Abstract

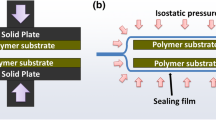

We present a room-temperature bonding technique which enables the sealing of micromolded water-swollen poly-2-hydroxy ethyl methacrylate (PHEMA)-based hydrogel modules to thermoplastic and elastomeric platforms. The core mechanism of the proposed method is to favor the formation of hydrogen bonds at the interface between the surface-reactive hydrated hydrogel components and the functionalized hydrophobic materials, by contacting the polymeric layers via a mild compression. Plasma oxygen and silanization processes using 3-amino-propyl trimethoxy silane have been optimized to generate surface hydroxyl functionalities on poly-methyl methacrylate (PMMA) and poly-dimethyl siloxane (PDMS) platforms which can react with the OH groups’ enriched surface of the microstructured PHEMA. The resulting microsystems can operate in a continuous perfusion mode while being soaked in water to keep the hydrogel hydrated. The method could also be applied to bond PHEMA thin layers (300 μm thick) to PMMA and PDMS microfluidic components. The sealing properties of the produced devices were demonstrated by liquid leakage tests and further validated by hydration–dehydration cycles of the systems and by monitoring methylene blue diffusion through the hydrogel matrix at the modules interface. The presented technique is suitable for cells-based hybrid materials microfluidic devices rapid prototyping.

Similar content being viewed by others

Abbreviations

- APS:

-

Ammonium persulfate

- APTES:

-

3-Amino-propyl trimethoxy silane

- EGDMA:

-

Ethylene glycol di-methacrylate

- LOC:

-

Lab on a chip

- PDMS:

-

Poly-dimethyl siloxane

- PHEMA:

-

Poly-hydroxyl ethyl methacrylate

- PMMA:

-

Poly-methyl methacrylate

- TEMED:

-

Tetramethyl ethylene diamine

- TMSPMA:

-

3-(Trimethoxysilyl)propyl methacrylates

References

Abraham S, Brahim S, Ishihara K, Guiseppi-Elie A (2005) Molecularly engineered p(HEMA)-based hydrogels for implant biochip biocompatibility. Biomaterials 26:4767–4778

Antia M, Herricks T, Rathod PK (2007) Microfluidic modeling of cell-cell interactions in malaria pathogenesis. PLoS Pathog 3:0939–0948

Barnes JM, Nauseef JT, Henry MD (2012) Resistance to fluid shear stress is a conserved biophysical property of malignant cells. PLoS ONE 7:1–12

Bruus H (2008) Hydraulic resistance and compliance. In: Theoretical microfluidics. Oxford University Press, New York, pp 71–88

Burdick JA, Vunjak-Novakovic G (2009) Engineered microenvironments for controlled stem cell differentiation. Tissue Eng A 15:205–219

Cha C, Antoniadou E, Lee M, Jeong JH, Ahmed WW, Saif TA, Boppart SA, Kong H (2013) Tailoring hydrogel adhesion to polydimethylsiloxane substrates using polysaccharide glue. Angew Chem Int Ed 52:6949–6952

Cheng SY, Heilman S, Wasserman M, Archer S, Shuler ML, Wu M (2007) A hydrogel-based microfluidic device for the studies of directed cell migration. Lab Chip 7:763–769

Chirila TV (2001) An overview of the development of artificial corneas with porous skirts and the use of PHEMA for such an application. Biomaterials 22:3311–3317

Chung BG, Lee KH, Khademhosseini A, Lee SH (2012) Microfluidic fabrication of microengineered hydrogels and their application in tissue engineering. Lab Chip 12:45–59

Cimetta E, Figallo E, Cannizzaro C, Elvassore N, Vunjak-Novakovic G (2009) Micro-bioreactor arrays for controlling cellular environments: design principles for human embryonic stem cell applications. Methods 47:81–89

Cimetta E, Sirabella D, Yeager K, Davidson K, Simon J, Moon RT, Vunjak-Novakovic G (2013) Microfluidic bioreactor for dynamic regulation of early mesodermal commitment in human pluripotent stem cells. Lab Chip 13:355–364

Cushing MC, Anseth KS (2007) Hydrogel cell cultures. Science 316:1133–1134

Deligkaris K, Tadele TS, Olthuis W, van den Berg A (2010) Hydrogel-based devices for biomedical applications. Sens Actuators B: Chem 147:765–774

Gan Z, Zhang L, Chen G (2011) Solvent bonding of poly(methyl methacrylate) microfluidic chip using phase-changing agar hydrogel as a sacrificial layer. Electrophoresis 32:3319–3323

Greiner AM, Hoffmann P, Bruellhoff K, Jungbauer S, Spatz JP, Moeller M, Kemkemer R, Groll J (2014) Stable biochemically micro-patterned hydrogel layers control specific cell adhesion and allow long term cyclic tensile strain experiments. Macromol Biosci 14:1547–1555

Guiseppi-Elie A, Dong C, Dinu CZ (2012) Crosslink density of a biomimetic poly(HEMA)-based hydrogel influences growth and proliferation of attachment dependent RMS 13 cells. J Mater Chem 22:19529–19539

Gupta K, Kim D-H, Ellison D, Smith C, Kundu A, Tuan J, Suh K-Y, Levchenko A (2010) Lab-on-a-chip devices as an emerging platform for stem cell biology. Lab Chip 10:2019–2031

Hawkes JJ, Barber RW, Emerson DR, Coakley WT (2004) Continuous cell washing and mixing driven by an ultrasound standing wave within a microfluidic channel. Lab Chip 4:446–452

Hegemann D, Brunner H, Oehr C (2003) Plasma treatment of polymers for surface and adhesion improvement. Nucl Instrum Methods Phys Res B 208:281–286

Hong W, Liu Z, Suo Z (2009) Inhomogeneous swelling of a gel in equilibrium with a solvent and mechanical load. Int J Solids Struct 46:3282–3289

Hung PJ, Lee PJ, Sabounchi P, Lin R, Lee LP (2005) Continuous perfusion microfluidic cell culture array for high-throughput cell-based assays. Biotechnol Bioeng 89:1–8

Johnson-Chavarria EM, Agrawal U, Tanyeri M, Kuhlman TE, Schroeder CM (2014) Automated single cell microbioreactor for monitoring intracellular dynamics and cell growth in free solution. Lab Chip 14:2688–2697

Kejlová K, Labský J, Jírová D, Bendová H (2005) Hydrophilic polymers–biocompatibility testing in vitro. Toxicol In Vitro 19:957–962

Kermis HR, Rao G, Barbari TA (2003) Transport properties of pHEMA membranes for optical glucose affinity sensors. J Membr Sci 212:75–86

Khademhosseini A, Langer R (2007) Microengineered hydrogels for tissue engineering. Biomaterial 28:5087–5092

Kim J, Surapaneni R, Gale BK (2009) Rapid prototyping of microfluidic systems using a PDMS/polymer tape composite. Lab Chip 9:1290–1293

Kwang WO, Lee K, Ahna B, Furlanib EP (2012) Design of pressure-driven microfluidic networks using electric circuit analogy. Lab Chip 12:515–545

Lai S, Cao X, Lee LJ (2004) A packaging technique for polymer microfluidic platforms. Anal Chem 76:1175–1183

Lee NY, Chung BH (2009) Novel poly(dimethylsiloxane) bonding strategy via room temperature “chemical gluing”. Langmuir 25:3861–3866

Lee HL, Boccazzi P, Ram RJ, Sinskey AJ (2006) Microbioreactor arrays with integrated mixers and fluid injectors for high-throughput experimentation with pH and dissolved oxygen control. Lab Chip 6:1229–1235

Lin C-C, Metters AT (2006) Hydrogels in controlled release formulations: network design and mathematical modeling. Adv Drug Deliv Rev 58:1379–1408

Lutolf MP, Raeber GP, Zisch AH, Tirelli N, Hubbell JA (2003) Cell-responsive synthetic hydrogels. Adv Mater 15:888–892

Makamba H, Kim JH, Lim K, Park N, Hahn JH (2003) Surface modification of poly(dimethylsiloxane) microchannels. Electrophoresis 24:3607–3619

Marcombe R, Cai S, Hong W, Zhao X, Lapusta Y, Suo Z (2010) A theory of constrained swelling of a pH-sensitive hydrogel. Soft Matter 6:784–793

Merrett K, Griffith CM, Deslandes Y, Pleizier G, Sheardown H (2001) Adhesion of corneal epithelial cells to cell adhesion peptide modified pHEMA surfaces. J Biomater Sci Polym Ed 12:647–671

Petersson F, Åberg L, Swärd-Nilsson AM, Laurell T (2007) Free flow acoustophoresis: microfluidic-based mode of particle and cell separation. Anal Chem 79:5117–5123

Ren K, Zhou J, Wu H (2013) Materials for microfluidic chip fabrication. Acc Chem Res 46:2396–2406

Setsuhara Y, Cho K, Takenaka K, Shiratani M, Sekine M, Hori M, Ikenaga E, Zaima S (2010) Low-damage surface modification of polymethylmethacrylate with argon oxygen mixture plasmas driven by multiple low-inductance antenna units. Thin Solid Films 518:3561–3565

Shin H, Zygourakis K, Farach-Carson MC, Yaszemski MJ, Mikos AG (2004) Attachment, proliferation, and migration of marrow stromal osteoblasts cultured on biomimetic hydrogels modified with an osteopontin-derived peptide. Biomaterials 25:895–906

Sunkara V, Park DK, Hwang H, Chantiwas R, Soper SA, Cho YK (2011) Simple room temperature bonding of thermoplastics and poly(dimethylsiloxane). Lab Chip 11:962–965

Tang L, Lee NY (2010) A facile route for irreversible bonding of plastic-PDMS hybrid microdevices at room temperature. Lab Chip 10:1274–1280

Tennico YH, Koesdjojo MT, Kondo S, Mandrell DT, Remcho VT (2010) Surface modification-assisted bonding of polymer-based microfluidic devices. Sens Actuators B 143:799–804

Tong Z, Liu X (1994) Swelling equilibria and volume phase transition in hydrogels with strongly dissociating electrolytes. Macromolecules 27:844–848

Tsougeni K, Tserepi A, Constantoudis V, Gogolides E, Petrou PS, Kakabakos SE (2010) Plasma nanotextured PMMA surfaces for protein arrays: increased protein binding and enhanced detection sensitivity. Langmuir 26:13883–13891

Vlachopoulou M-E, Tserepi A, Pavli P, Argitis P, Sanopoulou M, Misiakos K (2009) A low temperature surface modification assisted method for bonding plastic substrates. J Micromech Microeng 19:015007–015013

Wong I, Ho CM (2009) Surface molecular property modifications for poly(dimethylsiloxane) (PDMS) based microfluidic devices. Microfluid Nanofluidics 7:291–306

Yeo Y, Geng W, Ito T, Kohane DS, Burdick JA, Radisic M (2007) Photocrosslinkable hydrogel for myocyte cell culture and injection. J Biomed Mater Res B Appl Biomater 81B:312–322

Yoon J, Cai S, Suo Z, Hayward RC (2010) Poroelastic swelling kinetics of thin hydrogel layers: comparison of theory and experiment. Soft Matter 6:6004–6012

Yu W, Qu H, Hu G, Zhang Q, Song K, Guan H, Liu T, Qin J (2014) A microfluidic-based multi-shear device for investigating the effects of low fluid-induced stresses on osteoblasts. PLoS ONE 9:1–7

Zhang H, Bian C, Jackson JK, Khademolhosseini F, Burt HM, Chiao M (2014) Fabrication of robust hydrogel coatings on polydimethylsiloxane substrates using micropillar anchor structures with chemical surface modification. ACS Appl Mater Interfaces 6:9126–9133

Zhao W, Lenardi C, Webb P, Liu C, Santaniello T, Gassa F (2013) A methodology to analyse and simulate mechanical characteristics of poly (2-hydroxyethyl methacrylate) hydrogel. Polym Int 62:1059–1067

Acknowledgments

This work has been supported by Fondazione CARIPLO for the project ‘Hybrid Multifunctional Microdevices to Probe Cell Biology’, under the Program ‘Promuovere progetti internazionali finalizzati al reclutamento di giovani ricercatori’.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Tommaso Santaniello and Yunsong Yan have equally contributed to this work.

Rights and permissions

About this article

Cite this article

Santaniello, T., Yan, Y., Tocchio, A. et al. A room-temperature bonding technique for the packaging of hydrogel-based hybrid microfluidic devices. Microfluid Nanofluid 19, 31–41 (2015). https://doi.org/10.1007/s10404-015-1544-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-015-1544-x