Abstract

Uncontrolled release of acid mine drainage (AMD) causes widespread detrimental impacts on the receiving environment. Thus, effective treatment to neutralise AMD effluent pH and capture a suite of metals is required. In-situ hydrotalcite (HTC) precipitation is an emerging technology for AMD remediation. HTC has an inherent capacity to accommodate a range of cations and anions during in situ formation, offering a method of broad-spectrum contaminant removal. This study explored the feasibility of using seawater as an Mg source and synthetic AMD in HTC formation. The HTC was formed from a stoichiometric combination of synthetic AMD and seawater. While three initial stoichiometric M2+:M3+ ratios of 2:1, 3:1, and 4:1 were investigated, only HTC with an M2+:M3+ ratio of 2:1 was generated, as confirmed by both mineralogical and geochemical analyses. Importantly, the HTC was demonstrated to effectively remove a suite of metals present in AMD such as Cu, Zn, Al, and Mn with removal rates of between 99.97 to 99.99%. The HTC precipitate contained ≈6.6% Cu and 4.1% Zn, and thus shows the potential, if required, for future metal recovery. Since submarine placement is often used in metal mining and processing operations proximal to the coast, the stability of the HTC precipitate in seawater was also investigated. Importantly, only 0.2% of the Cu and 1.1% of the Zn within the HTC were subsequently leaching in decreasing increments into seawater over 30 days with decreasing increments after the initial seven days. This indicates robust element retention and confirms the potential of HTC for AMD remediation with direct submarine placement.

Zusammenfassung

Die unkontrollierte Freisetzung von saurem Grubenwasser (Acid Mine Drainage – AMD) verursacht weitreichende, schädliche Auswirkungen auf die Umwelt. Folglich ist eine effektive Behandlung zur Neutralisierung des pH-Werts und Immobilisierung einer Reihe von Metallen erforderlich. Die in-situ Fällung von Hydrotalkit (HTC) ist eine neue Technologie zur Sanierung von AMD. HTC weist während der in-situ Bildung eine hohe Kapazität zur Aufnahme diverser Kationen und Anionen auf, und bietet damit eine Methode zur Entfernung eines breiten Schadstoffspektrums. In der vorliegenden Studie wurde die Möglichkeit einer Verwendung von Meerwasser als Magnesiumquelle für die HTC-Bildung mit synthetischem AMD untersucht. HTC wurde aus einer stöchiometrischen Kombination von synthetischem AMD und Meerwasser hergestellt: Während anfänglich drei stöchiometrische Me2 + /Me3 + Verhältnisse von 2:1, 3:1 und 4:1 untersucht wurden, wurde gemäß sowohl mineralogischen als auch geochemischen Analysen nur HTC mit einem Me2 + /Me3 + Verhältnis von 2:1 erzeugt. Im HTC konnte eine Reihe von in AMD typischerweise vorkommenden Metallen wie Cu, Zn, Al und Mn mit Entfernungsraten zwischen 99,97 und 99,99% effektiv zurückgehalten werden. Die Ausfällungen enthielten rund 6,6% Cu und 4,1% Zn, womit Potenzial für eine zukünftige Rückgewinnung der Metalle gegeben ist. Da bei Metallbergbau und -verarbeitung in Küstennähe häufig eine unterseeische Ablagerung angestrebt wird, wurde auch die Stabilität der HTC-Ausfällungen in Meerwasser untersucht. Nur 0,2% des Cu und 1,1% des Zn aus dem HTC wurden mit abnehmender Tendenz (v.a. über die erste Woche) über 30 Tage in das Meerwasser ausgewaschen. Dies deutet auf eine stabile Einlagerung der Elemente hin und bestätigt das Potenzial von HTC für die AMD-Sanierung bei unterseeischer Ablagerung.

Resumen

El vertido incontrolado de drenaje ácido de minas (DAM) tiene efectos perjudiciales generalizados en el medio ambiente receptor. Por lo tanto, se requiere un tratamiento eficaz para neutralizar el pH de los efluentes de AMD en inmovilizar una serie de metales. La precipitación in situ de hidrotalcita (HTC) es una tecnología emergente para la remediación de AMD. La HTC tiene una capacidad inherente para acomodar una serie de cationes y aniones durante la formación in situ, ofreciendo un método de eliminación de contaminantes de amplio espectro. Este estudio exploró la viabilidad de utilizar agua de mar como fuente de Mg y AMD sintético en la formación de HTC. El HTC se formó a partir de una combinación estequiométrica de AMD sintético y agua de mar. Aunque se investigaron tres relaciones estequiométricas iniciales M2 + :M3 + de 2:1, 3:1 y 4:1, sólo se generó HTC con una relación M2 + :M3 + de 2:1, como confirmaron los análisis mineralógicos y geoquímicos. Se demostró que el HTC eliminaba eficazmente varios metales presentes en el AMD, como Cu, Zn, Al y Mn, con tasas de eliminación de entre el 99,97 y el 99,99%. El precipitado de HTC contenía ≈6,6% de Cu y 4,1% de Zn, por lo que muestra el potencial para la recuperación de metales en el futuro. Dado que el emplazamiento submarino se utiliza a menudo en operaciones de extracción y tratamiento de metales próximas a la costa, también se investigó la estabilidad del precipitado HTC en agua de mar. Es importante destacar que sólo el 0,2% del Cu y el 1,1% del Zn dentro del HTC se lixiviaron posteriormente en incrementos decrecientes en el agua de mar durante 30 días con incrementos decrecientes después de los siete días iniciales. Esto indica una fuerte retención de elementos y confirma el potencial del HTC para la remediación de AMD con ubicación submarina directa.

摘要

酸性矿井排水 (AMD) 的失控排出对接收环境造成了广泛且有害的影响。因此, 需要对其高效处理来中和AMD流出物的pH值, 并捕获一系列金属。原位水滑石 (HTC) 沉淀是一种新兴的AMD修复技术。在原位生成过程中, HTC具有容纳一系列阳离子和阴离子的固有能力, 提供了一种广谱污染物去除方法。本研究探讨了在HTC形成中使用海水作为镁源和合成AMD的可行性。HTC是由合成AMD与海水按比例结合而成的。经研究了三种初始化学计量比为2:1、3:1和4:1的M2 + : M3 + , 正如矿物学和地球化学分析所证实的那样, 只有M2 + :M3 + 比例为2:1的HTC被生产出来。重要的是, HTC被证明能够有效地去除AMD中存在的一系列金属, 如铜、锌、铝和锰, 去除率在99.97%至99.99%之间。HTC沉淀物含有约等于6.6%的铜和4.1%的锌, 因此显示了未来金属回收的潜力 (如果需要) 。由于在靠近海岸的金属采矿和加工作业中经常需要海底安置, 因此也对HTC沉淀物在海水中的稳定性进行了研究。重要的是, HTC中只有0.2%的铜和1.1%的锌在30天内以递减的方式浸出到海水中, 并从开始7天后递减速度降低。这表明, HTC具有强大的元素保留能力, 也证实了HTC直接在海底安置以修复AMD的潜力。

Similar content being viewed by others

Introduction

Acid mine drainage (AMD) has been categorised as one of the most crucial emerging environmental issues worldwide (United Nations 2010). AMD occurs primarily when exposed sulfide minerals react with water and atmospheric oxygen to produce sulfate and acidity, which leads to the dissolution and mobilisation of a variety of elements including metals and metalloids (Dold 2014; RoyChowdhury et al. 2015; Taylor et al. 2005).

An array of both passive and active remediation technologies have been established to remediate AMD (Acharya & Kharel 2020; Rodríguez-Galán et al. 2019; Skousen et al. 2019). Currently, lime neutralisation is the most globally applied method. This is because the technique is simple and the raw material, lime, is naturally abundant as limestone prior to calcination and relatively inexpensive (Aube & Zinck 2003; Olds et al. 2013; Tolonen et al. 2014). Nonetheless, lime treatment may produce voluminous gypsum-based sludges via the neutralisation of the sulfate acidity present in AMD. These sludges require substantial disposal areas, and where required, significant costs to dewater the produced lime sludge (Douglas 2014). The occurrence of armouring via Fe-oxyhydroxide precipitation (Mangunda 2021) also negatively affects the efficiency of this method. Given the recognised limitations of lime use in the neutralisation of AMD, efforts have been made to develop robust alternative technologies.

Hydrotalcites (HTC) are a sub-class of layered double hydroxide compounds (Cavani et al. 1991; George 2015; Miyata 1983; Shin et al. 1996; Ulibarri et al. 2001) and are considered as a viable alternative to lime-based AMD treatment (Douglas 2014; Douglas et al. 2010, 2014; Gomez et al. 2023). Within the HTC, positively charged metal hydroxide layers can accommodate a wide range of metals including divalent (M2+) and trivalent (M3+) cations, whilst the interlayers contain water molecules and anions. The M2+ and M3+ mixed layers have a trigonal structure akin to brucite (Mg(OH)2) (Debek et al. 2017). The empirical formula of HTCs is M(1-x)2+ Mx3+ (OH)2 An− yH2O, in which M2+ and M3+ refer to + 2 and + 3 cations and x represents the total + 3 cations, An− denotes anions with -n charge, while y is the number of water molecules.

In general, the HTC composition is dominated by Mg2+ and Al3+ (Lauermannova et al. 2020); however, other divalent and trivalent ions such as Fe3+, La3+, Ca2+, Ni2+, Mn2+, Zn2+, Cr2+/3+, and Zr2+ may also substitute into the structure (Cavani et al. 1991; Lozano et al. 2012; Shin et al. 1996; Ulibarri et al. 2001). In terms of anions, HTC interlayers can accommodate a range of major anions including SO42−, CO32− and Cl− amongst others (Cavani et al. 1991; Lozano et al. 2012; Shin et al. 1996; Ulibarri et al. 2001). Anion occupancy, is, however considered complex (e.g. Goh et al. 2008; Miyata 1983; Theiss et al. 2014) with both crytallinity (Hibino 2018) and composition (Delorme et al. 2013; Prasad et al. 2011) known to be influential. Given the inherent capacity of HTC to incorporate a range of cations and anions of different valencies, it can be used to remove a range of contaminants present in AMD during in situ formation. Additionally, relative to lime, HTC precipitation offers additional benefits such as rapid reaction kinetics and substantially less sludge production with a stable precipitate (Douglas 2014; Douglas et al. 2010, 2014). The use of soluble reagents during in situ HTC formation, where required, also overcomes challenges in mixing and dispersion often experienced in lime use and can often be achieved in-pipe without the use of costly mixing infrastructure. In addition, the settling of HTC, whether in pit or enhanced settling using mechanical means or alternatively dissolved air flotation (DAF), allows real-time, low-cost precipitate recovery from the co-existing solute (Douglas et al. 2010, 2013).

We have developed a method of in situ HTC precipitation from AMD (Douglas et al. 2010). This method has been demonstrated to quantitatively remove a wide range of + 2 and + 3 cations including transition metals, metalloids, rare earth elements, and radionuclides (Cheng et al. 2014; Douglas et al. 2010; Yan et al. 2020). Furthermore, HTC precipitation has also been integrated with reverse osmosis (Douglas 2014) and bioprocesses such as biological denitrification and sulfate reduction (Cheng et al. 2014, 2021; Yan et al. 2020).

Submarine tailings placement (STP) has been used as an alternative technology for disposal of waste materials that may include tailings and (neutralised) AMD where mines are located in coastal areas (Ramirez-Llodra et al. 2015; Whittington et al. 2003). In practice, STP is operated by discharging solids and effluent through a pipeline system to the deep ocean. The underwater gravity flow allows contaminants contained in AMD solids following neutralisation to be deposited on the seabed within or below the euphotic zone (Ramirez-Llodra et al. 2015). STP technology significantly reduces storage dam management issues related to dam failures and mine operational land requirements. Major contaminants of concern in AMD are frequently regulated under freshwater and marine water quality guidelines (e.g. Australian and New Zealand Water Quality Guideline for Fresh and Marine Water Quality 2018), requiring planned STP disposal to facilitate adequate environmental protection. Nonetheless, a potential exists for substantial release of contaminants from conventional STP practices (Embile et al. 2018; Pedersen et al. 2022; Vare et al. 2018).

In the current study, an improved method of submarine placement of AMD derived from coastal mines is proposed where in situ HTC precipitation is used to incorporate a suite of AMD contaminants. This concept involves pumping seawater from the ocean to be used as both a source of Mg (ca. 1270 mg/L) and partial bicarbonate alkalinity (pH 8.1), with subsequent in-line mixing with hydroxide alkalinity to produce a HTC precipitate prior to ocean discharge.

Here we used a synthetic AMD containing a diverse array of metals and sulfate. This AMD analogue was added to seawater to produce HTC in situ prior to separation and characterisation of the mineralogy and composition. Thereafter, seawater leaching tests were conducted to investigate the stability of the HTC in conditions similar to that experienced in an submarine placement environment.

Materials and Methods

Seawater Sampling and Analysis

Coastal seawater (20 L) was collected from Kwinana Beach, Western Australia, and filtered using a 0.45 µm filter. Analysis of major elements (Na, K, Ca, Mg, and S) and trace elements (Cu and Zn) was conducted by the ChemCentre, Western Australia using inductively coupled plasma-mass spectrometry (ICP-MS) according to the American Public Health Association (2005) method.

Preparation of AMD Solution

A synthetic AMD solution (2 × 5 L batches) were prepared as an analogue of acidic, metalliferous pit water from the Baal Gammon mine (Douglas 2014). Analytical grade reagents: AlCl3·6H2O (3.13 g), CuCl2·2H2O (0.54 g), FeCl3·6H2O (1.43 g), ZnSO4·7H2O (0.48 g), CaCl2·2H2O (2.38 g), Na2SO4 (1.05 g), KCl (0.08 g), MnCl2·4H2O (0.29 g), and MgCl2·7H2O (2.93 g) were placed in an acid-washed 2 L beaker followed by the addition of 18 M H2SO4 (3.5 mL), and MilliQ water (1 L). The synthetic AMD solution was adjusted to pH 3 by the addition of 1 M HCl and then brought to 5 L with MilliQ water. Both 5 L batches of AMD were mixed together prior to use to ensure uniformity.

Hydrotalcite (HTC) Synthesis

Three samples of synthetic AMD solution (3 L) were placed in acid-washed beakers and stirred using Teflon®-coated magnetic bars. Either 162, 349, or 536 mL of seawater was then added to the synthetic AMD samples to achieve M2+:M3+ molar ratios of 2:1, 3:1, and 4:1, respectively. To formulate these ratios, the moles of M2+ ions (Cu2+, Zn2+, Mn2+, and Mg2+) and the moles of M3+ ions (Al3+ and Fe3+) in synthetic AMD, as well as the moles of Mg2+ in seawater (1425 mg/L or 58.6 mM as measured), were considered.

The seawater volume used was calculated based on the supplemental moles of Mg2+ from seawater required to achieve the required 2:1, 3:1, and 4:1 M2+:M3+ ratios. As HTC forms at a pH range between 8 and 9.5, 1 M NaOH solution was added slowly until the pH endpoint was reached with constant stirring. The HTC suspensions were covered and stored for two weeks to facilitate an increased degree of crystallinity for x-ray diffraction (XRD) analysis. Thereafter, each HTC suspension was centrifuged, and the precipitate was washed three times using MilliQ water followed by oven-drying at 60 °C for seven days. An identical batch of freshly made HTC centrifuged and then resuspended in seawater was prepared for use in leaching experiments (see later).

X-Ray Diffraction (XRD) analysis of hydrotalcite (HTC) precipitates

The mineralogy of the HTC precipitates was determined by XRD analysis. The analyses were performed by CSIRO Land and Water, Adelaide. Micronisation in ethanol was conducted using about 1 g of each HTC sample for 10 min followed by pressing into a stainless-steel holder. A PANalytical X’pert Pro diffractometer was used to acquire the XRD data. The instrument was set using Co Kα radiation with an automatic divergence slit, accompanied by a post-diffraction monochromator, and X’Celerator fast Si strip detector using a 0.5 s counting time per step every 0.05° over 5 to 80° 2ϴ.

X-Ray Fluorescence (XRF) analysis of hydrotalcite (HTC) precipitates

The HTC precipitates were analysed by pressed powder XRF to determine major elements (wt%): MgO, Al2O3, SiO2, P2O5, SO3, Cl, K2O, CaO, TiO2, MnO, Fe2O3; and trace elements (mg/kg): Ni, Zn, Cs, Cu, Ba, La, and Ce. The XRF analyses were conducted at CSIRO Land and Water, Adelaide. Licowax binder (1 g) was mixed with each HTC sample (4 g) followed by vigorous shaking and pressing with boric acid backing up to 10 tonnes. The sample was then characterised using a Spectro X-Lab 2000 energy dispersive XRF using a Pd X-ray tube.

Hydrotalcite Leaching Experiments

Twelve acid-washed polyethylene containers containing 1 L of filtered seawater were prepared. Freshly made HTC suspensions in 2:1, 3:1, 4:1 ratios (110 mL equating to 0.2 g/L final HTC concentration) under 1 h in age were added to the polyethylene containers with seawater in triplicate with gentle mixing to ensure resuspension. The remaining triplicate seawater samples were used as controls. For each experiment, the pH was measured, and a subsample was taken after brief mixing and resuspension to homogenise the system and filtered (0.45 µm) after 0, 1, 7, 14, and 30 days. The subsamples were then analysed using an Agilent 7900 ICP-MS to determine Al, Ca, Cu, Fe, Mg, Mn, Zn, and S by the ChemCentre, Western Australia according to the American Public Health Association (2005) method.

Results

Coastal Seawater Characteristics

The physical and chemical characteristics of the coastal seawater sample are presented in Table 1. The seawater used in this study contained an elevated concentration of Mg of 1425 mg/L relative to an average seawater concentration of ca. 1270 mg/L (Villca et al. 2020), which was considered in the preparation of the HTC to produce the M2+: M3+ solution ratios of 2:1, 3:1, and 4:1.

Synthetic AMD and HTC Supernatant Characteristics.

The summary of physical and chemical characteristics of synthetic AMD before and after HTC precipitation is shown in Table 1. The addition of seawater and NaOH solution to the synthetic AMD solution substantially modified the composition of the synthetic AMD solution. The concentration of trace elements such as Zn, Fe, and Mn reduced significantly to below their respective detection limits following the precipitation of the 2:1, 3:1, and 4:1HTCs. Dissolved Cu was substantially reduced following precipitation of all three HTCs with concentrations of between 0.003 and 0.009 mg/L. In contrast, the concentration of some major elements in the AMD, in particular Ca, Mg, and SO42−, increased after HTC precipitation due to the addition of seawater. Whilst some residual Al was present at the initially elevated pH (9.50–9.75), this reduced further as the solution equilibrated with the ambient atmosphere via CO2 uptake to a final pH of ca. 8.5–8.7.

HTC Formation

The addition of 162 mL, 349 mL, and 536 mL of seawater to synthetic AMD solution to produce M2+:M3+ ratios of 2:1, 3:1, and 4:1 resulted in a slight increase in the pH of the solution from 3.0 to 3.02, 3.07, and 3.13, respectively. The addition of seawater contributed between 0.4% to 1.5% of the final total (HCO3− + OH−) alkalinity requirement. To achieve the endpoint pH of 9.5, an average of 72 mL of NaOH solution (1 M) was added for each ratio. The addition of NaOH to pH 9.5 resulted in the spontaneous precipitation of ≈2 g of HTC precipitate being produced using each of the three different M2+:M3+ ratios.

Mineralogy of Hydrotalcite Precipitates

The mineralogy of the HTC precipitates is shown in Fig. 1. The XRD diffractogram shows the three HTC samples, prepared from different initial M2+:M3+ ratios, have similar characteristics indicated by comparable peak positions, except for the occurrence of the broad peak at ca. 24° 2ϴ in the 2:1 HTC precipitate. The broad peaks produced in these diffractograms, however, are consistent with the HTC containing both mixed cations in the metal hydroxide layers and mixed anions in the interlayers. The mineralogy of the HTC as indicated by peaks at 11°, 23°, and 72° 2ϴ is similar to that of woodwardite, a Cu-SO4 bearing type of HTC with the formula: Cu1-xAlx(OH)2(SO4)x/2·nH2O (Fig. 1). The absence of other Mg or Fe minerals such as brucite and schwertmannite confirm that no other major, crystalline, non-target minerals were present in the final precipitate.

Composition of Hydrotalcite Precipitates

The composition of seawater-synthetic AMD-based HTC precipitates from XRF analysis is shown in Table 2. The geochemical composition was similar to a HTC 2:1 ratio, irrespective of the planned M2+:M3+ ratio, which is in agreement with the XRD analysis. The predominant elements were MgO (41.37%), Al2O3 (20.14%), Fe2O3 (12.86%), and MnO (2.35%), with SO42− as an interlayer anion expressed as SO3 (8.33%). The HTC also contained substantial Zn (4.1%) and Cu (6.6%). The HTCs also contained other trace and rare earth elements including Ni, Ba, Cs, La, and Ce at concentrations less than 50 mg/kg, all originally present as minor contaminants in the reagents used to produce the AMD or in the seawater.

Hydrotalcite Leaching Experiments

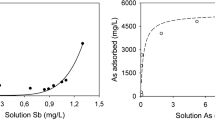

To simulate submarine placement of the HTC-immobilised AMD contaminants, the three HTC suspensions initially prepared from M2+:M3+ ratios of 2:1 to 4:1 were each placed into a large volume of seawater to examine the potential for leaching of cations and anions. The supernatant chemical compositions that evolved during the 30 day HTC leaching tests are shown in supplemental Table S-1 and Fig. 2.

A common set of trends is apparent in trace element behaviour from the 2:1, 3:1, and 4:1 HTC in seawater over 30 days (Fig. 2). In general, the 2:1 and 3:1 HTC have a similar extent and dynamics (shape) of release with most of the trace element release for Cu, Zn, and Mn occurring over the initial seven days; thereafter, the extent of release was much reduced approaching an asymptote of ≈ 0.016 mg/L, 0.030 mg/L, and 0.50 mg/L, respectively, at 30 days. In contrast, the extent of release from the 4:1 HTC was attenuated for Cu, Zn, and Mn concentrations over the 30 days with final concentrations of 0.014 mg/L, 0.026 mg/L, and 0.010 mg/L, respectively.

In contrast to the other dissolved metals, Al had an initial increase in dissolved concentrations to between 0.20 and 0.30 mg/L for the 2:1 and 3:1 HTC. This initial increase was followed by a rapid decline to below the detection limit at 30 days. Again, the extent of Al release was attenuated for the 4:1 HTC with an initial (maximum) concentration of 0.05 mg/L.

For Ca and Mg, similar increases occurred for all three of the HTC ratios (Fig. 2). Mg concentrations increased irregularly from ≈1440 mg/L to a final concentration of 1550 mg/L, whilst Ca concentrations increased from an initial ≈1480 mg/L to a final concentration of 1550 mg/L.

Discussion

Hydrotalcite Formation

Detailed mineralogy and composition analyses confirmed that the reaction of synthetic AMD solution and seawater produced a mixed metal and anion HTC of high purity with no other phases apparent. Importantly, it was demonstrated that seawater containing an inherently high concentration of Mg was effective as a feedstock for HTC formation.

Previous thermodynamic modelling of HTC formation from an acidic, metal-laden solute (Douglas et al. 2014) similar to AMD suggests that initial precipitation occurs at ≈pH 4 via the formation of a suite of metastable Fe, Al–OH-SO4 minerals, including one or more of jarosite (Na,KFe3(OH)6(SO4)2), alunite (K,NaAl3(SO4)2(OH)6), and schwertmannite (Fe8O8(SO4)1.5(OH)5·15H2O. With increasing pH above 5, a series of amorphous Al–OH phases including Al(OH)3 precipitated and subsequently redissolved into aluminate (Al(OH)4−) anions. Thereafter, with pH increasing above 9, most of the Mg from the AMD and seawater was present as brucite (Mg(OH)2. In the presence of aluminate, the brucite is incorporated via spontaneous, self-assembly into neoformed HTC. Low residual Mg solute concentrations between 33 to 174 mg/L following the formation of the HTC 2:1 to 4:1 precipitates, respectively, with similarly low concentrations of Al and other metal ions and the single mineralogy confirms their incorporation into the HTC (Tables 1, 2). A suite of anions including SO42−, HCO3−, and Cl- were similarly incorporated within the interlayers between the positively charged, metal hydroxide sheets (Tables 1, 2).

The experiments undertaken in this study highlight the ability of the HTC formed from a synthetic AMD and seawater to accommodate a range of metals including Cu, Zn, Fe, and Mn within its structure, with removal rates in this study between 99.97 to 99.99%. This is consistent with previous reports of the ability of HTC to act as a multi-element/contaminant repository (Douglas 2014; Douglas et al. 2010, 2014), albeit those studies used Mg salts of Mg(OH)2 as the M2+/Mg source.

As documented by XRD and XRF analysis, the 2:1, 3:1, and 4:1 HTC compositions lie on a mixing line between the AMD and seawater (Fig. 3) from the starting solution (pH 3.0) and final solute pH of ≈9.5. Interestingly, the XRD and XRF results (Table 2, Fig. 1) showed that irrespective of the planned HTC composition, with initial molar ratios of M2+: M3+ of 2:1, 3:1, and 4:1, all of the HTCs had a similar mineralogy and chemical composition consistent with a molar ratio of 2:1. The empirical formula for the mean of the 2:1, 3:1, and 4:1 HTC using SO42− as the likely predominant anion to be incorporated from the mixed AMD-seawater system was (Mg3.44Cu0.35Zn0.21)(Al1.34Fe0.55Mn0.11)SO4(OH)12·4H2O.

It has been noted in the production of other HTCs from waste streams such as the alumina industry that the pH during the precipitation process is an important factor in the final HTC ratio produced. According to Smith et al. (2005a, b), HTC incorporating an M2+:M3+ of 4:1 is only generated when the final pH is maintained below 9; above that pH, HTC incorporating an M2+:M3+ of 2:1 is likely to form, irrespective of the initial M2+:M3+ ratio. Since the final pH in this study was maintained at around 9.50–9.75, only HTCs containing an M2+:M3+ ratio of 2:1 was generated. Thus, a potential exists, based on the initial M2+:M3+ stoichiometry and the final pH of neutralisation to tailor the final HTC composition. This is particularly important considering the potential leachability of metals from HTC deposited as part of the STP, potentially with tailings, in the deep ocean (see later).

Potential for Recovery of Cu and Zn from HTC

Given the substantial element concentration factors documented in this study (e.g. Cu concentration factor of ≈1650 ± 70 times relative to the synthetic AMD), a potential exists for recovery of metal values of Cu (6.6%) and Zn (4.1%) contained within the HTC. Notably, the Cu contained in the HTC is three to five times that of hard rock Cu ore grades typically mined internationally (Northey et al. 2014) and thus constitutes a valuable, indirect pathway for increased value recovery from a mine. In addition, recovering Cu and other elements in HTC “ore” produced via seawater pumped onshore would reduce the final inventory of contaminants to be disposed of via submarine placement.

Potential pathways for Cu and other element recovery may include recycling via the primary metallurgical circuit, as acid-leaching would lead to complete HTC dissolution. Alternatively, investigation of partial leaching techniques to selectively recover the Cu and other elements could possibly underpin a smaller, but based on the HTC “ore” grade, a substantially higher value, parallel process that would in part offset the AMD treatment costs. If the Cu and other elements in the HTC “ore” were not recovered onshore, with HTC disposal via submarine placement, then the potential stability of this material in a (deep) oceanic environment needs to be considered. This is examined below.

Stability of Hydrotalcite Suspensions

Exposing the three HTC suspensions, prepared from different initial M2+:M3+ ratios of 2:1, 3:1, and 4:1, to seawater generally resulted in an initial increase in metal concentrations, such as Cu, Zn, Mn, and the major seawater cations Mg and Ca, but a significant decrease in the concentration of Al in seawater throughout the 30-day leaching experiment (Fig. 2). The Al from the synthetic AMD solution may not have been immediately incorporated during the HTC precipitation. Thereafter, the Al may have been removed by a combination of processes including secondary HTC formation (Angel et al. 2015) or the formation of aluminosilicate minerals (e.g. Nogami 2014).

The observation that less Cu, Zn, and Mn was leached, and less residual Al was also present, from HTC prepared with an increasing M2+:M3+ ratio from 2:1 to 4:1 represents an interesting and hitherto unforeseen outcome. Thus, whilst the final composition of the HTC with an M2+:M3+ ratio of 2:1 was consistent across all three precipitates, as indicated by XRD (Fig. 1) and XRF (Table 2) analyses, it may be that subtle differences are engendered in the HTC structure via the different initial ratios. This may occur due to the phenomena described in Smith et al. (2005a, b), where HTC with an M2+:M3+ other than 2:1 is only generated when the final pH is maintained below 9; above that pH, HTC incorporating an M2+:M3+ of 2:1 is likely to form irrespective of the initial M2+:M3+ ratio. It is perhaps that at as pH 9 is traversed, HTCs with initial M2+:M3+ ratios of 3:1 and 4:1 revert to a 2:1 M2+:M3+ ratio and there is a carryover of residual structural and compositional characteristics.

The observation that the metals and major cations followed a similar trend of the largest initial change (increase for Cu, Zn, Mn, Mg, and Ca) or decrease (Al) with the additional subtle influence imparted by the initial M2+:M3+ ratios in the first 0–14 days, followed by a period of substantially less change in concentration, is indicative of an HTC-solute equilibration phase. Importantly, in this context, HTC age is known to influence its stability. Palmer (2010) discovered that fresher HTCs were less stable in solution. Since freshly made HTCs were used in the leaching experiments and exposed to substantial dilution with fresh seawater, this may explain the changes in the concentration of metals and anions in the seawater leachate. Geochemical (XRF) analysis (Table 2) suggests a mixed anion suite with SO42− predominating and less Cl− present in the HTC interlayers. Nonetheless, at the elevated pH of the solutions during HTC precipitation; given that seawater has a HCO3− concentration of ≈140 mg/L, it is likely that a mixed anion suite including HCO3− was present.

Among the metals contained in the synthetic AMD, Cu and Zn are the major contaminants of concern in terms of potential toxicity in the marine environment as regulated under a range of international water quality guidelines. The average concentrations of Cu and Zn that leached into seawater across the three HTCs after 30 days were 0.016 mg/L and 0.027 mg/L, respectively, using a solid to solution ratio of 0.2 g of HTC solids per litre of seawater. Whilst approximately double Australian marine water guidelines (ANZG 2018), dilution factors during a post-submarine disposal will be substantial, with a solid to solution ratio likely many times lower, and with correspondingly lower solute concentrations than employed during the leaching tests used in this study. Based on the average concentrations of Cu and Zn in the HTC precipitates, only 0.2% of the Cu and 1.1% of the Zn were leached into the seawater over 30 days, indicating that these metal ions are likely stable within the HTC, more so given the final solute concentrations in the 2:1 and 3:1 HTC that had stabilised, with essentially no further leaching evident at 30 days.

As the proposed final disposal of HTC precipitates is via submarine disposal, it is crucial to meet the standard threshold of metals in a seawater ecosystem. In practice, if the substantial metal value accumulated within the HTC structure was not already recovered, submarine disposal would entail far higher dilution rates as a result of seawater mixing and dispersal, thus resulting in very low dissolved metal concentrations. Thus, HTCs prepared from a combination of AMD and seawater may constitute a viable repository to immobilise Cu and Zn contained in AMD solutions.

Conclusions

In this study, a combination of a synthetic AMD solution and seawater (as an Mg source) followed by the addition of alkali to increase the final pH to ≈9.5 was used to successfully form a HTC. From the three initial M2+:M3+ ratios (2:1, 3:1, and 4:1), only HTC with an M2+:M3+ ratio of 2:1 was generated, as indicated by both the mineralogical and geochemical analyses. The HTCs were demonstrated to effectively remove an array of metals present in AMD, including Cu, Zn, Al, and Mn with removal rates in this study between 99.97 to 99.99%. The HTC precipitates formed from the simulated AMD were composed of 6.6 and 4.1% Cu and Zn, respectively, and thus show the potential for future metal recovery from the precipitate prior to eventual submarine placement, post-metal extraction.

Although only an HTC with M2+:M3+ ratio of 2:1 was produced, leaching experiments indicated that the three HTC samples prepared from different initial M2+:M3+ ratios, behaved in a subtly different manner in seawater. A small increase in Cu, Mn, Mg, and Ca concentrations, as well as a more significant decrease in Al concentrations, were observed throughout the leaching period. HTC produced from an initial M2+:M3+ ratio of 2:1 displayed the greatest element mobility followed by HTC produced from an initial M2+:M3+ ratio of 3:1 and 4:1. Importantly, only 0.2% of the Cu and 1.1% of the Zn within the HTC were leached into the seawater over 30 days, indicating that these metal ions are stable within the HTC, with minimal leaching into the seawater. Nonetheless, further work should compare the stability of freshly prepared and aged HTCs in seawater to ensure the short- and long-term stability of HTCs as metal contaminant repositories.

Data availability

All data generated in this study can be made available to third parties for non-commercial purposes upon request.

References

Acharya BS, Kharel G (2020) Acid mine drainage from coal mining in the United States-an overview. J Hydrol 588:125061. https://doi.org/10.1016/j.jhydrol.2020.125061

Angel BM, Apte SC, Batley GE, Golding LA (2015) Geochemical controls on aluminium concentrations in coastal waters. Environ Chem 13:111–118. https://doi.org/10.1071/EN15029

APHA American Public Health Assoc (2005) Standard methods for the examination of water and wastewater, 21st edn. American public health assoc, Washington DC

Aube B, Zinck J (2003) Lime treatment of acid mine drainage in Canada. Brazil-Canada Seminar on Mine Rehabilitation. www.researchgate.net/publication/237648554_Lime_Treatment_of_Acid_Mine_Drainage_in_Canada

ANZG (2018) Australian and New Zealand Water Quality Guideline for Fresh and Marine Water Quality. Australian and New Zealand Governments and Australian state and territory governments, Canberra, ACT, Australia, Retrieved 3 March, 2023. https://www.waterquality.gov.au/anz-guidelines/guideline-values/default/water-quality-toxicants/search

Cavani F, Trifiro F, Vaccari A (1991) Hydrotalcite-type anionic clays: preparation, properties and applications. Catal Today 11(2):173–301. https://doi.org/10.1016/0920-5861(91)80068-K

Cheng KY, Kaksonen AH, Douglas GB (2014) Sequential in situ hydrotalcite precipitation and biological denitrification for treatment of high-nitrate industrial effluent. Bioresour Technol 172:373–381. https://doi.org/10.1016/j.biortech.2014.09.050

Cheng KY, Acuna CR, Kaksonen AH, Esslemont G, Douglas GB (2021) Treatment of neutral gold mine draiange by sequential in situ hydrotalcite precipitation, and microbial sulfate and cyanide removal. Sci Total Environ 801:149613. https://doi.org/10.1016/j.scitotenv.2021.149613

Debek R, Motak M, Grzybek T, Galvez ME, De Costa P (2017) A short review on the catalytic activity of hydrotalcite-derived materials for dry reforming of methane. Catalysts 7(1):12. https://doi.org/10.3390/catal7010032

Delorme F, Seron A, Vergnaud B, Galle-Cavalloni P, Jean-Prost V, Manguin J (2013) Evidence of the influence of the cationic composition on the anionic affinity of layered double hydroxides. J Mater Sci 48:5273–5279. https://doi.org/10.1007/s10853-013-7318-5

Dold B (2014) Evolution of acid mine drainage formation in sulphidic mine tailings. Minerals 4:621–641. https://doi.org/10.3390/min4030621

Douglas GB (2014) Contaminant removal from acidic mine pit water via in situ hydrotalcite formation. Appl Geochem 51:15–22. https://doi.org/10.1016/j.apgeochem.2014.09.005

Douglas GB, Wendling LA, Pleysier R, Trefry MG (2010) Hydrotalcite formation for contaminant removal from Ranger mine process water. Mine Water Environ 29:108–115

Douglas G, Shackleton M, Woods P (2013) Hydrotalcite formation facilitates effective contaminant and radionuclide removal from acidic uranium mine barren lixiviant. Appl Geochem 42:27–37

Douglas GB, Shacleton M, Woods P (2014) Hydrotalcite formation facilitates effective contaminant and radionuclide removal from acidic uranium mine barren lixiviant. Appl Geochem 42:27–37. https://doi.org/10.1016/j.apgeochem.2013.12.018

Embile RF, Walder IF, Schuh C, Donatelli JL (2018) Cu, Pb and Fe release from sulfide-containing tailings in seawater: Results from laboratory simulation of submarine tailings disposal. Mar Pollut Bull 137:582–592. https://doi.org/10.1016/j.marpolbul.2018.11.012

George W (2015) Mechanisms of UV Stabilization. In: George W (ed) Handbook of UV Degradation and Stabilisation. ChemTec Publishing, USA

Goh KH, Lim TT, Dong Z (2008) Application of layered double hydroxides for removal of oxyanions: a review. Water Res 42:1343–1368. https://doi.org/10.1016/j.watres.2007.10.043

Gomez MA, Ma X, Chen Y, Wang S, Pollastri S, Aquilanti G, Cui Y, Xiao YS (2023) Determination of As (V), Se (VI) and Mo (VI) bonding environments in MgAlFe (III) CO3SO4 Hydrotalcites relevant to uranium mill neutralization processes and tailings. Research Square (preprint). 100:8527

Hibino T (2018) Anion selectivity of layered double hydroxides: effects of crystallinity and charge density. Eur J Inorg Chem 2018:722–730. https://doi.org/10.1002/ejic.201701067

Lauermannova A, Paterova I, Patera J, Skrbek K, Jankovsky O, Bartunek V (2020) Hydrotalcite in Construction Materials. Appl Sci 22(10):7989. https://doi.org/10.3390/app10227989

Lozano RP, Rossi C, Iglesia AL, Matesanz E (2012) Zaccagnaite-3R, a new Zn-Al hydrotalcite polytipe from El Soplao Cave (Cantabria, Spain). Am Mineral 4(97):513–523. https://doi.org/10.2138/am.2012.3908

Mangunda CT (2021) An investigation into the precipitation of Fe(III) oxyhydroxides in lime neutralisation processes. PhD Thesis, Univ of Capetown. https://hdl.handle.net/11427/31743

Miyata S (1983) Anion-exchange properties of hydrotalcite-like compounds. Clays Clay Miner 31:305–311. https://doi.org/10.1346/CCMN.1983.0310409

Nogami K (2014) Relationship in chemical composition between mother solution and allophane-like aluminosilicate precipitate through neutralization of acid hydrothermal water by seawater. Earth Planets Space 56:457–462. https://doi.org/10.1186/BF03352498

Northey S, Mohr S, Mudd GM, Weng Z, Giurco D (2014) Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining. Resour Conserv Recycl 83:190–201. https://doi.org/10.1016/j.resconrec.2013.10.005

Olds WE, Tsang DCW, Weber PA, Weisener CG (2013) Nickel and zinc removal from acid mine drainage: roles of sludge surface area and neutralising agents. J Min 5:698031. https://doi.org/10.1155/2013/698031

Palmer SJ (2010) Stability of hydrotalcites formed from Bayer Refinery environmental control processes. Queensland Univ of Technology. https://eprints.qut.edu.au/48672/1/Sara_Palmer_Thesis.pdf

Pedersen KB, Lejon T, Jensen PE, Ottosen LM, Frantzen M, Evenset A (2022) Impacts of climate change on metal leaching and partitioning for submarine mine tailings disposal. Mar Poll Bull. 184:114197. https://doi.org/10.1016/j.marpolbul.2022.114197

Prasad BE, Kamath PV, Vijayamohanan K (2011) Anion exchange reaction potentials as approximate estimates of the relative thermodynamic stabilities of Mg/Al layered double hydroxides containing different anions. Langmuir 27(22):13539–13543. https://doi.org/10.1021/la2028675

Ramirez-Llodra E, Trannum HC, Evenset A, Levin LA, Andersson M, Finne TE, Hilario A, Flem B, Christensen G, Schaanning M, Vanreusel A (2015) Submarine and deep-sea mine tailing placements: a review of current practices, environmental issues, natural analogs and knowledge gaps in Norway and Internationally. Mar Poll Bull 97:13–35. https://doi.org/10.1016/j.marpolbul.2015.05.062

Rodríguez-Galán M, Baena-Moreno FM, Vázquez S, Arroyo-Torralvo F, Vilches LF, Zhang Z (2019) Remediation of acid mine drainage. Environ Chem Lett 17(4):1529–1538. https://doi.org/10.1007/s10311-019-00894-w

RoyChowdhury A, Sarkar D, Datta R (2015) Remediation of acid mine drainage-impacted water. Curr Poll Rep 1:131–141. https://doi.org/10.1007/s40726-015-0011-3

Shin HS, Kim MJ, Nam SY, Moon HC (1996) Phosphorus removal by HT compounds (HTLcs). Water Sci Technol 34: 161–168. http://hdl.handle.net/10203/7536

Skousen JG, Ziemkiewicz PF, McDonald LM (2019) Acid mine drainage formation, control and treatment: approaches and strategies. Extr Ind Soc 6(1):241–249. https://doi.org/10.1016/j.exis.2018.09.008

Smith HD, Parkinson GM, Hart RD (2005a) In situ absorption of molybdate and vanadate durimg the precipitation of hydrotalcite from sodium and aluminate solutions. J Cryst Growth. https://doi.org/10.1016/j.jcrysgro.2004.11.227

Smith HD, Parkinson GM, Hart RD (2005b) In situ absorption of molybdate and vanadate during precipitation of hydrotalcite from sodium aluminate solutions. J Cryst Growth 275(1):e1665–e1671. https://doi.org/10.1016/j.jcrysgro.2004.11.227

Taylor J, Pape S, Murphy N (2005) A Summary of Passive and Active Treatment Technologies for Acid and Metalliferous Drainage (AMD). Prepared for the Australian Centre for Minerals Extension and Research (ACMER), Issue. E. Systems

Theiss FL, Couperthwaite SJ, Ayoko GA, Frost RL (2014) A review of the removal of anions and oxyanions of the halogen elements from aqueous solution by layered double hydroxides. J Colloid Interface Sci 417:356–368. https://doi.org/10.1016/j.jcis.2013.11.040

Tolonen E, Sarpola A, Hu T, Ramo J, Lassi U (2014) Acid mine drainage treatment using by-products from quicklime manufacturing as neutralisation chemicals. Chemosphere 117:419–424. https://doi.org/10.1016/j.chemosphere.2014.07.090

Ulibarri MA, Pavlovic I, Barriga C, Hermosin MC, Cornejo J (2001) Adsorption of anionic species on hydrotalcite-like compounds: effect of interlayer anion and crystallinity. Appl Clay Sci 18(1–2):17–27. https://doi.org/10.1016/S0169-1317(00)00026-0

United Nations (2010) Water issues: contributing to the success of the eighteenth and nineteenth sessions of the commision of sustainable development. UNSGAB. 22:3342

Vare LL, Baker MC, Howe JA, Levin LA, Neira C, Ramirez-Llodra EZ, Reichelt-Brushett A, Rowden AA, Shimmield TM, Simpson SL, Soto EH (2018) Scientific considerations for the assessment and management of mine tailings disposal in the deep sea [Review]. Front Mar Sci. https://doi.org/10.3389/fmars.2018.00017

Villca G, Arias D, Jeldres R, Panico A, Rivas M, Cisternas LA (2020) Use of radial basis function network to predict optimum calcium and magnesium levels in seawater and application of pretreated seawater by biomineralization as crucial tools to improve copper tailings flocculation. Minerals 10:676. https://doi.org/10.3390/min10080676

Whittington BI, McDonald RG, Johnson JA, Muir DM (2003) Pressure acid leaching of arid-region nickel laterite ore: part i: effect of water quality. Hydrometallurgy 70:31–46. https://doi.org/10.1016/S0304-386X(03)00043-4

Yan S, Cheng KY, Morris C, Douglas GB, Ginige MP, Zheng G, Zhou L, Kaksonen AH (2020) Sequential hydrotalcite precipitation and biological sulfate reduction for acid mine drainage treatment. Chemosphere 252:126570. https://doi.org/10.1016/j.chemosphere.2020.126570

Acknowledgements

Ni Made Sri Suliartini acknowledges the financial support of an Australia Awards Scholarship for her research conducted at Curtin University, Australia.

Funding

Open access funding provided by CSIRO Library Services.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Suliartini, N.M.S., Joll, C.A. & Douglas, G.B. Evaluation of Hydrotalcites Produced in Seawater for Remediation of Metalliferous Acid Mine Drainage and Submarine Placement. Mine Water Environ 42, 230–239 (2023). https://doi.org/10.1007/s10230-023-00934-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-023-00934-6