Abstract

In this paper we present the measured isotherms of nitrogen, methane, ethane, and propane on three carbons: Norit RB2, Chemviron AP 4-60, and highly activated Saran. The measurements are taken at temperatures between 300 and 400 K, in 20 K steps. The measured data is fitted to the Sips adsorption model, where the Sips parameters are determined by a linearization method. The Sips parameters are further adjusted to realize a logic dependence on temperature and the parameter characteristics are discussed. Subsequently, the Sips model is modified to incorporate the temperature dependence. Including the temperature dependence results in a slightly higher error relative to the experimental results (typically 10 % as compared to 6 %). The immediate research product is a convenient expression for every adsorbate-adsorbent system which is discussed in this paper, for calculating the adsorption concentration as a function of temperature and pressure. A more general research product is a better understanding of the Sips parameter characteristics that should help in developing future adsorbents on demand.

Similar content being viewed by others

1 Introduction

Adsorption isotherm data is crucial input in the design of sorption compressors. These compressors can establish a pressurized gas flow by the cyclic adsorption and desorption of a working gas at a sorber (Prasad et al. 1996; Banker et al. 2004; Lu et al. 2006). These sorption compressors are thermally driven and operate without moving parts; meaning they are highly reliable, long life, and vibration free. They are suitable for driving Joule–Thomson (JT) cryogenic coolers. Cooling to about 80 K is usually obtained with nitrogen, whereas higher cooling temperatures can be obtained with other fluids, among which methane, ethane, and propane. The development of a sorption compressor for any working fluid relies on the adsorption isotherms at wide ranges of temperatures and pressures. These isotherms usually are not available in the literature and the measurements are done by the compressor developer (Prasad et al. 1996; Saha et al. 2012). In the present work we have performed adsorption measurements of nitrogen, methane, ethane, and propane on three adsorbents: Norit, Chemviron, and Saran. The experimental results are fitted to the Sips model (Sips 1948) which is a combined form of the Langmuir and Freundlich models and is suitable for describing heterogeneous adsorption systems at a wide range of pressures (Foo and Hameed 2010; Casas et al. 2012). In the current research the Sips parameters are derived by linearizing the experimental data, as was suggested by Wang et al. (2008).

The adsorption characteristics of the four gases on the three adsorbents are discussed, and the Sips model is described in detail. The Sips model is further modified to incorporate the temperature dependence (Tzabar and Grossman 2011; Park et al. 2014). The modified form allows for a direct calculation of the adsorption concentration as a function of the temperature and pressure at the expense of a slight reduction in accuracy.

2 Method of study

2.1 Experimental measurements of adsorption isotherms

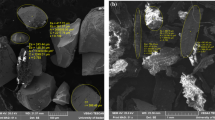

We have measured the adsorption of pure nitrogen, methane, ethane, and propane on three different adsorbents: Norit-RB2, Chemviron AP 4-60, and highly activated Saran. The properties of the three adsorbents are detailed in Table 1. For Norit and Chemviron activated carbons, the BET surface areas and the packing densities are provided by the adsorbent suppliers. The packing density of Saran is calculated by dividing the mass of the adsorbent by the sorption cell volume. The adsorbent pictures appear in Fig. 1. One should notice the difference between Saran, which consists of compressed spheres, and the two other activated carbons which have more unified bulk structures.

The experimental setup is schematically shown in Fig. 2. The volumes of the sorption cell and the connecting tube are premeasured and the mass of the adsorbent in the cell is determined by weighing the sorption cell. By means of an electric heater the adsorbent is stabilized at a uniform temperature. A specific amount of gas is allowed to flow into the sorption cell from a high-pressure gas bottle via a Bronkhorst M-12 mini-Coriolis flow controller. Temperature and pressure of the cell are measured once an equilibrium state is obtained. Next, this procedure is repeated so that at one temperature the amounts of gas adsorbed and corresponding pressures can be recorded. This is repeated at temperatures between 300 and 400 K in steps of 20 K, except for the system of methane—Saran where the maximum temperature is 380 K. In order to evaluate the adsorbed amount of the gas we need to correct for the void volume of the sorption cell and the connecting tube.

The adsorption concentration, C, is calculated as follows:

where \(\dot{m}\) is the gas mass flow into the cell, integrated over the time that the valve which introduces the fluid to the sorption cell is open. m s is the mass of the adsorbent, V void cell is the void volume in the sorption cell, V tube is the volume of the connecting tube, ρ is the density of the fluid, T amb is the ambient temperature, and T, p are the measured sorption cell temperature and pressure, respectively. The volume of the sorption cell for Chemviron and Norit is 18.6 cc and for Saran is 9.1 cc. In the present study we consider V void cell as the void volume around the adsorbent, not including the pore volumes. That makes the adsorption concentration, C, the known absolute adsorption (Gumma and Talu 2010).

The accuracies of the measured void volumes in the cell and the connecting tube are±2.5 and ±0.1 %, respectively. The accuracy of the adsorbent mass is ±0.3 % and the accuracy of the mass flow rate is estimated as ±2 %. The accuracy of the pressure measurement is ±0.1 % and for the temperature is ±1.5 %. As a consequence, the accuracy of the measured adsorption concentration, C, is about ±8 %. The accuracy of the method was verified by additional arbitrary “direct measurements” where we introduced a given amount of fluid to the sorption cell, rather than in steps (were the inaccuracies are accumulated). We repeated this for several gases at a few temperatures and pressures.

2.2 Sips adsorption model

The measured adsorption results of the pure gases were fitted to the adsorption model of Sips:

Where p is the pressure in bar, \(C_{0}\) is the saturated adsorption concentration, a is the adsorption affinity, and n is a dimensionless parameter that qualitatively characterizes the heterogeneity of the adsorbate-adsorbent system. The Sips isotherm is a combined form of Langmuir and Freundlich models deduced for predicting the adsorption in heterogeneous systems and circumventing the limitation of the rising adsorbate concentration associated with the Freundlich isotherm. At low adsorbate concentrations it reduces to the Freundlich isotherm; whereas at high concentrations it predicts a monolayer adsorption in a similar manner as the Langmuir isotherm. Therefore, the Sips isotherm shall be used to describe only monolayer adsorption systems. It is evident that multi-layer adsorption may occur at high pressures for the systems we study. Therefore, the Sips model is used to describe the adsorption at the pressure range of interest, and the C 0 parameter shall not be considered as the ultimate saturation adsorption.

In order to obtain the three parameters directly out of the experimental results, Eq. (2) is expressed in linear form as:

C 0 is iteratively found to obtain a linear relation between ln(p) and ln(C/(C 0 −C)), next n is determined by the slope and then a by the intersect point. This procedure is made for every adsorption isotherm, thus, the parameters are determined as a function of the temperature.

2.3 Modified Sips adsorption model

In order to have a single expression for covering the entire temperature range and to further allow extrapolations in temperature and pressure, the Sips model is modified. According to our experience, the parameters C 0 and n in the Sips model are assumed to linearly depend on temperature, whereas a is assumed to have an exponential dependence:

Here C A , C B , a A , a B , n A , and n B are fitting parameters, the pressure, p, is expressed in bar and the temperature, T, in K.

2.4 Deviation calculations

A deviation parameter, Dev, is defined for evaluating the agreement between the experimental and calculated isotherm results:

where N is the number of measured points at a given temperature.

3 Results and discussion

3.1 Experimental results

The experimental results of nitrogen, methane, ethane, and propane on Norit, Chemviron, and Saran are detailed in Tables 4–15, in the appendix. The symbols in Fig. 3 show the experimental results of each adsorbed gas on the three adsorbents at two of the six measured temperatures: the lowest and the highest measuring temperatures. Saran HA has the highest adsorption concentrations for all gases, and Norit RB2 has the lowest adsorption concentrations for all gases, except for propane at high temperatures. Nitrogen and methane have different adsorption characteristics then propane, where ethane is somewhere in between. The adsorption concentrations of nitrogen and methane are low at very low pressures and significantly increase with increasing pressure. The adsorption concentrations of propane at low pressures are already high and the increase at increasing pressure is much more moderate. In addition, the differences in propane adsorption concentrations among the three adsorbent are smaller than for the other gases.

Experimental results (symbols) and Sips isotherm (continuous lines) of nitrogen (a + b), methane (c + d), ethane (e + f) and propane (g + h) on Norit RB2 (filled diamond and solid lines), Chemviron AP 4-60 (filled circle and dotted lines), and Saran HA (filled triangle and dashed lines), at lowest and highest measuring temperatures. The Sips parameters are detailed in Table 2

3.2 Sips isotherms

The Sips parameters in Eq. (2) were derived by fitting them to the measured isotherms according to the procedure described in Sect. 2.2. Due to the limited accuracy of the measurements (±8 %), the Sips parameters show quite some scatter when plotted as functions of temperature. Also determining the Sips parameters using a non-linear regression procedure in the three-dimensional space of C 0 , a, and n results in a similar scattering of the results. Therefore, we use the linearization method as expressed in Eq. (3) to relate a and n to C 0 . As discussed in Sect. 2.2, the value of n is determined from the slop in Eq. (3) and a from the intersect. This reduces the problem to a single optimization parameter: C 0 . The adjustment of C 0 to obtain a more realistic dependence on temperature (more monotonous) also yields a more realistic behavior of a and n as a function of temperature. Here, the deviation parameter Dev as defined by Eq. (5) was used as the optimization parameter. The resulting Sips parameters are listed in Table 2.

Figure 4 shows the Sips parameters (presented in Table 2) of each gas on the three different adsorbents, as a function of temperature. Nitrogen, methane, and ethane show qualitatively similar characteristics where propane shows a different behavior which leads to the conclusion that the adsorption characteristics of propane are different, probably according to its molecule size.

Sips parameters (Table 2) for nitrogen (a–c), methane (d–f), ethane (g–i), and propane (j–l) on Norit RB2 (solid lines), Chemviron AP 4-60 (dashed dotted lines), and Saran HA (dashed lines), as a function of temperature

Figure 4 also shows that the dimensionless n parameter, which qualitatively characterizes the heterogeneity of the adsorbate-adsorbent system, is constantly decreasing with temperature and seems to depend on adsorbate rather than on adsorbent. Figure 5 compares the Sips parameters of each adsorbent for nitrogen, methane, and ethane, as a function of temperature. Propane is not considered in Fig. 5 since, as discussed earlier, it has different trends and adding its results to the figure disturbs analyzing the other gas results. In each graph of C 0 and n in Figs. 4 and 5 the curves show similar qualitative characteristics (e.g. all have a linear dependency on temperature). Fig. 5a, d, and g suggest that C 0 is more intensively influenced by the adsorbent, rather than by the adsorbate. That means that it is possible to increase the amount of adsorbed gas by adjusting the adsorbent parameters. It is not possible to state which component, the adsorbent or the adsorbate, affects the parameter a the most. It is clear that in most cases the parameter a exponentially decreases with increasing temperature.

Sips parameters (Table 2) for Norit RB2 (a–c), Chemviron AP 4-60 (d–f), and Saran HA (g–i) with nitrogen (solid lines), methane (dotted lines), and ethane (dashed lines), as a function of temperature

3.3 Modified Sips isotherms

The modified Sips parameters in Eq. (4) are derived from the trend lines presented in Figs. 4 and 5. The resulting modified Sips model parameters are given in Table 3. Covering all data, Figs. 6a, b, and c summarize the deviations of the Sips and the modified Sips models for Norit, Chemviron, and Saran, respectively.

Deviations of the Sips (symbols) and modified Sips (continuous lines) models from the experimental results, calculated by Eq. (5), as a function of temperature, for a Norit RB2, b Chemviron AP 4-60, and c Saran HA

The deviations of the Sips model are <0.06, and in most of the cases are lower than 0.02. The deviations of the modified Sips model are typically below 0.1. The somewhat larger deviation in the modified Sips model is the price we have to pay for a model that covers the whole range of pressures and temperatures as compared to the basic Sips model covering single isotherm data. The modified Sips parameters that are presented in Table 3 also show the difference between the adsorption characteristics of propane as compared to nitrogen, methane, and ethane. However, despite the difference in adsorption characteristics, the Sips model appears to be a valid model for describing the propane isotherms, and in this respect shows similar accuracy as in the case of the other three adsorbates.

4 Conclusions

The adsorption of nitrogen, methane, ethane, and propane on Norit RB2, Chemviron AP 4-60, and Saran HA is reported. Isotherm measurements were conducted between 300 and 400 K, at pressures up to 80 bar (8 MPa), when possible. A linearization method has been used to determine the Sips adsorption parameters out of the experimental data, which were further adjusted to comply with predefined temperature dependences. The dimensionless n parameter seems to be adsorbate dependent, whereas C 0 is more strongly affected by the adsorbent. The a parameter depends both on the adsorbent and the adsorbate in a similar manner.

Whereas the Sips parameters of nitrogen, methane, and ethane have similar trends, propane shows a different adsorption behavior. Nevertheless, the deviations of the Sips and the modified Sips models of propane are similar to these of nitrogen, methane, and ethane. The modified Sips model that is presented in shows a reasonable practical deviation of <10 %, in most cases. This model allows to calculate the adsorption in a direct convenient manner that improves numerical simulations of adsorption processes and cycles. We currently use the modified Sips model in the design of sorption compressors that are developed for refrigeration systems. More generally, a better understanding of the Sips parameter characteristics is reached for future adsorbent developments. For example, it is evident that Saran shows the highest adsorption concentrations for all adsorbates, despite its Sips parameters are similar to these of the other adsorbents. Moreover, Saran adsorbs more than Chemviron even though Chemviron has higher saturated adsorption concentrations.

Abbreviations

- a:

-

Sips adsorption affinity parameter, 1 bar−1

- C:

-

Adsorption concentration, mgadsorbate g −1adsorbent

- C0 :

-

Sips saturated adsorption concentration, mgadsorbate g −1adsorbent

- m:

-

Mass, g

- n:

-

Sips heterogeneity parameter

- N:

-

Number of measured points

- p:

-

Pressure, bar

- T:

-

Temperature, K

- V:

-

Volume, m3

- amb:

-

Ambient

- s:

-

Adsorbent

- Dev:

-

Deviation

- JT:

-

Joule–Thomson

References

Banker, N.D., Srinivasan, K., Prasad, M.: Performance analysis of activated carbon+ HFC-134a adsorption coolers. Carbon 42, 117–127 (2004)

Casas, N., Schell, J., Pini, R., Mazzotti, M.: Fixed bed adsorption of CO2/H2 mixtures on activated carbon: experiments and modeling. Adsorption 18, 143–161 (2012)

Foo, K.Y., Hameed, B.H.: Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 156, 2–10 (2010)

Gumma, S., Talu, O.: Net adsorption: a thermodynamic framework for supercritical gas adsorption and storage in porous solids. Langmuir 26, 17013–17023 (2010)

Lu, Z.S., Wang, R.Z., Wang, L.W., Chen, C.J.: Performance analysis of an adsorption refrigerator using activated carbon in a compound adsorbent. Carbon 44, 747–752 (2006)

Park, Y., Moon, D.K., Kim, Y.H., Ahn, H., Lee, C.H.: Adsorption isotherms of CO2, CO, N2, CH4, Ar and H2 on activated carbon and zeolite LiX up to 1.0 MPa. Adsorption 20, 631–647 (2014)

Prasad, M., Akkimardi, B.S., Rastogi, S.C., Rao, R.R., Srinivasam, K.: Adsorption characteristics of the charcoal-nitrogen system at 79–320 K and pressures to 5 MPa. Carbon 34, 1401–1406 (1996)

Saha, B.B., El-Sharkawy, I.I., Thrope, R., Critoph, R.E.: Accurate adsorption isotherms of R134a onto activated carbons for cooling and freezing applications. Int. J. Refrig 35, 499–505 (2012)

Sips, R.: On the structure of a catalyst surface. J. Chem. Phys. 16, 490–495 (1948)

Tzabar, N., Grossman, G.: Nitrogen, methane, and ethane sorption on activated carbon. Cryogenics 51, 499–508 (2011)

Wang, X.S., Tang, Y.P., Tao, S.R.: Removal of Cr(VI) from aqueous solutions by the nonliving biomass of alligator weed: kinetics and equilibrium. Adsorption 14, 823–830 (2008)

Acknowledgments

This work is supported by NanoNextNL, a micro and nanotechnology consortium of the government of the Netherlands and 130 partners.

Author information

Authors and Affiliations

Corresponding author

Appendix—experimental isotherms

Appendix—experimental isotherms

See Tables 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, and 15.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tzabar, N., ter Brake, H.J.M. Adsorption isotherms and Sips models of nitrogen, methane, ethane, and propane on commercial activated carbons and polyvinylidene chloride. Adsorption 22, 901–914 (2016). https://doi.org/10.1007/s10450-016-9794-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-016-9794-9