Abstract

The increasing amount of electronic waste (e-waste) has placed significant burdens on society and the environment, particularly with regards to waste printed circuit boards (WPCBs), which are essential in electronics manufacturing. As natural resources become scarce, it is crucial to effectively recycle and reclaim WPCBs due to their high value and large output. Comminuting printed circuit boards is a crucial step in enabling the recovery of valuable materials, and this review provides an in-depth analysis of WPCB comminution. It explores the structure, types, and composition of the WPCBs, including their mechanical properties. The review thoroughly surveys conventional mechanical comminution machinery and also discusses emerging technologies such as innovative pretreatment approaches, electrodynamic disintegration, high voltage electrical pulses, and abrasive waterjet cutting. The literature has been critically examined to identify research gaps and inconsistencies, and future directions for increased efficiency and sustainability are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

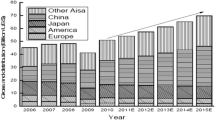

Electronic waste (e-waste) is among the fastest-growing waste categories worldwide. Frequent changes in product designs, along with both legal and illegal trade, contribute to the unpredictability of e-waste. This variability leads to low recycling rates [1,2,3,4,5]. In 2019, the worldwide e-waste generation was 53.6 Mt, or 7.3 kg per person. Global e-waste has climbed by 9.2 million tons since 2014 and is anticipated to reach 120 million tons by 2050, with an annual growth rate of 3–4% [6,7,8]. A major concern regarding e-waste is the presence of hazardous substances such as tetrabromobisphenol A (TBBPA), polybrominated diphenyl ethers (PBDEs), and brominated flame retardants (BFRs). These persistent organic pollutants (POPs) pose significant environmental and health risks due to their toxicity, longevity, and ability to accumulate in living organisms [9, 10].

Printed circuit boards (PCBs) form the basis of the electronics sector and are considered the most valuable and complex components of waste electrical and electronic equipment (WEEE) streams [11]. The amount of waste PCBs (WPCBs) increased from 2.7 million tons in 2016 to 3.0 million tons in 2019, and projections indicate continued growth in the next decade [12, 13]. Compared to natural ores, WPCBs contain higher concentrations of valuable metals, driving increased interest in metal recycling from WPCBs in recent years [14,15,16].

WPCBs are made up of 40% metals, 30% ceramics, and 30% polymers, but these percentages can vary depending on the PCB type, manufacturer, and year of production [17]. Despite representing only 6% of the total e-waste stream, recycling WPCBs is important because they contain valuable metals such as gold, silver, palladium, and copper. However, currently, recycling rates for metals from WPCBs remain low due to the complex design and high mechanical, chemical, and thermal resistance of PCBs [18, 19].

Recycling WPCBs can help prevent pollution, protect the environment, and conserve the energy required to extract, smelt, and process new raw minerals [20]. The main methods for treating WPCBs include physical, hydrometallurgical, pyrometallurgical, and biometallurgical processing. Pyrometallurgy and hydrometallurgy focus primarily on metal recovery but face challenges from decreasing precious metals content in electronics and increasing environmental concerns. As a result, they are being gradually replaced, and mechanical or physical processing techniques are now preferred and widely used in industrial WPCB recycling applications [9, 21,22,23]. In many cases, a combination of different recycling techniques is needed to achieve high recovery rates for targeted material species [24].

Comminution, the mechanical size reduction of materials through crushing, grinding and pulverization serves as a fundamental pretreatment step across WPCB recycling stages [22]. This process liberates and separates the metallic components on PCBs from plastic or ceramic encapsulations, enabling effective downstream extraction. In recent years, the importance of such mechanical force-dominated size reduction processes has grown across technical applications [25]. Through impact, compression, shearing, stretching, tearing, and bending, energy is directly applied to alter target solids. Possible results include reduced particle sizes, morphological changes, exfoliation (separating layered materials), phase transformations, or a combination of these effects [25, 26].

For WPCB recycling, comminution involves reducing the particle size to expose surfaces for improved reagents or microorganisms used in hydrometallurgical or biometallurgical processing [20]. In the pyrometallurgical route, comminution provides a prerequisite for efficient recovery given the process thermodynamics and technology constraints on acceptable input. Suitable comminution pretreatments generate simpler fractions that meet the criteria of downstream metallurgical separation [27, 28]. Additionally, the degree of comminution and liberation of WPCBs directly affects the efficiency of the physical separation process, including the recovery of the materials and purity of the products [20].

In addition to these technical considerations, optimizing WPCB comminution strategies has broader sustainability implications. The optimization of WPCB comminution strategies is in line with numerous Sustainable Development Goals (SDGs) adopted by the United Nations, among which are SDG 12—Responsible Production and Consumption. Improving the comminution technology of e-waste can advance resource efficiency and material recovery for the sustainable management of natural resources and reduce waste generation (SDG 12.2, 12.5). In addition, development of recycling infrastructures and operating procedures also helps in sustainable industrialization (SDG 9.4). Finally, executing these next-generation comminution techniques will also promise occupational and environmental health benefits (SDG 3) through the reduction of hazardous dust production (SDG 12.4), in turn preserving air and water quality for communities (SDG 11) [29, 30]. Thus, research on WPCB comminution delivers multifaceted sustainability impacts spanning resource conservation, infrastructure advancement, human health, and environmental quality.

This review provides a comprehensive analysis of WPCB comminution, which is a crucial step in the recovery and recycling of valuable metals. The structure, types, and composition of WPCBs, including their mechanical properties, are discussed. A thorough overview of conventional comminution machinery is presented, in addition to emerging comminution technologies for WPCBs. A critical perspective on the literature is provided, identifying gaps and inconsistencies in the research. Finally, future research directions for WPCB comminution are proposed, with an emphasis on improving the recovery and recycling rates of valuable metals while minimizing environmental impacts.

Structure, types, composition, and mechanical properties of WPCBs

PCBs are evolving toward greater complexity, with a growing number of them being multilayer, high-speed devices that are starting to rival semiconductor technology. The manufacturing materials used to make PCBs are determined by their application [28]. The key components of PCBs are as follows: (i) the base is a thin, rigid or flexible board of insulating material that holds all conductors and components; the general thickness of PCBs can range from approximately 0.2 to 3.2 mm or more, with the typical thickness for most common applications being in the range of 0.8–1.6 mm; (ii) conductors are typically high-purity copper thin strips securely bonded to the base material; and (iii) components are attached to the substrate, such as chips (Ga, In, Ti, Si, Ge, As, Sb, Se, and Te); connectors (Au, Ag); and capacitors (Ta, Al), etc. [31].

Base material

The substrate, which serves as a mechanical support and a medium for connecting circuit tracks, is the fundamental component of a PCB unit. Laminate is typically made of polytetrafluoroethylene with glass fibers, namely, FR-2 (phenolic cotton paper), FR-3 (cotton paper and epoxy), FR-4 (woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester), G-10 (woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (woven glass and epoxy), CEM-4 (woven glass and epoxy), and CEM-5 (woven glass and polyester). Epoxy, polyimide, and triazine polymers are a few of the commonly utilized matrix insulating materials. In general, a particular type of resin polymer consists of embedded glass fibers. FR-4 is one of the laminate materials that is most frequently used in electronics [32, 33]. Figure 1 depicts the cross section of a typical FR-4 laminate substrate for PCB production.

An optical view displaying the bundles of fibers buried in the epoxy matrix and a magnified SEM image of a typical fiber-reinforced FR-4 laminate [32]

While there are many different types of base materials, they all have three basic components: (1) the resin system and any additives, (2) the reinforcement(s), and (3) the type of conductor. Each of these elements is significant in and of itself, but their combined effect determines the qualities of the base material [34].

Epoxy resin systems are the most commonly used materials for PCBs due to their excellent mechanical, electrical, and physical properties combined with their lower cost compared to high-performance resins. Epoxy resins come in different forms and remain the workhorse of PCB materials. Other options, like phenolic and polyester resins, are available when specific performance is needed [33]. While several reinforcements are possible, woven fiberglass cloths are by far the most popular due to their balanced mechanical and electrical qualities [31].

Conductive materials

Copper is extensively used in the PCB industry due to its high conductivity, widespread availability, and low cost. The PCB industry utilizes various types of copper foil, each with its own advantages and disadvantages. The primary role of copper layers is to enable electrical conductivity between the PCB layers and the electronic components [35].

The most common copper foils used are electrodeposited (ED) and rolled annealed (RA) foils. The key difference lies in their grain structure. ED copper has a vertical grain structure, making it prone to cracking from stress concentration in the valley between the sharp surface peaks. Cracks can rapidly propagate through the boundaries. RA copper has a horizontal grain structure and smoother surface, with fewer stress concentrators. However, once a crack is initiated, it must work through many grain boundaries to fracture the entire copper structure [35].

Figure 2, adapted from Coonrod [36], illustrates the grain structures and typical crack paths in ED and RA foils under stress. The red line shows that the crack fails more easily across the ED copper while propagating more slowly through the RA grain boundaries.

Grain structure of two copper types (a) Electrodeposited copper and (b) Rolled-annealed copper [36]

Electronic components

Any item that works with electricity is considered an electronic component. Electronic components come in various forms and sizes and perform different electrical functions depending on the application. Common components include integrated circuits (ICs), central processing units (CPUs), resistors, tantalum capacitors, monolithic ceramic capacitors (MLCCs), and random access memory (RAM). These components are assembled on PCBs using conductive pathways or tracks, etched from copper sheets and aminated onto a nonconductive substrate [31]. Figure 3 shows the typical components found on a standard PCB surface.

Typical components on a standard PCB surface [37]

Various connection types attach electronic components to PCB assemblies. From a mechanical processing perspective, component mounting methods fall into two categories:

-

Attachment regimes, including fastening, inserting, welding, binding, wrapping, and coating/plating;

-

Inclusion regimes, including filling, encapsulating, alloying, and packing.

Broadly speaking, materials that are secured through fastening methods like screws, clinks, and rivets, as well as inserting, wrapping, and packaging, can be easily detached. On the other hand, materials that are locked in place through coating, binding, welding, and encapsulating are relatively difficult to detach, and those that are locked through alloying and filling cannot be released by mechanical means [38, 39].

Basic PCB types

Based on structure and alignment, there are three basic forms of PCB construction: single-sided, double-sided, and multilayered [40]. Single-sided boards have components and wiring on one side only, limiting component density [41]. Compared with single-sided boards, double-sided boards (Fig. 4) add wiring patterns on both sides of the insulating substrate, increasing capacity [10]. Multilayered PCBs (Fig. 4) have one or more conductor layers (usually power planes) buried inside, in addition to having a conductor layer on each outside surface. The inner layers are connected to each other and to the outer layers by plated through-holes or vias. The number of layers ranges from 3 to as many as 50 in special applications [9]. Flexibility also varies—flexible PCBs use thin, bendable laminates suitable where folding is needed, while rigid PCBs use rigid laminates and can be single-sided, double-sided or multilayered [32].

Schematics of single, double, and multilayered printed circuit boards along with a cross-sectional image of the real double-sided and multilayered PCBs [32]

PCBs can contain up to 60 different elements. Most of the elements are transition metals, precious metals, and heavy metals, in addition to nonmetals. Precious metal concentrations are much greater than those of natural ores, despite being lower than those of base metals, making WPCBs an economically viable urban mining source for recycling [42]. A mobile phone can contain more than 40 elements from the periodic table, with metals representing 23% of the weight of the phone [43]. Au, Ag, and Pd are commonly used as contact materials or plating layers in integrated circuits/chips due to their excellent conductivity and chemical stability [44].

Mechanical properties of the WPCBs

WPCBs have a multilayer structure composed of a substrate, laminate, solder, and silk screen. Among these components, the various laminates and substrates have different mechanical properties at room temperature [45]. Additionally, research has shown that the presence of metal components in WPCBs can affect their mechanical properties. WPCBs that contain higher amounts of metal tend to have improved mechanical properties when compared to those with lower metal contents [46].

The mechanical properties of WPCBs significantly impact the effectiveness of the comminution process [47]. The key factors include the tensile strength, compressive strength, bending strength, impact toughness, and elastic modulus. The influence of these properties varies depending on the type of comminution machine and its dominant loading mechanism [48]. Additionally, the differences in ductility and workability between the metal and nonmetal components of WPCBs strongly affect the comminution process. This is observed in the liberation size, size distribution of metals and nonmetals and shape of the resulting particles [21, 49,50,51,52,53,54,55,56,57]. According to Nekouei et al. [58], metal particles tend to be concentrated in larger mesh sizes, as the comminution process struggles to break them down further, resulting in elongated shapes and coarser particles. In contrast, the nonmetal content of WPCBs is brittle, so it tends to be more prevalent in finer fractions [59].

The mechanical properties of WPCBs and their components have been proposed to impact the comminution process during WPCB recycling. However, there are limitations in the existing literature that constrain generalizable conclusions. A study by Tiwary et al. [60] examined the fracture toughness and yield strength of polymer, oxide, and metal materials typically found in WPCBs (Fig. 5). They concluded that metals and oxides have higher stiffness and strength than polymers, leading to less deformation under the same load. Additionally, they found that polymers tend to have higher fracture strains at room temperature, becoming more brittle and fracturing into smaller pieces at lower temperatures. The fracture toughness and strength of metals and oxides are similar, leading to similar characteristic sizes. The interface between polymers, metals, and oxides in PCBs is strong, making separation difficult at both room and high temperatures. However, in this study, individual material samples rather than intact WPCBs were tested. The interactions between material components in complex WPCB structures may differ from those between the individual material properties.

Fracture toughness vs. yield strength for different materials [60]

Prestele [61] tested the mechanical behavior of custom-made PCBs under impact, bending, and tensile stresses to simulate forces in various comminution machines. They concluded that copper layers have minimal effects on strength during impact but more influence during bending and that PCBs fail abruptly in tension. However, the sample size, test conditions, and quantitative results were not reported. Additionally, custom PCBs do not represent the diverse components and complex geometries of real WPCBs.

These two studies presented contradictory conclusions regarding the effects of copper layers on WPCB mechanical strength. This suggests further testing is needed under standardized conditions to clarify the role of metallic components. Furthermore, both studies focused solely on comminution, while the mechanical properties could vary in other recycling processes, such as pyrolysis or dissolution.

While these initial studies suggest that the mechanical properties of WPCBs may impact comminution, substantial future research is needed to reliably quantify these effects. For testing, real-world WPCB samples, standard test methods, appropriate statistical analysis methods, and a wider range of size reduction techniques should be implemented. The current literature provides preliminary insights but remains limited to drawing definitive conclusions about the relationship between the mechanical properties of WPCBs and recycling processes.

Conventional mechanical comminution methods

Conventional mechanical comminution methods play a vital role in the processing of WPCBs once hazardous components have been removed during the dismantling stage. These methods, encompassing techniques such as crushing, shredding, and grinding, are essential for recovering valuable metals from materials such as resin, fiberglass, and plastics [43]. The comminution process can span coarse, fine, and ultrafine stages to attain the desired particle size, often necessitating multiple steps. Notably, employing a two-step crushing approach has demonstrated marked effectiveness for WPCBs under specific parameters [62,63,64,65]. Based on a review of the literature, Table 1 provides examples of the various mechanical comminution machinery utilized in the pretreatment of WPCBs prior to the upgrading stage.

A comprehensive understanding of the mechanisms and phenomena behind these methods is indispensable. Factors such as liberation, particle morphology, fine and dust generation, and energy consumption are intricately linked to the specific machinery used and associated loading/stressing mechanisms [66]. By examining the intricacies of comminution, it becomes possible to optimize the process for various objectives, including achieving target particle sizes, improving liberation and morphology, and reducing dust generation and energy use. Therefore, a detailed understanding of mechanical comminution is pivotal for tailoring this process to meet specific goals in WPCB recycling.

Mechanism

WPCBs exhibit both brittle and ductile behavior, with the ceramic components being more brittle and the metallic components displaying ductility. During the breakage process, the ductile particles are reduced in size through specific mechanisms. Initially, an increase in the dislocation density occurs, leading to high local strains. This results in the formation of microcracks within the crystal lattice. As breakage continues, the microcracks multiply and merge into single macroscopic cracks, which propagate throughout the particle, causing its fragmentation [75]. The overall behavior of WPCBs during comminution can be complex and difficult to predict, depending on factors like particle size, temperature, and strain rate [41].

The control parameters for particle breakage during comminution using conventional machinery include the loading mechanism, breakage mechanism, and breakage mode [63]. The breakage mechanism is influenced by the loading mechanism, the comminution environment, and material properties such as mechanical strength, toughness, and brittleness [63]. The comminution environment parameters include temperature, wet or dry processing, and grinding media. These factors can affect the resulting particle shape, size, and liberation. The breakage mode determines whether the breakage is random or nonrandom and is related to the breakage characteristics of the feed material [63].

Studies have shown that mineral crushers such as jaw, roller, and disc crushers provide limited size reduction and poor liberation when dealing with WPCBs [76]. Additionally, mills like rod and ring mills, which mainly utilize compressive stresses, have shown limited ability to reduce the size of ductile WPCB materials [77]. In contrast, nonbrittle material comminution machinery that employs shearing, shredding, and cutting stresses has proven to be more effective on WPCBs. Furthermore, unlike mineral ores, WPCBs do not have a specific size fraction for optimal liberation, as different types of elements are liberated at different size fractions [63].

The types of loading mechanisms found in comminution machinery for nonbrittle materials include the following: cutting stress (a) refers to the application of linear force along the knife edge, which causes the material to fail adjacent to the knife edge due to external compression. Fracture occurs as a result of shear and tensile stresses, the latter of which are caused by the splitting effect of the knife. The opposite knife provides support but does not actively participate in the comminution process [78]. Shearing stress (b), on the other hand, involves applying compression forces to a larger area. Increasing shear stresses cause the material to slide along the shear plane. Both knives, with a wedge angle of 90 degrees, actively contribute to the comminution process in this case. The formation of high shear stresses requires a small clearance, but as the clearance increases, the tensile stresses become more significant, leading to tearing stress (c) in combination with bending and torsion processes. Tearing stress occurs at clearances between the comminution tools that are multiple times the wall thickness of the feed material. The engagement of tearing tools in material voids facilitates coarse size reduction. The bending stress (d) in metals causes material breakage only in certain cases [78].

Although comminution methods relying on cutting, shearing, shredding, and low-intensity impacts have proven to be more effective than conventional mineral crushers, they also possess significant drawbacks. These drawbacks include high wear of cutting edges, reduced selectivity for separating WPCB components, and costly maintenance requirements [79]. In contrast, high-intensity impact comminution generates high stresses in the WPCB structure, destroying the bonding between the adhered layers. It also rapidly releases and uncovers the metallic and nonmetallic phases, enabling more efficient subsequent separation. The selectivity of impact fragmentation achieves a high level of comminution and becomes the primary factor in the mechanical enrichment of target metals from WPCBs [79]. However, Bachér et al. [70] reported that while impact crushing achieved good liberation, it also produced a substantially large amount of fines. This underscores the critical trade-offs that must be weighed between liberation efficacy and overgrinding.

A prime example of extensively studied comminution machinery is the hammer mill, which belongs to the impact crusher category. Hammer mills are known for their ability to rapidly blow at high tip speeds, typically in the range of 60–100 m/s, with the primary goal of achieving size reduction. This impact-driven process is executed through the action of components commonly referred to as “beaters”. Upon contact with the feed particles, these beaters transfer kinetic energy, resulting in the generation of impact and shearing stresses that facilitate the disintegration of the particles [80]. While hammer mills are traditionally employed for processing brittle materials, they have also been found to be applicable in e-waste processing, particularly due to their ability to induce impact stress, leading to the formation of spherical metal particles.

In contrast, there has been a noticeable absence of hammer shredders, which are rotary shredders, use in the literature for WPCB comminution. Hammer shredders have a distinct design, incorporating an anvil within the machinery. The hammer-anvil configuration creates shearing, tearing, bending, and compression stresses that are suitable for ductile, nonbrittle materials such as metals, which are major components of WPCBs [47, 81]. Compared to hammer mills operating at high tip speeds, hammer shredders typically function at lower tip speeds of 5–60 m/s and are more energy efficient for metals while also producing less fines, which could complicate downstream separation processes [82]. Their ability to handle bulky, irregular feed materials and the optimized intensity of size reduction through adjustable parameters like hammer-anvil clearance and rotational speed make them suitable for producing an ideal particle size distribution for metal liberation [81]. The distinctive mechanics and capabilities of hammer shredders present a compelling technology that merits in-depth exploration for its potential to offer significant advantages in the field of WPCB comminution. It is also of paramount importance to distinguish between hammer mills and hammer shredders given their substantial mechanistic differences and roles in comminution.

One distinct modification of hammer mills and hammer shredders is the use of swinging hammers instead of rigid ones. By using pivoting or swinging hammers, less force is exerted compared to rigidly attached hammers [80]. Schubert and Bernotat [47] provided an effective analysis of the various adjustments made to swing hammer mills. The primary method of comminution is similar across all modifications, relying mainly on impact with additional influences of shear, compression, and abrasion. These stress modes work together, making swing hammer mills appropriate for WPCBs that contain diverse material types, from brittle to ductile.

When WPCBs are processed by a hammer mill, selective milling occurs. The harder and more malleable metals, including copper and iron, concentrate in the coarser fractions. However, nonmetallic components are brittle and easily crumble. These materials are mostly found in the finer fraction and include resin, glass fiber, and plastic [59]. The hammer mill has been proven to have higher selectivity in WPCB comminution than the cutting mill since it predominantly utilizes impact stress, whereas the cutting mill involves shearing, compression, and attrition stresses. When WPCBs are subjected to the cutting head in the cutting mill, the head will cut through the phone from the targeted position, regardless of the ductility or brittleness of the material. Consequently, components and parts in the hammer mill are less likely to detach from each other at their weakest connection points, such as physical and surface joints or phase boundary regions [83]. In contrast, the distribution of energy in the hammer mill spreads over a larger area of the WPCBs than that in the cutting mill, which concentrates the energy on a smaller area [47, 48, 82]. Additionally, the high-intensity impact generated by the hammer mill results in high stresses within the structure of WPCBs, destroying the bonding between adhered layers and rapidly releasing and uncovering the metallic and nonmetallic fractions. This, in turn, makes further separation more efficient. Impact selectivity achieves a high level of fragmentation and becomes the main factor in the mechanical enrichment of target metals [84].

Another phenomenon associated with the use of hammer mills, according to a recent study by Otsuki et al. [59], is the selective agglomeration of certain ground components. This phenomenon occurs in the enrichment of Cu and Al in the coarse fraction (Fig. 6). The selective agglomeration was attributed to the mechano-chemical reaction that is intensified by the heat produced within the mill chamber and is favorable at the highest feed mass. However, the closed-lining hammer mill used by Otsuki et al. [59] allowed for substantial particle residence time, but such conditions cannot be replicated in continuous industrial mills where residence time is highly dependent on feed rate and variable choking conditions in the comminution chamber. These laboratory-scale results provide useful insights into ductile particle behaviors under impact stresses; however, the manifestation of selective agglomeration in industrial-scale systems currently remains circumstantial.

Cu agglomerate formed during hammer milling operation under optimal milling conditions [59]

Throughout the literature review on WPCB comminution, a recurring pattern is observed wherein there is a prevalence of mixing and misuse of terminology when discussing the loads and stresses involved in the process. Additionally, there is a tendency to rely on commercial names for comminution machinery, such as hammer crushers/mills, disc mills, cutting mills, and shearing mills. This can lead to confusion among readers and researchers since different manufacturers may use different terminologies for similar equipment. To enhance clarity and understanding in the field, it is crucial for researchers and authors to provide clear and standardized descriptions of the loads, stresses, and equipment used. One such naming system can be found in the work of Schubert and Bernotat [48], where comminution machinery for nonbrittle materials was classified into rotary shears, rotary cutters, and rotary shredders based on the dominant type of loading.

Notably, rotary shear, rotary shredder, and rotary cutter machines should be distinguished. A rotary shear machine has two or more counter-rotating shafts that use sharp blades to shear materials in a scissor-like motion. It is commonly used for shredding plastics, rubber, and is utilized in WPCB comminution for coarse- and medium-size reduction, serving as a primary crusher to prepare the input for subsequent crushing or grinding [23, 85]. On the other hand, a rotary shredder is a machine that employs a single rotating shaft with multiple cutting blades or hammers to impact materials and break them down into smaller pieces. It is commonly used for shredding WPCBs after a size reduction step to achieve a finely crushed output [62]. Rotary cutters resemble rotary shredders but utilize fixed knives on a rotor. The cut length can be adjusted by modifying the rotor’s speed and the number of knives positioned along its periphery [86]. Low- and high-speed rotary cutters have been used for fine crushing [74, 87, 88].

One clear gap in the current research on WPCB processing is the lack of reported data on the tip speeds of the mechanical comminution equipment utilized. Systematically delineating the typical tip speed regimes for various apparatuses, such as distinguishing between a hammer mill (60–100 m/s), shredder (5–60 m/s), and fine impact mill (> 100 m/s), would enable more incisive classification and comparisons of their capabilities. By shedding light on these variations in operational speed, a valuable context could be provided regarding the induced stresses and resulting outcomes in the comminution process.

Liberation

The liberation of valuable materials from WPCBs depends on several key factors related to the comminution process and the characteristics of the WPCB itself. The type and size of grinding equipment, operating conditions, and loading mechanisms influence the effectiveness of size reduction and material liberation. Feed characteristics like moisture content and particle size also affect comminution performance. Furthermore, the inherent properties of WPCBs, such as their mechanical strength, thermal stability, and material composition, necessitate tailored comminution strategies. For instance, components with high strength may require more aggressive size reduction tactics, while those sensitive to heat demand specialized approaches [41].

Zhang and Forssberg [38, 66] examined the liberation of WPCBs in personal computers (PCs) using a hammer mill. Research has revealed that metallic particles achieve near-complete liberation when their particle size is less than 2 mm. Notably, copper exhibited a lower degree of liberation from coarser particles than aluminum and ferrous metals. Building on this, Duan et al. [89] and Ogunniyi et al. [68] showed that a swing hammer mill with an internal sieve under 500 μm could achieve complete liberation of PCs, cell phones, and switchboards. Further studies by Li et al. [23], Guo et al. [54] and Quan et al. [63] using various comminution methods reinforced these results. Remarkably, across different equipment, approximate complete metal liberation occurred consistently in the size range below 0.59–0.42 mm.

However, it is crucial to recognize that components within WPCBs—namely printed wiring boards (PWBs), slots, and ICs—respond differently to the comminution process. Drawing from Gaudin's theory on mineral liberation, the liberation process for PWBs and ICs involves a combination of dispersion and disengaging mechanisms. In contrast, slots primarily undergo liberation through disengagement [64, 89]. This distinction manifests in their size-dependent liberation behavior, as depicted in Fig. 7, following sequential comminution via rotary shearing and hammer crushing. The data reveal notable variances. Slots achieve complete liberation even at coarse fractions less than 2 mm due to their disengaging mechanism. In contrast, the coupled liberation modes of PWBs and ICs lead to incomplete separation above 0.125 mm, necessitating more extensive particle size reductions to fully detach their composite materials [64].

Liberation degree of WPCB different components (redrawn from Wen et al. [64])

Koyanaka et al. [53] compared the destruction behaviors of PC and TV boards using an impact mill. PC boards consist of copper foil laminated onto glass fiber-reinforced epoxy resin (FRP). In contrast, TV boards have copper foil laminated onto a weaker paper-mixed phenol resin. High-speed photography revealed that the PC boards first lost their corners, with copper detaching from the FRP at the edges. This finding suggested that the FRP toughness promoted early cracking. However, the TV boards displayed linear crack propagation to the center due to the weaker resin, causing immediate fragmentation. After a certain reduction in size, the copper peeled from the smaller pieces [53].

From a selective liberation viewpoint, PCB destruction involves metal detachment then particle size adjustment, as depicted in Fig. 8. The base material strength dictates early cracking patterns. PC boards only detach copper once the FRP toughness decreases. Consequently, the initially liberated copper pieces remain larger. Conversely, rapid TV board shattering creates smaller fragments, demanding additional size reduction before copper liberation [53].

Comparative schematic diagram of destruction processes for two types of WPCBs [53]

Ogunniyi et al. [68] examined WPCB comminution fines under 75 μm and showed that quantitative microscopic analyses of polished sections suggest a liberation degree of approximately 99.48% (Fig. 9). However, subsequent scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDS) assessments revealed the persistence of composite particles (residual solder-attached copper trace) within this size range (Fig. 10). Considering the broad distribution of minor and trace elements within WPCBs, these sparse residuals can still have significant influence. Recent work by Nekouei et al. [58] underscored these stubborn interfacial boundaries between material phases, revealing that clustered aggregate particles resist separation even after extensive milling (Fig. 11). While certain components can be preremoved, fully selective metal liberation is ultimately impossible via only mechanical means.

Optical microscopy images of polished sections of PCB comminution fines: a particles ranging from − 75 to 38 µm magnified 50 times; b close-up of particles within 75 to 38 µm, magnified 100 times; c particles smaller than 38 µm, enlarged 100 times; d further magnified view of particles under 38 µm, at 200× magnification [68]

SEM images: a section of PCB comminution fines within the − 75 to 38 μm range; b detailed view of a particle where complete liberation has not been achieved [68]

Optical microscope images of a mounted WPCB powder cross-section for 800 µm: a low magnification and b high magnification (jointed materials highlighted by red circles) [58]

The impact of crushing mechanisms on WPCB liberation was the focus of a study by Bachér et al. [70]. This study introduced an insightful comparison between two distinct types of comminution machinery: a high-speed hammer mill and a low-speed rotary cutter. The results (Fig. 12) demonstrated that the high-speed hammer mill excelled at liberating WPCBs, yielding an overall liberation grade of 77%, while the low-speed rotary cutter yielded a grade of 58%. The selective nature of the hammer mill, attributed to its reliance on impact stress, was in stark contrast to that of the rotary cutter, which encompasses shearing, compression, and attrition stresses.

Distribution patterns of WPCB particles after processing by hammer and cutting mills [70]

Further exploring the hammer mill, Bachér et al. [70] investigated the impact of agitation speed on the WPCB grade and recovery rates. High agitation rates (84 m/s tip speed) were found to provide sufficient energy to achieve a WPCB grade above 86%. In contrast, a slow agitation rate (42 m/s tip speed) resulted in a lower grade, with just slightly more than 30% of the WPCB particles being fully liberated. This finding underscores the sensitivity of liberation outcomes to agitation speed and highlights the need for meticulous control of operational parameters.

However, an important consideration raised by Menad et al. [90] involved the limited applicability of the manual dismantling and classification methods used in these foundational studies to automated, industrial-scale recycling processes. Additionally, as Bachér et al. [70] noted, pursuing maximal liberation by minimizing particle size can increase fine generation, creating an economic trade-off between recovery efficiency and material losses. Therefore, the optimal liberation degree likely depends on specific process objectives and equipment constraints within an industrial context. More research is needed to translate these foundational laboratory-scale findings to real-world automated systems focused on balancing liberation, fines minimization, and throughput.

Using digital microscopy and SEM‒EDS, Gonçalves et al. [91] made a significant impact on the study of how metals are released under various grinding conditions. Their approach, which combined multiple imaging techniques, allowed for precise analysis of how metals are liberated in different size fractions, marking a significant step forward. However, Otsuki et al. [92] noted that the results from these analytical methods can vary. There were notable differences between traditional methods like optical microscopy and newer methods such as micro-XRF and X-ray tomography, highlighting the need to standardize how these measurements are performed across different tools. By developing reliable ways to correlate the results of these various techniques through thorough comparative studies, we could greatly improve the accuracy and consistency of how we assess the process of metal liberation.

Produced particle morphology

Comminution breaks down large particles into smaller particles, altering their shape, size, and surface area. Various factors, including equipment type, applied stress, material properties, and retention time, determine the extent of these changes [93,94,95]. The resulting particles from electronic waste comminution exhibit diverse shapes, such as angular, fibrous, flaky, granular, modular, spherical, and irregular. The particle morphology significantly affects subsequent mechanical and physicomechanical separation techniques that rely on physical and material properties for material separation [96].

One of the seminal studies in this field, conducted by Zhang and Forssberg [38], employed an impact crusher (hammer mill) in the comminution of WPCB samples. The outcome was a diverse spectrum of liberated materials, showcasing shapes such as wire bundles, bars (both straight and bent), compacted cubics, and bent plates. To quantify this morphological diversity, a shape factor (F-shape) was employed, revealing significant variability within and among fractions. This underscores the inherent heterogeneity of electronic scrap fragments, making the recycling process inherently complex. Quan et al. [63] corroborated these findings, further elucidating how nonmetal shapes vary with particle size, as discerned through SEM analysis.

However, under specific operating conditions, an impact crusher (hammer mill) can yield surprisingly uniform and spherical copper particles from WPCBs, as demonstrated by Koyanaka et al. [57]. The attainment of sphericity and homogeneity was shown to be contingent upon the circumferential speed of the mill and the screen aperture size. However, their study was restricted to copper and did not examine the morphology of other metals or nonmetals. Notably, the distinct shapes of copper, glass fiber, and epoxy resin were revealed, with copper adopting a spherical form due to its ductility and malleability, while glass fiber-reinforced epoxy resin displayed angular characteristics owing to its brittle fracturing tendencies [55].

Particle morphology is also profoundly affected by the type of crushing mechanism employed. Zhu et al. [97] shed light on this phenomenon, highlighting that impact crushing tends to produce flaky metal particles, whereas shear crushing results in spherical metal particles (Fig. 13). The fundamental distinction lies in the forces at play: impact forces segregate metal and nonmetal components, leading to the formation of sheet-like metal particles, while shear forces engender spherical shapes, transforming plastic metal particles into spheres.

Comparative morphological analysis of particulate dissociation under a impact crushing and b shear crushing [97]

Fines and dust generation

The reason for the inefficient liberation and overgrinding of WPCBs is that mechanical comminution is not designed specifically to liberate valuable minerals but rather to reduce the size of the ore aggregates that contain them, with liberation occurring as a secondary effect. Consequently, current breakage methods are unable to fully liberate metals from wiring boards and may result in overgrinding, leading to fines and dust generation. As a consequence, high energy consumption, increased costs, and environmental issues are associated with conventional mechanical comminution [52].

Reducing particle size seems to be a logical approach to enhancing liberation. However, this strategy has its own set of limitations. Flotation, shaking, and electrostatic separation, often employed for beneficiation, exhibit diminished efficiency for particle sizes less than 0.074 mm, translating to substantial metal losses [70]. Owing to their large surface energy, fine particles face the added challenge of nonselective agglomeration. The result is a less-than-optimal separation process, accentuating the loss of precious metals [70].

Due to the strength and tenacity of WPCBs, crushing them at normal temperatures can generate a significant amount of dust and harmful gases, necessitating the use of an effective dust collection system [42]. Wang et al. [24] examined the dust generated during the mechanical recycling of WPCBs for resource recovery and environmental protection. According to their analysis of dust collected from a typical crushing and separation recycling line, 73.1% of the material was composed of organic matter, 4.65% was Al, 4.55% was Fe, 2.67% was Cu, and 1.06% was Pb. The majority of the metals were liberated at a 0.075 mm particle size, with an increase in the content of elemental metals and magnetic materials liberated as the particle size decreased.

In Bachér et al.’s research [70], the impact of different crushing mechanisms on fine generation in WPCB size reduction was examined. Two crushers, a fast-rotating hammer mill and a slow-rotating rotary cutter, were used. The study revealed that the hammer mill generated more than two times more fines than did the rotary cutter, which contained silicon, base metals, noble metals, and harmful elements. Although both crushers produced fines with similar elements, the concentrations varied. The hammer mill is better at reducing brittle materials, resulting in coarser ductile materials, while the rotary cutter shears particles regardless of their material type. Consequently, the cutting mill produced higher concentrations of ductile materials such as gold and copper in the fine fraction.

WPCB comminution fines and dust harbor an intriguing economic aspect. This seemingly insignificant byproduct contains valuable metals such as gold, silver, and palladium. Astonishingly, the concentrations of these metals in the dust can rival or even surpass those found in high-grade printed circuit assemblies [70]. However, the same dust also poses significant health and environmental hazards. Hazardous dust generated during WPCB comminution contains over 50% by weight of fine particulate matter less than 75 μm [98]. Furthermore, the dust contains trace toxic metals, chlorine, bromine and 73% organic compounds [24]. Worker health (SDG 3) thus becomes vulnerable to the severe effects of this mix of suspended particulates and contaminants, with fine particles causing respiratory and cardiovascular diseases [99]. In addition, dust that is not properly managed becomes enriched in receiving waters (SDG 6) as hydrophilic metals and organics leach from landfilled waste. The high fraction of particles less than 10 μm (PM10) also deteriorates air quality and enhances the release of related environmental health issues in surrounding areas (SDG 11) [99]. Minimization of dust generation is crucial for dealing effectively with such multifaceted health and eco-toxicity threats.

To mitigate fine generation and overgrinding, researchers have explored strategies such as increasing the number of comminution-separation stages. The rationale is straightforward: by separating materials immediately after liberation, further breakage of liberated particles is prevented [100]. Furthermore, the combination of a hammer mill and rotary shredders has shown promise, with lower dust losses observed during the milling process than when rotary shredders are used alone [101]. However, these approaches demand further investigations encompassing parameters such as feed rate, feed size, WPCB characteristics, and comminution machinery operating conditions, including revolution speed.

Energy consumption

Comminution processes are widely recognized as energy-intensive operations [102]. The efficient management of energy resources in this domain is not only a matter of cost-effectiveness but also a significant environmental concern. Minimizing energy consumption should be a primary objective, which involves both avoiding comminution where possible and selecting the most energy-efficient technologies when necessary.

The work of Prestele [61] highlights an essential point: the trade-off between energy consumption and processing time. While the planetary ball mill demonstrated a lower power draw of 93 W and 186 W for 60- and 120-min milling times, respectively, its extended milling duration resulted in higher total energy consumption than that of the industrial grab shredder (axial gap rotary shear). Specifically, the grab shredder required 2200 J for the first shredding cycle and approximately 1000–1200 J for subsequent cycles, while 60- and 120-min ball milling consumed 5.58 kWh and 11.16 kWh, respectively. This considerable difference demonstrates the trade-off between power and time. This trade-off is a critical consideration for process optimization, where efficiency should not come at the expense of excessive processing durations. However, the study was limited by the use of only two comminution methods on a small scale. Further research should investigate a wider range of techniques at industrial scales.

Martino et al.’s [103] comparison of a hammer mill with electrodynamic fragmentation, an emerging comminution technology discussed in the next section), emphasizes the need for comprehensive assessments of energy consumption. It is clear that the specific energy consumption is influenced by various factors, such as the output material characteristics, shredder specifications, and material filling levels, underlining the complexity of the issue. Specifically, the hammer mill was found to have a specific energy consumption of 23 kWh/t over a 119 s shredding cycle. In contrast, the electrodynamic fragmentation process consumed 132 kWh/t, 877 kWh/t, and 1485 kWh/t for the depopulation stage, delamination stage, and fragmentation stage, respectively. This considerable difference highlights that while the hammer mill requires less energy, the fragmentation ability of electrodynamic fragmentation allow for more effective liberation of valuable materials from WPCBs. This highlights the subtleties of energy efficiency, where increased energy use can lead to significantly better separation results later in the process. Future studies should focus on refining these processes to enhance both energy efficiency and separation performance at the same time.

Despite the crucial importance of the relationship between WPCB comminution and associated energy consumption, surprisingly few studies have directly examined the relationship between specific comminution methods and their energy consumption. This represents a considerable research gap that demands further investigation. Determining the comparative energy efficiencies of different mechanical, emerging, and hybrid technologies would provide valuable insights into optimizing comminution processes. In addition to comparing specific energy consumptions, researchers must also evaluate the total energy requirements based on operating parameters such as cycle times and throughput. While certain techniques may require less power, extended processing durations can lead to greater overall energy use. By investigating these complex factors, it may be possible to reduce the energy consumption of WPCB comminution.

To enhance the understanding of energy-efficient comminution methods and their implications for WPCB recycling, it is worthwhile to consider studies such as those by Adewuyi et al. [104] and Diani et al. [105]. Adewuyi et al. demonstrated up to a 24% reduction in grindability for minerals such as copper and gold-copper ores using different pretreatment methods. Although not performed on WPCBs, their experimental methodology of comparing energy consumption between pretreated and conventionally crushed ore samples could be adapted to assess potential energy savings in WPCB comminution. Similarly, Diani et al. [105] developed models to evaluate the energy consumption of shredding and grinding operations during glass fiber-reinforced plastic recycling. This modeling approach, which accounts for factors such as throughput, power draw, and material hardness, could be applied to optimize and benchmark the energy performance of various mechanical comminution methods in WPCB recycling. While not specific to WPCB comminution, these studies' methodologies and findings provide frameworks for evaluating the comparative energy efficiency of different emerging and conventional comminution techniques for WPCB size reduction.

Emerging comminution technologies

As discussed in “Conventional mechanical comminution methods”, shredding and grinding have been widely used for WPCB processing, but these methods have several limitations, including high energy consumption, excessive generation of fines, and low recovery rates of valuable metals. Additionally, if WPCBs are crushed continuously and directly, there is a risk of generating high local temperatures that can trigger pyrolysis and the emission of hazardous substances. The surface temperature of WPCBs can exceed 300–350 °C when crushed for more than 3 s [106].

To overcome these limitations, several emerging comminution technologies have been developed for WPCB processing. These technologies aim to improve the recovery rates of valuable metals, reduce the generation of fine particulates, and lower energy consumption during the comminution process. Each comminution technique has distinct advantages and disadvantages, as shown in Table 2, which makes the optimal choice context dependent. Ultimately, the most effective comminution process may involve a combination of several techniques tailored to meet specific goals and conditions.

Innovative pretreatment prior to conventional comminution

To overcome the drawbacks of conventional comminution methods, researchers have developed pretreatment methods to improve the crushing efficiency of WPCBs. This section describes four pretreatment approaches: cryogenic milling, thermal shock, coheating swelling, and microwave-induced pyrolysis.

Cryogenic comminution is a technique used to reduce the size of materials by crushing or grinding them at low temperatures. This process is particularly advantageous for materials that become more brittle at low temperatures, making it easier for them to break down into smaller particles [107]. Furthermore, this technique prevents or minimizes the buildup of heat, which can otherwise cause material degradation or fusion [107]. Studies by Suponik et al. [108] and Franke et al. [109] inferred that subjecting materials to cryogenic temperatures has a beneficial impact on the size and morphology of grains. As a result, the proposed method supports the extraction of metals from WPCBs. Both studies also mentioned that the cooled material was ground at a significantly faster rate, leading to a greater degree of metal liberation. Despite these benefits, the economic viability of cryogenic milling is still under debate, highlighting the need for a comprehensive economic analysis for large-scale application.

Recent studies have explored the potential of rapid cryogenic treatment to include significant internal stresses and cracks in the matrix of polymer composites, which could aid in the recycling of WPCBs. This technique relies on the thermal expansion mismatch between polymeric resins and glass reinforcements or metallic elements within WPCBs, theoretically improving recyclability by facilitating material separation [110]. However, Yuan et al. [110] contradicted this hypothesis. Their findings indicate that the thermal mismatch among WPCB components is insufficient to generate stresses that can crack the resin or debond the interface. Additionally, the thermal stress induced by cryogenic treatment is deemed inadequate for causing significant weakening or microcracking in materials. Consequently, Yuan et al. concluded that cryogenic treatment does not enhance the recyclability of PCBs or contribute to reducing the energy cost associated with current recycling processes [110].

Thermal shock treatment has emerged as a promising approach to overcome the limitations of conventional crushing techniques for WPCBs [106]. According to the study by Yan et al. [49], employing a combination of mechanical crushing with heat pretreatment has been shown to enhance the crushing efficiency of WPCBs. The study showed that increasing the temperature or duration of the heat treatment improved the crushing effect. Importantly, heat pretreatment also facilitates copper enrichment within a specific particle size range. Specifically, within just 60 s of treatment, the yield of copper in the 0.3–1 mm size range increased by 9.74%. This copper enrichment is important because it can enhance the economic viability of recycling processes by increasing the recovery of valuable metals.

Coheating swelling is another pretreatment method used to induce structural damage in WPCBs. By coheating WPCBs with an organic solvent, the different thermal expansion coefficients of the materials can lead to structural damage. The resin in WPCBs, a high-molecular-weight organic compound, reacts with the solvent. During this process, the solvent penetrates the inner layers of the boards, softening and expanding them. This expansion weakens the bond between layers, as illustrated in Fig. 14. Subsequently, this treatment is combined with a crushing process to facilitate the liberation of metal and nonmetal components from the coarse fraction of the WPCBs [111].

The swelling process of WPCBs by organic solvents [112]

In the study by Han et al. [112], the crushing effect of WPCBs was investigated using rotary shear after coheating and swelling with dimethylacetamide as the organic solvent. The results showed that coheating and swelling treatment of WPCBs led to significant changes in their mechanical properties and structure. The flexural strength decreased by 57% after treatment, resulting in the destruction of the nonmetal interface and cracks at the metal and nonmetal interfaces. This process facilitated the liberation of metals from the WPCBs and their enrichment in the coarse fraction, reducing the content of fine particles by more than 8% compared to that of the untreated sample and thus improving subsequent treatment.

While a substantial body of research has been conducted on the pyrolysis of WPCBs, most studies have utilized externally heated devices such as thermal gravimetric analyzers, rotary kilns, and fixed-bed reactors. These methods involve heating through external mechanisms such as conduction, convection, and radiation. In contrast, microwave heating is a form of internal and volumetric heating that results in selectivity toward different materials. Microwave-induced pyrolysis of WPCBs could be conducted in an energy-efficient manner due to its selective nature [113, 114]. In the work by Sun et al. [115], the byproducts of microwave-induced pyrolysis of WPCBs underwent rough shredding via a rotary shredder. The study demonstrated that effective liberation of metals from nonmetallic components was achieved by reducing the stiffness of the woven glass fibers, resulting in the production of hairy glass fibers. Crushing the pyrolysis residues released more than 99% of the metals from the base plate. The majority of metals and nonmetals were found in the coarse fraction (> 0.9 mm). Nonmetals, particularly fragile coke, were distributed in the finest fraction (< 0.28 mm), whereas metals and glass fibers were present mainly in the coarse fractions. This suggests that subsequent separation processes should be suitable for the treatment of coarse particles.

High-voltage electrical pulse and electrodynamic fragmentation

Recently, a technique called high-voltage electrical pulse (HVEP) has emerged as an effective method for breaking down ores and concrete materials to recover valuable resources. This method utilizes shock waves generated by high pressures exceeding 103 MPa to achieve crushing. Compared with conventional mechanical crushing methods, HVEP has proven to be more efficient at crushing various materials, including copper sulfides, ilmenite ores, and chromates. It has the ability to release more valuable minerals while minimizing the effects of attrition on the ore. These findings have been documented in several studies, such as those of Andres [116] and Wang et al. [117].

Composite materials in WPCBs can cause electrical and acoustical property discontinuities. This discontinuity in dielectric permittivity increases the electrical field and creates discharge channels, resulting in shock waves with local pressures up to 10,000 bar. Shock waves concentrate tensile stress at interfaces, leading to selective fragmentation of materials along boundaries, weakening of materials along particle boundaries, or reducing of material size without contamination. HVEP offers benefits such as coarse element liberation, energy savings, recovery of original-size elements, selective liberation of valuable metals, and efficient separation of WPCB composites without the need for fine comminution [41].

Duan et al. [118] conducted a study using high-voltage electrical pulses to process WPCBs with the aim of efficiently liberating metal and nonmetal materials while keeping costs low. Due to the varying electrical properties between metals and nonmetals, HVEP energy primarily acts on the interface of copper foil-GFC, resulting in effortless liberation of these two components (Fig. 15). The results showed that HVEP achieved a greater degree of metal liberation than conventional mechanical crushing for a relatively coarse size range. The results obtained with HVEP depend on the operating parameters, such as voltage levels and the number of pulses.

Comminution process of WPCBs by the HVEP [118]

Another technique, electrodynamic fragmentation (EDF), is effective at breaking apart WPCBs and exposing copper foils for leaching. By generating electrical discharge, an EDF can selectively fragment materials, remove electronic components, open structures, and reduce the size of materials. This method can be applied to weaken minerals and recycle various materials, including WPCBs, carbon fibers, and bottom ash [103]. The results of the EDF are influenced by various operational parameters, such as voltage, frequency, and pulse number. Compared to conventional mechanical comminution methods, EDF produces fewer fine materials, making the liberated materials more efficiently processed downstream, particularly when dealing with valuable end-of-life electronic equipment. The EDF technique comprises three stages: depopulation, delamination, and complete fragmentation. Depopulation is necessary for removing electronic components, followed by delamination, which is essential for recycling WPCBs. (Note: The energy consumption comparison between EDF and conventional comminution methods has already been discussed in “Energy consumption”.

Abrasive waterjet cutting

Another nontraditional comminution technique that has recently shown promise is abrasive waterjet cutting (AWJ). The jet plume of AWJ machining is used as a “cutting tool” to break down hard materials such as ceramics, glass, and stone into smaller pieces. This is achieved through high-velocity mixtures of abrasives and water, without any additional chemical substances. In addition, this method has recognized advantages such as high efficiency and the absence of heat generation [119].

Yang et al. [46] performed a study in which different e-waste materials of different thicknesses and hardnesses were subjected to AWJ cutting. The purpose of this study was to evaluate the ability of AWJ cutting to crush and recover metal resources from e-waste. The results showed that the weight of particles larger than 154 µm increased, while those smaller than 154 µm decreased due to abrasive wear and the production of microsized debris from the CPU. The study revealed that broken products with large particle sizes were rare and mostly complex fractions, while products with small sizes were mostly single-component substances due to the thin layers of WPCBs favoring the production of micron-sized particles. The study also showed that WPCBs can be crushed into micron-sized particles in a one-step process, allowing for excellent liberation of metals from the WPCB layers without requiring additional equipment for size reduction and dust collection.

The mechanism of AWJ cutting involves high-speed, liquid‒solid two-phase flow with abrasive particles mixed in high-pressure water. For surface layer crushing, the erosion and impact of abrasive particles at high speeds cause material removal. For inner layer crushing, the different deformations of metallic and nonmetallic materials in WPCBs under abrasive jet cutting led to the dissociation of metals from nonmetals (Fig. 16). Metallic and nonmetallic materials exhibit effective dissociation performance due to their different tensile strengths and elastic moduli. The removal of components at high impact angles is more effective for dissociating metals from nonmetals in WPCBs [46].

Schematic of WPCB cutting using AWJ [46]

Conclusion and future perspective

This review article provides a comprehensive assessment of WPCB comminution, highlighting its pivotal role in enabling the recovery and recycling of valuable metals from e-waste. As natural resource availability decreases and e-waste volumes increase, optimizing comminution strategies is imperative for improving recycling process efficiency. Additionally, realizing optimized comminution strategies has broader sustainability implications aligned with SDGs related to responsible production, sustainable industrialization, human health, and environmental quality.

WPCBs present a complex mechanical comminution challenge due to their multicomponent structure containing an intricate blend of polymers, metals, and other elements. This composition results in diverse mechanical properties and comminution behaviors influenced by synergistic component interactions. The amalgamation of polymers, metals, and other constituents in WPCBs creates dynamic interplay, presenting both obstacles and opportunities for effective comminution and metal liberation.

The study highlights that shearing, shredding, and cutting stresses exhibit superior effectiveness compared to mineral crushers (jaw, roller, and disc crushers), but exhibit elevated wear and maintenance costs. High-intensity impact crushers, particularly hammer mills, have emerged as extensively researched comminution machinery capable of achieving selective milling effects by leveraging impact stresses to liberate metals in coarser fractions. However, the perpetual challenge of striking a balance between liberation efficacy and overgrinding remains a central concern. This review also highlights the promise of rotary shredders such as hammer shredders in terms of energy efficiency and particle size control. Moreover, standardized comminution terminology could bring much-needed clarity to this evolving field.

This review examines the crucial facets of conventional mechanical WPCB comminution, covering breakage mechanisms, liberation efficiency, particle morphology, fine and dust generation, and energy consumption. Achieving optimal selective liberation entails a delicate equilibrium between throughput, recovery rate, and fines minimization, influenced by equipment selection, operational parameters, and feed characteristics. However, research reveals that it is extremely difficult to achieve complete liberation of all components through purely mechanical crushing, even with extensive size reduction. Tiny composite particles with stubborn interfacial boundaries persist, necessitating more advanced separation processes downstream. Comminution mechanisms also profoundly impact the resulting particle shapes, influencing other upgrading stages. Conventional comminution processes, primarily aimed at reducing material size, inadvertently lead to the generation of fines and dust, a byproduct that, while holding economic value, often becomes a source of significant environmental and health concerns. The environmental risks are represented by hazardous dust containing toxic metals, chlorine, bromine, and fine particulate matter that poses major health and environmental concerns. Furthermore, studies have shown the inherent trade-off between energy efficiency and processing performance that comminution systems must balance. However, comparative energy efficiency assessments of the various comminution techniques are currently lacking.

Throughout this review, it becomes evident that the choice of comminution method is central to the selective liberation of valuable components from WPCBs. Conventional mechanical comminution, while prevalent, has limitations, including high energy consumption, excessive fine generation, and other technical and environmental challenges. Emerging methods utilize principles such as electrical pulses, abrasive water jets, and cryogenic milling. Each technique offers unique advantages and challenges, which require further evaluation and optimization for industrial-scale viability.

Realizing optimized WPCB comminution strategies that balance efficiency, economic viability, and sustainability will require research progress on multiple fronts. Several high-priority areas stand out as warranting attention:

-

Systematic studies quantitatively correlate WPCB composition, structure, and mechanical properties with comminution outcomes using standardized, statistically robust methods. This fundamental knowledge will enable tailoring comminution strategies.

-

Technoeconomic analyses and lifecycle assessments comparing emerging vs. conventional comminution techniques using consistent frameworks and data-driven models. This approach will support informed selection based on sustainability metrics.

-

Hybrid methods that strategically combine emerging and traditional approaches to leverage complementary advantages should be explored. This approach promises improved performance over individual techniques.

-

Scaling effects must be rigorously evaluated, with studies traversing laboratory, pilot, and industrial settings at varying throughputs. This approach will facilitate the translation of academic findings.

-

This research explicitly addresses industrial comminution requirements and demonstrates feasibility under real-world conditions. Tighter academia-industry coordination can align exploratory work with practical needs.

-

Investigating adaptable multistage comminution strategies and integrating process analytical technologies to handle varying, evolving WPCB materials. This approach will ensure that recycling keeps pace with technological advances.

-

Pursuing interdisciplinary research intersecting technical, social, and sustainability dimensions of advancing WPCB comminution strategies. Aligning innovation pathways with UN SDGs on responsible production, health, environment, and infrastructure ensures a holistic approach optimizing societal benefit.

With thorough research covering these interconnected aspects, the development of next-generation WPCB comminution processes holds great potential.

References

Brigden K, Labunska I, Santillo D, Allsopp M (2005) Recycling of electronic wastes in China and India: workplace and environmental contamination. Greenpeace International. https://www.greenpeace.org/international/publication/7051/recycling-of-electronic-waste-in-india-and-china-summary/

Wong CSC, Wu SC, Duzgoren-Aydin NS et al (2007) Trace metal contamination of sediments in an e-waste processing village in China. Environ Pollut 145:434–442. https://doi.org/10.1016/j.envpol.2006.05.017

Cobbing M (2008) Toxic tech: not in our backyard. Greenpeace International. https://www.greenpeace.org/usa/research/toxic-tech-not-in-our-backyard/

Williams E, Kahhat R, Allenby B et al (2008) Supporting information for : environmental, social and economic implications of global reuse and recycling of personal computers. Electronics 42:1–9

Kumar A, Holuszko M, Espinosa DCR (2017) E-waste: an overview on generation, collection, legislation and recycling practices. Resour Conserv Recycl 122:32–42. https://doi.org/10.1016/j.resconrec.2017.01.018

Baldé CP, Wang F, Kuehr R, Huisman J (2015) The global e-waste monitor – 2014. United Nations University. https://ewastemonitor.info/gem-2014/

Kumar A, Holuszko ME, Janke T (2018) Characterization of the non-metal fraction of the processed waste printed circuit boards. Waste Manag 75:94–102. https://doi.org/10.1016/j.wasman.2018.02.010

World Economic Forum (2019) A new circular vision for electronics, time for a global reboot. Platform for Accelerating the Circular Economy (PACE). https://www.weforum.org/publications/a-new-circular-vision-for-electronics-time-for-a-global-reboot/

Hao J, Wang Y, Wu Y, Guo F (2020) Metal recovery from waste printed circuit boards: a review for current status and perspectives. Resour Conserv Recycl 157:104787. https://doi.org/10.1016/j.resconrec.2020.104787

Mir S, Dhawan N (2022) A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resour Conserv Recycl 178:106027. https://doi.org/10.1016/j.resconrec.2021.106027

Hubau A, Chagnes A, Minier M et al (2019) Recycling-oriented methodology to sample and characterize the metal composition of waste printed circuit boards. Waste Manag 91:62–71. https://doi.org/10.1016/j.wasman.2019.04.041

Evangelopoulos P, Kantarelis E, Yang W (2017) Experimental investigation of the influence of reaction atmosphere on the pyrolysis of printed circuit boards. Appl Energy 204:1065–1073. https://doi.org/10.1016/j.apenergy.2017.04.087

Chen B, He J, Sun X et al (2020) Separating and recycling metal mixture of pyrolyzed waste printed circuit boards by a combined method. Waste Manag 107:113–120. https://doi.org/10.1016/j.wasman.2020.04.006

Ilankoon IMSK, Ghorbani Y, Chong MN et al (2018) E-waste in the international context—a review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. Waste Manag 82:258–275. https://doi.org/10.1016/j.wasman.2018.10.018

Holgersson S, Steenari BM, Björkman M, Cullbrand K (2018) Analysis of the metal content of small-size waste electric and electronic equipment (WEEE) printed circuit boards—part 1: internet routers, mobile phones and smartphones. Resour Conserv Recycl 133:300–308. https://doi.org/10.1016/j.resconrec.2017.02.011

Arshadi M, Yaghmaei S, Mousavi SM (2018) Content evaluation of different waste PCBs to enhance basic metals recycling. Resour Conserv Recycl 139:298–306. https://doi.org/10.1016/j.resconrec.2018.08.013

Hadi P, Xu M, Lin CSK et al (2014) Waste printed circuit board recycling techniques and product utilization. J Hazard Mater 283:234–243. https://doi.org/10.1016/j.jhazmat.2014.09.032

Fogarasi S, Imre-Lucaci F, Egedy A et al (2015) Eco-friendly copper recovery process from waste printed circuit boards using Fe3+/Fe2+ redox system. Waste Manag 40:136–143. https://doi.org/10.1016/j.wasman.2015.02.030

Park YJ, Fray DJ (2009) Recovery of high purity precious metals from printed circuit boards. J Hazard Mater 164:1152–1158. https://doi.org/10.1016/j.jhazmat.2008.09.043

Tan Z, He Y, Xie W et al (2011) Size distribution of wet crushed waste printed circuit boards. Min Sci Technol 21:359–363. https://doi.org/10.1016/j.mstc.2011.05.004

Li J, Xu Z, Zhou Y (2007) Application of corona discharge and electrostatic force to separate metals and nonmetals from crushed particles of waste printed circuit boards. J Electrostat 65:233–238. https://doi.org/10.1016/j.elstat.2006.08.004

Yoo JM, Jeong J, Yoo K et al (2009) Enrichment of the metallic components from waste printed circuit boards by a mechanical separation process using a stamp mill. Waste Manag 29:1132–1137. https://doi.org/10.1016/j.wasman.2008.06.035

Li J, Lu H, Guo J et al (2007) Recycle technology for recovering resources and products from waste printed circuit boards. Environ Sci Technol 41:1995–2000. https://doi.org/10.1021/es0618245

Wang F, Zhao Y, Zhang T et al (2015) Mineralogical analysis of dust collected from typical recycling line of waste printed circuit boards. Waste Manag 43:434–441. https://doi.org/10.1016/j.wasman.2015.06.021

He H, Di G, Gao X, Fei X (2020) Use mechanochemical activation to enhance interfacial contaminant removal: a review of recent developments and mainstream techniques. Chemosphere 243:125339. https://doi.org/10.1016/j.chemosphere.2019.125339

Yang Y, Zhang S, Wang S et al (2015) Ball milling synthesized MnOx as highly active catalyst for gaseous POPs removal: significance of mechanochemically induced oxygen vacancies. Environ Sci Technol 49:4473–4480. https://doi.org/10.1021/es505232f

Meskers CEM, Hagelüken C, Salhofer S, Spitzbart M (2009) Impact of pre-processing routes on precious metal recovery from PCs. Proc - Eur Metall Conf EMC 2009(2):527–540

Goodship V, Stevels A, Huisman J (2012) Waste Electrical and Electronic Equipment (WEEE) handbook. Woodhead Publishing

United Nations (2018) The United Nations and E-waste: system-wide action on addressing the full life-cycle of electrical and electronic equipment. UN Environment Management Group (UNEMG). https://unemg.org/images/emgdocs/ewaste/E-waste%20Synthesis%20Report%20-%20unedited%20version.pdf

Balde CP, Forti V, Gray V et al (2017) The global e-waste monitor–2017, United nations university (UNU), international telecommunication union (ITU) and international solid waste association (ISWA) Bonn/Geneva/Vienna

Khandpur RS (2011) Printed circuit boards: design, fabrication. McGraw-Hill, Assembly and Testing

Ambat R, Piotrowska K (2021) Materials and processes for electronic devices and components: how they contribute to corrosion reliability? In: Humidity and electronics corrosion reliability issues and preventive measures, 1st edn. Woodhead Publishing, pp 197–250. https://doi.org/10.1016/B978-0-323-90853-5.00006-2