Abstract

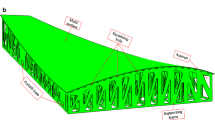

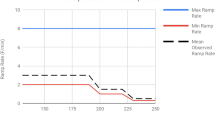

For large composite parts manufactured by autoclave curing process, temperature uniformity of the mold is essential to ensure final part quality. This paper aims to investigate the influence of mold placement variation in autoclave on heating performance of a large framed mold and find the optimal mold placement parameters for improving the temperature uniformity and heating rate. Firstly, a computational fluid dynamics (CFD) based autoclave simulation model is established and validated, which offers reliable prediction of the mold temperature field and flow distribution in autoclave. Then, numerical experiments are performed based on the autoclave simulation model and response surface methodology (RSM) to establish relations between mold placement variables and responses including temperature uniformity and heating rate. Finally, using the established regression model, multi-objective optimization is conducted considering both temperature uniformity and heating rate. The optimal mold placement parameters are obtained successfully which improves the temperature uniformity significantly with little change in heating rate comparing to the commonly adopted mold placement approach. The strategies provided by mold placement optimization can be applied for various large framed molds in composite manufacturing improving the autoclave curing process.

Similar content being viewed by others

References

Michael, C.N., Michael, N.: Composite Airframe Structures, 5th edition. Hong Kong Conmilit Press (2005)

Nele, L., Caggiano, A., Teti, R.: Autoclave Cycle Optimization for High Performance Composite Parts Manufacturing. Procedia CIRP 57(C), 241–6 (2016) https://doi.org/10.1016/j.procir.2016.11.042

Johnston, A.: An Integrated Model of the Development of Process-Induced Deformations in Autoclave Processing of Composite Structures. Ph.D. thesis, University of British Columbia, Vancouver (1997)

Xie, G.N., Liu, J., Zang, W.H., et al.: Simulation and Improvement of Temperature Distributions of a Framed Mold during the Autoclave Composite Curing Process. J. Eng. Thermophys. 22(1), 43–61 (2013)

Parlevliet, P.P., Bersee, H.E.N., Beukers, A.: Residual Stresses in Thermoplastic Composites – a Study of the Literature. Part III: Effects of Thermal Residual Stresses. Compos. A: Appl. Sci. Manuf. 38(6), 0-1596 (2007)

Kim, J.S., Lee, D.G.: Development of an Autoclave Cure Cycle with Cooling and Reheating Steps for Thick Thermoset Composite Laminates. J. Compos. Mater. 31, 2264–2282 (1997)

Park, H.C., Goo, N.S., Min, K.J., et al.: Three-Dimensional Cure Simulation of Composite Structures by the Finite Element Method. Compos. Struct. 62(1), 51–57 (2003)

Gopal, A.K., Adali, S., Verijenko, V.E.: Optimal Temperature Profiles for Minimum Residual Stress in the Cure Process of Polymer Composites. Compos. Struct. 48(1–3), 99–106 (2000)

Guo, Z.S., Du, S., Zhang, B.: Temperature Field of Thick Thermoset Composite Laminates during Cure Process. Compos. Sci. Technol. 65(3–4), 517–523 (2005)

Aleksendrić, D., Carlone, P., Ćirović, V.: Optimization of the Temperature-Time Curve for the Curing Process of Thermoset Matrix Composites. Appl. Compos. Mater. 23(5), 1–17 (2016)

Struzziero, G., Skordos, A.A.: Multi-objective Optimization of the Cure of Thick Components. Compos. A: Appl. Sci. Manuf. 93, 126–136 (2017)

Bohne, T., Frerich, T., Jendrny, J., Jürgens, J.P., Ploshikhin, V.: Simulation and Validation of Airflow and Heat Transfer in an Autoclave Process for Definition of Thermal Boundary Conditions during Curing of Composite Parts. J. Compos. Mater. 52(12), 1677–1687 (2018)

Hudek, M.: Examination of Heat Transfer during Autoclave Processing of Polymer Composites. Master’s Thesis, University of Manitoba, Canada (2001)

Chen, F., Zhan, L., Xu, Y.: Simulation of Mold Temperature Distribution in a Running Process Autoclave. Iran. Polym. J. 24(11), 927–934 (2015)

Chen, F., Zhan, L., Li, S.: Refined Simulation of Temperature Distribution in Molds during Autoclave Process. Iran. Polym. J. 25(9), 775–785 (2016)

Wang, Q., Wang, L., Zhu, W., Xu, Q., Ke, Y.: Design Optimization of Molds for Autoclave Process of Composite Manufacturing. J. Reinf. Plast. Compos. 36(21), 1564–1576 (2017)

Wang, L., Zhu, W., Wang, Q., Xu, Q., Ke, Y.: A Heat-Balance Method for Autoclave Process of Composite Manufacturing. J. Compos. Mater. 53(5), 641–652 (2019)

Kluge, J.N.E., Lundström, T.S., Ljung, A.L., et al.: An Experimental Study of Temperature Distribution in an Autoclave. J. Reinf. Plast. Compos. 35(7), 566–578 (2016)

Kluge, J.N.E., Lundström, T.S., Westerberg, L.G., et al.: Modelling Heat Transfer Inside an Autoclave: Effect of Radiation. J. Reinf. Plast. Compos. 35(14), 1126–1142 (2016)

Weber, T.A., Arent, J.C., Munch, L., Duhovic, M., Balvers, J.M.: A Fast Method for the Generation of Boundary Conditions for Thermal Autoclave Simulation. Compos. A: Appl. Sci. Manuf. 88, 216–25 (2016)

Maffezzoli, A., Grieco, A.: Optimization of Parts Placement in Autoclave Processing of Composites. Appl. Compos. Mater. 20(3), 233–48 (2013)

Dumont, F., Fröhlingsdorf, W., Weimer, C.: Virtual Autoclave Implementation for Improved Composite Part Quality and Productivity. CEAS Aeronaut. J. 4(3), 277–89 (2013)

ANSYS FLUENT User’s Guide, version 12.0 (2009)

Design Expert, 10.0v, Stat-Ease Inc., 2021 East Hennepin Avenue, Suite 480, Minneapolis

Acknowledgments

This research is supported by the National Natural Science Foundation of China (No. 51805476)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dolkun, D., Wang, H., Wang, H. et al. Influence of Large Framed Mold Placement in Autoclave on Heating Performance. Appl Compos Mater 27, 811–837 (2020). https://doi.org/10.1007/s10443-020-09835-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09835-1