Abstract

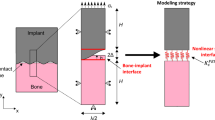

Cementless implants are widely used in orthopedic and dental surgery. However, debonding-related failure still occurs at the bone–implant interface. It remains difficult to predict such implant failure since the underlying osseointegration phenomena are still poorly understood. Especially in terms of friction and adhesion at the macroscale, there is a lack of data and reliable models. The aim of this work was to present a new friction formulation that can model the tangential contact behavior between osseointegrated implants and bone tissue, with focus on debonding. The classical Coulomb’s law is combined with a state variable friction law to model a displacement-dependent friction coefficient. A smooth state function, based on the sliding distance, is used to model implant debonding. The formulation is implemented in a 3D nonlinear finite element framework, and it is calibrated with experimental data and compared to an analytical model for mode III cleavage of a coin-shaped, titanium implant (Mathieu et al. in J Mech Behav Biomed Mater 8(1):194–203, 2012). Overall, the results show a close agreement with the experimental data, especially the peak and the softening part of the torque curve with a relative error of less than 2.25%. In addition, better estimates of the bone’s shear modulus and the adhesion energy are obtained. The proposed model is particularly suitable to account for partial osseointegration.

Similar content being viewed by others

Notes

In principle, \(\phi _{0}\) follows from an evolution law that describes the healing/osseointegration process (\(\phi _{0}\) increasing from 0 to 1). However, this is not considered here. Here, only the (further) evolution of \(\phi\) during debonding (\(\phi\) decreasing from 1 to 0) is studied.

(R2018b, The MathWorks, Natick, MA, USA).

The strain energy inside the bodies, which generally should also be accounted for, is negligible in this case.

References

Albrektsson T, Brånemark P, Hansson H, Lindström J (1981) Osseointegrated titanium implants: requirements for ensuring a long-lasting, direct bone-to-implant anchorage in man. Acta Orthop Scand 52(2):155–170

Berahmani S, Janssen D, van Kessel S, Wolfson D, de Waal Malefijt M, Buma P, Verdonschot N (2015) An experimental study to investigate biomechanical aspects of the initial stability of press-fit implants. J Mech Behav Biomed Mater 42:177–185

Biemond JE, Aquarius R, Verdonschot N, Buma P (2011) Frictional and bone ingrowth properties of engineered surface topographies produced by electron beam technology. Arch Orthop Trauma Surg 131(5):711–718

Bishop NE, Höhn J-C, Rothstock S, Damm NB, Morlock MM (2014) The influence of bone damage on press-fit mechanics. J Biomech 47(6):1472–1478

Borden MJ, Scott MA, Evans JA, Hughes TJR (2011) Isogeometric finite element data structures based on Bezier extraction of NURBS. Int J Numer Methods Eng 85(1):15–47

Bragdon C, Burke D, Lowenstein J, O’Connor D, Ramamurti B, Jasty M, Harris W (1996) Differences in stiffness of the interface between a cementless porous implant and cancellous bone in vivo in dogs due to varying amounts of implant motion. J Arthroplasty 11(8):945–951

Brånemark R, Ohrnell LO, Nilsson P, Thomsen P (1997) Biomechanical characterization of osseointegrazion during healing: an experimental in vitro study in the rat. Biomaterials 18:969–978

Brånemark R, Öhrnell L-O, Skalak R, Carlsson L, Brånemark P-I (1998) Biomechanical characterization of osseointegration: an experimental in vivo investigation in the beagle dog. J Orthop Res 16(1):61–69

Castellani C, Lindtner RA, Hausbrandt P, Tschegg E, Stanzl-Tschegg SE, Zanoni G, Beck S, Weinberg A-M (2011) Bone–implant interface strength and osseointegration: biodegradable magnesium alloy versus standard titanium control. Acta Biomater 7(1):432–440

Chateauminois A, Fretigny C, Olanier L (2010) Friction and shear fracture of an adhesive contact under torsion. Phys Rev E 81(2):026106

Chong D, Hansen U, Amis A (2010) Analysis of bone–prosthesis interface micromotion for cementless tibial prosthesis fixation and the influence of loading conditions. J Biomech 43(6):1074–1080

Corbett CJ, Sauer RA (2014) NURBS-enriched contact finite elements. Comput Methods Appl Mech Eng 275:55–75

Corbett CJ, Sauer RA (2015) Three-dimensional isogeometrically enriched finite elements for frictional contact and mixed-mode debonding. Comput Methods Appl Mech Eng 284:781–806

Damm N, Morlock M, Bishop N (2015) Friction coefficient and effective interference at the implant–bone interface. J Biomech 48(12):3517–3521

Dammak M, Shirazi-Adl A, Zukor D (1997) Analysis of cementless implants using interface nonlinear friction-experimental and finite element studies. J Biomech 30(2):121–129

Dieterich JH (1978) Time-dependent friction and the mechanics of stick-slip. In: Byerlee JD, Wyss M (eds) Rock friction and earthquake prediction. Contributions to Current Research in Geophysics (CCRG), vol 6. Birkhäuser, Basel, pp 790–806

Dieterich JH (1979) Modeling of rock friction: 1. Experimental results and constitutive equations. J Geophys Res Solid Earth 84(B5):2161–2168

Duong TX, Sauer RA (2019) A concise frictional contact formulation based on surface potentials and isogeometric discretization. Comput Mech 64(4):951–970

Fitzpatrick C, Hemelaar P, Taylor M (2014) Computationally efficient prediction of bone–implant interface micromotion of a cementless tibial tray during gait. J Biomech 47(7):1718–1726

Gao X, Fraulob M, Haiat G (2019) Biomechanical behaviours of the bone–implant interface: a review. J R Soc Interface 16(156):20190259

Ghosh R, Gupta S (2014) Bone remodelling around cementless composite acetabular components: the effects of implant geometry and implant–bone interfacial conditions. J Mech Behav Biomed Mater 32:257–269

Grant JA, Bishop NE, Götzen N, Sprecher C, Honl M, Morlock MM (2007) Artificial composite bone as a model of human trabecular bone: the implant–bone interface. J Bomech 40(5):1158–1164

Haïat G, Wang H-L, Brunski J (2014) Effects of biomechanical properties of the bone–implant interface on dental implant stability: from in silico approaches to the patient’s mouth. Annu Rev Biomed Eng 16:187–213

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194(1):4135–4195

Jasty M, Bragdon C, Burke D, O’connor D, Lowenstein J, Harris W (1997) In vivo skeletal responses to porous-surfaced implants subjected to small induced motions. J Bone Joint Surg 79(5):707-14

Kim S-H, Cho J-H, Chung K-R, Kook Y-A, Nelson G (2008) Removal torque values of surface-treated mini-implants after loading. Am J Orthod Dentofac Orthop 134(1):36–43

Laursen TA (2013) Computational contact and impact mechanics: fundamentals of modeling interfacial phenomena in nonlinear finite element analysis. Springer, Berlin

Laursen TA, Simo JC (1993) A continuum-based finite element formulation for the implicit solution of multibody, large deformation frictional contact problems. Int J Numer Meth Eng 36(1):3451–3485

Marin C, Granato R, Suzuki M, Janal MN et al (2010) Biomechanical and histomorphometric analysis of etched and non-etched resorbable blasting media processed implant surfaces: an experimental study in dogs. J Mech Behav Biomed Mater 3(5):382–391

Mathieu V, Anagnostou F, Soffer E, Haïat G (2011a) Ultrasonic evaluation of dental implant biomechanical stability: an in vitro study. Ultrasound Med Biol 37(2):262–270

Mathieu V, Anagnostou F, Soffer E, Haïat G (2011b) Numerical simulation of ultrasonic wave propagation for the evaluation of dental implant biomechanical stability. J Acoust Soc Am 129(6):4062–4072

Mathieu V, Vayron R, Barthel E, Dalmas D, Soffer E, Anagnostou F, Haïat G (2012) Mode III cleavage of a coin-shaped titanium implant in bone: effect of friction and crack propagation. J Mech Behav Biomed Mater 8(1):194–203

Mathieu V, Vayron R, Richard G, Lambert G, Naili S, Meningaud J, Haïat G (2014) Biomechanical determinants of the stability of dental implants: Influence of the bone-implant interface properties. J Biomech 47(1):3–13

Mergel JC, Sahli R, Scheibert J, Sauer RA (2019) Continuum contact models for coupled adhesion and friction. J Adhes 95(12):1101–1133

Novitskaya E, Chen P, Hamed E, Jun L, Lubarda VA, Jasiuk I, McKittrick J (2011) Recent advances on the measurement and calculation of the elastic moduli of cortical and trabecular bone: a review. Theor Appl Mech 38(3):209–297

Pettersen SH, Wik TS, Skallerud B (2009) Subject specific finite element analysis of implant stability for a cementless femoral stem. Clin Biomech 24(6):480–487

Pilliar R, Lee J, Maniatopoulos C (1986) Observations on the effect of movement on bone ingrowth into porous-surfaced implants. Clin Orthop Relat Res 208:108–113

Rancourt D, Shirazi-Adl A, Drouin G, Paiement G (1990) Friction properties of the interface between porous-surfaced metals and tibial cancellous bone. J Biomed Mater Res A 24(11):1503–1519

Rho JY, Ashman RB, Turner CH (1993) Young’s modulus of trabecular and cortical bone material: ultrasonic and microtensile measurements. J Biomech 26(2):111–119

Rice J, Ruina AL (1983) Stability of steady frictional slipping. J Appl Mech 50(2):343–349

Rittel D, Dorogoy A, Shemtov-Yona K (2018) Modeling the effect of osseointegration on dental implant pullout and torque removal tests. Clin Implant Dent Relat Res 20(5):683–691

Rønold HJ, Ellingsen JE (2002) The use of a coin shaped implant for direct in situ measurement of attachment strength for osseointegrating biomaterial surfaces. Biomaterials 23(10):2201–2209

Rønold HJ, Lyngstadaas SP, Ellingsen JE (2003) Analysing the optimal value for titanium implant roughness in bone attachment using a tensile test. Biomaterials 24(25):4559–4564

Ruina A (1983) Slip instability and state variable friction laws. J Geophys Res Solid Earth 88(B12):10359–10370

Sauer RA (2011) Enriched contact finite elements for stable peeling computations. Int J Numer Meth Eng 87(6):593–616

Sauer RA, De Lorenzis L (2013) A computational contact formulation based on surface potentials. Comput Methods Appl Mech Eng 253:369–395

Sauer RA, De Lorenzis L (2015) An unbiased computational contact formulation for 3d friction. Int J Numer Methods Eng 101(4):251–280

Sharma NK, Sehgal DK, Pandey RK (2012) Comparative study of locational variation in shear and transverse elastic modulus of buffalo cortical bone. IERI Proc 1:205–210

Shirazi-Adl A (1992) Finite element stress analysis of a push-out test part 1: fixed interface using stress compatible elements. J Biomech Eng 114(1):111–118

Shirazi-Adl A, Dammak M, Paiement G (1993) Experimental determination of friction characteristics at the trabecular bone and porous-coated metal interface in cementless implants. J Biomed Mater Res A 27(2):167–175

Skripitz R, Aspenberg P (1999) Attachment of PMMA cement to bone: force measurements in rats. Biomaterials 20(4):351–356

Sul Y, Johansson C, Jeong Y, Röser K, Wennerberg A, Albrektsson T (2001) Oxidized implants and their influence on the bone response. J Mater Sci Mater Med 12(10–12):1025–1031

Tang T, Ebacher V, Cripton P, Guy P, McKay H, Wang R (2015) Shear deformation and fracture of human cortical bone. Bone 71:25–35

Tschegg E, Lindtner R, Doblhoff-Dier V, Stanzl-Tschegg S, Holzlechner G, Castellani C, Imwinkelried T, Weinberg A (2011) Characterization methods of bone–implant-interfaces of bioresorbable and titanium implants by fracture mechanical means. J Mech Behav Biomed Mater 4(5):766–775

Vayron R, Barthel E, Mathieu V, Soffer E, Anagnostou F, Haïat G (2011) Variation of biomechanical properties of newly formed bone tissue determined by nanoindentation as a function of healing time. Comput Methods Biomech Biomed Eng 14(sup1):139–140

Vayron R, Barthel E, Mathieu V, Soffer E, Anagnostou F, Haïat G (2012) Nanoindentation measurements of biomechanical properties in mature and newly formed bone tissue surrounding an implant. J Biomech Eng 134(2):021007

Wennerberg A, Jimbo R, Stübinger S, Obrecht M, Dard M, Berner S (2014) Nanostructures and hydrophilicity influence osseointegration: a biomechanical study in the rabbit tibia. Clin Oral Implant Res 25(9):1041–1050

Wriggers P (2006) Computational contact mechanics. Springer, Berlin

Zhang Y, Ahn PB, Fitzpatrick DC, Heiner AD, Poggie RA, Brown TD (1999) Interfacial frictional behavior: cancellous bone, cortical bone, and a novel porous tantalum biomaterial. J Musculoskelet Res 3(04):245–251

Zienkiewicz O, Taylor R (2005) The finite element method for solid and structural mechanics. Butterworth-Heinemann, Oxford

Acknowledgements

This work has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Grant Agreement No. 682001, Project ERC Consolidator Grant 2015 BoneImplant). This work was supported by the Jülich Aachen Research Alliance Center for Simulation and Data Science (JARA-CSD) School for Simulation and Data Science (SSD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The authors Guillaume Haiat and Roger A. Sauer have contributed equally in this work.

Appendices

Appendix 1

Contact formulation

In this section, the basic contact mechanics and the numerical discretization are briefly summarized. For the formulation of sliding contact, one can use elastoplasticity theory in order to incorporate friction response in the tangential direction (see, e.g., Laursen 2013; Wriggers 2006; Sauer and De Lorenzis 2015). In the context of this work, we use another approach that is based on the surface potential-based contact formulations of Duong and Sauer (2019) and Sauer and De Lorenzis (2013). The reader is referred to Corbett and Sauer (2014, 2015) for the NURBS-enriched contact finite element discretization.

1.1 Contact surface description

Considering a 3D body \({\mathcal {B}}\), its boundary \(\partial {\mathcal {B}}\), such as its contact surface \(\partial _{\text{c}}{{\mathcal {B}}}\), can be described by the mapping

which maps a point \({\varvec{\xi }}= \left\{ \xi ^1, \xi ^2 \right\}\) lying in the 2D parameter space \({\mathcal {P}}\) to the surface point \(\varvec{x}\in \partial _{\text{c}}{{\mathcal {B}}}\). Then, a set of covariant tangent vectors on \(\partial _{\text{c}}{{\mathcal {B}}}\) can be defined as

with the normal vector

With Eqs. (23) and (24), the contact surface can then be characterized by the surface metric components

The dual tangent vectors \(\varvec{a}^\alpha\) defined by the relation \(\varvec{a}^\alpha \cdot \varvec{a}_\beta = \delta ^\alpha _\beta\) can be related to the covariant tangent vectors in Eq. (23) by \(\varvec{a}_\alpha = a_{\alpha \beta } \, \varvec{a}^\beta\). To track changes of \(\partial _{\text{c}}{{\mathcal {B}}}\) during deformation, one chooses a reference configuration \(\partial _{\text{c}}{{\mathcal {B}}}_0\), where the tangent vectors \({\varvec{A}}_\alpha\) and the surface metric tensor components \(A_{\alpha \beta }\) can be defined as in Eqs. (23) and (25), respectively.

1.2 Contact kinematics and contact traction

To formulate frictional contact between two bodies \({\mathcal {B}}_1\) and \({\mathcal {B}}_2\), we consider interactions between a so-called slave point\(\varvec{x}_k \in \partial _{\text{c}}{{\mathcal {B}}}_k\) (\(k=\) 1 or 2) and a neighboring master surface \(\partial _{\text{c}}{{\mathcal {B}}}_\ell\) (\(l=\) 2 or 1). For the classical full-pass contact algorithm (see Laursen and Simo 1993), k is either set to 1 or 2. Further, we assume point interaction, i.e., \(\varvec{x}_k\) can only interact with at most one point \(\varvec{x}_\ell \in \partial _{\text{c}}{{\mathcal {B}}}_\ell\) at a given time.

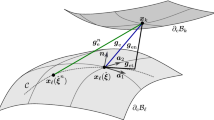

Frictional contact kinematics at current time \(t_{n+1}\): current slave point \(\varvec{x}_k\), current position of the previous interacting point \(\displaystyle \varvec{x}_\ell ({\hat{{\varvec{\xi }}}}^n)\), current interacting point \(\varvec{x}_\ell ({\hat{{\varvec{\xi }}}})\), the current elastic gap vector \(\varvec{g}_{\text{e}}\) and its components, previous elastic gap \(\varvec{g}_{\text{e}}^n\), and the sliding path \({\mathcal {C}}\). Adopted and modified from Duong and Sauer (2019)

In the following, for the sake of conciseness, all variables without superscript n are evaluated at the current time \(t_{n+1}\), if not stated otherwise. To characterize the interaction between the two bodies, we consider a penalty formulation, with the penalty parameter \(\epsilon\) (considered equal in normal and tangential direction). In order to determine the contact traction at the current time step, according to the contact formulation of Duong and Sauer (2019), a so-called interacting (elastic) gap vector \(\varvec{g}_{\text{e}}({\hat{{\varvec{\xi }}}})\) is introduced (see Fig. 11). This gap vector is defined between the current slave point \(\varvec{x}_k\) and the so-called current interacting point \(\varvec{x}_\ell ({\hat{{\varvec{\xi }}}})\) on the master surface \(\partial _{\text{c}}{{\mathcal {B}}}_\ell\) (defined below), i.e.,

The current gap vector can be further decomposed into a tangential and normal component \(\varvec{g}_{\text{e}}({\hat{{\varvec{\xi }}}}) = \varvec{g}_{\text{en}}+ \varvec{g}_{\text{et}}\), with

According to the penalty formulation, the total (normal and tangential) frictional contact traction is proportional to the interacting gap vector \(\varvec{g}_{\text{e}}({\hat{{\varvec{\xi }}}})\), according to

which follows from using the contact potential \(W:=\frac{1}{2}\epsilon \, \varvec{g}_{\text{e}}\cdot \varvec{g}_{\text{e}}\). At initial contact, the interacting point \(\varvec{x}_\ell ({\hat{{\varvec{\xi }}}})\) is equal to the closest projection point of \(\varvec{x}_k\). During sticking, the current interacting point is equal to the previous interacting point \({\hat{{\varvec{\xi }}}}^n\). Therefore, for sticking, the current contact gap vector \(\varvec{g}_{\text{e}}\) is determined from Eq. (26) with \({\hat{{\varvec{\xi }}}} = {\hat{{\varvec{\xi }}}}^n\). During sliding, the current interacting point \({\hat{{\varvec{\xi }}}}\) is the solution of the kinematic constraint equation

in the current configuration (see Duong and Sauer 2019). \(\varvec{g}_{\text{e}}\) then follows from Eq. (26). The critical value during sliding \(\varvec{g}_{\text{et}}^{{\max }}\) is defined by the chosen friction law. For example, for Coulomb’s friction, it is defined as

where \({\varvec{\tau }}\) denotes the sliding direction and can be computed by projecting the previous interacting gap \(\varvec{g}_{\text{e}}^n\) onto the tangent plane at the current interaction point \(\varvec{x}_\ell ({\hat{{\varvec{\xi }}}})\), i.e.,

where \(\varvec{a}_\alpha ,\,\varvec{a}^\alpha ,\) are evaluated at \(\varvec{x}_\ell ({\hat{{\varvec{\xi }}}})\).

The computation of the friction coefficient \(\mu\) in Eq. (13) requires the knowledge of the accumulated sliding distance \(g_{\text{s}}\). Here, we approximate Eq. (12) by accumulating the distance from the initial interacting point to the current interacting point, i.e.,

1.3 Finite element discretization

For the finite element formulation, the contact bodies are discretized into \(n_{\mathrm{el}}\) elements. The geometry of an element e in the current configuration can be interpolated from the positions of the elemental nodes, or control points \({\mathbf {x}}_e\), as

where \({\mathbf {N}}_e := \left[ N_1\varvec{I}, N_2\varvec{I}, \ldots , N_{n_{\mathrm{el}}}\varvec{I}\right]\) denotes the element shape function array. Following the 3D contact enrichment approach of Corbett and Sauer (2014, 2015), the bulk of the bodies is discretized by linear elements with standard Lagrange interpolation following Sauer (2011), while the contact surfaces are discretized by non-uniform rational B-Splines (NURBS) interpolation (see, e.g., Hughes et al. 2005). The NURBS basis functions can be computed element-wise by employing the Bézier extraction operator \({\mathbf {C}}^e\) of Borden et al. (2011) and the Bernstein polynomials \({\mathbf {B}}\). Then, the shape function of control point A can be computed by

with the corresponding weight \(w_A\), and the B-spline basis functions

The finite element forces acting on the slave surface element e and the master surface element \({\hat{e}}\) are then given by

where \(\Gamma\) denotes the surface element domains on the corresponding surfaces. As NURBS elements are at least \(C^1\) continuous over the element boundaries, this gives us an accurate representation of the geometry, as well as an efficient and stable framework for contact computations.

Appendix 2: Derivation of the new analytical model with modified Coulomb’s friction

Given the modified Coulomb’s law in Sect. 2.2.3, a new analytical model can be derived. In general, the torque T, as a function of the rotation angle \(\theta\), can be computed analytically, as

Due to symmetry, the tangential traction component \(\sigma _{\theta z}\) is distributed radially symmetric along the BII, while the radial traction component \(\sigma _{zr}\) is zero. With the definition of the critical radius c from Eq. (17) we have \(c(\theta _{\text{lin}}) = R\) and

Assuming bone and implant to be linear elastic bodies, we know that for sticking, the tangential traction will be proportional to the applied rotation angle \(\theta\) and the current radius r, i.e.,

where \(\lambda\) is a constant stress per length. Thus, the torque for the sticking region becomes

If we calculate the slope of the torque at \(\theta = \theta _{\text{lin}}\) and \(c(\theta _{\text{lin}})\), we get (Fig. 12)

New analytical model: critical radius for stick/slip transition c as a function of the imposed rotation angle \(\theta\) from Eq. (17)

We also know that for linear elasticity

where C is the effective shear stiffness of the system, that is approximately proportional to the shear modulus of bone. If we equate Eqs. (41) and (42), we obtain

and inserting \(\lambda\) into Eq. (39) yields

Applying the definition in Eq. (38) to Eq. (44) yields

i.e.,

Together with Eq. (17), we finally obtain the tangential traction component for sticking

In the sliding region \(r \ge c\), the tangential traction follows the modified Coulomb’s law

with \(\mu = \mu (g_{\text{s}})\) from Eq. (11). Here, we assume p to be homogeneously distributed along the contact surface. As long as a part of the interface remains sticking

The tangential contact traction as a function of the rotation angle can then be summarized by combining Eqs. (47) and (48) to Eq. (18).

Appendix 3: Mesh and load step sensitivity

To analyze the convergence behavior, three different finite element meshes were constructed, denoted coarse, medium, and fine with 3390, 12,354, and 47,130 degrees of freedom, respectively. In addition, different load step sizes [\(0.1^{\circ }\), \(0.05^{\circ }\), \(0.02^{\circ }\), \(0.01^{\circ }\), \(0.005^{\circ }\), \(0.004^{\circ }\)] were investigated, corresponding to a number of load steps of [100, 200, 500, 1000, 2000, 2500], respectively. For the parameters, data set 1 with \(\mu _{{\mathrm{b}}}=0.4\) was chosen. To compare the different setups, we define the mean relative torque error

where here \(T_{\max }\) is the maximum torque obtained by the numerical solution.

Figure 13 shows the convergence behavior of the different meshes. It can be seen that \(e_{T}^{\mathrm{mp}}\) reaches its limit for all meshes after 1000 load steps to 0.0175, 0.0171, and 0.017, respectively. This is also the case for the mean percentage error shown in Table 7, with its lowest value of 2.176% for the fine mesh and the highest value of 2.241% for the coarse mesh. In addition, the error is increasing with the number of load steps for the coarse mesh. This stems from the coarse resolution of the peak for larger load steps and thus leading to the torque values to be closer to the experimental data. It should be noted that the mesh size has a small effect on the outcome of the parameter study and thus, both \(e_{T}^{\mathrm{mp}}\) and \(e_{T}^{\mathrm{rel}}\) can be further minimized by performing a separate parameter estimation for each mesh.

Mesh sensitivity: mean relative error \(e_{T}^{\mathrm{rel}}\) according to Eq. (50) for different configurations of data set 1 (\(\mu _{{\mathrm{b}}}=0.4\))

Rights and permissions

About this article

Cite this article

Immel, K., Duong, T.X., Nguyen, VH. et al. A modified Coulomb’s law for the tangential debonding of osseointegrated implants. Biomech Model Mechanobiol 19, 1091–1108 (2020). https://doi.org/10.1007/s10237-019-01272-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-019-01272-9