Abstract

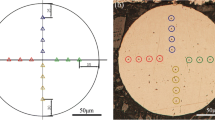

Torsion tests are performed on microscale copper wires of diameters ranging from 25 to 50 μm, with and without passivation layers, to investigate the size and passivation effects. The copper wires coated with titanium are prepared by magnetron sputtering. An increase in the yield strength and flow stress arising from diameter reduction and the passivation layer is observed in the experiments. Compared with unpassivated wires, passivated wires exhibit more potent size effects. The normalized torque of passivated wires increases more significantly with the diameter decrease. The theoretical predictions based on the Fleck-Hutchinson strain gradient plasticity theory agree well with the experimental observations. The physical mechanism of the passivation layers affecting the torsional deformation of wires is elucidated.

摘要

本文对直径在25–50微米、有无钝化层的微尺度铜丝进行了扭转测试, 开展了尺度效应与钝化效应的实验研究. 通过磁控溅射 制备了镀钛铜丝试样, 在扭转测试中观察到直径减小和钝化层存在引起的屈服强度和流动应力的增加. 与未钝化铜丝相比, 钝化铜丝 中存在更加明显的尺度效应, 钝化铜丝的规范化扭矩随着直径减小而增加更为显著. 基于Fleck-Hutchinson应变梯度塑性理论对铜丝的 扭转响应进行了预测, 数值结算结果与实验数据吻合较好, 并阐明了钝化层对铜丝扭转变形影响的物理机制

Similar content being viewed by others

References

N. A. Fleck, G. M. Muller, M. F. Ashby, and J. W. Hutchinson, Strain gradient plasticity: Theory and experiment, Acta Metall. Mater. 42, 475 (1994).

D. Liu, Y. He, X. Tang, H. Ding, P. Hu, and P. Cao, Size effects in the torsion of microscale copper wires: Experiment and analysis, Scripta Mater. 66, 406 (2012).

S. Guo, Y. He, J. Lei, Z. Li, and D. Liu, Individual strain gradient effect on torsional strength of electropolished microscale copper wires, Scripta Mater. 130, 124 (2017).

S. Guo, Y. He, M. Tian, D. Liu, Z. Li, J. Lei, and S. Han, Size effect in cyclic torsion of micron-scale polycrystalline copper wires, Mater. Sci. Eng.-A 792, 139671 (2020).

J. G. Swadener, E. P. George, and G. M. Pharr, The correlation of the indentation size effect measured with indenters of various shapes, J. Mech. Phys. Solids 50, 681 (2002).

Z. S. Ma, Y. C. Zhou, S. G. Long, and C. Lu, On the intrinsic hardness of a metallic film/substrate system: Indentation size and substrate effects, Int. J. Plast. 34, 1 (2012).

B. Ehrler, X. D. Hou, T. T. Zhu, K. M. Y. P’ng, C. J. Walker, A. J. Bushby, and D. J. Dunstan, Grain size and sample size interact to determine strength in a soft metal, Philos. Mag. 88, 3043 (2008).

I. Hayashi, M. Sato, and M. Kuroda, Strain hardening in bent copper foils, J. Mech. Phys. Solids 59, 1731 (2011).

C. Cheng, M. Wan, B. Meng, R. Zhao, and W. P. Han, Size effect on the yield behavior of metal foil under multiaxial stress states: Experimental investigation and modelling, Int. J. Mech. Sci. 151, 760 (2019).

N. A. Fleck, and J. W. Hutchinson, Strain gradient plasticity, Adv. Appl. Mech. 33, 295 (1997).

N. A. Fleck, and J. W. Hutchinson, A reformulation of strain gradient plasticity, J. Mech. Phys. Solids 49, 2245 (2001).

N. A. Fleck, and J. R. Willis, A mathematical basis for strain-gradient plasticity theory. Part II: Tensorial plastic multiplier, J. Mech. Phys. Solids 57, 1045 (2009).

W. D. Nix, and H. Gao, Indentation size effects in crystalline materials: A law for strain gradient plasticity, J. Mech. Phys. Solids 46, 411 (1998).

P. Gudmundson, A unified treatment of strain gradient plasticity, J. Mech. Phys. Solids 52, 1379 (2004).

M. E. Gurtin, A gradient theory of small-deformation isotropic plasticity that accounts for the Burgers vector and for dissipation due to plastic spin, J. Mech. Phys. Solids 52, 2545 (2004).

M. E. Gurtin, and L. Anand, A theory of strain-gradient plasticity for isotropic, plastically irrotational materials. Part I: Small deformations, J. Mech. Phys. Solids 53, 1624 (2005).

G. Z. Voyiadjis, and Y. Song, Strain gradient continuum plasticity theories: Theoretical, numerical and experimental investigations, Int. J. Plast. 121, 21 (2019).

S. S. Chakravarthy, and W. A. Curtin, Stress-gradient plasticity, Proc. Natl. Acad. Sci. USA. 108, 15716 (2011).

A. Hosseini-Hooshyar, and A. Nayebi, Application of stress gradient plasticity model in different passivated problems, Mech. Mater. 159, 103923 (2021).

S. S. Chakravarthy, and W. A. Curtin, Stress gradient plasticity: Concept and applications, Procedia IUTAM 10, 453 (2014).

D. J. Dunstan, and A. J. Bushby, Theory of deformation in small volumes of material, Proc. R. Soc. Lond. A 460, 2781 (2004).

D. J. Dunstan, B. Ehrler, R. Bossis, S. Joly, K. M. Y. P’ng, and A. J. Bushby, Elastic limit and strain hardening of thin wires in torsion, Phys. Rev. Lett. 103, 155501 (2009).

D. J. Dunstan, Validation of a phenomenological strain-gradient plasticity theory, Philos. Mag. Lett. 96, 305 (2016).

J. F. Nye, Some geometrical relations in dislocated crystals, Acta Metall. 1, 153 (1953).

M. F. Ashby, The deformation of plastically non-homogeneous materials, Philos. Mag.-J. Theor. Exp. Appl. Phys. 21, 399 (1970).

H. Gao, and Y. Huang, Geometrically necessary dislocation and size-dependent plasticity, Scripta Mater. 48, 113 (2003).

L. Bardella, A deformation theory of strain gradient crystal plasticity that accounts for geometrically necessary dislocations, J. Mech. Phys. Solids 54, 128 (2006).

L. Xiang, H. Y. Wang, Y. Chen, Y. J. Guan, and L. H. Dai, Elastic-plastic modeling of metallic strands and wire ropes under axial tension and torsion loads, Int. J. Solids Struct. 129, 103 (2017).

A. Arya, S. Suwas, and A. H. Chokshi, Strengthening in tension and weakening in torsion in drawn nickel microwires, Mater. Sci. Eng.-A 856, 143955 (2022).

H. Ban, Y. Yao, S. Chen, and D. Fang, The coupling effect of size and damage in micro-scale metallic materials, Int. J. Plast. 95, 251 (2017).

H. Ban, Z. Peng, D. Fang, Y. Yao, and S. Chen, A modified conventional theory of mechanism-based strain gradient plasticity considering both size and damage effects, Int. J. Solids Struct. 202, 384 (2020).

Y. Xiang, and J. J. Vlassak, Bauschinger and size effects in thin-film plasticity, Acta Mater. 54, 5449 (2006).

N. Srinivasan, and S. S. Kumaran, The effects of strain on stability of passivation in austenitic stainless steels: Comparison with heat treatment, Exp. Tech. 45, 207 (2021).

A. G. Evans, and J. W. Hutchinson, A critical assessment of theories of strain gradient plasticity, Acta Mater. 57, 1675 (2009).

P. Gudmundson, and C. F. O. Dahlberg, Isotropic strain gradient plasticity model based on self-energies of dislocations and the Taylor model for plastic dissipation, Int. J. Plast. 121, 1 (2019).

F. Hua, and D. Liu, On dissipative gradient effect in higher-order strain gradient plasticity: The modelling of surface passivation, Acta Mech. Sin. 36, 840 (2020).

M. Kuroda, and A. Needleman, A simple model for size effects in constrained shear, Extreme Mech. Lett. 33, 100581 (2019).

N. A. Fleck, J. W. Hutchinson, and J. R. Willis, Strain gradient plasticity under non-proportional loading, Proc. R. Soc. A. 470, 20140267 (2014).

T. Luo, F. Hua, and D. Liu, Modeling of cyclic bending of thin foils using higher-order strain gradient plasticity, Acta Mech. Solid Sin. 35, 616 (2022).

F. Hua, D. Liu, Y. Li, Y. He, and D. J. Dunstan, On energetic and dissipative gradient effects within higher-order strain gradient plasticity: Size effect, passivation effect, and Bauschinger effect, Int. J. Plast. 141, 102994 (2021).

R. M. Keller, S. P. Baker, and E. Arzt, Quantitative analysis of strengthening mechanisms in thin Cu films: Effects of film thickness, grain size, and passivation, J. Mater. Res. 13, 1307 (1998).

Y. Mu, J. W. Hutchinson, and W. J. Meng, Micro-pillar measurements ofplasticity in confined Cu thin films, Extreme Mech. Lett. 1, 62 (2014).

E. Hall, The deformation and ageing of mild steel: III Discussion of results, Proc. Phys. Soc. Sect. B 64, 747 (1951).

N. Petch, The cleavage strength of polycrystals, J. Iron Steel Inst. 174, 25 (1953).

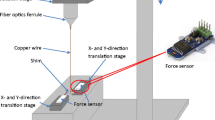

J. Hu, L. Zeng, P. Hu, Y. He, and D. Liu, A new torsion tester based on an electronic autocollimator for characterizing the torsional behaviors of microfibers, Rev. Sci. Instrum. 92, 103905 (2021).

D. Liu, Y. He, D. J. Dunstan, B. Zhang, Z. Gan, P. Hu, and H. Ding, Toward a further understanding of size effects in the torsion of thin metal wires: An experimental and theoretical assessment, Int. J. Plast. 41, 30 (2013).

M. E. Gurtin, and A. Needleman, Boundary conditions in small deformation, single-crystal plasticity that account for the Burgers vector, J. Mech. Phys. Solids 53, 1 (2005).

L. Bardella, and A. Panteghini, Modelling the torsion of thin metal wires by distortion gradient plasticity, J. Mech. Phys. Solids 78, 467 (2015).

E. Martínez-Pañeda, C. F. Niordson, and L. Bardella, A finite element framework for distortion gradient plasticity with applications to bending of thin foils, Int. J. Solids Struct. 96, 288 (2016).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11972013, 12002129, and 11972168). The authors also thank the financial support of the Fundamental Research Funds for the Central Universities (Grant No. 2020kfyXJJS074).

Author information

Authors and Affiliations

Contributions

Yuyang Xie investigated the research and wrote the first draft of the manuscript. Yuyang Xie and Fenfei Hua created the models, performed the simulation and processed the data. Jianhui Hu and Dabiao Liu provided the experimental instrument. Yuyang Xie, Jian Lei, Dabiao Liu and Yuming He revised and edited the final version. Jian Lei and Yuming He acquired the financial support for the project leading this publication and oversighted the research activity planning and execution.

Corresponding authors

Rights and permissions

About this article

Cite this article

Xie, Y., Lei, J., Hua, F. et al. Size and passivation effects in the torsion of thin metallic wires. Acta Mech. Sin. 39, 422346 (2023). https://doi.org/10.1007/s10409-022-22346-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-022-22346-x