Abstract

An analytical approach is established to analyze the mechanical behavior of a unidirectional (UD) composite subjected to an in-plane shear. The effects of the interface debonding on the in-plane shear strength and plasticity of the composite are evaluated respectively. The volume-averaged internal stresses of the fiber and matrix are calculated through Bridging Model. Owing to the stress fluctuation in the matrix caused by other phases (such as the imbedded fiber and interface crack), the homogenized matrix stresses must be converted into true values based on a stress concentration factor (SCF). A new in-plane shear SCF of a composite with debonded interface is derived and applied to the predictions of strain and strength in this paper. Moreover, the contribution of the relative slippage between fiber and matrix to the non-linear shear deformation of the composite is analyzed. Finally, the efficiency and accuracy of our theory are verified with a series of examples. The approach is very efficient because the calculation can be achieved with explicit expressions mainly based on the constituent material properties. The comparisons between predicted strength and deformation with the experimental results show that our analytical approach can give out reliable underlying data for multi-scale analysis. Moreover, this theoretical method can tell if and how much the interface of a composite needs to be modified for a given load environment.

Similar content being viewed by others

References

Petit, P.: A simplified method of determining the inplane shear stress-strain response of unidirectional composites, in Composite Materials: Testing and Design., ASTM International (1969)

Walrath, D., Adams, D.: The losipescu shear test as applied to composite materials. Exp. Mech. 23(1), 105–110 (1983)

Lee, S., Munro, M.: Evaluation of in-plane shear test methods for advanced composite materials by the decision analysis technique. Composites 17(1), 13–22 (1986)

Daniels, B., Harakas, N., Jackson, R.: Short beam shear tests of graphite fiber composites. Fibre Science and Technology 3(3), 187–208 (1971)

Friedrich, K.: Application of fracture mechanics to composite materials. Vol. 6.: Elsevier. (2012)

Bradley, W.L.: Relationship of matrix toughness to interlaminar fracture toughness, in Composite materials series. Composite Materials Series, Chapter 5 (1989)

Yeow, Y., Brinson, H.: A comparison of simple shear characterization methods for composite laminates. Composites 9(1), 49–55 (1978)

Whitney, J., Halpin, J.: Analysis of laminated anisotropic tubes under combined loading. J. Compos. Mater. 2(3), 360–367 (1968)

Purslow, D.: Matrix fractography of fibre-reinforced thermoplastics, Part 2. Shear failures. Composites 19(2), 115–126 (1988)

Chen, J., Wan, L., Ismail, Y., Peng, F.H., Ye, J.Q., Yang, D.M.: Micromechanical analysis of UD CFRP composite lamina under multiaxial loading with different loading paths. Compos. Struct. 269(1), 114–124 (2021)

Khosravani, M. R., Anders, D., Weinberg, K.: Influence of strain rate on fracture behavior of sandwich composite T-joints. European Journal of Mechanics-A/Solids 78, 103821 (2019)

Gautham, S., Sasmal, S.: Determination of fracture toughness of nano-scale cement composites using simulated nanoindentation technique. Theoretical and Applied Fracture Mechanics 103, 102275 (2019)

Bilisik, K., Erdogan, G., Sapanci, E., Gungor, S.: Three-dimensional nanoprepreg and nanostitched aramid/phenolic multiwall carbon nanotubes composites: Experimental determination of in-plane shear. J. Compos. Mater. 53(28–30), 4077–4096 (2019)

Park, I.K., Park, K.J., Kim, S.J.: Rate-dependent damage model for polymeric composites under in-plane shear dynamic loading. Comput. Mater. Sci. 96, 506–519 (2015)

Bilisik, K., Karaduman, N., Erdogan, G., Sapanci, E., Gungor, S.: In-plane shear of nanoprepreg/nanostitched three-dimensional carbon/epoxy multiwalled carbon nanotubes composites. J. Compos. Mater. 53(24), 3413–3431 (2019)

Danial, A.V., Karolina, M., Bent, F. S., Brian, N. L.: Experimental and numerical studies of the micro-mechanical failure in composites. 19th International Conference on Composite Materials, ICCM 2013, July 28, - August 2, Montreal, QC, Canada: International Committee on Composite Materials (2013)

Kaw, A. K.: Mechanics of composite materials.: CRC press (2005)

Vargas, G., Ramos, J. A., Mondragon, I., Mujika, F.: In-plane shear properties of multiscale hybrid FMWCNTS / long carbon fibres / epoxy laminates. in European Conference on Composite Materials (2012)

Lee, S.M.: Mode II delamination failure mechanisms of polymer matrix composites. J. Mater. Sci. 32(5), 1287–1295 (1997)

O'Brien, T. K.: Composite Interlaminar Shear Fracture Toughness, G IIc: Shear Measurement or Sheer Myth?, in Composite Materials: Fatigue and Fracture: 7th Volume., ASTM International (1998)

Swanson, S., Messick, M., Toombes, G.: Comparison of torsion tube and Iosipescu in-plane shear test results for a carbon fibre-reinforced epoxy composite. Composites 16(3), 220–224 (1985)

Huang, Z.M., Liu, L.: Predicting strength of fibrous laminates under triaxial loads only upon independently measured constituent properties. Int. J. Mech. Sci. 79(1), 105–129 (2014)

Liu, L., Huang, Z.M.: Stress concentration factor in matrix of a composite reinforced with transversely isotropic fibers. J. Compos. Mater. 48(1), 81–98 (2014)

Huang, Z.M., Xin, L.M.: Stress Concentration Factor in Matrix of a Composite Subjected to Transverse Compression. Int. J. Appl. Mech. 08(03), 1650034 (2016)

Totry, E., Molina-Aldareguía J.M., González C., LLorca J.: Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites. Composites Science and Technology 70(6), 970–980 (2010)

Purslow, D.: Some fundamental aspects of composites fractography. Composites 12(4), 241–247 (1981)

Heutling, F., Franz, H., Friedrich, K.: Microfractographic analysis of delamination growth in fatigue loaded-carbon fibre/thermosetting matrix composites 29(5), 239–253 (1998)

Rogers, C. E.: Investigating the micromechanisms of mode II delamination in composite laminates. Imperial College London (2010)

Arcan, L., M., Daniel I. M.: SEM fractography of pure and mixed-mode interlaminar fractures in graphite/epoxy composites, in Fractography of Modern Engineering Materials: Composites and Metals., ASTM International (1987)

Argüelles, A., Viña, J., Canteli, A.F., Bonhomme, J.: Influence of resin type on the delamination behavior of carbon fiber reinforced composites under mode-II loading. Int. J. Damage Mech 20(7), 963–978 (2011)

Kusaka, T., Arcan, M., Daniel, I.M.: Rate-dependent mode II interlaminar fracture behavior of carbon fiber/epoxy composite laminates. Journal of the Society of Materials Science 48(6), 98–103 (1999)

Tanks, J., Sharp, S., Harris, D.: Charpy impact testing to assess the quality and durability of unidirectional CFRP rods. Polym. Testing 51, 63–68 (2016)

Zhang, K., Y. Gu, Zhang Z.: Effect of rapid curing process on the properties of carbon fiber/epoxy composite fabricated using vacuum assisted resin infusion molding. Materials and Design 54, 624–631 (2014)

Xu, Z., Huang, Y., Zhang, C., Liu, L., Zhang, Y., Wang, L.: Effect of γ-ray irradiation grafting on the carbon fibers and interfacial adhesion of epoxy composites. Compos. Sci. Technol. 67(15), 3261–3270 (2007)

Yan, K.F., Zhang, C.Y., Qiao, S.R., Han, D., Li, M.: In-plane shear strength of a carbon/carbon composite at different loading rates and temperatures. Mater. Sci. Eng., A 528(3), 1458–1462 (2011)

Gutkin, R., Pinho, S.T., Robinson, P., Curtis, P.T.: A finite fracture mechanics formulation to predict fibre kinking and splitting in CFRP under combined longitudinal compression and in-plane shear. Mech. Mater. 43(11), 730–739 (2011)

Gaur, U., Miller, B.: Microbond method for determination of the shear strength of a fiber/resin interface: Evaluation of experimental parameters. Compos. Sci. Technol. 34(1), 35–51 (1989)

Lee, S.M.: Mode II interlaminar crack growth process in polymer matrix composites. J. Reinf. Plast. Compos. 18(13), 1254–1266 (1999)

Zhong, Z., Meguid, S.: Interfacial debonding of a circular inhomogeneity in piezoelectric materials. Int. J. Solids Struct. 34(16), 1965–1984 (1997)

Steif, P.S., Dollar, A.: Longitudinal shearing of a weakly bonded fiber composite. J. Appl. Mech. 55(3), 618–623 (1988)

Teng, H., Agah-Tehrani, A.: Interfacial slippage of a unidirectional fiber composite under longitudinal shearing. J. Appl. Mech. 59(3), 547–551 (1992)

Huang, Z.M.: Simulation of the mechanical properties of fibrous composites by the bridging micromechanics model. Compos. A 32(2), 143–172 (2001)

Benveniste, Y., Dvorak, G.J., Chen, T.: Stress fields in composites with coated inclusions. Mech. Mater. 7(4), 305–317 (1989)

Zhou, Y., Huang, Z.M., Liu, L.: Prediction of Interfacial Debonding in Fiber-Reinforced Composite Laminates. Polym. Compos. 40(5), 1828–1841 (2019)

Zhou, Y., Huang, Z.M.: Failure of fiber-reinforced composite laminates under longitudinal compression. J. Compos. Mater. 53(24), 1–17 (2019)

Zhang, X., Hasebe, N.: Antiplane shear problems of perfect and partially damaged matrix-inclusion systems. Arch. Appl. Mech. 63(3), 195–209 (1993)

Smiley, A.J., Pipes, R.B.: Rate sensitivity of mode II interlaminar fracture toughness in graphite/epoxy and graphite/PEEK composite materials. Compos. Sci. Technol. 29(1), 1–15 (1987)

Zhang, Y., Zhang, L., Liu, Y., Liu, X., Chen, B.: Oxidation effects on in-plane and interlaminar shear strengths of two-dimensional carbon fiber reinforced silicon carbide composites. Carbon 98, 144–156 (2016)

Teng, H.: On stiffness reduction of a fiber-reinforced composite containing interfacial cracks under longitudinal shear. Mech. Mater. 13(2), 175–183 (1992)

Miyagawa, H., Sato, C., Ikegami, K.: Mode II interlaminar fracture toughness of multidirectional carbon fiber reinforced plastics cracking on 0//0 interface by Raman spectroscopy. Mater. Sci. Eng., A 308(1–2), 200–208 (2001)

Selzer, R., Friedrich, K.: Inluence of water up-take on interlaminar fracture properties of carbon fibre-reinforced polymer composites. J. Mater. Sci. 30(2), 334–338 (1995)

Canturri, C., Greenhalgh, E.S., Pinho, S.T.: The relationship between mixed-mode II/III delaminationand delamination migration in composite laminates. Compos. Sci. Technol. 105(10), 102–109 (2014)

Johannesson, T., Sjöblom, P., Seldén, R.: The detailed structure of delamination fracture surfaces in graphite/epoxy laminates. J. Mater. Sci. 19(4), 1171–1177 (1984)

Huang, Z.M.: On micromechanics approach to stiffness and strength of unidirectional composites. J. Reinf. Plast. Compos. 38(4), 167–196 (2019)

Zhou, Y., Huang, Z.M.: Shear deformation of a composite until failure with a debonded interface. Compos. Struct. 254, 112–797 (2020)

Soden, P. D., Hinton, M. J., Kaddour, A. S.: Lamina properties, lay-up configurations and loading conditions for a range of fibre-reinforced composite laminates. Composites Science and Technology 58(7), 1011–1022 (1998)

Kaddour, A., Hinton, M.: Input data for test cases used in benchmarking triaxial failure theories of composites. J. Compos. Mater. 46(19–20), 2295–2312 (2012)

Kaddour, A.S., Hinton, M.J., Smith, P.A., Li, S.: Mechanical properties and details of composite laminates for the test cases used in the third world-wide failure exercise. J. Compos. Mater. 47(20–21), 2427–2442 (2013)

Chan, P. H., Tshai, K. Y., Johnson, M., L. S.: Finite element analysis of combined static loadings on offshore pipe riser repaired with fibre-reinforced composite laminates. J Reinforced Plastics and Comp 33(6), 514–525 (2013)

Swanson, S. R., Toombes, G. R.: Characterization of prepreg tow carbon/epoxy laminates. J Engg Mater Techno, Trans ASME;111:150–3(1989)

Kim, R.Y., Crasto, A.S.: A longitudinal compression test for composites using a sandwich specimen. J. Compos. Mater. 26(13), 1915–1929 (1992)

Daniel, I. M., Hsiao, H. M., Wooh, S. C., Vittoser, J. In: AMD, vol 162, mechanics of thick composites. ASME publication, 107–26(1993)

Sun, C. T., Jun A. W.: Effect of matrix non-linear behaviour on the compressive strength of fibre composites. In AMD, vol 162, mechanics of thick composites. ASME, 91–105(1993)

Sun, C.T., Zhou, S.G.: Failure of quasi-isotropic composite laminates with free edges. J. Reinf. Plast. Compos. 7(6), 515–557 (1988)

Crossan, M.: Mechanical Characterization and Shear Test Comparison for Continuous-Fiber Polymer Composites. Elec Thesis and Dissert Repos, 5408 (2018)

Chiao, C.C., Moore, R.L., Chiao, T.T.: Measurement of shear properties of fibre composites: Part 1. Evaluation of test methods. Composites 8(3), 161–169 (1977)

Herraez, M., Andrew, C. B., Carlos, G., Lope. C.S.: Modeling Fiber Kinking at the Microscale and Mesoscale. Tech report, NASA/TP2018220105(2018)

Terry, G.: A comparative investigation of some methods of unidirectional, in-plane shear characterization of composite materials. Composites 10(4), 233–237 (1979)

Bednarcyk, B.A., Aboudi, J., Arnold, S.M.: Micromechanics modeling of composites subjected to multiaxial progressive damage in the constituents. AIAA J. 48(7), 1367–1378 (2010)

Toledo, M.W., Nallim, L.G., Luccioni, B.M.: A micro-macromechanical approach for composite laminates. Mech. Mater. 40(11), 885–906 (2008)

Laurin, F., Carrere, N., Huchette, C., Maire, J.F.: A multiscale hybrid approach for damage and final failure predictions of composite structures. J. Compos. Mater. 47(20–21), 2713–2747 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A. Homogenized Internal Stresses by Bridging Model

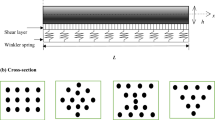

For a UD composite with both fiber and matrix in an elastic deformation stage, the relationships between internal stresses of the fiber and matrix and the stresses applied on the composite are expressed as [42]

The first coordinate, x1, is along the fiber axial direction. x3 is along plate thickness directions. The arbitrary stress vector applied on the composite has six components as {σj} = {σ11, σ22, σ33, σ23, σ13, σ12}T, and the vectors \(\left\{\sigma_i^f\right\}\) and \(\left\{\sigma_i^m\right\}\) have the same form. Vf and Vm (= 1-Vf) are the fiber and matrix volume fractions and [I] is a unit tensor. Explicit expressions for the bridging tensor [Aij] in Eqs. (20) and (21) are given as [42]

In the equations above, \(E_{11}^f\), \(E_{22}^f\), \(G_{12}^f\) and \(v_{12}^f\) are, respectively, longitudinal, transverse and in-plane shear moduli, and longitudinal Poisson’s ratio of the fiber. Em, Gm and νm are Young’s and shear moduli and Poisson’s ratio of the matrix. α and β are bridging parameters, which can be calibrated from comparison between the predicted in-plane shear and transverse Yong’s moduli of the composite, respectively. It is noted that

If no adjustment from an experiment is applicable, both α and β can be assumed to be 0.3 in most cases [42].

Appendix B. Expressions of Matrix SCFs

Definition of a SCF of the matrix in a composite is generally given by [23]

\(K_{ij}\) is the SCF related to \(\sigma_{ij}^m\) or \(d\sigma_{ij}^m\cdot{\left(\sigma_{ij}^m\right)}_{BM}\) is the matrix stress calculated from Bridging Model \(\widetilde\sigma_{ij}^m\) and is a point-wise matrix stress generally obtained through an elasticity on a CCA (coaxial cylinder assemblage) model. \(\overrightarrow R\) is a vector along a line perpendicular to the fracture surface of the composite under the given load. \(\overrightarrow R^{a}\) and \(\overrightarrow R^{b}\) are the vectors of ending at the surfaces of the fiber and matrix cylinders, respectively. a is the radius of the fiber. b and a are correlated as \(b=\frac\alpha{\sqrt{V_f}}\). Explicit formulae for the SCFs of matrix in a composite are listed as follows [22,23,24].

The transverse tension SCF of the matrix having a perfect interface bonding with the fiber, \(K_{22}^{t}\) is given by

The expression of transverse compressive SCF of the matrix, \(K_{22}^{c}\), is

\(E_{11}^f\), \(E_{22}^f\), and \(G_{12}^f\) are, respectively, longitudinal, transverse, and in-plane shear moduli of the fiber, \(v_{23}^f\)is its transversal Poisson’s ratio, \(v_{12}^f\) and is its longitudinal Poisson’s ratio. Em and Gm are Young’s and shear moduli of the matrix, respectively, and νm is its Poisson’s ratio.

The formula of in-plane shear SCF of the matrix, is shown as

\(G_{12}^f\) and Gm are the longitudinal shear moduli of the fiber and matrix, respectively.

Besides, the transverse tension SCF of the matrix after the interface debonding, is given by

The functions in Eq. (35), N, N1, N2 and N3, are given by

The debonding half angle, \(\psi\) is the solution to the following equation [44]:

If = 1, no solution for \(\psi\) is available, and the corresponding interface crack is singular. But, one can always adjust a fiber or matrix property so that 1, as deviation exists in measurement of it \(v_{23}^f\). is the transverse Poisson’s ratio of the fiber. \(\sigma_{u,\;t}^m,\;\sigma_{u,\;c}^m\), and \(\sigma_{u,\;s}^m\) are, respectively, the matrix tensile, compressive and shear strengths.

Appendix C. Integration After Interface Debonding

For a certain longitudinal section located at \(x_3=x_3^0,\alpha\leq x_3^0\leq b\), the length of the integration line between the starting and the ending points is \(\sqrt{2\left[b^2-\left(x_3^0\right)^2\right]}\). Thus, the matrix shear SCF along this line is given by

Note that \(b=a/ \sqrt{V_f}\), where Vf is the fiber volume fraction and S is along the integration line. In Eq. (57), \({\left(\sigma_{12}^m\right)}_{BM}\) is the matrix in-plane shear stress calculated through Bridging Model. is a point-wise stress in the matrix given by Eq. (7). Since dS equals (-\(\sqrt2\) dx2) on the integration line (the value of x3 is a constant), the line integration of Eq.(57) is changed to (noticing that \(x_3^0=x_3\)).

Substituting ψ = 0.5π into Eq. (7), one has

Replacing z in Eq. (59) with x2 + ix3 and taking the integration along the x2 axis gives

Now let us derive the integration on the function N with respect to \(x_{2}\)

Setting \(R_0\left(x_2\right)=\left(x_2+x_3i-\alpha i\right)^{0.5}\left(x_2+x_3i-\alpha i\right)^{0.5}\), its derivative with respect to \(x_{2}\) is

Similarly, setting \(R_1\left(x_2\right)=\frac{\alpha\left(x_2+x_3i-\alpha i\right)^{0.5}\left(x_2+x_3i+\alpha i\right)}{x_2+x_3i}\) and taking a derivative with respect to \(x_{2}\) results in

Based on Eqs. (63) and (64), one can obtain that

Therefore, the integration on Eq. (60) is found to be

Substituting Eq. (66) into Eq. (58), one obtains

It should be noted that Eq. (67) is obtained only for a particular longitudinal cross-section. As done in Ref. [44], the matrix in-plane shear SCF must be determined based on an average along the thickness direction from to. This gives rise to

Letting \(m=-\sqrt{b^2-x_3^2}+x_3i\) and \(R_2=-\left(\sqrt{b^2-x_3^2}+x_3i-\alpha i\right)^{0.5}\left(-\sqrt{b^2-x_3^2}+x_3i-\alpha i\right)^{0.5}=\left(m-\alpha i\right)^{0.5}\left(m+\alpha i\right)^{0.5}\)

Eq. (68) is changed to

The expression in Eq. (70) containing R2 is hard to integrate, and must be converted into a function of m. However, \((m-\alpha{i})^{0.5}(m+\alpha{i})^{0.5}\) might equal to \((m^{2}+\alpha^{2})^{0.5}\) or \(-(m^{2}+\alpha^{2})^{0.5}\). We need to choose the correct form within the integration range. Because x3 ∈ [a, b], the phase angles of \((m-\alpha{i})\) and \((m+\alpha{i})\) are within [0.5π, π]. Thus, the phase angles of both and are in between [0.25π, 0.5π]. Hence, the phase angle of is in the second quadrant, indicating that its imaginary part is positive.

As \((m^2+\alpha^2)^{0.5}=({(b^2-2x_3^2+\alpha^2)-2x_3i\sqrt{b^2-x_3^2})}^{0.5}\) and \(\mathrm{Im}(-2x_3i\sqrt{b^2-x_3^2})<0\), the phase angle of \((b^2-x_3^2+\alpha^2)-2x_3i\sqrt{b^2-x_3^2}\) is in between -π and 0. The corresponding square root is within [-0.5π,0], and the imaginary part of \((m^2+\alpha^2)^{0.5}\) is negative. Overall, for x3 ∈ [a, b] and \(m=-\sqrt{b^2-x_3^2}+x_3i\), one has \((m-\alpha{i})^{0.5}(m+\alpha{i})^{0.5}=-(m^2-\alpha{2})^{0.5}\)

Next, from \(\frac{dm}{dx_3}=\frac{x_3}{\sqrt{b^2-x_3^2}}+i=\frac{x_3+i\sqrt{b^2-x_3^2}}{\sqrt{b^2-x_3^2}}=\frac{x_3-i\sqrt{b^2-x_3^2}}{\sqrt{b^2-x_3^2}}=\frac m{i\sqrt{b^2-x_3^2}}\), one derives

Similarly,

Now, let us derive the integration for the other part of Eq. (68), which contains

As \(\left(x_3i-\alpha i\right)^{0.5}\left(x_3i+\alpha i\right)^{0.5}=i\sqrt{x_3^2-\alpha^2}\), Eq. (73) equals to \(\frac{\alpha\sqrt{x_3^2-}\alpha^2}{x_3\sqrt{b^2}-x_3^2}\)

The integration on Eq. (73) becomes

In order to get the explicit integral expression, the parameter \(x(0\leq x\leq\sqrt{b^2-\alpha^2})\) in Eq. (74) is replaced with \((\sqrt{b^2-\alpha^2}\sin\left(\theta\right),\;0\leq\theta\leq0.5\pi)\). It becomes

Making use of the integral formula

\(\int\frac1{\alpha+b\;\cos\left(x\right)}d\left(x\right)=\frac2{\alpha+b}\sqrt{\frac{\alpha+b}{\alpha-b}}\;{\mathrm{arc}\tan}\left(\sqrt{\frac{\alpha-b}{\alpha+b}}\tan\frac x2\right)\),

Eq. (75) is simplified to \(\frac{\alpha\pi}2-\alpha\left[\sqrt{V_f}\;arc\tan\left(\sqrt{V_f}\;\tan\frac\theta2\right)\right]\left|\begin{array}{c}\pi\\0\end{array}=\right.\frac{\alpha\pi}2\left(1-\sqrt{V_f}\right).\)

Combining Eqs. (67), (70), (71), (72) and (75), one finally obtains the expression of the in-plane shear SCF with debonded interface as Eq. (8).

Rights and permissions

About this article

Cite this article

Zhou, Y., Huang, ZM. Prediction of In-Plane Shear Properties of a Composite with Debonded Interface. Appl Compos Mater 29, 901–935 (2022). https://doi.org/10.1007/s10443-021-09982-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09982-z