Abstract

A precise tangential contact damping model is proposed, which includes the lateral contact of the upper–lower asperities and the interaction of adjacent asperities. The effects of the normal static preload, frequency, and amplitude of tangential displacement on the tangential contact damping were analyzed by simulation, respectively. Furthermore, the results of simulation are verified by experiment. The tangential contact damping of considering the interaction and lateral contact of asperity is very close to the experimental results.

Similar content being viewed by others

Abbreviations

- \(F_i \) :

-

Normal static force on asperity

- \(Q_i \) :

-

Tangential dynamic force on asperity

- z :

-

Asperity height from the mean height for asperities to the asperity top

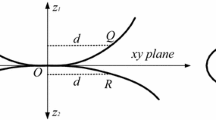

- d :

-

The distance between the smooth rigid plane and the mean height of the asperities

- h :

-

The distance between the smooth rigid flat and the mean height of the rough surface

- \(y_\mathrm{s} \) :

-

The gap between the mean surface height and the mean asperity height

- R :

-

Equivalent radius of asperity

- \(R_1, R_2 \) :

-

Mean asperity radii on the upper and lower rough surfaces, respectively

- \(\xi \) :

-

Tangential displacement

- \(\sigma \) :

-

The mean square deviation of the equivalent rough surface

- \(\sigma _z \) :

-

The standard height deviation of asperity

- \(\beta \) :

-

The topographic characteristics of the rough surface

- \(\eta \) :

-

The density of asperities per unit area

- \(P_n \) :

-

A uniform pressure

- \(A_\mathrm{l} \) :

-

The territory of the local deformation

- 2a :

-

A square shape with length

- \(\delta \) :

-

Total deformation of an asperity

- \(\delta _s \) :

-

The deformation by contacting

- \(\delta _g \) :

-

The deformation by interaction

- E :

-

Equivalent Young’s modulus

- \(E_1, E_2 \) :

-

Young’s moduli of upper and lower rough surfaces, respectively

- \(\nu _1, \nu _2 \) :

-

Poisson’s ratios of upper and lower rough surfaces, respectively

- G :

-

Equivalent shear modulus

- \(\delta _\mathrm{c} \) :

-

The critical deformation that marks the transition from the elastic to the elastic-perfectly plastic deformation regime

- \(F_{ic}\) :

-

Critical force

- \(S_\mathrm{y}\) :

-

Yield strength

- L :

-

Hardness factor

- B :

-

The material dependent exponent

- \(e_\mathrm{y}\) :

-

The yield strength to elastic modulus ratio

- \(H_\mathrm{G}\) :

-

Geometrical hardness limit

- \(r_{i(j)}^*\) :

-

The radius of the contact area in the elastic and elastic-plastic stages

- \(\xi _c^*\) :

-

The dimensionless critical displacement that causes initial gross sliding

- \(\mu \) :

-

Friction coefficient

- \(F_n\) :

-

Normal static force

- \(F_\tau \) :

-

Tangential dynamic force

- \(n\hbox {o}\tau \) :

-

Global coordinate system

- \(n^{\prime }\hbox {o}^{\prime }{\tau }^{\prime }\) :

-

Local coordinate system

- \(\theta \) :

-

The contact angle between two lateral contacting asperities

- \(Q_{in}\) :

-

Normal component split by the tangential force

- \(Q_{i\tau }\) :

-

Tangential component split by the tangential force

- \(F_{in}\) :

-

Normal component split by the normal force

- \(F_{i\tau }\) :

-

Tangential component split by the normal force

- \(E_{i(j)}^*\) :

-

Energy dissipation of a pair of contacting asperities during one cycle

- A :

-

Nominal contact area

- \(n_z \) :

-

The number of contacting asperity

- m :

-

Related to a number of cycles the contact has undergone.

- n :

-

The number of the lateral contact asperities

- \(C^{{*}}\) :

-

Equivalent viscous damping

- \(\omega ^{*}\) :

-

The dimensionless angular frequency

- \(\xi _m^*\) :

-

The dimensionless amplitude of tangential displacement

- f :

-

The dynamic tangential force

- \(m_{1}\) :

-

The mass of the middle test piece

- \(K_{\tau }\) :

-

Interfacial tangential stiffness

- \(C_{\tau }\) :

-

Interfacial tangential damping

- \(x_{1}, sx_{2}\) :

-

Displacements of the left and right test pieces, respectively

- \({\ddot{x}}_1\) :

-

Acceleration

- \(x_\tau \) :

-

Relative displacement of interface

- \(f_\tau \) :

-

Tangential dynamic force

- \(F_\tau \) :

-

The amplitude of the dynamic tangential force

- \(\omega \) :

-

Angular frequency

- t :

-

Time

References

Burdekin M, Back N, Cowley A. Analysis of the local deformations in machine joints. Arch J Mech Eng Sci 1959–1982 (vol 1–23), 1979; 21(1):25–32.

Ibrahim RA, Pettit CL. Uncertainties and dynamic problems of bolted joints and other fasteners. J Sound Vib. 2005;279(3):857–936.

Gorbatikh L, Popova M. Modeling of a locking mechanism between two rough surfaces under cyclic loading. Int J Mech Sci. 2006;48(9):1014–20.

Zhao B, Zhang S, Qiu Z. Analytical asperity interaction model and numerical model of multi-asperity contact for power hardening materials. Tribol Int. 2015;92:57–66.

Ciavarella M, Greenwood JA, Paggi M. Inclusion of “interaction” in the Greenwood and Williamson contact theory. Wear. 2008;265(5–6):729–34.

Chandrasekar S, Eriten M, Polycarpou AA. An improved model of asperity interaction in normal contact of rough surfaces. J Appl Mech. 2013;80(1):1025.

Jeng YR, Peng SR. Elastic-plastic contact behavior considering asperity interactions for surfaces with various height distributions. J Tribol. 2006;128(2):665–97.

Chang WR, Etsion I, Bogy DB. An elastic-plastic model for the contact of rough surfaces. J Tribol. 1987;109(2):257–63.

Abdo J, Farhang K. Elastic-plastic contact model for rough surfaces based on plastic asperity concept. Int J Nonlin Mech. 2005;40(4):495–506.

Etsion I. A static friction model for elastic-plastic contacting rough. J Tribol. 2004;126(1):34–40.

Li L, Etsion I, Talke FE. Contact area and static friction of rough surfaces with high plasticity index. J Tribol. 2010;132(3):031401

You JM, Chen TN. Statistical model for normal and tangential contact parameters of rough surfaces. Arch Proc Inst Mech Eng Part C J Mech Eng Sci 1989–1996 (vols 203–210), 2011; 1(1):1–15.

Kogut L, Etsion I. A finite element based elastic-plastic model for the contact of rough surfaces. Modell Simul Eng. 2011;3:383–90.

Kadin Y, Kligerman Y, Etsion I. Unloading an elastic-plastic contact of rough surfaces. J Mech Phys Solids. 2006;54(12):2652–74.

Jackson RL, Green I. A statistical model of elasto-plastic asperity contact between rough surfaces. Tribol Int. 2006;39(9):906–14.

Jackson RL, Green I. A finite element study of elastoplastic hemispherical contact against a rigid flat. J Tribol. 2005;127(2):343–54.

Jäger J. Axi-symmetric bodies of equal material in contact under torsion or shift. Arch Appl Mech. 1995;65(7):478–87.

Sepehri A, Farhang K. Closed-form equations for three dimensional elastic-plastic contact of nominally flat rough surfaces. J Tribol. 2009;131(4):041402.

Zhao Y, Chang L. A model of asperity interactions in elastic-plastic contact of rough surfaces. J Tribol. 2001;123(4):857.

Zhao Y, Maietta DM, Chang L. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J Tribol. 2000;122(1):86–93.

de Saint-Venant B. Memoire sur la torsion des prismes. Memoire sur la flexion des prismes. Übersetzung aus dem Französischen von A. A. Parijskij. Unter Redaktion und mit einem einleitenden Artikel von G. Yu. Dzhanelidze 2017.

Love AEH. The stress produced in a semi-infinite solid by pressure on part of the boundary. Philos Trans R Soc London. 1929;228(659–669):377–420.

Cattaneo C. Sul contatto di due corpi elastici: distribuzione locale degli sforzi. I, II, III, 1938;27.

Mindlin RD, Deresiewicz H. Elastic spheres in contact under varying oblique forces. J Appl Mech. 1953;20(3):327–44.

Brizmer V, Kligerman Y, Etsion I. Elastic–plastic spherical contact under combined normal and tangential loading in full stick. Tribol Lett. 2007;25(1):61–70.

Bryant MD, Keer LM. Rough contact between elastically and geometrically identical curved bodies. J Appl Mech. 1982;49(2):345–52.

Eriten M, Polycarpou AA, Bergman LA. Physics-based modeling for fretting behavior of nominally flat rough surfaces. Int J Solids Struct. 2011;48(10):1436–50.

Fujimoto T, Kagami J, Kawaguchi T, Hatazawa T. Micro-displacement characteristics under tangential force. Wear. 2000;241(2):136–42.

Jackson RL, Green I, Dan BM. Predicting the coefficient of restitution of impacting elastic-perfectly plastic spheres. Nonlin Dyn. 2010;60(3):217–29.

Greenwood JA, Williamson JBP. Contact of nominally flat surfaces. Proc R Soc London. 1966;295(1442):300–19.

Greenwood JA, Tripp JH. The contact of two nominally flat rough surfaces. Arch Proc Inst Mech Eng 1847–1982 (vols 1–196); 185(1970):625–634.

Nayak PR. Random process model of rough surfaces. J Lubr Technol. 1971;93(3):398.

Nayak PR. Random process model of rough surfaces in plastic contact. Wear. 1973;26(3):305–33.

Mccool JI. Predicting microfracture in ceramics via a microcontact model. J Tribol. 1986;108(3):380–6.

Fu WP, Huang YM, Zhang XL, Guo Q. Experimental investigation of dynamic normal characteristics of machined joint surfaces. J Vib Acoust. 2000;122(4):393–8.

Thomson WT. Theory of vibration with applications, 3rd edn. 1996;19(1):15–27.

Acknowledgements

This research was supported by National Natural Science Foundation of China under Grant Nos. 51275407, 51475363. The authors gratefully acknowledge financial support provided by NNSF.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, W.P., Gao, Z.Q., Wang, W. et al. A Model of Tangential Contact Damping Considering Asperity Interaction and Lateral Contact. Acta Mech. Solida Sin. 31, 758–774 (2018). https://doi.org/10.1007/s10338-018-0050-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-018-0050-6