply chain” anywhere in the paper. We also limited the search to review papers written in the English language. A total of 51 literature reviews were identified, and only the articles relevant to the applications of DL in SCM or one of the functions of supply chains [including procurement, production/ manufacturing, warehousing, logistics, and retailing (Nguyen et al. 2018)] were explored, resulting in seven papers to be addressed.

Zhou et al. (2019) conducted a review addressing the applications of DL in the food industry problems including food recognition, calorie prediction, food quality, freshness, contamination detection, and food supply chain. In the area of the food supply chain Zhu et al. (2021) presented a survey on machine learning, DL algorithms, and machine vision methods and their applications in food processing such as product quality and safety management, process controlling, packaging, and foreign object detection.

Bertolinia et al. (2021) performed a review focusing on the potentialities and criticalities of machine learning algorithms in operation management. They concluded that there is a continuous upward trend in the number of publications using DL algorithms especially in the domain of maintenance, quality, production planning, defect analysis, and SCM. Al-Sahaf et al. (2019) reviewed evolutionary computation techniques such as machine learning, transfer learning, and deep learning evolutionary algorithms and their application areas including computer vision, scheduling, and computer optimization in dairy, wine, and seafood supply chain and manufacturing.

Nti et al. (2021) focused on artificial intelligence (AI) algorithms and their applications in the fields of engineering and manufacturing. Their results demonstrated that fault detection, manufacturing cost and energy consumption, and autonomous computing and driving are the most studied problems using AI tools. Kotsiopoulos et al. (2021) described the frequently used machine learning and DL algorithms in the industry 4.0 era, focusing on their use in the smart manufacturing and the smart grid field. Wang et al. (2018) comprehensively reviewed DL techniques, their pros and cons, and their applications in smart manufacturing.

Table 1 summarizes the related literature reviews’ directions and their differences compared to our review. As mentioned in almost all of the above literature reviews, in recent years, DL algorithms are becoming widespread in different areas of decision-making, especially in the future’s smart supply chains. However, there is a lack of a comprehensive systematic literature review investigating various angles of using DL in SCM, clarifying its advantages and disadvantages, and highlighting future research directions. Such a gap in scientific publications encouraged us to focus on this topic. To the best of our knowledge, it is the first systematic literature review addressing the applications of DL in the SCM to explore the potential of DL algorithms to advance the performance of supply chains in different industries and determine the promising avenues for future research.

2.3 Material collection

In this section, the process of collecting papers is specified. To answer the questions of this review, in the search process, we considered two synonyms of “Deep Learning”, “Deep Neural Network” and “Deep Machine Learning”. These keywords have to be accompanied by the term “Supply Chain”. The determined keywords must be found in the title, abstract, or keywords of the publications. Therefore, the following research query has been used in this systematic review:

“TITLE-ABS-KEY ((“Deep Neural Network” OR “Deep Learning” OR “Deep Machine Learning”) AND “Supply Chain”)”

Because DL algorithms have recently become popular in various areas, we did not set any date range limitation on the search query. The search was conducted on the most used academic search engine Scopus (Portugal et al. 2018) on August 14, 2021. The result of the search has been a total of 193 publication entries. By including publications written in English, 189 papers remained. Then we limited the selected material to articles published in peer-reviewed journals that have been 59 papers and excluded the other publications (8 reviews, 70 conference papers, 46 conference reviews, 3 books, 2 book chapters, and 1 Erratum). Finally, we studied the abstracts of 59 remained papers to make sure whether they are related to the scope of our review or not. Through this investigation, 16 publications that were not directly related to the supply chain or did not use DL algorithms have been excluded, and a final sample of 43 publications was selected for further review. Figure 1 displays a summary of the systematic literature search process. Table 2 shows the main information of the selected papers.

3 Systematic review results

After collecting material, the steps of descriptive analysis, structural categories selection, and the evaluation of the collected material are presented in this section.

3.1 Descriptive analysis

In this section, to better understand the breadth of the collected material, we analyze them from various perspectives. To do so, the bibliometric package of the R language named Bibliometrix has been used. Bibliometrix supports data imported from different databases and provides useful tools for quantitative and analytical research on collected material (Ariaa and Cuccurullo 2017). By doing this analysis, we try to answer the following questions adapted from Barbosa-Povoa et al. (2018):

(Q1) When the use of DL has become widespread in the SCM area?

(Q2) Where are located the authors working on the applications of DL in SCM?

(Q3) What topics have been mostly studied when it comes to the use of DL in SCM?

(Q4) Who has been doing research in this area?

To answer Q1, papers have been analyzed based on their publication year in the Sect. 3.1.1. To address Q2, the countries of the authors’ institutions are presented in Sect. 3.1.2. In Sect. 3.1.3, Q3 is explored through the analysis of keywords using several tools such as word could, co-occurrence network, word dynamics, and so on. Finally, the journals where selected papers have been published are examined to answer Q4 in Sect. 3.1.4.

3.1.1 Descriptive analysis based on publication year

Figure 2 displays the annual scientific papers. Although we did not set any time limitation in our research query, as can be seen in Fig. 2, DL has been used in the SCM in the year 2016 for the first time and experienced an incremental trend in the last two years. Another point about this chart is that at the time of writing this review i.e., in August 2021, the number of published papers for 2021 is less than 2020, but it is expected to exceed it in the remained months.

3.1.2 Descriptive analysis based on authors’ country

Figure 3 displays the number of papers written by the authors of each country. As can be seen in both figures, China has the highest number of publications (30 papers) followed by the United States (11) and the United Kingdom (10). For more information, Table 3 shows the trend of publications over the years in different countries.

3.1.3 Descriptive analysis based on keywords

Figure 4 shows a three-field plot of the selected papers. The three-field map summarizes the relationship among top keywords, top authors, and top title words. In this figure, the left field displays the keywords, the middle field represents the authors and the right field shows the frequently used words in the titles. The term “forecasting” appeared in both keywords and titles several times. Forecasting is one of the important problems of supply chain management that have recently made advantage of DL methods. One of the areas of forecasting in SCM is demand forecasting and we can see that the word “demand” is the other frequently used word in the titles of the papers. Among deep learning methods, the LSTM method has mostly appeared in the keywords of papers.

Moreover, the other top keyword is the internet of things technology that provide companies with a huge volume of data and can be used, managed, and optimized effectively by DL techniques (Khan et al. 2020). Image processing and text mining are two main processes that can be efficiently done using DL algorithms. The keyword “Text mining” has also been used frequently in the collected material according to the three-field plot. Interestingly, the covid-19 is also one of the frequently used keywords that shows the current situation caused by this pandemic has affected supply chains considerably and can be addressed by the use of DL algorithms.

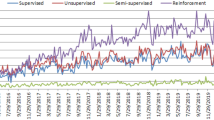

Figure 5 shows the yearly trend of using keywords with the most growth in appearance. Generally, the figure shows an incremental trend for all of these keywords. However, we can see two keywords referring to the convolutional neural networks, the second and the fifth keywords. The second keyword, “Convolutional neural network” has not been found until the year 2019 in the papers and then found in 6 and 10 papers in 2020 and 2021 respectively and the fifth keyword, “Neural network CNN” reached 7 in 2021. It demonstrates the increasing use of this DL algorithm in the SCM research field. The other keywords with the most growth are “Supply chain management” and “Supply chain sales”, both of them appeared in 6 papers in the year 2021. It can be concluded that the DL methods have been recently used in the sales area more than the last years. The keyword “Food supply chain” also indicates the promising application of DL methods in the food industry in recent publications. Finally, the other found keywords are “Deep neural network” and “BP neural network” each of them appeared in 5 papers in the year 2021.

3.1.4 Descriptive analysis based on Journals

To answer the fourth question of descriptive analysis, we explored the sources of selected papers. This analysis represents the key forums of DL applications in the SCM and can help the authors to find the most appropriate journals to submit their work. The 43 selected papers have been published in 38 journals. 34 journals of them, only published one paper. The number of papers and citations of journals with more than five citations has been displayed in Fig. 6. Journals of “SUSTAINABLE ENERGY GRIDS AND NETWORKS”, “REMOTE SENSING OF ENVIRONMENT”, and “INTERNATIONAL JOURNAL OF ENVIRONMENTAL RESEARCH AND PUBLIC HEALTH” have the highest citations that are 270, 138, and 64. “INTERNATIONAL JOURNAL OF PRODUCTION RESEARCH” published three papers which is the highest number of papers with 38 total citations. “COMPUTERS IN INDUSTRY”, “INDUSTRIAL MANAGEMENT AND DATA SYSTEMS”, and “SENSORS”, each published two papers with 6, 14, and 23 total citations, respectively.

3.2 Category selection

To retrieve information from the selected papers and effectively approach research questions, publications are categorized based on four structural dimensions, among them the first one is related to the supply chain structure and the three other dimensions represent the algorithmic specifications.

D1—Supply chain problem: After carefully reviewing the supply chain problems of the selected papers, we summed up the problems into nine major groups of 1—Forecasting, 2—Quality management, 3—Financial management, 4—Product classification, 5—Inventory management, 6—Traceability, 7—Information security, 8—Cost management, and 9—Supply chain mapping. These problems have been introduced and discussed in the Sect. 3.3.1.

D2—DL algorithm category: Seven main DL categories (Alom et al. 2019) used in the reviewed papers are 1—Deep neural network (DNN), 2—Convolutional neural network (CNN), 3—Recurrent neural network (RNN), 4—Deep auto-encoder (DAE), 5—Restricted Boltzmann Machine (RBM), 6—Generative adversarial network (GAN), and 7—Deep reinforcement learning (DRL). Each of these algorithms has been briefly introduced in Sect. 3.3.2.

D3—Data type: The type of input data of deep learning models can be structured, semi-structured, or unstructured. Structured data is generated with a formal structure (Biswas and Sen 2017) such as qualitative and quantitative data tables and GPS tracking (Halawi et al. 2022). Semi-structured data contains distinct semantic elements but does not have formal nature such as HTML and XML files (Biswas and Sen 2017). Unstructured data does not have any identifiable formal structure such as image, text, web content, video, and voice (Biswas and Sen 2017).

D4—The approach of research: This structural dimension determines that the studies have a theoretical approach or deal with a practical application in the SCM. We can say that the papers having a theoretical approach proposes a method to solve a problem and use simulation or experimental numeric analysis to verify the performance of that method. On the other hand, papers with a practical approach address real-life cases.

3.3 Material evaluation

In this section, we intend to answer the main research questions using the defined structural dimensions and content analysis of collected material.

3.3.1 What SCM problems have been addressed by the use of DL algorithms? (Answer to RQ1)

To answer the first question, we explored the selected publications based on the first dimension which is the supply chain problem. The results of categorization based on D1 are demonstrated in Table 4 and Fig. 7. To be more specific, the categories of each reviewed paper have been specified in Table 4, and the corresponding shares of categories in the sample publications have been displayed in Fig. 7.

It is evident that the forecasting problem has the maximum share. The high weight of the forecasting category had also been found in the descriptive analysis. Quality management comes in the second stage, followed by financial management, product classification, and inventory management in the third stage. To make it clearer, we briefly describe the main work of each paper based on the SCM problem addressed in the paper. To do so, we carefully studied selected papers and summarized their problems in the following paragraphs.

3.3.1.1 Forecasting

Forecasting is the process of taking historical data and using them as inputs to predict future trends (Bousqaoui et al. 2021). Supply chain managers need short-term to long-term forecasts to effectively make operational, tactical, and strategic decisions (Punia et al. 2020). DL algorithms by having high levels of abstraction are expected to improve the accuracy of the prediction process (Mocanu et al. 2016). The forecasting problem in the collected material refers to source forecasting (Charmchi et al. 2021), demand forecasting (Nikolopoulos et al. 2021; Chien et al. 2020; Koç and Türkoğlu 2021; Bousqaoui et al. 2021; Mocanu et al. 2016; Kilimci et al. 2019; Punia et al. 2020; Tang and Ge 2021), sales forecasting (Weng et al. 2019a; Liu et al. 2020; Piccialli et al. 2021), price forecasting (Weng et al. 2019a, b; Guo 2020), performance forecasting (Shankar et al. 2020), or a combination of these problems named as hybrid forecasting (Khan et al. 2020; Wu et al. 2021).

Source forecasting Accurate forecasting of sources is a crucial factor for the optimal performance of hydro reservoirs (Charmchi et al. 2021). In this regard, (Charmchi et al. 2021) introduced a hydropower pinch analysis (HyPoPA) by the use of the water/energy nexus concept as a supply management method for the operational optimization of multi-purpose reservoirs. Moreover, they predicted the effects of climate change and supply uncertainties to deal with downstream energy and water sinks variability under ideal conditions through the proposed HyPoPA. Finally, they forecasted sources using a hybrid DL network on the data from the Karkheh hydro reservoir as a case study.

Demand forecasting Demand forecasting is defined as the forecast of demands for the products in stock that comes from the customers wanting to buy these goods for their use (Thomopoulos 2015). Demand uncertainty encounters supply chains with many problems such as the bullwhip effect (Bousqaoui et al. 2021). Therefore, using accurate demand forecasting methods can reduce such effects. These methods also help supply chains to optimize inventories, reduce costs, increase profit, and gain more customer loyalty (Kilimci et al. 2019).

In the retail industry, daily operations are cost-oriented (Shavaki and Jolai 2021; Hossein Nia Shavaki and Jolai 2021) so, retailers need to manage their stock to have lower financial risks (Kilimci et al. 2019). they also require demand forecasts to make their stock-related decisions (Punia et al. 2020). The authors of Kilimci et al. (2019) developed a demand forecasting system consisting of time series analysis methods, machine learning, and DL algorithms. The developed system has been tested using data from SOK Market which is a fast-growing retail company in Turkey. Bousqaoui et al. (2021) presented a comparative analysis to evaluate the performance of four demand forecasting models including ARIMA, and three DLs (MLP, LSTM, and CNN) to forecast demands for products of a supermarket in Morocco. Punia et al. (2020) proposed a cross-temporal hierarchical forecasting framework to facilitate retailers’ decision-making at all strategic, tactical, and operational levels using a DL algorithm. The proposed framework has been evaluated by the data of a multi-channel retailer.

In production and manufacturing, row materials’ demand plan usually deviates from the actual requirement and the plans should be revised several times (Pechmann and Zarte 2017). Having an accurate material demand forecast can reduce purchasing and production costs of supply chains (Tang and Ge 2021). The authors Tang and Ge (2021) proposed a forecasting model that uses sales demand and previous material demand time series data as input and determines material demand value as output for consumer products. Chien et al. (2020) developed a novel framework based on deep reinforcement learning (DRL) to select the optimal demand forecasting model among a series of various forecasting models for each item distributed by an electronics distributor considering the demand pattern of the items.

With the outbreak of Covid-19, a significant increase has occurred in the demand for various products especially healthcare equipment, so forecasting of these increasing demands enables countries to effectively plan and manage their limited resources (Koç and Türkoğlu 2021). Following these changes, Nikolopoulos et al. (2021) proposed several forecasting methods based on the nearest neighbor approach for the Covid-19 growth rate, and compared their results with the results from many other forecasting algorithms including time-series, machine learning algorithms, epidemiological methods, and a DL method to show better performance of their proposed methods. Then they used the output of the Covid-19 growth rate forecasting as the input for demand forecasting of grocery, electronic, fashion, and automotive products and services during a pandemic condition. Koç and Türkoğlu (2021) presented a DL-based model to forecast the demand for medical equipment and the outbreak spread in turkey.

In energy supply chains, the prediction of the behavior of energy systems is important to mitigate corresponding uncertainties on one hand and is complex because of being affected by several factors such as climate, building architecture, and occupancy patterns on the other hand (Mocanu et al. 2016). The authors Mocanu et al. (2016) investigated two DL-based stochastic prediction models for time series-based forecasting of energy consumption of individual buildings.

Sales forecasting A sales forecast is an estimate based on previous sales performance and a study of anticipated market circumstances (Gahirwal 2013). DL algorithms have also been applied for sales forecasting because of the ability of these methods to effectively consider the patterns and context-specific non-linear relationships between critical factors (Liu et al. 2020). Weng et al. (2019a) designed a hybrid model to forecast long-term sales of different products and used a grocery sales data set to train their model. Liu et al. (2020) proposed a DL-based model to develop a sales forecasting and analysis system. Two real-world sales datasets from a supermarket and a company selling pesticides have been used to verify the performance of the model. In the healthcare industry, Piccialli et al. (2021) proposed a predictive framework to forecast a 7-day sequence of respiratory disease bookings based on a hybrid neural network. Bookings time series data of the healthcare authorities of Campania Region in Italy as well as air quality and weather data have been used in the forecasting model.

Price forecasting Price forecasting is an important aspect of economic decision-making. Individuals can use forecasts to earn profits from speculative activities, decide on the best government policies, or make financial decisions (Stockman 1987). In this category, Weng et al. (2019a, b) investigated three different methods to forecast the price of horticultural products in the short term (daily) and long term (weekly and monthly) based on prices available on websites. Forecasting the price of horticultural products can be also beneficial for designing a cropping plan. In the cross-border e-commerce field, (Guo 2020) proposed a hybrid model to encode image features, and capture the image features of commodities. Then, this evaluation process is transformed into price perception. Finally, product market share is predicted utilizing a consumer selection mathematical model, and a nonlinear constraint programming model is solved to calculate the best price.

Performance forecasting Container logistics is a high-cost industry in which any improvement in decisions to be made at different levels can lead to a huge cost reduction. One of the issues of this industry is container throughput forecasting (Shankar et al. 2020). Container throughput can be considered one of the important key performance indicators of any port (Awah et al. 2021). In this regard, the authors Shankar et al. (2020) used a DL network to forecast container throughput using data from the Port of Singapore.

Hybrid forecasting In the last subcategory of forecasting, Khan et al. (2020) integrated new technologies of IoT and blockchain with DL to develop an optimized supply chain provenance system in the food sector. They proposed a hybrid model to forecast the supply and demand of food. Wu et al. (2021) predicted oil market behavior during the Covid-19 era. The authors collected vast online news data and extracted relevant information. Then, the extracted text features, financial market data, and historical data related to the oil market were used to forecast the price, production, and consumption of oil with several prediction techniques.

3.3.1.2 Quality management

The process of coordination, integration, and optimization of quality operations across supply chain members is referred to as supply chain quality management. It effectively controls product quality and procedures to obtain a competitive edge, customer satisfaction, and market share (Robinson and Malhotra 2005). One of the studied areas in this category is product freshness control. Guo et al. (2020) developed a system for meat freshness monitoring using cross-reactive colorimetric barcode combinatorics and a DL algorithm. This system provides both scent fingerprint and fingerprint recognition via a smartphone APP interface. In another study, Cavallo et al. (2018) proposed a methodology based on DL for Non-destructive evaluation of packaged vegetable freshness using product images.

Garillos-Manliguez and Chiang (2021) suggested a multimodal classification to estimate fruit maturity using DL. The classification is done by feature concatenation of data captured from two imaging means including visible-light and hyperspectral imaging systems. Their proposed method can classify fruit maturity into six stages and can be useful in defining optimal harvest time. Jagtap et al. (2019) proposed an automated IoT-based system to determine the total amount of waste through advanced image processing and load cell technologies. Using such techniques can reduce the amount of food waste, save limited resources, decrease food production costs, and finally result in more sustainable food supply chains (Biggs et al. 2015). Another important issue of the food supply chains is food safety and one way to assure consumers about it is by displaying required information on the product pack label. However, labeling mistakes or legibility problems may occur in the packaging process (Thota et al. 2020). To address this problem, Thota et al. (2020) proposed a DL domain adaptation system that identifies and verifies the existence and legibility of use-by-date information on package labels. The system uses the photos taken from products as they pass along the production line.

Yasutomi and Enoki (2020) presented a DL architecture that defines the position of an inspection device in belt conveyors. The inspection device consists of an inertial measurement unit (IMU) inside a moving object joined with an algorithm to find anomalies in the conveyor lines. Belt conveyors are used to transport products in production lines or distribution centers. Having anomalies may damage transported items and must be detected through regular inspections. One of the other quality-related issues in supply chains is the defect detection of products. In this regard, Chakraborty et al. (2021) presented a methodology to classify printing faults of fabrics based on industrial fabric images.

3.3.1.3 Financial management

In general, supply chain financial management refers to the control of capital inflow and outflow with the ultimate purpose of increasing the financial efficacy of the system as a whole (Wang et al. 2008). In this area, Mao et al. (2018) proposed a credit evaluation system based on blockchain technology to improve the supervision and management of various stakeholders within the food supply chain by regulators. The system collects credit evaluation text data using smart contracts on the blockchain, analyzes the text data by a DL network, and determines stakeholders’ credit. The author (Hu 2020) used DL and a fuzzy algorithm to analyze the supply chain financial credit risk. Supply chain financial credit evaluation is also beneficial for banks to control their risks and gain more profit. Zhou et al. (2020) proposed a distributed approach for supply chain financial fraud detection using a DL model. The approach discovers fraudulent financing behaviors and thus reduces supply chain losses from such behaviors. Tosida et al. (2020) applied a DL approach to classifying telematics SMEs in Indonesia based on their need for financial assistance.

3.3.1.4 Product classification

The classification is the process of dividing the data into distinct categories based on certain constraints (Kumar and Verma 2012). In the area of precision farming, Cai et al. (2018) proposed an in-season crop type classification DL-based network. This method provides planting and harvesting crop areas information that can be used by government and private sectors in various monitoring and decision-making processes such as product insurance, field rental, logistics and marketing requirements, and crop yield prediction. In another paper, Kong et al. (2021) presented a fine-grained visual recognition model to classify crop species. The model has a multi-stream hybrid DL architecture able to recognize interclass discrepancy and intra-class variances. The authors of Cai et al. (2018) used time-series Landsat images as their data source while the authors of Kong et al. (2021) applied crop images in their model.

In the food supply chain, Vo et al. (2020) developed an approach consisting of a DL-based model and image processing techniques to extract regions of interest from lobster images and calculate grading attributes (size, weight, and color) of lobsters in the southern rock lobster supply chain. It is stated that this work is part of a broader project aiming to provide a low-cost biometric identification tool to be used along the entire lobster supply chain. Wang (2020) presented a classification method for online tourism products that provides a reference for developing a personalized data-driven recommendation system in the tourism supply chain. The method analyzes the information of user reviews and tourism products/services reviews to generate personalized recommendation lists.

3.3.1.5 Inventory management

Inventory management is a part of supply chain management that coordinates the efficient forward and reverse movement of products, services, and associated information between the point of origin and the point of consumption to fulfill customers’ needs (Singh and Verma 2018). In the category of inventory management, Ahmadimanesh et al. (2020) used DL to design an inventory management model for a blood transfusion network. The solutions of the model facilitate the prediction of the amount of hospital blood demand, the amount of safety stock, the optimal number of orders, and the optimal amount of delivery. Consequently, the model by predicting the optimal behavior of blood suppliers and customers can reduce the waste, return, and shortage of blood.

Shajalal et al. (2021) proposed a model to predict product backorders. This model improves inventory decisions by predicting the levels of product backorders and evaluates the expected achievable profit by the planned backorder policies. Moreover, it is useful in adjusting inventory levels in the distribution system and optimizing transportation routes to prevent item backorder.

Vanvuchelen et al. (2020) developed an algorithm based on DRL to determine the replenishment policy of a group of collaborative companies under a physical internet network. Physical internet is an interconnected logistics network in which companies share freight and resources (Montreuil 2011). The proposed algorithm decides on the amount and the time of ordering and shipping considering the periodic review of joint replenishment policies and aims to minimize companies’ transportation, holding, and backorder costs.

In the retail industry, having multiple products with uncertain demands and different lead times makes determining the optimal inventory replenishment policy highly challenging (Meisheri et al. 2021). The authors of Meisheri et al. (2021) addressed these challenges in a multi-period and multi-product system using DRL.

3.3.1.6 Cost management

All measures aimed at influencing cost structures and behavior in a precocious manner are included in cost management (Klaus and Franz 1994). Costs in the value chain must be examined, planned, regulated, and evaluated as part of these processes (Klaus and Franz 1994). In this category, Zhao and You (2020) introduced a framework for robust chance-constrained programming based on a generative adversarial network to minimize the total cost of a supply chain. The total cost consists of capital cost and the costs of procurement, operation, inventory, and transportation. The proposed framework designs the supply chain network and operations under demand uncertainty. Chen et al. (2021) used DRL to develop a blockchain-based framework to manage the production and storage of agri-food products with maximum profit. By the use of this framework, considering the demand and cost, factories can cost-effectively supply retailers and retailers can highly satisfy consumers’ demands. Moreover, it provides reliable product traceability for agri-food supply chains.

3.3.1.7 Traceability

The ability to track product flow throughout the supply chain is defined as supply chain traceability (Roth et al. 2008). In the textile industry, Wang et al. (2019) used DL for the traceability of fabrics. Their proposed technique captures the visual features of textile yarns and transforms them into a traceability signature that can be recognized as a tag and used for product classification. In another effort, Chuaysi and Kiattisin (2020) proposed a classification method based on DL to classify fishing vessels’ behavior using their trajectory data. This method provides transparency and traceability to the seafood supply chain by monitoring the shipping behavior of the vessels and preventing illegal unreported and unregulated fishing.

3.3.1.8 Supply chain mapping

The representation of the links and members of a supply chain, as well as some information about the general nature of the map, is known as supply chain mapping (Gardner and Cooper 2003). In this category, the authors Wichmann et al. (2020) utilized DL on natural language text to determine buyer–supplier relations and extract supply chain maps in complex products supply chains. This approach can help decrease the risk associated with the lack of transparency in multi-tier supply networks.

3.3.1.9 Information security

Through the management of supply chain activities, information security assures uninterrupted and undisturbed business handling and reduces the harm caused by security incidents (Michelberger and Lábodi 2009). For instance, in recent years the outbreak of Covid-19 has significantly increased E-retailer’s sales and transactions (Roggeveen and Sethuraman 2020); On the other hand, the fast development of e-commerce has enforced serious challenges in information security during transactions (Deng Ge 2019). E-cash, data manipulation, and fraud in credit/debit cards are the essential risks of cybersecurity (Yalan and Wei 2021). To mitigate these challenges, Yalan and Wei (2021) developed a deep logistic learning framework to decrease computational time and increase data propagation accuracy in online transactions by analyzing consumers’ visit data. Such cybersecurity challenges have also increased in power supply chains due to the digitalization and the rise of industrial control systems (Khaw et al. 2021). In this regard, the authors of Khaw et al. (2021) used DL to develop a cyber-attack detection system to be used in transmission line protective relays in power substations. The system analyses the current and voltage measurements to detect the measurements that are maliciously inserted by attackers.

3.3.2 DL algorithms applied in the field of SCM (Answer to RQ2)

As the second research question, we intend to identify what DL techniques have been mostly used in SCM-related literature. To do so, we categorized papers based on the structural dimensions D2 and D3, investigated the relationship between DL methods and SCM problems, briefly introduced each algorithm applied in the field, and finally explained where and how these algorithms have been used by the authors in the SCM.

Table 5 shows DL algorithm categories (D2) used in papers either as a single algorithm or as part of a hybrid architecture. As the same DL approach can be used with different data types (Alom et al. 2019), Table 5 also demonstrates the type of data used in the papers to explore what algorithms with what data types are most frequently used in the SCM. From this table, it can be seen that the structured data types (25 papers) have been used more than unstructured data types (17 papers) in the SCM field. Among unstructured data types, image data has had the highest usage.

Figure 8 Displays the share of DL algorithm categories. From this chart, it can be seen that CNN had the maximum share followed by RNN and DNN

The relationship between the DL algorithm category and the research approach (D4) has been displayed in Table 6. From this table, it can be seen that the majority of the reviewed papers have a theoretical approach. Moreover, the papers with a practical approach used CNN and RNN algorithms that show the potential of these methods to have different applications. In practical applications, Kong et al. (2021) and Vo et al. (2020) used CNN for product classification in the agriculture and food supply chains respectively. Garillos-Manliguez and Chiang (2021), Chakraborty et al. (2021), Jagtap et al. (2019), Yasutomi and Enoki (2020), Thota et al. (2020), Cavallo et al. (2018), and Guo et al. (2020) used DL for quality management of agricultural, food, textile, and consumer products. Liu et al. (2020) proposed a decision-making platform for sales forecasting using RNN. Mao et al. (2018) presented a credit evaluation system for financial management in the food supply chain.

In the following paragraphs, we briefly describe the concept of each DL algorithm and its applications in the SCM in the reviewed papers.

3.3.2.1 Deep neural network (DNN) and its applications in the SCM

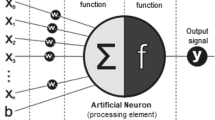

Artificial neural networks (ANNs) originated from human-brain behavior (Deng and Yu 2014). ANNs consist of units called perceptrons. A unit or node is the basic computational element (neuron) of ANN that gets inputs from external sources. During the training process, internal parameters of the unit including weight and biases are learned to produce outputs (Schmidhuber 2015). ANNs (also known as feed-forward NNs) are Multilayer Perceptrons (MLP) containing one or more hidden layers so that each layer has multiple hidden units (Alom et al. 2019). DNNs, by employing deep architectures in ANNs, are capable of representing learning functions with more complexity when the number of layers as well as units in a layer increases (Liu et al. 2017).

Shajalal et al. (2021) proposed a classification model using DNN to predict whether a product order would be back ordered or not. In this context, they handled the class imbalance problem using four different techniques. Kilimci et al. (2019) employed a multilayer feed-forward artificial neural network (MLFANN) along with several other forecasting methods (different time series and regression methods, and support vector regression) for the demand forecasting problem and then integrated the prediction of all algorithms to make the best decision.

Hu (2020) used particle swarm optimization (PSO) to train their BP feed-forward neural network to be used in the prediction of the financial credit level of a supply chain. Cai et al. (2018) presented a DNN to classify crop types. Ahmadimanesh et al. (2020) used a feed-forward neural network to design an inventory management model. Chuaysi and Kiattisin (2020) combined KNN classifier with MLP on statistical and trajectory features of fishing vessels to enable their traceability at sea. Yalan and Wei (2021) used DNN as part of a deep logistic learning framework (DLLF) to improve data security and purchasing waiting time problems in e-commerce transactions.

3.3.2.2 Applications of Convolutional neural network (CNN) and its variants in the SCM

CNN is one of the popular and frequently used DL networks (LeCun and Bengio, Convolutional networks for images, speech, and time series 1995) which has been used in a lot of reviewed papers. It is a multi-layer feed-forward neural network that was firstly designed for 2-dimensional image processing (LeCun et al. 1998) and then employed in other applications such as natural language processing, speech recognition, and computer vision (Pouyanfar et al. 2018). In comparison with DNNs, CNNs have some advantages such as more similarity to the human visual processing system, having a powerful structure for 2D and 3D image processing, and having effective performance in extracting and learning abstractions of complex 2D features (Alom et al. 2019). Wang et al. (2018) briefly described the construction of CNNs as follows: “CNN learns features by the use of alternating and stacking convolutional layers as well as pooling operations. The convolutional layers use several local kernel filters to convolve with raw input data, and then next pooling layers extract the most influential features with an over-sliding window of the raw input data through pooling operations. Finally, the fully-connected layers convert a 2D feature map to a 1D vector and transfer it to a softmax function to construct the model”.

Tosida et al. (2020) used a CNN model to classify telematics companies based on their need for assistance analyzing their general information, financial information, business obstacles, and prospects. Zhou et al. (2020) applied CNN on a supply chain financial dataset for fraud detection. Guo (2020) constructed a CNN to extract commodities’ features from their images to be used for price forecasting in e-commerce.

Jagtap et al. (2019) presented a CNN to classify the categories of potato wastage in a production line based on captured images. The Visual Geometry Group (VGG) architecture has been used in this study. Cavallo et al. (2018) utilized a CNN architecture for quality evaluation of packaged fresh-cut iceberg lettuce to identify the region of the package without artefact, then used a 3-Nearest Neighbors classifier to determine the quality level of the product among 5 levels using the output of the CNN. Thota et al. (2020) used CNN with Resnet-50 architecture to identify and verify the information on food packaging label images. Guo et al. (2020) employed ResNet 101 architecture of CNN to categorize meat into three groups of fresh, less fresh, or spoiled based on data captured from artificial scent screening systems.

Garillos-Manliguez and Chiang (2021) applied seven multimodal CNN architectures for classifying fruits based on their maturity. The used architectures were MD-AlexNet, MD-VGG16, MD-VGG19, MD-ResNet50, MD-ResNeXt50, MD-MobileNet, and MD-MobileNetV2, among them the MD-VGG16 architecture had the best performance. Chakraborty et al. (2021) also used CNN with several architectures including simple CNN, VGG16, VGG19, DenseNet-201, Inception-V3, and Xception to process fabric printing images aiming at defect detection. Among the tested architectures, VGG16 outperformed the other ones. Bousqaoui et al. (2021) did a comparative analysis on the performance of ARIMA, CNN, MLP, and LSTM methods in the demand forecasting problem. Their experiments showed better forecasting results of CNN compared to the other tested methods.

In 2014, Girshick et al. (2014) combined Selective Search algorithms with CNNs to determine Regions of Interest (RoI), for object detection. However, in their proposed method the two parts of the network were not trained at the same time, resulting in a tedious training process (Wang et al. 2019). To improve the speed and accuracy of training, then Fast Region-based CNN (Fast R-CNN) (Girshick, Fast R-CNN 2015), Faster R-CNN (Ren et al. 2015), and Mask-RCNN (He et al. 2017) were proposed. Wang et al. (2019) used Faster R-CNN for textile fabrics’ traceability problem. Vo et al. (2020) used Mask-RCNN for lobster grading. Kong et al. (2021) presented a multi-stream CNN architecture named as MCF-Net to classify crop species in practical farmland scenes. The CSPNet backbone network, three parallel sub-networks, and cross-level fusion layers are all parts of this architecture.

3.3.2.3 Applications of recurrent neural network (RNN) and its variants in the SCM

The other widely used DL category is RNN. Previously introduced DL methods namely DNN and CNN have some limitations that RNN can eliminate. Firstly, DNN and CNN accept a fixed-size input vector and produce a fixed-size output vector. Secondly, the number of their computational steps is fixed. In contrast, the RNN allows sequential operations over time (Alom et al. 2019). An RNN can be considered as several short-term memory units consisting of input layer X, hidden layer S, and output layer Y (Pouyanfar et al. 2018). However, RNN has difficulties in capturing long-term dependencies due to the vanishing and exploding gradient problem during the training process (Wang et al. 2018). To address this issue, the gated recurrent unit (GRU) was proposed giving the RNN a long-term memory (Liu et al. 2020). The other common RNN is Long Short-Term Memory (LSTM) network (Hochreiter and Schmidhuber 1997) which provides memory blocks in its recurrent connections (Pouyanfar et al. 2018). The LSTM can be effectively used to forecast complex time-series data (Punia et al. 2020).

As mentioned earlier, RNN especially the LSTM, has been extensively used for the forecasting problem. In the logistics industry, Shankar et al. (2020) applied an LSTM network to forecast container throughput. Punia et al. (2020) presented a cross-temporal forecasting framework (CTFF) based on an LSTM network for retail supply chain demand forecasting. Koç and Türkoğlu (2021) presented a model consisting of three steps of normalization, multilayer LSTM network, and dropout-dense-regression layers to forecast the Covid-19 disease cases and the demand for medical equipment. Nikolopoulos et al. (2021) also used the LSTM and many other forecasting methods to forecast the Covid-19 growth rate and compared their results. Although the LSTM is a powerful DL network, the other used methods showed better performance in this study (as discussed in Sect. 3.3.3). Weng et al. (2019a, b) employed ARIMA, BPNN, and RNN for forecasting the price of horticultural products and showed the better performance of RNN compared to the other two methods.

For retail sales prediction, Liu et al. (2020) designed F-TADA (future-aware TADA), a model built from trend alignment with dual-attention (TADA) multi-task recurrent neural networks (Chen et al. 2018). TADA is inspired by the RNN Encoder-Decoder model (Cho et al. 2014) and has two major components of a multi-task LSTM encoder and a dual-attention-based LSTM decoder. Khan et al. (2020) proposed a hybrid model that uses the LSTM and the GRU for forecasting the supply and demand of the supply chain and employs a genetic algorithm (GA) to optimize the hyperparameters of the hybrid model. They integrated advanced DL with IoT–blockchain data of Industry 4.0 in the food sector. Charmchi et al. (2021) also combined the LSTM and the GRU to forecast the supply of hydro reservoirs. Weng et al. (2019a) combined the LSTM with lightGBM (that is a machine learning algorithm) for supply chain sales forecasting. In their model, the LSTM mines information from data, and the lightGBM increases the interpretability of the model.

Mao et al. (2018) presented a credit evaluation system based on blockchain technology and an LSTM network. The system analyzes the traders’ transactions and credit evaluation text and categorizes them into two classes “positive” and “negative”. Wichmann et al. (2020) proposed a bidirectional LSTM (BiLSTM) model to extract buyer–supplier relationship maps in multi-tier supply chains by analyzing natural language text such as news reports or blog posts. In bidirectional RNNs, the model can train the data in both normal and reverse sequences of data which may be insightful in some contexts.

3.3.2.4 Deep auto-encoder (DAE) and its application in the SCM

The DAE is a special DNN without class labels in which the input vectors and output vectors have equal dimensionality (Deng and Yu 2014). The initial goal of the auto-encoder is learning and representation (encoding) of the input data for dimension reduction, compression, fusion, and so on (Alom et al. 2019). It consists of two parts: 1—The encoder that is responsible for data compression by mapping high dimensional input data to a hidden layer, 2—The decoder that regenerates the actual features of the input Wang et al. (2018). Khaw et al. (2021) proposed a cyber-attack detection system for power substations using a one-dimensional convolutional-based autoencoder. The proposed system is trained with current and voltage datasets and represents various types of faults happening on the protective relays of transmission lines.

3.3.2.5 Restricted Boltzmann machine (RBM) and its application in the SCM

RBM is a type of neural network that consists of a visible layer and a hidden layer with no visible-visible or hidden-hidden connections (LeCun and Bengio, Convolutional networks for images, speech, and time series 1995). Conditional Restricted Boltzmann Machine (CRBM), and Factored Conditional Restricted Boltzmann Machine (FCRBM) are two methods derived from RBM. In the CRBM the RBM is extended by including a conditional history layer (Mnih et al. Conditional Restricted Boltzmann Machines for Structured Output Prediction, 2012). FCRBM (Taylor et al. 2011) is constructed by adding styles and the concept of factored, multiplicative, three-way interactions to the CRBM (Mocanu et al. 2016). The authors Mocanu et al. (2016) investigated the use of CRBM and FCRBM for time series-based forecasting of the energy consumption of individual buildings. Their experiments showed better performance of FCRBM compared to CRBM and RNN.

3.3.2.6 Generative adversarial network (GAN) and its application in the SCM

Another class of DL methods has been introduced in 2014 is GAN (Goodfellow et al. 2014). This network can learn deep representations without greatly annotated training data by obtaining backpropagation signals using a competitive process involving two networks (Creswell et al. 2018) in a zero-sum game. A generative model aims at studying a set of training examples and learning the probability distribution that generated them (Goodfellow et al. 2020). Therefore, GANs are capable to generate more samples from the learned probability distribution (Goodfellow et al. 2020). In the SCM field, (Zhao and You 2020) employed the GAN to construct a distributionally robust chance constrained programming framework. This framework tries to minimize the supply chain total cost. The authors used the Sample average approximation (SAA) method for solving the chance-constrained programming problem after reformulating it into a conventional chance-constrained programming problem. The GAN produced all of the needed data samples for the SAA technique from start to finish. As a result, GAN may extract distributional information from historical data while concurrently generating data samples.

3.3.2.7 Deep reinforcement learning (DRL) and its applications in the SCM

Reinforcement Learning (RL) is a class of machine learning algorithms in which an agent (software or hardware) learns from interacting with an environment to obtain rewards (Mousavi et al. 2016). Unlike the other machine learning algorithms, RL is defined by characterizing a learning problem instead of the learning method. Deep reinforcement learning (DRL) is the combination of DL and RL that has been able to solve various complex decision-making problems in many domains such as healthcare, robotics, smart grids, finance, and so on (Francois-Lavet et al. 2018). Two DRL techniques applied in the reviewed papers are Deep Q-Network (DQN) proposed by Mnih et al. (2015) and Proximal Policy Optimization (PPO) introduced by Schulman et al. (2017). Meisheri et al. (2021) employed both the DQN and PPO methods to determine the optimum replenishment decisions for retail businesses under uncertain demand, having multiple products with different lead times and cross-product constraints. Their results showed a better performance for the DQN. Vanvuchelen et al. (2020) used the PPO to develop joint replenishment policies in the Physical Internet industry. Chen et al. (2021) also employed the DQN technique to decide on the production and storage of agri-food products aiming at profit optimization.

3.3.2.8 Applications of Hybrid architectures in the SCM

Some of the authors combined two or more DL networks to solve their research problem. In this regard, Wu et al. (2021) forecasted oil market behavior in the Covid-19 era. To do so, they used CNN to extract textual information from online oil news. Then employed the Vector autoregressive (VAR) model to determine the appropriate lay order of the outputs of CNN and historical data, and finally used several prediction methods including MLR, BPNN, SVM, RNN, and LSTM to forecast price, production, consumption, and inventory of oil. Tang and Ge (2021) combined CNN and LSTM to design a material forecast model analyzing three independent variables including sales demand forecast, transit warehouse inventory, and material features. Piccialli et al. (2021) proposed a hybrid framework consisting of LSTM-Autoencoder, CNN, and several machine learning algorithms to forecast the respiratory diseases bookings. In this framework, the LSTM-Autoencoder extracts the features, and the CNN recognizes short-term behaviors and relations between the forecasts provided by machine learning algorithms of Ridge, Lasso, RFR, and XGB. Yasutomi and Enoki (2020) proposed a hybrid architecture based on the CNN and LSTM for inspection of belt conveyors (to find any anomalies in belt lines) in production or distribution processes. In this method, the convolutional layers of CNN, extract signal features from each window and the LSTM find the relation between the windows.

Wang (2020) proposed a classification model based on CNN, DNN, and factorization machine technology to construct a personalized tourism service system. In this model, the CNN processes review information of users and tourism service items, the DNN processes the necessary information of users and tourism service items, and the factorization machine technology learns the interaction between the extracted features. Chien et al. (2020) proposed a demand forecasting framework using the DRL model of DQN to select the optimal forecasting model among Naïve, Simple moving average, Single exponential smooth, Syntetos–Boylan approximation (SBA), ANN, RNN, and SVR models.

To sum up this section, Fig. 9 illustrates the relationship between Dl algorithms, supply chain problems, and the investigated industries. As the forecasting problem consists of several sub-problems, the sub-categories and the papers that belonged to each are also shown in this illustration to give a complete picture to readers. it is evident that using RNN in the forecasting problem has the maximum number of papers (13 papers), followed by using CNN for the quality management (7 papers), and CNN for the forecasting (5 papers), respectively. In terms of studied industries, we can see that in the consumer products industry, forecasting (demand forecasting in Tang and Ge (2021), Nikolopoulos et al. (2021), Bousqaoui et al. (2021), and Punia et al. (2020), and sales forecasting in Weng et al. (2019a), Liu et al. (2020) is the most frequent problem solved with RNN and its variants. The quality management in the food supply chain using CNN is the second most frequent combination, followed by forecasting in the consumer products supply chain applying CNN.

3.3.3 Which alternative techniques have been used, by other scholars, to tackle the same problems? Is deep learning better than these alternative techniques and through which evaluation metrics? (Answer to RQ3)

Having higher levels of abstraction, DL algorithms, as an advancement of artificial neural networks, are expected to improve the results (Mocanu et al. 2016) in comparison to machine learning, time series, and other algorithms. To clarify what other algorithms have been compared with the DL algorithms and through which metrics their performance has been evaluated, we explored the numerical analysis of the reviewed papers. The results of this investigation have been summarized in Tables 7, 8, and 9. Table 8 includes the papers that studied multiple DL techniques and compared their performances together and to the other algorithms.

Table 8 demonstrates the comparison of proposed hybrid algorithms (that combine two or more DL techniques) to the other algorithms. In this group of papers, the authors showed that their method outperform the other tested algorithms.

Table 9 shows the papers focused on a single DL algorithm, compared its performance with other methods and demonstrated that their proposed methods have better performances.

From these tables it can be concluded that DL algorithms can lead to better results compared to machine learning techniques. As the most frequently tested algorithm, many of researchers compared their proposed algorithms with support vector machine (SVM) (Cai et al. 2018; Weng et al. 2019a; Chien et al. 2020; Wichmann et al. 2020; Koç and Türkoğlu 2021; Mocanu et al. 2016; Mao et al. 2018; Wu et al. 2021; Zhou et al. 2020). Random forest (RF) (Cai et al. 2018; Weng et al. 2019a; Shajalal et al. 2021), Gradient boosting (Weng et al. 2019a; Shajalal et al. 2021; Piccialli et al. 2021), and artificial neural network (ANN) (Chien et al. 2020; Shankar et al. 2020; Mocanu et al. 2016), are the other tested algorithms. Meanwhile, some authors compared the performance of different regression methods including ridge regression (Weng et al. 2019a; Piccialli et al. 2021), Lasso regression (Piccialli et al. 2021), support vector regression (SVR) (Piccialli et al. 2021; Chien et al. 2020), logistic regression (LR) (Shajalal et al. 2021), and multiple linear regression (MLR) (Wu et al. 2021), with their proposed DLs. In all of the above-mentioned papers, DLs outperformed over the other methods. In terms of time-series forecasting methods autoregressive integrated moving average (ARIMA) has been the most tested method (Weng et al. 2019a, b; Piccialli et al. 2021; Koç and Türkoğlu 2021; Bousqaoui et al. 2021; Mao et al. 2018) that could not perform as good as DLs.

Although in all of the papers displayed in Tables 7, 8, and 9 the proposed DLs led to better performance than other methods, (Nikolopoulos et al. 2021) used and compared 52 various methods including time-series, machine learning, nearest neighbor based approaches, and epidemiological methods as well as LSTM deep learning to forecast the Covid-19 growth rate to be used in the demand forecasting process. They showed that their proposed nearest neighbor-based approaches named Partial Curve Nearest Neighbor methods (PC-NN) and Multivariate Clustering-based Partial Curve Nearest Neighbor methods (CPC-NN) outperform the other methods in forecasting the Covid-19 growth rate and also developed their demand forecasting models based on these methods. However, the performance of the LSTM has been better than many of the employed methods.

Evaluation metrics are described in Appendix 1. Among all of the metrics mentioned in Tables 7, 8, and 9, RMSE and Accuracy have been used by the authors of 5 papers, followed by F1-Score, Precision, and MAE that have been employed in 4 papers have been the most popular metrics.

4 Research gaps and future directions

In this section, we identify gaps in existing DL research when compared to the needs of real-world SCM problems. We believe that tackling these research gaps is critical if we want our systems to get deployed, used, and have positive and lasting impacts.

The results of this study showed that, although there were 43 papers for DL applications in SCM in the last 5 years, the DL applications in SCM were still in a developmental phase, because DL applications in the supply chain are still quite blurred. As well, even though DL algorithms were found to be frequently used in SCM, their applications were executed in an unbalanced way, and their distributions were relatively uneven, as it was found that many of the papers addressed forecasting and quality management problems while the other areas of supply chains are not still well-studied using DL techniques. Moreover, in terms of supply chain functions, manufacturing and retailing have been dealt with by many researchers, however, the other functions specially warehousing and logistics that are two costly functions of supply chains can benefit from DL methods and need to be studied more in the future.

On the other hand, most of the papers developed a theoretical model and investigated the results through simulation and experimental analysis. The number of papers that presented practical applications of DL methods in SCM is still limited. Meanwhile, DL methods can be integrated with other technologies such as IoT and blockchain to improve the performance and integrity of supply chains.

As described in the research methodology, in this paper, we explored the studies published in the Scopus database, however, it is suggested to the researchers go through other databases like Google Scholar, ProQuest, and Web of Science in order to have a more comprehensive review.

Consequently, there is a marvelous opportunity to encourage researchers to advance the available knowledge in this area. The gaps in the available literature, future research directions, and implications are divided into six categories:

-

1.

Supply Chain Risk Management (SCRM) Protecting supply chains from disruptions has received enlarged attention these days. Supply Chain Risk Management is a part of SCM that can be used to reduce supply chain risk by predicting their incidence and diminishing their adverse effects and increasing the transparency and robustness of value-added processes in order to counteract any supply chain interruptions or even avoid them altogether (Schlüter et al. 2019). The review suggests several research gaps in this area including using DL delay/shortage risk, operational risk, out-of-stock risk, delay risk, and demand risk to identify potential risks.

-

2.

Supply Chain Financial Management (SCFM) Recently, financing becomes the bottleneck that impedes the growth of companies in an uncertain competitive environment and is less equipped with human and capital resources. SCFM optimizes both the cost of capital and the availability of suppliers and buyers by managing the cash flow of transaction activities and processes in the supply chain (Melamed and Rogers 2015). Hence, future research should focus more on capital structure considerations, cash flow management, bank financing, payment terms management, and payment collection management.

-

3.

Supply Chain Planning (SCP) Amid technological developments, Supply Chain Planning is considered the main backbone of a company because it plays an important role in the running of business operations at the company. The forward-looking process of coordinating assets to maximize the delivery of goods, services, and information from supplier to consumer while balancing supply and demand is known as supply chain planning (Simatupang and Sridharan 2002). So, for future research, these concepts i.e., supply planning, production planning, warehouse planning, logistics planning, and demand fulfillment planning in the framework of sales and operations planning (S&OP), integrated business planning (IBP), and Material requirements planning (MRP) play an important role in any industry.

-

4.

Supply Chain Execution (SCE) Companies need ever-faster delivery of products to an increasing extent of demanding customers, who are most often outspread the world. Therefore, it explains why supply chain execution has become so crucial to companies’ prosperity. Supply chain execution (SCE) is focused on supplier relationship management (SRM), production management, inventory management, service delivery management, and customer relationship management (CRM) within the enterprise, as well as throughout the extended supply chain, in essence, getting supply chain items where they need to go (Vlachopoulou and Manthou 2005). To catalyze the rapid progress of DL applications in SCM, future research should balance the focus on all segments equally.

-

5.

Supply Chain Hotspots Companies increasingly need detailed information on global impacts and trends concerning their products and services. Rather than treading on the heels of change, companies should try to get ahead of the trends that are shaping the future of SCM. These trends, including supply chain resiliency, supply chain sustainability, supply chain visibility, supply chain coordination, supply chain transparency, green supply chain, closed-loop supply chain and reverse supply chain have crucial impacts on SCM which are neglected by researchers and need in-depth notice for future investigations.

-

6.

Supply Chain Digitization Through digital transformation, the supply chain has been going through a fundamental change over the past decade with next-generation technology which can improve efficiencies, revenue growth, and customer experiences (Manavalan and Jayakrishna 2019). Moving forward, supply chain leaders are increasingly being called to use new technologies to foster greater efficiency and innovation. But unfortunately, not enough research is done in this realm that supports companies to adapt to the ever-changing digitalization era (Jayabalan 2021). These technologies, including Blockchain technology, Internet of things (IoT), Industry 4.0, and Artificial Intelligence can change global business forever and need much more focus by researchers.

At the end of this section, it should be noted that these results were found using the material collection process described in Sect. 2.3. Using other supply chain or deep learning related keywords or different filters may lead to finding more papers that can be considered as a future research direction.

5 Conceptual framework

Following the foundation of this study, where the emphasis is on how the different authors have applied different DL algorithms on the SCM and lack of consensus on SCM dimensions, different aspects were recognized far from being utterly considered. Consequently, there is a marvelous opportunity to encourage researchers to advance the available knowledge in this area. To draw a future research agenda, we propose the research framework presented in Fig. 10. This framework categorizes different areas that should be considered when using DL algorithms.

6 Managerial implications

According to the outcomes of this study, the DL has come to the forefront in driving the rapid increase of data, helping SCM to be optimized. This review accelerates the research advances and business growth for both academic researchers and practitioners. Furthermore, it provides a solid background of DL applications in the field of SCM. Besides, it can be a reference for scholars to have an overview of different applications of DL algorithms and issues to work on in future studies. The study contributes to the literature on SCM by being the first study focusing on applications of DL in SCM. A conceptual framework is developed, which may be followed up by researchers as a roadmap in further directions.

Organizations must evolve their SCM continuously to stay at the top. They are exposed to a wealth of knowledge coming from new business trends which consist of innovations in businesses; uncertainties together with shorter and tougher business cycles; expanding and demanding consumer base; converging wages and increasing costs; and the evolution of big data. The supply chain leaders will have to factor in these trends and their potential implications on the business. They will have to develop their supply chain strategy by considering the design of future logistics networks, improving the responsiveness of the supply chain, and working towards supply chain operational excellence.

For this reason, they may have the struggle to do proper action that is most suitable for their supply chain performance. But with the help of DL, they can understand the underlying trends that shape supply chains and develop the next generation supply chain. Advancements in robotics and product identification technology, a smart container that knows what goods it carries and the location to which it carries them, devising micro customer segmentations and providing tailored offerings to them, understanding customer mindsets through social networks, becoming agile, robust and sustainable across five functions- production, capital asset, purchasing, product development and planning, all of these need an ability to capture and analyze data with advanced algorithms which is possible to do by DL.

7 Conclusion

This paper, through a systematic and structured review of papers published on using DL algorithms in different areas of the SCM from 2016 onwards searched on the Scopus database, provides answers to three research questions as were presented at the beginning of this paper. As a result, 43 research articles were obtained and closely analyzed.