Abstract

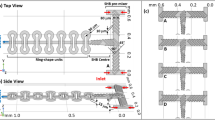

A planar split and merge (SAM) passive micromixer with labyrinthine microchannels is proposed to efficiently mix biomolecular solutions by combining several advantages of existing micromixer designs in one realization. First, to demonstrate the labyrinth-SAM micromixer advantages, it is compared with three passive micromixers of different geometries, i.e., a zigzag, a spiral, and a linear one, with respect to their mixing efficiency, by means of a computational study. The geometrical specifications are imposed from flexible printed circuit (FPC) technology which is used for their fabrication and the diffusion coefficient from the applications to be implemented, i.e., the mixing of biochemical reagents. The computations include the numerical solution of continuity, Navier–Stokes, and mass conservation equations in 3d. It is demonstrated that the labyrinth-SAM micromixer exhibits the highest mixing efficiency. Specifically, compared to a linear micromixer, which shows a mixing efficiency of 0.328, the spiral micromixer improves the mixing efficiency by 8 %, the zigzag by 11 %, and the SAM by 92 %; the diffusion coefficient of the biomolecules is 10−10 m2/s, the Reynolds number is 0.5, and the volume of each micromixer is 2.54 μl. Second, the proposed SAM micromixer is realized simply and inexpensively, with a small footprint, implementing FPC technology, commonly available in the production lines of printed circuit board manufacturers. Finally, its mixing efficiency is experimentally evaluated by means of fluorescence microscopy, while it is further validated for enzymatic digestion of DNA. The latter is achieved even within 30 s of sufficient mixing of DNA and enzyme solutions through the SAM. Despite the numerous works on micromixers, the labyrinth-SAM is a novel design of an efficient passive micromixer. The efficiency together with its simplicity, which is manifested by (a) the planar (and not complex three-dimensional) geometry, (b) the two-inlet, instead of multiple-inlet, configuration, (c) the small number of fabrication steps, and (d) the compatibility with mass production, makes the proposed micromixer a good candidate for integration in bioanalytical miniaturized platforms.

Similar content being viewed by others

References

Afzal A, Kim K-Y (2014) Three-objective optimization of a staggered herringbone micromixer. Sens Actuators B-Chem 192:350–360

Alam A, Kim K-Y (2012) Analysis of mixing in a curved microchannel with rectangular grooves. Chem Eng J 181–182:708–716

Ali Asgar SB, Erik TKP, Ian P (2007) A passive planar micromixer with obstructions for mixing at low Reynolds numbers. J Micromech Microeng 17:1017

Aracil C, Perdigones F, Moreno JM, Luque A, Quero JM (2015) Portable Lab-on-PCB platform for autonomous micromixing. Microelectron Eng 131:13–18

Bhopte S, Sammakia B, Murray B (2010) Numerical study of a novel passive micromixer design. In: 12th IEEE intersociety conference on thermal and thermomechanical phenomena in electronic systems (ITherm) Las Vegas, NV, 2–5 June 2010, pp 1–10

Capretto L, Cheng W, Hill M, Zhang X (2011) Micromixing within microfluidic devices. Top Curr Chem 304:27–68

Fu L-M, Lin C-H (2007) A rapid DNA digestion system. Biomed Microdevices 9:277–286

Fu LM, Fang WC, Hou HH, Wang YN, Hong TF (2014) Rapid vortex microfluidic mixer utilizing double-heart chamber. Chem Eng J 249:246–251

Gobby D, Angeli P, Gavriilidis A (2001) Mixing characteristics of T-type microfluidic mixers. J Micromech Microeng 11:126

Hessel V, Hardt S, Löwe H, Schönfeld F (2003) Laminar mixing in different interdigital micromixers: i. Experimental characterization. AIChE J 49:566–577

Imec (2013) Novel microfluidic material breakthrough for wafer-scale mass production of lab-on-chip. Phys.org. http://phys.org/news/2013-11-microfluidic-material-breakthrough-wafer-scale-mass.html. Accessed 29 Dec 2013

Jeon W, Shin CB (2009) Design and simulation of passive mixing in microfluidic systems with geometric variations. Chem Eng J 152:575–582

Jiang F, Drese KS, Hardt S, Küpper M, Schönfeld F (2004) Helical flows and chaotic mixing in curved micro channels. AIChE J 50:2297–2305

Kee SP, Gavriilidis A (2008) Design and characterisation of the staggered herringbone mixer. Chem Eng J 142:109–121

Kim J, Kim I, Paik K-W (2011) Investigation of various photo-patternable adhesive materials and their processing conditions for MEMS sensor wafer bonding. In: Electronic components and technology conference (ECTC), 2011 IEEE 61st, May 31 2011–June 3 2011, pp 1839–1846

Knight JB, Vishwanath A, Brody JP, Austin RH (1998) Hydrodynamic Focusing on a Silicon Chip: Mixing Nanoliters in Microseconds. Phys Rev Lett 80:3863–3866

Lee C-Y, Chang C-L, Wang Y-N, Fu L-M (2011) Microfluidic Mixing: A Review. Int J Mol Sci 12:3263–3287

Mansur EA, Ye M, Wang Y, Dai Y (2008) A state-of-the-art review of mixing in microfluidic mixers. Chin J Chem Eng 16:503–516

Moschou D et al (2013) Integrated biochip for PCR-based DNA amplification and detection on capacitive biosensors. In: SPIE (ed) Bio-MEMS and medical microdevices, Grenoble, France, May 28 2013. SPIE, p 87650L

Nguyen N-T (2008) Micromixers fundamentals, design and fabrication. Willian Andrew, Norwich

Ottino JM, Wiggins S (2004) Introduction: mixing in microfluidics. Philos Trans R Soc A 362:923–935

Papadopoulos VE et al (2014) A passive micromixer for enzymatic digestion of DNA. Microelectron Eng 124:42–46

Scherr T et al (2012) A planar microfluidic mixer based on logarithmic spirals. J Micromech Microeng 22:055019

Schönfeld F, Hardt S (2004) Simulation of helical flows in microchannels. AIChE J 50:771–778

Song H, Tice JD, Ismagilov RF (2003) A microfluidic system for controlling reaction networks in time. Angew Chem Int Edit 42:768–772

Stroock AD, Dertinger SK, Ajdari A, Mezic I, Stone HA, Whitesides GM (2002) Chaotic mixer for microchannels. Science 295:647–651

Sudarsan AP, Ugaz VM (2006) Fluid mixing in planar spiral microchannels. Lab Chip 6:74–82

Vladimir V, Mohammad N (2013) A novel generation of 3D SAR-based passive micromixer: efficient mixing and low pressure drop at a low Reynolds number. J Micromech Microeng 23:055023

Wang L, Liu D, Wang X, Han X (2012) Mixing enhancement of novel passive microfluidic mixers with cylindrical grooves. Chem Eng Sci 81:157–163

Wangler N et al (2011) High-resolution permanent photoresist laminate TMMF for sealed microfluidic structures in biological applications. J Micromech Microeng 21:095009

Wu A, Wang L, Jensen E, Mathies R, Boser B (2010) Modular integration of electronics and microfluidic systems using flexible printed circuit boards. Lab Chip 10:519–521

Yang J, Liu Y, Rauch CB, Stevens RL, Liu RH, Lenigk R, Grodzinski P (2002) High sensitivity PCR assay in plastic micro reactors. Lab Chip 2:179–187

Ying Li DZ, Feng Xiaojun, Youzhi Xu, Liu Bi-Feng (2012) A microsecond microfluidic mixer for characterizing fast biochemical reactions. Talanta 88:6

Acknowledgments

This work was partly supported by the GSRT projects “SYNERGASIA 2011-Converging Lamb wave sensors with microtechnologies towards an integrated Lab-on-chip for clinical diagnostics-LambSense” (11Syn_5_502) and “DoW-DNA on waves: an integrated diagnostic system” (LS7-276, program “Supporting post-doctoral researchers,” Ministry of Education, Lifelong Learning, and Religious Affairs); the source of funding is the European Social Fund (ESF)—European Union and National Resources. The fluorescence experiments were performed at the Immunoassays and Immunosensors Laboratory of the Institute of Nuclear and Radiological Sciences and Technology, Energy and Safety of NCSR “Demokritos”; the authors would like to thank Drs. P. S. Petrou and S. E. Kakabakos for their guidance on fluorescence measurements. The enzymatic digestion experiments were performed at the Biosensors Laboratory of the Dept. of Biology, Univ. Crete and IMBB-FORTH, Crete, and the authors are thankful to Prof. E. Gizeli for that. In addition, the authors would like to thank Dr. D. Moschou for useful discussions and Dr. D. Papageorgiou for his help on the fabrication of the chip holder.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kefala, I.N., Papadopoulos, V.E., Karpou, G. et al. A labyrinth split and merge micromixer for bioanalytical applications. Microfluid Nanofluid 19, 1047–1059 (2015). https://doi.org/10.1007/s10404-015-1610-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-015-1610-4