Abstract

This review critically examines the effects of AMD from the gold mines of South Africa and available options. We also critically analyse case studies, research gaps, and the challenges and opportunities presented by the AMD. Our assessment indicates the availability of potential technological advancements that might flip the paradigm in favour of less sludge being produced, lower operational costs, and more effective AMD treatment strategies. This has led to the development of long-term plans for AMD treatment technologies and the recovery of important minerals. There is currently a demand for integrated AMD technologies that take a holistic approach to long-term AMD treatment. Reusing water and recovering valuable resources like sulphuric acid, rare earth elements, and other metals have received a lot of attention. Continued study and implementation of such strategies will support sustainable gold mining, address the environmental damage caused by AMD, and optimize resource and revenue-generating potentials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acid mine drainage (AMD) is a persistent by-product of present and past mining activity in South Africa and around the world. Both current and inactive or abandoned mines generate AMD from waste rock piles, mill tailings, open pits, shafts, and tunnels below the ground. Low pH and high concentrations of metals and dissolved sulphate are common features of AMD, which if left untreated, can cause serious environmental damage, including pollution of water sources, the extinction of aquatic life, and the poisoning of natural habitats (Akcil and Koldas 2006; Charuseiam et al. 2021; Sahoo et al. 2013). Sulphide-containing minerals can generate AMD for hundreds of years after commercial mining operations have ended (Chetty et al. 2021a).

There have been discussions and reports of gold mine AMD in South Africa, with the western, central, and eastern basins of the Witwatersrand Gold Fields being the most well-known (Abiye et al. 2022) due to the environmental harm that AMD from these mines create, especially on the freshwater supplies in the higher sections of the Vaal River and the risks associated with AMD decant and flooding in low-lying areas. Indeed, the flooding of mines in priority zones and subsequent AMD decant into the environment cause many detrimental ecological effects.

AMD has been remedied and its detrimental effects on the receiving environment have been reduced using conventional wastewater treatment techniques such as neutralization, precipitation, membrane processes, ion exchange, and biological sulphate removal. The problem with most of these approaches, though, is that most of the components of AMD have not traditionally been thought of as valuable resources. Even though most of the components are hazardous, they can still be collected and converted into useful commodities that can be sold. Rare earth elements (REEs) and sulfuric acid are two examples. Examples of REEs-bearing minerals resulting from gold mining in South Africa are allanite, fergusonite, apatite, and euxenite (Battsengel 2018; Borra 2015; Yang 2019).

Water reuse and resource recovery have received a lot of attention along with the demand for more sustainable AMD treatment. This has led to a paradigm shift towards lowering the amount of sludge produced, as well as the operational cost, and increasing AMD treatment effectiveness. This review article summarizes the current condition of AMD flowing from South African gold mines and its environmental and economic consequences. This paper also outlines the mechanism, benefits, and drawbacks of AMD-mitigating technologies, and compares and evaluates the research gap between traditional and more modern AMD treatment technologies.

Acid Mine Drainage from South Africa’s Gold Mines

South Africa was once a large producer of gold (Usher and van Biljon 2006) and was ranked 8th in world production in 2022. While the country’s peak mining days have ended, there are still a small number of operational mines that occupy the western, central, and eastern basins in Johannesburg (Fig. 1). Although gold mining still benefits the South African economy through its exports (≈ 110 t in 2023), there have been many mine closures since the boom period of 1950–1990 (Marais et al. 2022). The discharge of mine water has become a national environmental concern and has attracted much interest since water from the old mines in the Krugersdorp area began decanting into the Cradle of Humankind (McCarthy 2011). In view of the environmental and socio-economic consequences of AMD, an inter-ministerial committee on AMD was created in 2010 by the South African government where a technical team of experts examined the challenges and investigated possible solutions (AMD Committee Report 2010). More attention was given to the operating gold mines and the non-operational mines in the western Basin (Krugersdorp area), the central basin (Roodepoort to Boksburg), and eastern basin (Brakpan, Springs, and Nigel area).

Certain factors differentiate AMD in South Africa from the global perspective, especially the level of connectivity between large voids, the degree of operations at the Witwatersrand, and the trend that several affected problematic areas are situated in or close to major urban centres (McCarthy 2011). Thus, large-scale programmes are needed to target the challenges of AMD.

The vast mining industry in South Africa has given rise to several challenges that cannot be handled with due diligence by the government or the mining operators by themselves. The mine voids flood once pumping of underground water from the mines stop. This occurrence was brought to light in 2002 when water from a deserted mine shaft in the Mogale City/Randfontein area of the western basin started overflowing onto the surface due to the flooding of the mines.

A similar situation is taking place in the Johannesburg and Springs areas where major efforts are being conducted by the Department of Mineral Resources (DMR), Department of Water and Sanitation (DWS), Department of Environmental Affairs (DEA), and Department of Science and Technology (DST)) to investigate and manage the problem. The central basin is the largest basin and water levels there have increased at an average rate of 0.59 m/d since 2009. By 2010, the mine water level reached an elevation of ≈ 1155 m above mean sea level, which was ≈ 510 m below the surface (mbs). In addition, flooding of the Witwatersrand Gold Field mines resulted in the decant of the western basin in 2002. Therefore, the urgency of initiating intervention measures is paramount before mine water flows onto the surface there and affects heavily populated areas. Consideration must also be given to the adverse effects this AMD will have on South Africa’s major river systems.

Meanwhile, pumping at the number 3 shaft of the Grootvlei mine has maintained water levels in the eastern basin at a depth of ≈ 700 mbs. However, there are financial constraints that place the continuation of pumping at the Grootvlei mine at risk and treatment of the mine water there has not occurred for a long time. If action is not taken soon, the pump station there will flood, eventually causing untreated mine water to rise and decant from the mine.

Therefore, mitigation and control measures are urgently needed at the western, central, and eastern basins. For the western basin, an upgrade of the pumping facilities is needed as well as the construction of a neutralisation plant to complement the current treatment capacity. This also applies to the central basin, where a pumping facility is required in the mine shafts along with the development of a neutralisation plant of similar capacity. At the eastern basin, the pumping capacity in the number 3 shaft of the Grootvlei Mine and the dysfunctional treatment plant should be brought back into use as soon as possible. If these mitigating measures are put into place, then the volumes of surface contamination from these three basins will decrease.

It is worth noting that the release of mine water into receiving environments will cause conditions to resemble what existed during periods of active mining. This approach is not feasible or sustainable in the long-term because it contributes high salt loading in the receiving water bodies. Other options for using the mine wastewater, such as direct use of the treated mine water or desalination and selling of the water to communities, should be further investigated. Eventually, the water quality is expected to improve as the inundation prevents additional pyrite oxidation, which will help decrease the costs of managing this water (Usher and Vermeulen 2006), but that will likely take decades.

The Effects of AMD on Water Quality

Formation of AMD in the Gold Mines

Gold is mined at Witwatersrand by extracting gold-carrying conglomerates, which are brought to the surface and crushed. If the gold concentrations are too low for extraction, some conglomerates are left and used as support for the mine workers underground. After the gold is extracted, the residual crushed rock is stored on waste heaps (slimes) or tailings dumps. This crushed rock waste contains ≈ 3% pyrite, which remains in the dumps and forms AMD. This polluted water ends up in streams around the dumps that have high concentrations of acid, sulphates, and metals. Surrounding groundwater continuously streams into the mines and must be pumped out to avoid flooding. Some of this water is used in mining operations and the rest is released into surrounding water bodies after some pre-treatment. When mining operations cease, and the mines become inundated, this water becomes acidic and contaminated with metals. This polluted water drains out slowly, starting at the lowest lying, which is currently happening in the western basin mine in the Krugersdorp area. An old, abandoned western basin gold mine in the Republic of South Africa is shown in Fig. 1. Although the area’s mining operations were abandoned in the early 1980s, a sizable volume of acidic water is still being released into the environment there through unused underground workings.

AMD Affects Water Quality, Water Resources, and the Water Network

Witwatersrand Central Basin Water Quality

The gold mining legacy in the Witwatersrand Central Basin started in 1886 and ended in the late 1990s and early 2000s after the Roodeport Deep and the East Rand Propriety Mines closed, which represented the western and eastern basins, respectively (Durand 2012). The years of mining at large-scale operational levels followed by progressive mine closures gave rise to extremely contaminated drainage going into outlying tributaries, specifically the Klip River and Klipspruit (Durand 2012; Humphries et al. 2017; Naicker et al. 2003). This posed a potentially high risk of an uncontrolled mine water discharge (Chetty et al. 2021b).

The pumping of mines stopped in 2008 due to a lack of sufficient ventilation at the East Rand Propriety Mine pump station. After this pumping stopped, a link between seismic activity and the flooding of the Central Basin was noted and because of this, a short-medium term seismic activity monitoring programme was created and implemented to predict potential flooding of mines and allow a prompt response to reduce possible socio-economic and environmental consequences (Expert Team of the Inter-Ministerial Committee 2010).

The mine water coming from the Central Basin was acidic, with high sulphate, iron, and metal concentrations. Therefore, any untreated mine water that enters or leaves the water system will aggravate the already existing issue of poor surface water quality in the Klip River (Chetty et al. 2021b). Previous studies have established that high levels of nickel (Ni), cobalt (Co), zinc (Zn), and uranium (U) in the Klip River were a result of AMD coming from tailing storage facilities (TSFs), non-operational gold mines, partly treated mine water or secondary land use, including informal settlements, industrial areas, and wastewater treatment plants. In such instances, AMD got into the water network through surface run-off or groundwater permeation (Chetty et al. 2021; Naidoo 2022).

A recent study (Chetty et al. 2021b) studied the physico-chemical characteristic changes in water and sediment samples obtained at the Klipspruit, the Klip River, and its wetland zones. The results emphasised that the Klipspruit stream had water containing high levels of trace metals, electrical conductivity (EC), iron (Fe), aluminium (Al), Co, Ni, and Zn. Sulphate levels were not determined as part of this research; however, the Rand Water data showed fluctuating sulphate levels with “unacceptable” levels being obtained at certain sites as per the in-stream water quality guidelines for the Klip Catchment (Rand water 2023). Recent water quality data published by the Trans-Caledon Tunnel Authority (TCTA) for January-February 2023 showed that levels of Mg, Na, sulphate, and EC were regularly not complying with the in‐stream water quality guidelines for the Klip Catchment. However, the sulphate and EC levels were found to be acceptable according to the less severe limits from the DWS directive (TCTA 2023).

Recommendations can be made on short- and long-term corrective actions that should be taken, based on information such as the regularly monitored water quality variables and the results from previous studies that touch on the measured variables that were present at “unacceptable” levels at the central basin and surrounding water systems. The guidelines for water quality should be consistently used by all relevant stakeholders and needs to be discussed, agreed on, and implemented, considering the requirements of the many users and environmental sustainability. Selected desalination technologies should be commissioned as soon as possible to be used at the central basin to help decrease the total dissolved solids (TDS) and EC levels of mine water discharge and surrounding water systems. Relevant authorities, such as the DWS, should be included as key stakeholders in the Klip River Water Stewardship and can provide support and resources, which may be needed for progress and ground-level implementation of the Integrated Management Plan.

Witwatersrand Western Basin Water Quality

The shafts of the western basin are badly affected by AMD since they began decanting from 2002, which has contributed to the contamination of the Tweelopiespruit that drains into the Krugersdorp Game Reserve (DWA 2013). This increased when waste from the abandoned mines and the entry of water into the shafts became indirect sources of AMD and the DWA issued a directive to all operational mines to pump and treat the AMD. However, the main challenge was the lack of capacity of these mines to treat AMD. In addition, the mines are abandoned, which means that the government has no options but to gather funding for pumping and treating the AMD. AMD drains into three old mine shafts at an average volume of 20 million litres per day (ML/d). Approximately 12 ML/d is partially treated, while the rest flows into the Tweelopiespruit. About 27 ML/d of AMD has to be treated to allow the water levels to remain below the environmental critical level (ECL). This refers to the water level in the shafts, which must not overflow into the environment and affect groundwater.

Many variables for water quality were measured for the Tweelopiespruit and were found to be non-compliant with the recommended guidelines for aquatic ecosystems. Water permeating from the western basin had high sulphate levels of ≈ 3500 mg/L with a pH ranging between 2 and 3 (Expert Team of the Inter-Ministerial Committee 2010). This surpasses the upper limit for Class I (for long-term domestic use) according to DWS’ water quality guidelines where a maximum sulphate concentration of 400 mg/L and a pH of between 5 and 6 or between 9 and 9.5 is recommended. High concentrations of Fe and other metals were also present, which is reflected by the presence of a bright orange streak (yellow boy) along the riverbanks.

Witwatersrand Eastern Basin Water Quality

The Grootvlei Propriety Mine in Springs operated from 1934 to 2010 and due to its location within the Blesbokspruit wetland attracted a lot of attention (Ambani and Annegarn 2015). This wetland, being among the largest in the country, was listed as a Ramsar Wetland of International Importance in 1986, based on its biodiversity-rich ecosystem (Ambani and Annegarn 2015; Jonah et al. 2016). The national government permitted the discharge of effluents from the Grootvlei Propriety Mine only when the risks of flooding of a network of existing gold mines came to the fore (Lourenco and Curtis 2021a).

The Grootvlei Propriety Mine received a government directive to cease pumping in 1995 when red-colored AMD precipitates were found at the surface. However, pumping started up once again in 1996 on the basis that the water was being treated using a high-density sludge (HDS) method before its discharge (Thorius 2009). Besides the high dissolved salt levels, the effluent quality discharged into the Blesbokspruit after the HDS treatment improved considerably (Lourenco and Curtis 2021a). Despite this, the closure of the mine and the cessation of pumping in 2010 brought about a recharge of previously dewatered areas, which became a key risk where mine water was percolating to the surface with no interventions (de Wet and Sidu 2013).

The TCTA’s two-phase response to the risk of the potential decanting of AMD in 2016 involved the building and commissioning of a full-scale HDS treatment plant at the Grootvlei Propriety Mine shaft number 3, which was the first phase (Trans-Caledon Tunnel Authority 2017). Phase Two would involve using desalination technologies to decrease the levels of salinity of the treated mine water before it was released into the Blesbokspruit water network (Trans-Caledon Tunnel Authority 2017).

The variabilities of water quality data across the Blesboksprui wetland and downstream are well documented, which matches closely to events recorded historically of the Grootvlei Propriety Mine (Lourenco and Curtis 2021a). This was to ensure that the water quality improved after the mine closed, and pumping was to be discontinued in 2010. The mine had major irregularities from 2013 to 2016 before the new HDS plant was built, but this decreased from 2016 to 2019 after it was commissioned (Lourenco and Curtis 2021a). Increased volumes of water flow and sharp increases in Al, EC, magnesium (Mg), sodium (Na), chloride, and sulphate levels were also found (Lourenco and Curtis 2021a). Ecosystem integrity was not compromised by the increase in Al levels; however, the increased chloride, conductivity, Mg, Na, and sulphate levels were unacceptable to meet the water quality management targets set by the Blesbokspruit Forum (Lourenco and Curtis 2021a). Moreover, the quality of the water trends noted at sites downstream from the site of impact, including one at the Marievale Bird Sanctuary, were like those noted at the impact site. This showed that the new HDS system efficiently improved the water quality in certain instances while simultaneously contributing to unwanted environmental conditions elsewhere.

High levels of sulphate, Mg, chloride, and Na in the Blesbokspruit stream from 2016 to 2022 were the source of the high TDS levels. This promoted the encroachment of reeds on open areas of water and affected certain downstream aquatic species and their adaptations, community structure, and microbial and ecological processes. Furthermore, the discharge of high TDS-loaded effluents from the new HDS plant will add to the existing challenge of highly saline water in the Vaal River at their confluence between the Vaal Dam and the Vaal Barrage (du Plessis 2023). Water from the Vaal Barrage is a main source of drinking water in the region and the river water is also used for a range of domestic, agricultural, and industrial activities (Mararakanye et al. 2022).

Gold Mining AMD: Selected Case Studies

High density sludge (HDS) technology

Most large AMD treatment plants around the world neutralize the mine water with lime and use some version of the high-density sludge (HDS) technology, which recycles most of the sludge that is generated during neutralisation (Aubé and Zinck 1999). The pH of the treated effluent is adjusted if necessary and then the treated water is released (Aubé and Zinck 1999).

The main advantage of the HDS process is that the sludge density is generally high, which reduces sludge disposal volumes and hence sludge handling and disposal costs (Aubé and Zinck 1999). Furthermore, even though flocculant is used, which effectively raises total chemical cost, the HDS process is efficient and uses less neutralising chemicals, thereby also lowering costs (Aubé and Zinck 1999).

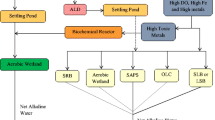

One of the largest HDS treatment facilities in the world, the eastern basin chemical AMD treatment facility, began operations in August 2016. The plant is located upstream of the Blesbokspruit Wetland and close to the closed Grootvlei Mine in Springs, South Africa. The DWS contracted the TCTA to operate and maintain these HDS plants to ensure that the quantity and quality standards of treated water are met and that water recharge into the mine voids meet their respective environmental critical levels (Aubé and Zinck 1999). Even though these treatment plants are effective at rectifying water quality parameter concentrations to within acceptable ranges, the treated water is still characterised by elevated TDS and EC (Chetty et al. 2021c). Figure 1 illustrates the process flow diagram of the HDS treatment technology.

CSIR ABC (alkali–barium–calcium) technology

The ABC process is fundamentally a precipitation-based process that was developed by our research division within the CSIR in South Africa. This method has three major phases, specifically neutralization and metal removal (stage 1), sulphate removal using BaCO3 (stage 2), and sludge processing (stage 3). The first stage enables the removal of acids and metals by the addition of lime and BaS to the mine water. Then the barium carbonate is added to the pre-treated effluent, which removes most of the sulphate from the water by the precipitation of barium sulphate (Simate and Ndlovu 2014a). The last stage, which involves sludge reduction via a coal-fired kiln, allows the recovery of much of the lime and barium carbonate and creates an all-new, low-waste technology (Mulopo et al. 2015).

This AMD treatment process was first demonstrated at a 1 m3/h pilot plant constructed in the western basin of the Witwatersrand goldfields, to which AMD was pumped directly from a gold mine shaft for treatment. Mine water was fed into the plant, which operated on continuous mode for 24 h per day and 7 days per week. Water samples were collected and analyzed on-site to measure pH, sulphate, calcium, Mg, and Fe at different stages of the process (de Beer et al. 2010). The results indicated that the CSIR ABC process effectively neutralizes AMD, lowers TDS by 86%, removes metals, lowers sulphate to values less than 100 mg/l and recovers the raw materials utilised in the sludge processing stage. Figure 2 illustrates the process flow diagram of the CSIR ABC treatment process.

CSIR Magnesite-Softeners-Reverse-Osmosis (MASRO) Technology

Another AMD treatment technology recently developed by the CSIR in South Africa is called MASRO (magnesite, softeners, and reverse osmosis) technology. The MASRO technology is a five-stage process with a clarifier that also acts as a mixer. The first stage involves the use of magnesite to neutralize the AMD and remove all metals from the mine water; the sulphate stays in solution as a MgSO4 complex. Thereafter, the residual sulphate and Mg are removed as gypsum and brucite respectively by the addition of limestone in stage 2 of the process. Stage 3 involves the synthesis of limestone by the addition of soda ash, which in effect removes the residual calcium and hydrated calcium carbonate. Thereafter, stages 4 and 5 include HCl dosing to neutralise the water, water filtration via a reverse osmosis process, and the storage of products (brine and water) in separate tanks.

The pilot plant demonstrated at the CSIR research innovation site, Pretoria, South Africa treated 3500 L of gold AMD per day and produces water that is compliant with the SANS 241 drinking water standards as well as valuable minerals, namely gypsum, limestone, and iron-based minerals (Masindi 2017). These minerals can be sold to offset the operational costs of the plant, rendering it both environmentally sustainable and self-sustaining. However, some areas that were found to require improvement prior to full-scale industrial implementation include the evaluation of plant stability, factoring in of maintenance costs, establishment of quality grading for the recovered materials, running of the plant for more than six months at the CSIR site or on-site to test the sustainability of the developed system under harsh ecological conditions. Figure 3 shows the process flow diagram of the MASRO treatment technology.

SAVMIN Technology

The technology of sulfate removal by precipitation as a component of ettringite was developed by Mintek, Randburg, South Africa and called the SAVMIN technology. The SAVMIN technology is a six-stage gold mine AMD treatment technology, which utilises successive stages of precipitation to remove sulphate from mine water. First, lime is added to the mine water to increase its alkalinity to a pH of 12 to promote the precipitation of metal and magnesium hydroxides. In stage 2, gypsum is precipitated and removed from the supersaturated solution, catalysed by the seeding of gypsum crystals therein. Thereafter, stage 3 involves the addition of aluminium hydroxide to the water, which is still supersaturated with gypsum, resulting in the precipitation of both calcium and sulphate in the form of ettringite. Removal of the ettringite from the feed water is accomplished through filtration and subsequent thickening. Stages 4 and 5 involves the use of sulphuric acid to decompose the ettringite slurry at a pH of 6.5 in a solution supersaturated with gypsum. Aluminium hydroxide is produced, which is recycled to the third stage of the process, the gypsum supersaturated solution is diverted to stage 2 where it’s seeded with crystals to remove gypsum, and the remaining solution is recycled (van Rooyen et al. 2021). The lowering of the feed water’s pH by the addition of CO2 is the last stage, during which CaCO3 precipitates. Even though waste disposal is expensive due to the large amount of sludge generated by this process, the potable water, metal hydroxides, gypsum, and calcite can be marketed and sold.

A SAVMIN demonstration plant was erected at the Witwatersrand gold mines in the western basin that treated 500 m3 of gold mine water at throughputs of up to 1100 L/hr. The dissolved sulphates and metals were removed to very low levels in the treated water. The dissolved metals and sulphate content met the target water quality for the three different purposes considered, specifically for discharge, high quality industrial use, and potable water. Recently, further developments on the SAVMIN technology have been made in partnership with Veolia Water Solutions and Technologies. The original design of the SAVMIN technology consisted of five stages as described above; this was improved by eliminating two reactors and two thickeners from the technology as shown in Fig. 4. As reported by van Rooyen (2016), development was performed around the reagent regeneration process step, resulting in an impressive reduction in the operating cost of the process.

Slurry Precipitation and Recycling Reverse Osmosis (SPARRO) Technology

A process developed and patented in USA by the Chamber of Mines Research Organisation (COMRO) is the SPARRO (slurry precipitation and recycling reverse osmosis) technology. As shown in Fig. 5, SPARRO uses membrane desalination to treat AMD. The SPARRO technology was designed to augment water recovery in waste disposal of an AMD with high calcium and sulfate concentrations. In this process, calcium sulphate removal precedes membrane treatment and involves the addition of seed crystals into the feed water by the recycling of waste slurry. According to Pulles et al. (1992), RO system operation at a high recovery was enabled by recycling a slurry of calcium sulfate seeds, which provides preferential precipitation sites to the supersaturating solution. The erosive effect of the needle-like gypsum crystals flowing through the membrane is the SPARRO process’ troublesome aspect.

This process was piloted at the eastern basin of the Witwatersrand gold mine where a pilot plant of 3.1 m3/h was designed, constructed, and commissioned by COMRO at the Hercules Shaft of the East Rand Propriety Gold Mine. The findings indicated that although the process demonstrated high salt rejection and water recovery, its development was constrained by its high energy consumption, limited control of CaSO4 seeds, and membrane fouling (Juby 1996). Hence, developing membranes to improve their performance may increase the economic feasibility of the SPARRO technology.

Gypsum – Continuous Ion Exchange (GYP-CIX) Technology

Another process developed in South Africa is gypsum – continuous ion exchange (GYP-CIX). It is a continuous fluidised bed ion exchange process designed to remove calcium and sulphate from gypsum-saturated waters such as neutralised AMD (Schoeman and Steyn 2001). During the first stage of the GYP-CIX process, cations are removed by cation exchange resins. After cation removal, anions are then removed by anion exchange resins. When required, the anion and cation exchange resins are regenerated by lime and sulphuric acid, respectively. This can provide a treated water that has a neutral pH and low levels of dissolved calcium, sulphate, and metals.

Application of the GYP-CIX process was tested at a 11.4 m3/h pilot plant constructed to treat AMD generated by the Grootvlei gold mine. Flows of feed and treated water were continuous and uninterrupted with flow rates of 13.6 m3/hr and the process reduced the TDS levels in the mine water from 2000 to 4000 mg/L to less than 240 mg/L at water recoveries of 50–90%. It was found that GYP-CIX, similar to the SPARRO process, was suitable for the treatment of scaling mine waters, produces water of a high quality that can be used or sold as drinking water, and generates a brine that would have high disposal costs. Other benefits of this process include its use of low-cost chemicals and the generation of calcium and sulphate precipitates of relatively high quality with potential for reuse (Juby 1996). It was also suggested that the inclusion of a lime or limestone pre-treatment process could reduce the operational costs of this process. The study also indicated that the use of phosphoric or nitric acid for cation resin regeneration and ammonia or potassium carbonate or hydroxide for anion resin regeneration will increase costs but provide an opportunity to generate effluents that can be reacted with each other to produce ammonium and potassium nitrates and phosphates, which can be used as fertilizers. The process flow schematic of the GYP-CIX technology is shown in Fig. 6.

The Rhodes BioSURE Process

The Rhodes BioSURE process, developed in the early 1990s at the Rhodes University in South Africa, is a biological treatment used to remove acid from AMD using sewage sludge or organic wastes. Bench-level studies of the BioSURE process conducted at the University were followed by the construction and operation of a 40 kL/d pilot plant at the Grootvlei Mine in Springs and thereafter the construction of a technical-scale 2 ML/d plant at Ekurhuleni Water Care Company’s (ERWAT) Ancor wastewater treatment plant, which was connected by a 2.4 km pipeline to the Grootvlei Mine feed water. The success of this initiative prompted the design and construction of a full-scale 10 ML/d plant that was operated using primary sewage sludge from the treatment plant as an electron and carbon donor with the aim of reducing the sulphate content of the mine water. Figure 7 depicts the BioSURE process flow diagram.

Unfortunately, this plant only operated for a short period after completion of the acceptance tests due to the financial constraints experienced by Pamodzi Gold (Pty) Ltd. However, findings of the series of experiments and pilot-scale tests indicated that the re-use of sewage sludge or organic waste provided a considerable advantage of the BioSURE treatment process, which would reduce landfill loads and costs. It was thus both a cost-effective and environmentally sustainable treatment process (Corbett 2001). While using these wastes will make treatment cheaper, they could also be a potentially limiting reagent if sufficient stock is unavailable.

Current Challenges and Opportunities

The water that is discharged into the Blesbokspruit and Klip rivers by the HDS treatment plant has high salinity levels (Na and chloride) together with high levels of EC and TDS, mainly due to the sulphate concentrations. This is posing a risk to the ecology and environment and compromises the area’s water security in the near future (Lourenco and Curtis 2021b). Development and commissioning of desalination technologies, which are part of the TCTA’s long-term strategy to tackle the challenges of AMD at the Witwatersrand Basins, have not yet been introduced (TCTA 2020). It was reported by the TCTA that this delay is due to the procurement process not going smoothly including some financial challenges being faced by the DWS. This means that two-thirds of the funding is unavailable, which may disrupt the process and aggravate the impacts of the highly saline effluents being discharged into the Vaal water network. The water quality parameters that are used by stakeholders are not standard since the TCTA applies the prescribed limits from the DWS whilst others take into consideration the in-stream water quality guidelines developed by the Blesbokspruit and Klip Fora (Chetty et al. 2021c).

Research, development, and improvement initiatives are required. These should ensure that the water quality variables that were deemed “unacceptable” from previous studies are included in water quality monitoring programmes to ensure consistency when advising on immediate and long-term corrective measures. Furthermore, the water quality guidelines should be discussed, agreed upon, and accepted by all of the stakeholders, considering the requirements of multiple users as well as environmental sustainability. Other possible sources of TDS need to be confirmed based on the key data collected and analysed. This is because substantial increases in TDS might have long-term effects on aquatic creatures that have adapted to thrive in freshwater. The status quo of the Blesbokspruit riparian zones and their assimilative capacities must be established so that it is in accordance with the generation of effective and practical improvement and management plans. Water flow data should be included in the water quality monitoring programmes to extend the current baseline data and recommend applied, site-specific approaches to maintain the ecology of the Vaal system. The relevant authorities (including the DWS) must be represented at the relevant fora (e.g. the Blesbokspruit Forum and Klip River Forum) and should always be included as important stakeholders in projects, such as the Klip River Water Stewardship Initiative (KlipWaS). This will ensure that they provide the support and resources needed for development and ground-level implementation of the initiative, plan, or programme. Furthermore, looking at the highly saline waters in the Vaal system, it is vital that the desalination aspect of TCTA’s response to the AMD risks be implemented as soon as possible. Alternative methods of obtaining the required fundings or resources should be looked at and tracked, such as approaching international environmental organisations and creating public-private partnerships.

The possibility of recovering valuable products presents an opportunity that could partially offset the cost of the AMD treatment. For example, the REEs found in AMD from gold mines are of extreme value. Furthermore, sulphuric acid can be recovered from AMD and used to manufacture fertilisers, dyes, drugs, pigments, explosives, and storage batteries (Martí-Calatayud et al. 2014).

Conclusions and Future Prospects

AMD is a major environmental and social concern in South Africa and the rest of the world. It is only relatively recently that the environmental harm that South Africa’s gold mining industry has caused and will continue to inflict in the years to come has been fully understood. This article examined various potential strategies, treatment technologies, and resource recovery solutions, as well as important research gaps, problems, and opportunities associated with the AMD from South Africa’s gold mines.

Several active, passive, abiotic, and biotic treatment technologies have been investigated and, in some instances, implemented. However, chemical neutralisation remains very expensive and produces large amounts of potentially toxic waste. In addition, in many countries of the world, AMD occurs at old, abandoned, or ownerless mine sites, which implies that the governments of these countries must pay for AMD treatment. Further, AMD treatment can be required for years, decades, or even in perpetuity, thus resulting in high, long-term costs. Therefore, there is an urgent need to find ways to improve AMD treatment so that it is more environmentally, socially, and economically sustainable. Various active and passive treatments involving abiotic, biotic, or a combination of both techniques have been investigated and are generally promising at laboratory-scale and a few at pilot-plant scale. Alternative treatments offer several advantages including the requirement for less new materials because of recycling and reduced costs for treatment and disposal of potentially toxic sludge waste. However, to date, none of the newer techniques developed to treat large volumes of AMD have been implemented and proven to work on a large scale for an extended period. Thus, the next step for many of the newer treatments remains full-scale implementation and successful, long-term operation. Often, constraints like very costly initial capital expenses are a factor that needs to be overcome.

However, there is the real potential to produce by-products that could be sold to offset some of the initial capital costs as well as the on-going operational treatment costs. Some new technologies have successfully reclaimed valuable products such as REEs, other valuable minerals, and sulphuric acid.

With the possibility of more gold mines coming to the end of their productive lives, the research into more sustainable methods to treat AMD needs to be intensified. However, specific emphasis must now be on full-scale implementation of the most promising techniques that recover and sell valuable and marketable by-products. In turn, this could greatly offset the cost of traditional AMD treatment technologies and promote a circular economy in South Africa and the rest of the world.

References

Akcil A, Koldas S (2006) Acid Mine Drainage (AMD): causes, treatment, and case studies. J Clean Prod 14:1139–1145. https://doi.org/10.1016/j.jclepro.2004.09.006

Ambani A-E, Annegarn H (2015) A reduction in mining and industrial effluents in the Blesbokspruit Ramsar Wetland, South Africa: has the quality of the surface water in the wetland improved? Water SA 41:648–659. https://doi.org/10.4314/WSA.V41I5.08

Aubé BC, Zinck JM (1999) Comparison of AMD treatment processes and their impact on sludge characteristics. Proc Sudbury 99:261–270

Battsengel A (2018) Recovery of Rare Earth elements from apatite ores by hydrometallurgical processes. PhD Diss, Akita Univ

Borra CR, Pontikes Y, Binnemans K, Van Gerven T (2015) Leaching of rare earths from bauxite residue (red mud). Min Eng 76:20–27. https://doi.org/10.1016/j.mineng.2015.01.005

Charuseiam Y, Chotpantarat S, Sutthirat C (2021) Acid mine drainage potential of waste rocks in a gold mine (Thailand): application of a weathering cell test and multivariate statistical analysis. Environ Geochem Health 44:1049–1079. https://doi.org/10.1007/s10653-021-00976-1

Chetty S, Pillay L, Humphries MS (2021) Gold mining’s toxic legacy: pollutant transport and accumulation in the Klip River catchment, Johannesburg. S Afr J Sci 117:1–11. https://doi.org/10.17159/SAJS.2021/8668

Corbett CJ (2001) The Rhodes BioSURE process in the treatment of acid mine drainage wastewaters. Doctoral dissertation, Rhodes Univ, South Africa

De Beer M, Maree JP, Wilsenach J (2010) Acid mine water reclamation using the ABC process. Proc, IMWA Symposium. http://hdl.handle.net/10204/5137

De Wet L, Sidu S (2013) Water quality and compliance monitoring of treated underground and surface water at the Grootvlei proprietary mines and the Blesbokspruit wetland, springs, South Africa. Reliable Mine Water Technol:825–830

Du Plessis A (2023) South Africa’s water predicament: freshwater’s unceasing decline. Springer Nat. https://doi.org/10.1007/978-3-031-24019

Durand JF (2012) The impact of gold mining on the Witwatersrand on the rivers and karst system of Gauteng and North-West Province, South Africa. J Afr Earth Sci 68:24–43. https://doi.org/10.1016/J.JAFREARSCI.2012.03.013

DWA (2013) Feasibility study for a long-term solution to address the acid mine drainage associated with the East, Central and West Rand underground mining basins. Study Report no. 5.3: Options for use or discharge of water - DWA Report no. P RSA 000/00/16512/3. Pretoria

Expert Team of the Inter-Ministerial Committee (2010) Mine water management in the Witwatersrand Gold Fields with special emphasis on acid mine drainage. Report to the Inter-Ministerial Committee on Acid Mine Drainage, Pretoria

Humphries MS, McCarthy TS, Pillay L (2017) Attenuation of pollution arising from acid mine drainage by a natural wetland on the Witwatersrand. S Afr J Sci 113:9. https://doi.org/10.17159/sajs.2017/20160237

Jonah FE, Boateng I, Osman A (2016) Shoreline change analysis using end point rate and net shoreline movement statistics: an application to Elmina, Cape Coast and Moree section of Ghana’s coast. Reg Stud Mar Sci 7:19–31. https://doi.org/10.1016/J.RSMA.2016.05.003

Juby GJG (1996) Development of a novel membrane desalination technique for treating calcium sulphate scaling mine water: The SPARRO process. 3322–3322

Lourenco M, Curtis C (2021) The influence of a high-density sludge acid mine drainage (AMD) chemical treatment plant on water quality along the blesbokspruit wetland, South Africa. Water SA 47:35–44. https://doi.org/10.17159/wsa/2021.v47.i1.9443

Mararakanye N, Le Roux JJ, Franke AC (2022) Long-term water quality assessments under changing land use in a large semi-arid catchment in South Africa. Sci Total Environ 818:151670. https://doi.org/10.1016/J.SCITOTENV.2021.151670

Martí-Calatayud MC, Buzzi DC, García-Gabaldón M, Ortega E, Bernardes AM, Tenório JAS, Pérez-Herranz V (2014) Sulfuric acid recovery from acid mine drainage by means of electrodialysis. Desalination 343:120–127. https://doi.org/10.1016/j.desal.2013.11.031

Masindi V (2017) Recovery of drinking water and valuable minerals from acid mine drainage using an integration of magnesite, lime, soda ash, CO2 and reverse osmosis treatment processes. J Environ Chem Eng 5:3136–3142. https://doi.org/10.1016/j.jece.2017.06.025

McCarthy TS (2011) The impact of acid mine drainage in South Africa. S Afr J Sci 107. https://doi.org/10.4102/sajs.v107i5/6.712

Mulopo J (2015) Continuous pilot scale assessment of the alkaline barium calcium desalination process for acid mine drainage treatment. J Environ Chem Eng 3(2):1295–1302. https://doi.org/10.1016/j.jece.2014.12.001

Naicker K, Cukrowska E, McCarthy TS (2003) Acid mine drainage arising from gold mining activity in Johannesburg, South Africa and environs. Environ Pollut 122:29–40. https://doi.org/10.1016/S0269-7491(02)00281-6

Naidoo S (2022) Background on the Eastern Basin and the Blesbokspruit. In: Soc Constr Water Qual S Africa. Springer International Publishing, pp 31–59. https://doi.org/10.1007/978-3-030-98237-9_3

Pulles W, Juby GJG, Busby RW (1992) Development of the slurry precipitation and recycle reverse osmosis (SPARRO) technology for desalinating scaling mine waters. Water Sci Technol 25:177–192. https://doi.org/10.2166/wst.1992.0246

PwC (2018) Artificial intelligence in India – hype or reality. Retrieved from: https://www.pwc.in/consulting/technology/data-and-analytics/artificial-intelligence-in-india-hype-or-reality.html (accessed April 2023)

Rand water (2023) Rand water analysis standards. https://randwater.co.za/media/sans241/12month_Johannesburg_Feb2023.pdf (Accessed 4 August 2023)

Sahoo PK, Kim K, Equeenuddin SkMd, Powell MA (2013) Current Approaches for Mitigating Acid Mine Drainage. In: Rev Environ Contam Toxicol Vol 226. Springer New York, pp 1–32. https://doi.org/10.1007/978-1-4614-6898-1_1

Schoeman JJ, Steyn A (2001) Investigation into alternative water treatment technologies for the treatment of underground mine water discharged by Grootvlei Proprietary Mines Ltd into the Blesbokspruit in South Africa. Desalinat 133:13–30. https://doi.org/10.1016/S0011-9164(01)00079-0

Simate GS, Ndlovu S (2014) Acid mine drainage: challenges and opportunities. J Environ Chem Eng 2:1785–1803. https://doi.org/10.1016/j.jece.2014.07.021

TCTA (2017) 30 Years of Water Delivery, Integrated Annual Report

TCTA (2020) TCTA Financial Report 2019/2020. 1–27

Thorius T (2009) The effect of Grootvlei mine water on the Blesbokspruit. Univ of Johannesburg, MS thesis, Dept of Geography Environment & Energy. https://hdl.handle.net/10210/1989

Usher B, van Biljon W (2006) The impacts of coal and gold mining on the associated water resources in South Africa. Groundw Pollut Afr 301:314. https://doi.org/10.1201/9780203963548

van Rooyen M (2016) Acid mine drainage water treatment using SAVMIN™ process. SAIMM Hydromet 52:60

van Rooyen M, van Staden PJ, du Preez KA (2021) Sulphate removal technologies for the treatment of mine-impacted water. SAIMM 121:1–7. https://doi.org/10.17159/2411-9717/1541/2021

Yang X (2019) Leaching characteristics of rare earth elements from bituminous coal-based sources. Doctoral Dissertation, Univ of Kentucky https://doi.org/10.13023/etd.2019.229

Acknowledgements

The authors acknowledge the support received for this study from the Council for Scientific and Industrial Research (CSIR).

Funding

Open access funding provided by Council for Scientific and Industrial Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Baloyi, J., Ramdhani, N., Mbhele, R. et al. Acid Mine Drainage from Gold Mining in South Africa: Remediation, Reuse, and Resource Recovery. Mine Water Environ (2024). https://doi.org/10.1007/s10230-024-00994-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10230-024-00994-2