Abstract

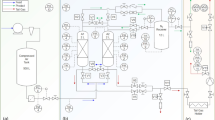

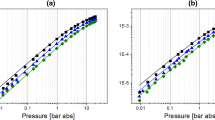

A two-dimensional model is established to simulate the rapid pressure swing adsorption (RPSA) process used for air separation with single bed. The model considers the transport phenomena occurring in both axial and radial direction. The decision variables include five factors (two heights of dead zone, durations of pressurization and adsorption steps, product extraction ratio), and the performance indexes consist of four variables (product purity, product recovery, bed size factor and average volume product yield). Based on an L16 (45) orthogonal design, 16 cases are arranged and the corresponding simulations are performed until the cycle steady states are reached from a given initial state. Range analysis is used to investigate the relative importance of the five factors on each performance index. Each factor’s optimal level and the corresponding combination is found out for each performance index successively.

Similar content being viewed by others

Abbreviations

- a :

-

Thermal diffusion coefficient, m2 s-1

- d p :

-

Diameter of adsorbent particle, m

- D im :

-

Mass dispersion rate, m2 s-1

- e f :

-

Total fluid energy, kJ kg-1

- e p :

-

Total solid medium energy, kJ kg-1

- F :

-

Momentum source term, kg m-2 s-2

- H in :

-

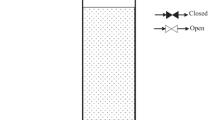

Dead-zone height of feed-in, m

- H out :

-

Dead-zone height of product-end, m

- ΔH :

-

Heat of adsorption, J mol-1

- K i :

-

Langmuir parameter, mol kg-1 kPa-1

- K ij :

-

Summation of experimental results of factor j at level i

- \(\bar{K}_{ij}\) :

-

The average of K ij

- k 1 :

-

Langmuir temperature dependence constant, mol kg-1 kPa-1

- k 2 , k 4 :

-

Langmuir temperature dependence constant, K

- k 3 :

-

Langmuir temperature dependence constant, kPa-1

- k :

-

Mass transfer rate coefficient, s-1

- k t :

-

Turbulent kinetic energy, m2 s-2

- k eff :

-

Effective bed thermal conductivity, W m-2 K

- k p :

-

Solid medium thermal conductivity, W m-2 K

- k f :

-

Fluid phase thermal conductivity, W m-2 K

- \(\dot{m}_{{\text {O}_{2} }}\) :

-

O2-enriched product gas per cycle, lbs moles cycle-1

- M i :

-

Molar weight of component i, kg mol-1

- M w :

-

Molar weight of fluid, kg mol-1

- q :

-

Solid-phase adsorbate concentration, mol kg -1

- \(q_{feed}\) :

-

Feeding flow rate, kg s-1

- q penetrate :

-

Molar flow rate of gas penetrated, mol s-1

- \(\bar{q}_{prod}\) :

-

Average product flow rate, L min-1

- \(\bar{q}_{purge}\) :

-

Average purge mass flow rate, kg s-1

- q * :

-

Adsorbate concentration in equilibrium with gas phase, mol kg -1

- Q penetrate :

-

Total amount of gas penetrated from the adsorber top per cycle, mol

- Q product :

-

Total amount of production obtained per cycle, mol

- Q purge :

-

Total mount enriched gas used to purge the adsorber per cycle, mol

- r :

-

Radial coordinate, m

- R :

-

Gas constant, J mol-1 K-1/ radius of bed, m

- Rec:

-

Oxygen recovery

- S i :

-

Mass source term of the ith component, kg m-3 s-1

- S m :

-

Total mass source term, kg m-3 s-1

- tc :

-

Total cycle time of PSA process, s

- T :

-

Temperature, K

- T ad :

-

Adsorption time, s

- T dp :

-

Desorption time,s

- T pg :

-

Purge time, s

- T pr :

-

Pressurization time, s

- u i :

-

Velocity in the i direction, m s-1

- \({\mathbf{u}}\) :

-

Velocity vector, m s-1

- w :

-

The total amount of zeolite adsorbent in the system, lbs

- y :

-

Distance from the adsorber side wall, m

- y i :

-

Mass fraction of component i

- y O2 :

-

Transient oxygen mole fraction

- \(y_{{{\text O}_{2} ,feed}}\) :

-

Oxygen mass fraction in feed-in gas

- \(\bar{Y}_{{{\text O}_{2} }}\) :

-

Average oxygen mole fraction of product gas

- \(\bar{Y}_{{{ \text O}_{2} ,n}}\) :

-

Average oxygen mole fraction of product gas of the nth cycle

- z :

-

Axial coordinate, m

- ε :

-

Porosity of the fixed bed

- ε t :

-

Dissipation rate of turbulence kinetic energy, m2 s-3

- ρ p :

-

Density of adsorbent particle, kg m-3

- ρ f :

-

Fluid density, kg m-3

- γ :

-

Product extraction ratio

- f :

-

Fluid

- p :

-

Particle

- r :

-

Radial

- i :

-

Species

- *:

-

Equilibrium

References

Beck, J., Friedrich, D., Brandani, S., Fraga, E.S.: Multi-objective optimisation using surrogate models for the design of VPSA systems. Comput. Chem. Eng. 82, 318–329 (2015)

Beh, C.C.K., Webley, P.A.: A practical method for the dynamic determination of the product oxygen concentration in pressure-swing adsorption systems. Ind. Eng. Chem. Res. 42, 5287–5292 (2003)

Chai, S.W., Kothare, M.V., Sircar, S.: Rapid pressure swing adsorption for reduction of bed size factor of a medical oxygen concentrator. Ind. Eng. Chem. Res. 50, 8703–8710 (2011)

Chai, S.W., Kothare, M.V., Sircar, S.: Numerical study of nitrogen desorption by rapid oxygen purge for a medical oxygen concentrator. Adsorption 18, 87–102 (2012)

Cruz, P., Magalhães, F.D., Mendes, A.: On the optimization of cyclic adsorption separation processes. AlChE J. 51, 1377–1395 (2005)

Ergun, S.: Fluid flow through packed columns. Chem. Eng. Prog. 48(2), 89–94 (1952)

Ferreira, D., Boaventura, M., Bárcia, P., Whitley, R.D., Mendes, A.: Two-stage vacuum pressure swing adsorption using AgLiLSX zeolite for producing 99.5+% oxygen from air. Ind. Eng. Chem. Res. 55, 722–736 (2016)

Fiandaca, G., Fraga, E.S., Brandani, S.: A multi-objective genetic algorithm for the design of pressure swing adsorption. Eng. Optim. 41, 833–854 (2009)

Fischer, R., Wanka, E.R., Einhaeupl, F., Voll, K., Schiffl, H., Lang, S.M., Gruss, M., Ferrari, U.: Comparison of portable oxygen concentrators in a simulated airplane environment. Respir. Med. 107, 147–149 (2013)

Gu, D., Sun, J., Ma, C., Lu, J.: Orthogonal test of self-pumping mechanical seals based on numerical simulation. CIESC J. 66, 2464–2473 (2015) (In chinese with english abstract)

Haghpanah, R., Majumder, A., Nilam, R., Rajendran, A., Farooq, S., Karimi, I.A., Amanullah, M.: Multiobjective optimization of a four-step adsorption process for postcombustion CO2 capture via finite volume simulation. Ind. Eng. Chem. Res. 52, 4249–4265 (2013)

Khajuria, H., Pistikopoulos, E.N.: Optimization and control of pressure swing adsorption processes under uncertainty. AlChE J. 59, 120–131 (2013)

Kim, Y.H., Lee, D.G., Moon, D.K., Byeon, S.-H., Ahn, H.W., Lee, C.H.: Effect of bed void volume on pressure vacuum swing adsorption for air separation. Korean J. Chem. Eng. 31, 132–141 (2014)

Ko, D., Moon, I.: Multiobjective optimization of cyclic adsorption processes. Ind. Eng. Chem. Res. 41, 93–104 (2002)

Li, J.: The experimental study of a new pressure equalization step in the pressure swing adsorption cycle of a portable oxygen concentrator. Biomed. Mater. Eng. 24, 1771–1779 (2014)

Li, Y.F., Christophe, J., Anderson, C.J., Xiao, G., Webley, P.A., Hoadley, A.F.A.: Multi-objective optimisation of a hybrid vacuum swing adsorption and low-temperature post-combustion CO2 capture. J. Clean. Prod. 111, 193–203 (2016)

Liu, Y., Sun, F.: Parameter estimation of a pressure swing adsorption model for air separation using multi-objective optimisation and support vector regression model. Expert Syst. Appl. 40, 4496–4502 (2013)

Liu, Y.S., Zheng, X.G., Dai, R.F.: Numerical study of flow maldistribution and depressurization strategies in a small-scale axial adsorber. Adsorption 20, 757–768 (2014)

Rama Rao, V., Kothare, M.V., Sircar, S.: Novel design and performance of a medical oxygen concentrator using a rapid pressure swing adsorption concept. AlChE J. 60, 3330–3335 (2014)

Rama Rao, V., Kothare, M.V., Sircar, S.: Anatomy of a rapid pressure swing adsorption process performance. AlChE J. 61, 2008–2015 (2015a)

Rama Rao, V., Wu, C.W., Kothare, M.V., Sircar, S.: Comparative perfomances of two commercial samples of LiLSX zeolite for production of 90% oxygen from air by a novel rapid pressure swing adsorption system. Sep. Sci. Technol. 50, 1447–1452 (2015b)

Rama Rao, V., Kothare, M.V., Shivaji, S.: Performance of a medical oxygen concentrator using rapid pressure swing adsorption process: effect of feed air pressure. AlChE J. 62, 1212–1215 (2016)

Rege, S.U., Yang, R.T.: Limits for separation by adsorption with LiX zeolite. Ind. Eng. Chem. Res. 36(12), 5358–5865 (1997)

Ruthven, D.M., Farooq, M.S., Knaebel, K.S.: Pressure Swing Adsorption. VCH Publishers, New York (1994)

Sankararao, B., Gupta, S.K.: Multi-objective optimization of pressure swing adsorbers for air separation. Ind. Eng. Chem. Res. 46, 3751–3765 (2007)

Wei, Z., Wu, C.-S., Ni, Y.: Optimum hydrodynamic design of helical strake on spar platforms based on orthogonal design and CFD method. J. Ship Mech. 17, 1133–1139 (2013) (chinese with english abstract)

Wu, C.-W., Vemula, R.R., Kothare, M.V., Sircar, S.: Experimental study of a novel rapid pressure-swing adsorption based medical oxygen concentrator: effect of the adsorbent selectivity of N2 over O2. Ind. Eng. Chem. Res. 55, 4676 (2016)

Yang, R.T.: Gas Separation by Adsorption Processes. Imperial College Press, London (1997)

Yin, S.H., Wu, A.X., Li, X.W.: Orthogonal polar difference analysis for sensitivity of the factors influencing the ore pillar stability. J. China Coal Soc. 37, 48–52 (2012) (chinese with english abstract)

Zheng, X.G., Liu, Y.S., Liu, W.H.: Two-dimensional modeling of the transport phenomena in the adsorber during pressure swing adsorption process. Ind. Eng. Chem. Res. 49, 11814–11824 (2010)

Žilinskas, A., Fraga, E.S., Beck, J., Varoneckas, A.: Visualization of multi-objective decisions for the optimal design of a pressure swing adsorption system. Chemom. Intell. Lab. Syst. 142, 151–158 (2015)

Acknowledgements

The authors acknowledge the financial support provided by the National Key Technology R&D Program (No. 2015BAA01B02), Ministry of Science and Technology, People’s Republic of China. The authors also thank the anonymous reviewers and the editor for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 Oxygen contour varying with time inside adsorber .mpeg: This animation shows the oxygen concentration varying with time during 14 cycles. (MOV 11884 KB)

Supplementary material 2 yo2’s variation along axial line.mpeg: This animation shows the axial oxygen concentration’s variation during 14 cycles. (MOV 17918 KB)

Supplementary material 3 yo2’s swing of point pvent.mpeg: This animation shows the oxygen concentration’s swing of point pvent during 14 cycles. (MOV 3036 KB)

Supplementary material 4 pressure’s swing of point pvent.mpeg: This animation shows the pressure’s swing of point pvent during 14 cycles. (MOV 3260 KB)

Rights and permissions

About this article

Cite this article

Zheng, X., Yao, H. & Huang, Y. Orthogonal numerical simulation on multi-factor design for rapid pressure swing adsorption. Adsorption 23, 685–697 (2017). https://doi.org/10.1007/s10450-017-9886-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-017-9886-1