Abstract

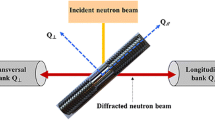

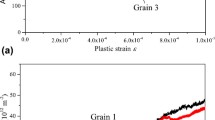

Structure materials under severe irradiations in nuclear environments are known to degrade because of irradiation hardening and loss of ductility, resulting from irradiation-induced defects such as vacancies, interstitials and dislocation loops, etc. In this paper, we develop an elastic–viscoplastic model for irradiated multi-phase polycrystalline BCC materials in which the mechanical behaviors of individual grains and polycrystalline aggregates are both explored. At the microscopic grain scale, we use the internal variable model and propose a new tensorial damage descriptor to represent the geometry character of the defect loop, which facilitates the analysis of the defect loop evolutions and dislocation-defect interactions. At the macroscopic polycrystal scale, the self-consistent scheme is extended to consider the multiphase problem and used to bridge the individual grain behavior to polycrystal properties. Based on the proposed model, we found that the work-hardening coefficient decreases with the increase of irradiation-induced defect loops, and the orientation/loading dependence of mechanical properties is mainly attributed to the different Schmid factors. At the polycrystalline scale, numerical results for pure Fe match well with the irradiation experiment data. The model is further extended to predict the hardening effect of dispersoids in oxide-dispersed strengthened steels by the considering the Orowan bowing. The influences of grain size and irradiation are found to compete to dominate the strengthening behaviors of materials.

Graphical Abstract

Comparison of numerical modeling results (solid lines) with experimental results (square lines) for the polycrystalline BCC iron. We develop an elastic–viscoplastic model for irradiated multiphase polycrystalline BCC materials, based on a dislocation-based model at the grain scale, and the self-consistent scheme at the macroscopic scale. This model can be easily applied to predict the hardening behaviors of irradiated multi-phase polycrystalline materials.

Similar content being viewed by others

References

Bruemmer, S.M., Simonen, E.P., Scott, P.M., et al.: Radiation-induced material changes and susceptibility to intergranular failure of light-water-reactor core internals. J. Nucl. Mater. 274, 299–314 (1999)

Byun, T.S., Farrell, K.: Plastic instability in polycrystalline metals after low temperature irradiation. Acta Mater. 52, 1597–1608 (2004)

Luppo, M.I., Bailat, C., Schaublin, R., et al.: Tensile properties and microstructure of 590 MeV proton-irradiated pure Fe and a Fe–Cr alloy. J. Nucl. Mater. 283, 483–487 (2000)

Singh, B.N., Horsewell, A., Toft, P.: Effects of neutron irradiation on microstructure and mechanical properties of pure iron. J. Nucl. Mater. 271, 97–101 (1999)

Barton, N.R., Arsenlis, A., Marian, J.: A polycrystal plasticity model of strain localization in irradiated iron. J. Mech. Phys. Solids 61, 341–351 (2013)

Krishna, S., Zamiri, A., De, S.: Dislocation and defect density-based micromechanical modeling of the mechanical behavior of fcc metals under neutron irradiation. Philos. Mag. 90, 4013–4025 (2010)

Patra, A., Mcdowell, D.L.: Crystal plasticity-based constitutive modelling of irradiated bcc structures. Philos. Mag. 92, 861–887 (2012)

Zinkle, S.J., Farrell, K.: Void swelling and defect cluster formation in reactor-irradiated copper. J. Nucl. Mater. 168, 262–267 (1989)

Ghaly, M., Nordlund, K., Averback, R.S.: Molecular dynamics investigations of surface damage produced by kiloelectronvolt self-bombardment of solids. Philos. Mag. Phys. Condens. Matter Struct. Defects Mech. Prop. 79, 795–820 (1999)

Osetsky, Y.N., Bacon, D.J., Serra, A., et al.: One-dimensional atomic transport by clusters of self-interstitial atoms in iron and copper. Philos. Mag. 83, 61–91 (2003)

Arakawa, K., Ono, K., Isshiki, M., et al.: Observation of the one-dimensional diffusion of nanometer-sized dislocation loops. Science 318, 956–959 (2007)

Matsukawa, Y., Zinkle, S.J.: One-dimensional fast migration of vacancy clusters in metals. Science 318, 959–962 (2007)

Uberuaga, B.P., Hoagland, R.G., Voter, A.F.: Direct transformation of vacancy voids to stacking fault tetrahedra. Phys. Rev. Lett. 99, 135501 (2007)

Wirth, B.D.: How does radiation damage materials? Science 318, 923–924 (2007)

Bacon, D.J., Osetsky, Y.N., Stoller, R., et al.: MD description of damage production in displacement cascades in copper and alpha-iron. J. Nucl. Mater. 323, 152–162 (2003)

Seeger, A.K.: On the theory of radiation damage and radiation hardening (No. A/CONF. 15/P/998). Max-Planck-Inst. fur Metallforschung, Technischen Hochschule, Stuttgart (1959)

Odette, G.R., Frey, D.: Development of mechanical property correlation methodology for fusion environments. J. Nucl. Mater. 85, 817–822 (1979)

Blewitt, T.H., Coltman, R.R., Jamison, R.E., et al.: Radiation hardening of copper single crystals. J. Nucl. Mater. 2, 277–298 (1960)

Singh, B.N., Foreman, A.J.E., Trinkaus, H.: Radiation hardening revisited: role of intracascade clustering. J. Nucl. Mater. 249, 103–115 (1997)

Arsenlis, A., Wirth, B.D., Rhee, M.: Dislocation density-based constitutive model for the mechanical behaviour of irradiated Cu. Philos. Mag. 84, 3617–3635 (2004)

Robach, J.S., Robertson, I.M., Wirth, B.D., et al.: In-situ transmission electron microscopy observations and molecular dynamics simulations of dislocation-defect interactions in ion-irradiated copper. Philos. Mag. 83, 955–967 (2003)

Lee, H., Wirth, B.D.: Molecular dynamics simulation of dislocation-void interactions in BCC Mo. J. Nucl. Mater. 386–88, 115–118 (2009)

Osetsky, Y.N., Stoller, R.E., Rodney, D., et al.: Atomic-scale details of dislocation-stacking fault tetrahedra interaction. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 400, 370–373 (2005)

Krishna, S., De, S.: A temperature and rate-dependent micromechanical model of molybdenum under neutron irradiation. Mech. Mater. 43, 99–110 (2011)

Patra, A., Mcdowell, D.L.: Continuum modeling of localized deformation in irradiated bcc materials. J. Nucl. Mater. 432, 414–427 (2013)

Eshelby, J.D.: The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 241, 376–396 (1957)

Kroner, E.: Berechnung der elastischen konstanten des vielkristalls aus den konstanten des einkristalls. Z. Phys. 151, 504–518 (1958) (in German)

Hill, R.: Continuum micro-mechanics of elastoplastic polycrystals. J. Mech. Phys. Solids 13, 89 (1965)

Iwakuma, T., Nematnasser, S.: Finite elastic plastic-deformation of polycrystalline metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1984, 87–119 (1806)

Clausen, B., Tome, C.N., Brown, D.W., et al.: Reorientation and stress relaxation due to twinning: modeling and experimental characterization for Mg. Acta Mater. 56, 2456–2468 (2008)

Hutchinson, J.W.: Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 348, 101–127 (1976)

Molinari, A., Canova, G.R., Ahzi, S.: A self-consistent approach of the large deformation polycrystal viscoplasticity. Acta Metall. 35, 2983–2994 (1987)

Weng, G.J.: A self-consistent scheme for the relaxation behavior of metals. J. Appl. Mech. Trans. Asme. 48, 779–784 (1981)

Weng, G.J.: Self-consistent determination of time-dependent behavior of metals. J. Appl. Mech. Trans. Asme 48, 41–46 (1981)

Nematnasser, S., Obata, M.: Rate-dependent, finite elastoplastic deformation of polycrystals. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1986, 343–375 (1833)

Li, J., Weng, G.J.: A secant-viscosity approach to the time-dependent creep of an elastic-viscoplastic composite. J. Mech. Phys. Solids 45, 1069–1083 (1997)

Turner, P.A., Tome, C.N.: Self-consistent modeling of viscoelastic polycrystals—application to irradiation creep and growth. J. Mech. Phys. Solids 41, 1191–1211 (1993)

Wang, H., Wu, P.D., Tome, C.N., et al.: A finite strain elastic-viscoplastic self-consistent model for polycrystalline materials. J. Mech. Phys. Solids 58, 594–612 (2010)

Molinari, A.: Averaging models for heterogeneous viscoplastic and elastic viscoplastic materials. J. Eng. Mater. Technol. Trans. Asme. 124, 62–70 (2002)

Mercier, S., Molinari, A.: Homogenization of elastic-viscoplastic heterogeneous materials: self-consistent and Mori–Tanaka schemes. Int. J. Plast. 25, 1024–1048 (2009)

Berbenni, S., Favier, V., Lemoine, X., et al.: Micromechanical modeling of the elastic-viscoplastic behavior of polycrystalline steels having different microstructures. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 372, 128–136 (2004)

Mercier, S., Molinari, A., Berbenni, S.: Comparison of different homogenization approaches for elastic-viscoplastic materials. Model. Simul. Mater. Sci. Eng. 20, 024004 (2012)

Paquin, A., Berbenni, S., Favier, V., et al.: Micromechanical modeling of the elastic-viscoplastic behavior of polycrystalline steels. Int. J. Plast. 17, 1267–1302 (2001)

Paquin, A., Sabar, H., Berveiller, M.: Integral formulation and self-consistent modelling of elastoviscoplastic behavior of heterogeneous materials. Arch. Appl. Mech. 69, 14–35 (1999)

Sabar, H., Berveiller, M., Favier, V., et al.: A new class of micro–macro models for elastic-viscoplastic heterogeneous materials. Int. J. Solids Struct. 39, 3257–3276 (2002)

Coulibaly, M., Sabar, H.: New integral formulation and self-consistent modeling of elastic-viscoplastic heterogeneous materials. Int. J. Solids Struct. 48, 753–763 (2011)

Xiao, X., Song, D., Xue, J., et al.: A self-consistent plasticity theory for modeling the thermo-mechanical properties of irradiated FCC metallic polycrystals. J. Mech. Phys. Solids 78, 1–16 (2015)

Kiener, D., Hosemann, P., Maloy, S.A., et al.: In situ nanocompression testing of irradiated copper. Nat. Mater. 10, 608–613 (2011)

Gussev, M.N., Byun, T.S., Busby, J.T.: Description of strain hardening behavior in neutron-irradiated fcc metals. J. Nucl. Mater. 427, 62–68 (2012)

Klueh, R.L., Nelson, A.T.: Ferritic/martensitic steels for next-generation reactors. J. Nucl. Mater. 371, 37–52 (2007)

Chen, C.Q., Cui, J.Z., Duan, H.L., et al.: Perspectives in mechanics of heterogeneous solids. Acta Mech. Solida Sin. 24, 1–26 (2011)

Duan, H.L., Weissmüller, J., Wang, Y.: Instabilities of core-shell heterostructured cylinders due to diffusions and epitaxy: spheroidization and blossom of nanowires. J. Mech. Phys. Solids 56, 1831–1851 (2008)

Duan, H.L., Yi, X., Huang, Z.P., et al.: A unified scheme for prediction of effective moduli of multiphase composites with interface effects. Part I: theoretical framework. Mech. Mater. 39, 81–93 (2007)

Duan, H.L., Yi, X., Huang, Z.P., et al.: A unified scheme for prediction of effective moduli of multiphase composites with interface effects: Part II—application and scaling laws. Mech. Mater. 39, 94–103 (2007)

Berbenni, S., Favier, V., Berveiller, M., et al.: Micromechanical modelling of the elastic-viscoplastic behaviour of interstitial-free and dual-phase steels. Revue De Metall. Cah. D Info. Tech. 101, 381 (2004)

Seeger, A.: Why anomalous slip in body-centred cubic metals? Mater. Sci. Eng. A 319–321, 254–260 (2001)

Kothari, M., Anand, L.: Elasto-viscoplastic constitutive equations for polycrystalline metals: applications to tantalum. J. Mech. Phys. Solids 46, 51 (1998)

Robertson, I.M., Jenkins, M.L., English, C.A.: Low-dose neutron-irradiation damage in alpha-iron. J. Nucl. Mater. 108–109, 209–221 (1982)

Little, E.A.: Neutron-irradiation hardening in irons and ferritic steels. Int. Metall. Rev. 21, 25–60 (1976)

Xiao, X., Song, D., Xue, J., et al.: A size-dependent tensorial plasticity model for FCC single crystal with irradiation. Int. J. Plast. 65, 152–167 (2015)

Arsenlis, A., Rhee, M., Hommes, G., et al.: A dislocation dynamics study of the transition from homogeneous to heterogeneous deformation in irradiated body-centered cubic iron. Acta Mater. 60, 3748–3757 (2012)

Wang, Y., Weissmüller, J., Duan, H.L.: Mechanics of corrugated surfaces. J. Mech. Phys. Solids 58, 1552–1566 (2010)

Mecking, H., Kocks, U.F.: Kinetics of flow and strain-hardening. Acta Metall. 29, 1865–1875 (1981)

Gilbert, M.R., Queyreau, S., Marian, J.: Stress and temperature dependence of screw dislocation mobility in alpha-Fe by molecular dynamics. Phys. Rev. B 84, 174103 (2011)

Konobeev, Y.V., Dvoriashin, A.M., Porollo, S.I., et al.: Swelling and microstructure of pure Fe and Fe–Cr alloys after neutron irradiation to similar to 26 dpa at 400 degrees C. J. Nucl. Mater. 355, 124–130 (2006)

Oksiuta, Z., Olier, P., de Carlan, Y., et al.: Development and characterisation of a new ODS ferritic steel for fusion reactor application. J. Nucl. Mater. 393, 114–119 (2009)

de Carlan, Y., Bechade, J.L., Dubuisson, P., et al.: CEA developments of new ferritic ODS alloys for nuclear applications. J. Nucl. Mater. 386–88, 430–432 (2009)

Asgharzadeh, H., Kim, H.S., Simchi, A.: Microstructure, strengthening mechanisms and hot deformation behavior of an oxide-dispersion strengthened UFG Al6063 alloy. Mater. Charact. 75, 108–114 (2013)

Acknowledgments

The authors would like to thank the support provided by the Major State Basic Research Development Program of China (Grant 2011CB013101), and the National Natural Science Foundation of China (NSFC) (Grants 11225208 and 91226202). Duan acknowledges support from the key subject “Computational Solid Mechanics” of the China Academy of Engineering Physics. Chu acknowledges the support provided by the Shanghai Eastern-Scholar Plan and by the State Key Laboratory for Mechanical Behavior of Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, D., Xiao, X., Xue, J. et al. Mechanical properties of irradiated multi-phase polycrystalline BCC materials. Acta Mech Sin 31, 191–204 (2015). https://doi.org/10.1007/s10409-015-0447-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-015-0447-0