Abstract

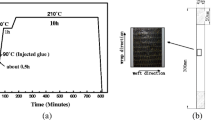

Tensile properties and failure mechanism of a newly developed three-dimensional (3D) woven composite material named 3D nonorthogonal woven composite are investigated in this paper. The microstructure of the composite is studied and the tensile properties are obtained by quasi-static tensile tests. The failure mechanism of specimen is discussed based on observation of the fracture surfaces via electron microscope. It is found that the specimens always split along the oblique yarns and produce typical v-shaped fracture surfaces. The representative volume cell (RVC) is established based on the microstructure. A finite element analysis is conducted with periodical boundary conditions. The finite element simulation results agree well with the experimental data. By analyzing deformation and stress distribution under different loading conditions, it is demonstrated that finite element model based on RVC is valid in predicting tensile properties of 3D nonorthogonal woven composites. Stress distribution shows that the oblique yarns and warp yarns oriented along the x direction carry primary load under x tension and that warp yarns bear primary load under y tension.

Similar content being viewed by others

References

Kamiya, R., Cheeseman, B.A., Popper, P., Chou, T.-W.: Some recent advances in the fabrication and design of three-dimensional textile preforms: a review. Compos. Sci. Technol. 60, 33–47 (2000). doi:10.1016/S0266-3538(99)00093-7

Mouritz, A.P., Bannister, M.K., Falzon, P.J., Leong, K.H.: Review of applications for advanced three-dimensional fibre textile composites. Compos. Part A Appl. Sci. Manuf. 30, 1445–1461 (1999). doi:10.1016/S1359-835X(99)00034-2

Gu, H., Zhili, Z.: Tensile behavior of 3D woven composites by using different fabric structures. Mater. Des. 23, 671–674 (2002). doi:10.1016/S0261-3069(02)00053-5

Sun, B., Gu, B., Ding, X.: Compressive behavior of 3-D angle-interlock woven fabric composites at various strain rates. Polym. Test. 24, 447–454 (2005). doi:10.1016/j.polymertesting.2005.01.005

Liang, Y., Wang, H., Soutis, C., Lowe, T., Cernik, R.: Progressive damage in satin weave carbon/epoxy composites under quasi-static punch-shear loading. Polym. Test. 41, 82–91 (2015). doi:10.1016/j.polymertesting.2014.10.013

Zhang, Y., Sun, F., Wang, Y., Chen, L., Pan, N.: Study on intra/inter-ply shear deformation of three dimensional woven preforms for composite materials. Mater. Des. 49, 151–159 (2013). doi:10.1016/j.matdes.2013.02.025

Ansar, M., Xinwei, W., Chouwei, Z.: Modeling strategies of 3D woven composites: a review. Compos. Struct. 93, 1947–1963 (2011). doi:10.1016/j.compstruct.2011.03.010

Wang, X.F., Wang, X.W., Zhou, G.M., Zhou, C.W.: Multi-scale analyses of 3D woven composite based on periodicity boundary conditions. J. Compos. Mater. 41, 1773–1788 (2007). doi:10.1177/0021998306069891

Tan, P., Tong, L., Steven, G.: Modelling for predicting the mechanical properties of textile composites—A review. Compos. Part A Appl. Sci. Manuf. 28, 903–922 (1997). doi:10.1016/S1359-835X(97)00069-9

Drach, A., Drach, B., Tsukrov, I.: Processing of fiber architecture data for finite element modeling of 3D woven composites. Adv. Eng. Softw. 72, 18–27 (2014). doi:10.1016/j.advengsoft.2013.06.006

Xia, Z., Zhang, Y., Ellyin, F.: A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 40, 1907–1921 (2003). doi:10.1016/S0020-7683(03)00024-6

Lu, Z., Xia, B., Yang, Z.: Investigation on the tensile properties of three-dimensional full five-directional braided composites. Comput. Mater. Sci. 77, 445–455 (2013). doi:10.1016/j.commatsci.2013.04.010

Rao, M.V., Mahajan, P., Mittal, R.K.: Effect of architecture on mechanical properties of carbon/carbon composites. Compos. Struct. 83, 131–142 (2008). doi:10.1016/j.compstruct.2007.04.003

Acknowledgments

The work is partially funded by the National Natural Science Foundation of China (No.11272147), the Research Fund of State Key Laboratory of Mechanics and Control of Mechanical Structures (Nanjing University of Aeronautics and Astronautics) (Grant No. 0214G02), the Fundamental Research Funds for the Central Universities and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Sun, J., Cai, D. et al. Tensile Properties and Failure Mechanism of a New 3D Nonorthogonal Woven Composite Material. Appl Compos Mater 23, 1117–1135 (2016). https://doi.org/10.1007/s10443-016-9503-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9503-6