Abstract

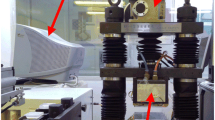

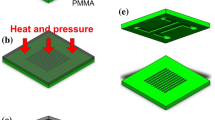

An oxygen plasma-assisted thermal bonding technique is demonstrated for sealing a two-dimensional (2D) polymer-based nanofluidic device. A polymethyl methacrylate (PMMA) substrate with 2D nanochannels and polyethylene terephthalate (PET) cover plate with microchannels was treated with optimized oxygen plasma parameters: chamber pressure of 1 mbar, power of 30 W and time of 2 min. The effective bonding area and bonding strength were significantly improved under the optimized bonding temperature of 70 °C, pressure of 0.5 MPa and time of 10 min. Nanoindentation experiments showed that oxygen plasma treatment did not change the PET or the PMMA modulus, which provides a novel sampling method to observe the profile structures of the deformation of 2D nanochannels by scanning electron microscope. The 2D PMMA–PET nanofluidic device with 89 (±2) nm wide and 84 (±2) nm deep nanochannels was successfully bonded under optimized process parameters. The total dimension loss of the 2D nanochannels was estimated to be 2 (±4) nm in width and 12 (±4) nm in depth. The deformation loss in depth is mainly attributed to sagging of the PET cover plate (10 nm) during the thermal bonding process. Experiments with Rhodamine B solution showed good sealing properties of the polymer-based 2D nanofluidic device without leakages and clogging. This bonding process provides a high potential technique for fabrication of 2D polymer-based nanofluidic device with low deformation loss, low cost and high throughput.

Similar content being viewed by others

References

Abgrall P, Low LN, Nguyen NT (2007) Fabrication of planar nanofluidic channels in a thermoplastic by hot-embossing and thermal bonding. Lab Chip 7:520–522. doi:10.1039/b616134k

Becker H, Gartner C (2000) Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis 21:12–26. doi:10.1002/(SICI)1522-2683(20000101)21:1<12:AID-ELPS12>3.3.CO;2-Z

Brown L, Koerner T, Horton JH, Oleschuk RD (2006) Fabrication and characterization of poly(methylmethacrylate) microfluidic devices bonded using surface modifications and solvents. Lab Chip 6:66–73. doi:10.1039/b512179e

Cao H, Yu Z, Wang J, Tegenfeldt JO, Austin RH, Chen E, Wu W, Chou SY (2002) Fabrication of 10 nm enclosed nanofluidic channels. Appl Phys Lett 81:174–176. doi:10.1063/1.1489102

Chantiwas R, Hupert ML, Pullagurla SR, Balamurugan S, Tamarit-Lopez J, Park S, Datta P, Goettert J, Cho YK, Soper SA (2010) Simple replication methods for producing nanoslits in thermoplastics and the transport dynamics of double-stranded DNA through these slits. Lab Chip 10:3255–3264. doi:10.1039/c0lc00096e

Chantiwas R, Park S, Soper SA, Kim BC, Takayama S, Sunkara V, Hwang H, Cho YK (2011) Flexible fabrication and applications of polymer nanochannels and nanoslits. Chem Soc Rev 40:3677–3702. doi:10.1039/c0cs00138d

Chen ZF, Gao YH, Su RG, Li CW, Lin JM (2003) Fabrication and characterization of poly(methyl methacrylate) microchannels by in situ polymerization with a novel metal template. Electrophoresis 24:3246–3252. doi:10.1002/elps.200305534

Cheng E, Zou H, Yin Z, Jurčíček P, Zhang X (2013) Fabrication of 2D polymer nanochannels by sidewall lithography and hot embossing. J Micromech Microeng 23:075022. doi:10.1088/0960-1317/23/7/075022

Cheng E, Yin Z, Zou H, Jurčíček P (2014) Experimental and numerical study on deformation behavior of polyethylene terephthalate two-dimensional nanochannels during hot embossing process. J Micromech Microeng 24:015004. doi:10.1088/0960-1317/24/1/015004

Chou SY, Krauss PR, Renstrom PJ (1995) Imprint of sub-25 nm vias and trenches in polymers. Appl Phys Lett 67:3114–3116. doi:10.1063/1.114851

Chou HP, Spence C, Scherer A, Quake S (1999) A microfabricated device for sizing and sorting DNA molecules. Proc Natl Acad Sci USA 96:11–13

Daiguji H (2010) Ion transport in nanofluidic channels. Chem Soc Rev 39:901–911. doi:10.1039/b820556f

Gu J, Gupta R, Chou CF, Wei Q, Zenhausern F (2007) A simple polysilsesquioxane sealing of nanofluidic channels below 10 nm at room temperature. Lab Chip 7:1198–1201. doi:10.1039/b704851c

He Q, Chen S, Su Y, Fang Q, Chen H (2008) Fabrication of 1D nanofluidic channels on glass substrate by wet etching and room-temperature bonding. Anal Chim Acta 628:1–8. doi:10.1016/j.aca.2008.08.040

Karnik R, Fan R, Yue M, Li D, Yang PD, Majumdar A (2005) Electrostatic control of ions and molecules in nanofluidic transistors. Nano Lett 5:943–948. doi:10.1021/nl050493b

Karnik R, Duan C, Castelino K, Daiguji H, Majumdar A (2007) Rectification of ionic current in a nanofluidic diode. Nano Lett 7:547–551. doi:10.1021/nl062806o

Kim SJ, Song YA, Han J (2010) Nanofluidic concentration devices for biomolecules utilizing ion concentration polarization: theory, fabrication, and applications. Chem Soc Rev 39:912–922. doi:10.1039/b822556g

Mao P, Han JY (2005) Fabrication and characterization of 20 nm planar nanofluidic channels by glass–glass and glass–silicon bonding. Lab Chip 5:837–844. doi:10.1039/b502809d

Ng SH, Tjeung RT, Wang ZF, Lu ACW, Rodriguez I, de Rooij NF (2008) Thermally activated solvent bonding of polymers. Microsyst Technol 14:753–759. doi:10.1007/s00542-007-0459-1

Pisignano D, D’Amone S, Gigli G, Cingolani R (2004) Rigid organic molds for nanoimprint lithography by replica molding of high glass transition temperature polymers. J Vac Sci Technol, B 22:1759–1763. doi:10.1116/1.1767108

Scheer HC, Bogdanski N, Wissen M, Konishi T, Hirai Y (2005) Polymer time constants during low temperature nanoimprint lithography. J Vac Sci Technol B 23:2963–2966. doi:10.1116/1.2121727

Schift H (2008) Nanoimprint lithography: an old story in modern times? A review. J Vac Sci Technol B 26:458–480. doi:10.1116/1.2890972

Schoch RB, Han J, Renaud P (2008) Transport phenomena in nanofluidics. Rev Mod Phys 80:839–883. doi:10.1103/RevModPhys.80.839

Shao PE, van Kan A, Wang LP, Ansari K, Bettiol AA, Watt F (2006) Fabrication of enclosed nanochannels in poly(methylmethacrylate) using proton beam writing and thermal bonding. Appl Phys Lett 88:093515. doi:10.1063/1.2181631

Sun Y, Kwok YC, Nguyen NT (2006) Low-pressure, high-temperature thermal bonding of polymeric microfluidic devices and their applications for electrophoretic separation. J Micromech Microeng 16:1681–1688. doi:10.1088/0960-1317/16/8/033

Tsao CW, DeVoe DL (2009) Bonding of thermoplastic polymer microfluidics. Microfluid Nanofluid 6:1–16. doi:10.1007/s10404-008-0361-x

Tsukahara T, Mawatari K, Hibara A, Kitamori T (2008) Development of a pressure-driven nanofluidic control system and its application to an enzymatic reaction. Anal Bioanal Chem 391:2745–2752. doi:10.1007/s00216-008-2198-2

Umbrecht F, Mueller D, Gattiker F, Boutry CM, Neuenschwander J, Sennhauser U, Hierold C (2009) Solvent assisted bonding of polymethylmethacrylate: characterization using the response surface methodology. Sens Actuator A Phys 156:121–128. doi:10.1016/j.sna.2009.03.028

Ussing T, Petersen LV, Nielsen CB, Helbo B, Hojsle L (2007) Micro laser welding of polymer microstructures using low power laser diodes. Int J Adv Manuf Technol 33:198–205. doi:10.1007/s00170-007-0969-0

Wang XD, Jin J, Li X, Li XJ, Ou Y, Tang QS, Fu SJ, Gao FH (2011) Low-pressure thermal bonding. Microelectron Eng 88:2427–2430. doi:10.1016/j.mee.2011.01.022

Xie Q, Zhou Q, Xie F, Sang J, Wang W, Zhang HA, Wu W, Li Z (2012) Wafer-scale fabrication of high-aspect ratio nanochannels based on edge-lithography technique. Biomicrofluidics 6:016502. doi:10.1063/1.3683164

Acknowledgments

This project is supported by National Natural Science Foundation of China (No. 91023046, No. 51075059) and Specialized Research Fund for the Doctoral Program of Higher Education of China (SRFDP).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, E., Yin, Z., Zou, H. et al. Surface modification-assisted bonding of 2D polymer-based nanofluidic devices. Microfluid Nanofluid 18, 527–535 (2015). https://doi.org/10.1007/s10404-014-1451-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-014-1451-6