Abstract

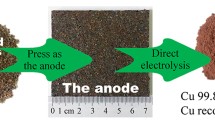

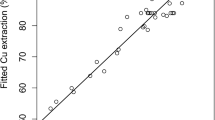

The copper recovery from waste printed circuit boards is of great significance to protect natural resource and environment. Direct current electrodeposition has been applied to extract metal from hydrometallurgical leach solutions. However, during the direct current electrodeposition process, concentration polarization and hydrogen evolution reaction often exist, which reduces current efficiency and metal recovery capability. In this work, a pulse current was applied to electrodeposit copper. The electrolyte was the leach solution of waste printed circuit boards obtained using a sulfuric acid-hydrogen peroxide system. The influence of process parameters in the leaching stage and the electrodeposition process on current efficiency were both investigated. The results showed that the current efficiency was 95.1% in pulse current electrodeposition, while that was only 90.9% in direct current electrodeposition. The increased current efficiency was proposed to be attributed to the fact that pulse current electrodeposition could improve the mass transfer of copper ions which suppressed concentration polarization and hydrogen evolution reaction. These results demonstrate that pulse current electrodeposition is a promising approach for recovering copper from waste-printed circuit boards.

Similar content being viewed by others

Data availability

The data provided in this paper are available.

References

Pinho SC, Ribeiro C, Ferraz CA, Almeida MF (2021) Copper, zinc, and nickel recovery from printed circuit boards using an ammonia – ammonium sulphate system. J Mater Cycles Waste Manage 23:1456–1465. https://doi.org/10.1007/s10163-021-01226-3

Barrueto Y, Hernández P, Jiménez Y, Morales J (2021) Leaching of metals from printed circuit boards using ionic liquids. J Mater Cycles Waste Manage 23:2028–2036. https://doi.org/10.1007/s10163-021-01275-8

Desmarais M, Pirade F, Zhang J, Rene ER (2020) Biohydrometallurgical processes for the recovery of precious and base metals from waste electricl and electronic equipments: Current trends and perspectives. Bioresource Technology Reports. https://doi.org/10.1016/j.biteb.2020.100526

Abdelbasir SM, Hassan SSM, Kamel AH, El-Nasr RS (2018) Status of electronic waste recycling techniques: a review. Environ Sci Pollut Res 25:16533–16547. https://doi.org/10.1007/s11356-018-2136-6

Akcil A, Agcasulu I, Swain B (2019) Valorization of waste LCD and recovery of critical raw material for circular economy: a review. Resour Conserv Recycl 149:622–637. https://doi.org/10.1016/j.resconrec.2019.06.031

Seif El-Nasr R, Abdelbasir SM, Kamel AH, Hassan SSM (2020) Environmentally friendly synthesis of copper nanoparticles from waste printed circuit boards. Separation Purification Technology. https://doi.org/10.1016/j.seppur.2019.115860

Kyung KS, Lee JC, Yoo K et al (2018) Kinetics of indium dissolution from marmatite with high indium content in pressure acid leaching. Waste Manage 199:69–76. https://doi.org/10.1007/s12598-016-0762-z

Choi JW, Song MH, Bediako JK, Yun YS (2020) Sequential recovery of gold and copper from bioleached wastewater using ion exchange resins. Environ Pollut. https://doi.org/10.1016/j.envpol.2020.115167

Wang J, Chen S, Zeng X et al (2021) Recovery of high purity copper from waste printed circuit boards of mobile phones by slurry electrolysis with ammonia-ammonium system. Separation Purification Techn. https://doi.org/10.1016/j.seppur.2021.119180

Yu L, Miao C, Nie S et al (2021) Feasible preparation of Cu6Sn5 alloy thin-film anode materials for lithium-ion batteries from waste printed circuit boards by electrodeposition. Solid State Ionics. https://doi.org/10.1016/j.ssi.2021.115625

Fogarasi S, Imre-Lucaci F, Ilea P, Imre-Lucaci Á (2013) The environmental assessment of two new copper recovery processes from waste printed circuit boards. J Clean Prod 54:264–269. https://doi.org/10.1016/j.jclepro.2013.04.044

Su J, Lin X, Zheng S et al (2017) Mass transport-enhanced electrodeposition for the efficient recovery of copper and selenium from sulfuric acid solution. Sep Purif Technol 182:160–165. https://doi.org/10.1016/j.seppur.2017.03.056

Silva MSBD, Melo RACD, Lopes-Moriyama AL, Souza CP (2019) Electrochemical extraction of tin and copper from acid leachate of printed circuit boards using copper electrodes. J Envi Manag 246:410–417. https://doi.org/10.1016/j.jenvman.2019.06.009

Sun ZHI, Xiao Y, Sietsma J et al (2016) Complex electronic waste treatment – An effective process to selectively recover copper with solutions containing different ammonium salts. Waste Manage 57:140–148. https://doi.org/10.1016/j.wasman.2016.03.015

Wei KX, Zhou HR, Jia FL et al (2021) Mechanical behaviors of graphene/copper matrix composite foils fabricated by pulse electrodeposition. Surfaces Interfaces 24:1–7. https://doi.org/10.1016/j.surfin.2021.101142

Young KE, Seuk KM, Lee JC et al (2011) Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manage 57:245–252. https://doi.org/10.1016/j.hydromet.2020.105427

Zhang X, Zhang X, Liu Z et al (2019) Journal of Environmental Chemical Engineering Pulse current electrodeposition of manganese metal from sulfate solution. J Envi Chem Eng. https://doi.org/10.1016/j.jece.2019.103010

Zhang S, Li Y, Wang R et al (2017) Superfine copper powders recycled from concentrated metal scraps of waste printed circuit boards by slurry electrolysis. J Clean Prod 152:1–6. https://doi.org/10.1016/j.jclepro.2017.03.087

Guo X, Qin H, Tian Q, Li D (2020) Recovery of metals from waste printed circuit boards by selective leaching combined with cyclone electrowinning process. J Hazardous Materials. https://doi.org/10.1016/j.jhazmat.2019.121355

Su J, Lin X, Zheng S et al (2017) Mass transport-enhanced electrodeposition for the efficient recovery of copper and selenium from sulfuric acidsolution. Sep Purif Technol 182:160–165. https://doi.org/10.1016/j.seppur.2017.03.056

Ning D, Yang C, Wu H (2019) Ultrafast Cu2+ recovery from waste water by jet electrodeposition. Sep Purif Technol 220:217–221. https://doi.org/10.1016/j.seppur.2019.03.059

Sharma VK, Kukreja N, Mausam K (2021) Application of pulse plating technique to improve hardness. Materials Today: Proceedings 45:3449–3451. https://doi.org/10.1016/j.matpr.2020.12.934

Nurmi P, Özkaya B, Kaksonen AH et al (2010) Predictive modelling of Fe(III) precipitation in iron removal process for bioleaching circuits. Bioprocess Biosyst Eng 33:449–456. https://doi.org/10.1007/s00449-009-0346-5

Vicenzo A, Bonelli S, Cavallotti PL (2010) Pulse plating of matt tin: effect on properties. Trans Inst Met Finish 88:248–255. https://doi.org/10.1179/002029610X12791981507802

Ataie SA, Zakeri A (2016) Improving tribological properties of (Zn-Ni)/nano Al2O3 composite coatings produced by ultrasonic assisted pulse plating. J Alloy Compd 674:315–322. https://doi.org/10.1016/j.jallcom.2016.02.111

Wu L, Graves JE, Cobley AJ (2018) Mechanism for the development of Sn-Cu alloy coatings produced by pulsed current electrodeposition. Mater Lett 217:120–123. https://doi.org/10.1016/j.matlet.2018.01.094

Tian Q, Li J, Guo X et al (2021) Efficient electrochemical recovery of tellurium from spent electrolytes by cyclone electrowinning. J Sustainable Metallurgy 7:27–45. https://doi.org/10.1007/s40831-020-00317-z

Elomaa H, Halli P, Sirviö T et al (2018) A future application of pulse plating–silver recovery from hydrometallurgical bottom ash leachant. Trans Inst Met Finish 96:253–257. https://doi.org/10.1080/00202967.2018.1507320

Hao J, Wang X, Wang Y et al (2022) Optimizing the leaching parameters and studying the kinetics of copper recovery from waste printed circuit boards. ACS Omega 7:3689–3699. https://doi.org/10.1021/acsomega.1c06173

Dela Pena EM, Roy S (2018) Electrodeposited copper using direct and pulse currents from electrolytes containing low concentration of additives. Surf Coat Technol 339:101–110. https://doi.org/10.1016/j.surfcoat.2018.01.067

Leisner P, Møller P, Fredenberg M, Belov I (2007) Recent progress in pulse reversal plating of copper for electronics applications. Trans Inst Met Finish 85:40–45. https://doi.org/10.1179/174591907X161973

Landolt D, Marlot A (2003) Microstructure and composition of pulse-plated metals and alloys. Surf Coat Technol 169–170:8–13. https://doi.org/10.1016/S0257-8972(03)00042-2

Ghaemi M, Binder L (2002) Effects of direct and pulse current on electrodeposition of manganese dioxide. J Power Sources 111:248–254. https://doi.org/10.1016/S0378-7753(02)00309-9

Qiang L, Pinto ISS, Youcai Z (2014) Sequential stepwise recovery of selected metals from fl ue dusts of secondary copper smelting. J Clean Prod 84:663–670. https://doi.org/10.1016/j.jclepro.2014.03.085

Cocchiara C, Dorneanu SA, Inguanta R et al (2019) Dismantling and electrochemical copper recovery from waste printed circuit boards in H2SO4–CuSO4–NaCl solutions. J Clean Prod 230:170–179. https://doi.org/10.1016/j.jclepro.2019.05.112

Nikolić ND, Pavlović LJ, Krstić SB et al (2008) Influence of ionic equilibrium in the CuSO4-H2SO4-H2O system on the formation of irregular electrodeposits of copper. Chem Eng Sci 63:2824–2828. https://doi.org/10.1016/j.ces.2008.02.022

Liu Y, Song Q, Zhang L, Xu Z (2021) Targeted recovery of Ag-Pd Alloy from polymetallic electronic waste leaching solution via green electrodeposition technology and its mechanism. Separation Purification Tech. https://doi.org/10.1016/j.seppur.2021.118944

Song YB, Chin DT (2002) Current efficiency and polarization behavior of trivalent chromium electrodeposition process. Electrochim Acta 48:349–356. https://doi.org/10.1016/S0013-4686(02)00678-3

Cao X, Xu L, Shi Y et al (2019) Electrochemical behavior and electrodeposition of cobalt from choline chloride-urea deep eutectic solvent. Electrochim Acta 295:550–557. https://doi.org/10.1016/j.electacta.2018.10.163

Haccuria E, Ning P, Cao H et al (2017) Effective treatment for electronic waste - selective recovery of copper by combining electrochemical dissolution and deposition. J Clean Prod 152:150–156. https://doi.org/10.1016/j.jclepro.2017.03.112

Tanaka Y (2007) Chapter 11 Limiting Current Density. Membrane Science and Technology https://doi.org/10.1016/S0927-5193(07)12011-8

Sharma A, Bhattacharya S, Sen R et al (2012) Influence of current density on microstructure of pulse electrodeposited tin coatings. Mater Charact 68:22–32. https://doi.org/10.1016/j.matchar.2012.03.002

Deo Y, Ghosh R, Nag A et al (2021) Electrochimica Acta Direct and pulsed current electrodeposition of Zn-Mn coatings from additive-free chloride electrolytes for improved corrosion resistance. Electrochim Acta. https://doi.org/10.1016/j.electacta.2021.139379

Hua G, Zhicheng X, Dan Q et al (2020) Chemosphere Fabrication and characterization of porous titanium-based PbO2 electrode through the pulse electrodeposition method : Deposition condition optimization by orthogonal experiment *. Chemosphere. https://doi.org/10.1016/j.chemosphere.2020.128157

He A, Liu ÆQ, Ivey ÆDG (2008) Electrodeposition of tin : a simple approach. J Mater Sci Mater Electron 19:553–562. https://doi.org/10.1007/s10854-007-9385-3

Xu Z, Guo X, Tian Q et al (2020) Electrodeposition of tellurium from alkaline solution by cyclone electrowinning. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2020.105316

Ben AI, Dhahbi M (2011) Electrochemical study and electrodeposition of copper in the hydrophobic tri-n-octylmethylammonium chloride ionic liquid media. J Mol Liq 161:13–18. https://doi.org/10.1016/j.molliq.2011.03.018

Portela AL, Teijelo ML, Lacconi GI (2006) Mechanism of copper electrodeposition in the presence of picolinic acid. Electrochim Acta 51:3261–3268. https://doi.org/10.1016/j.electacta.2005.09.029

Srinivasan S, Gileadi E (1966) The potential-sweep method: a theoretical analysis. Electrochim Acta 11:321–335. https://doi.org/10.1016/0013-4686(66)87043-3

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant No. 2018YFC1902501 and 2018YFC1903605), the Beijing Nova Program (Grant number Z211100002121091), the Fundamental Research Funds for the Central Universities (Grant No. 048000546320506), and International Research Cooperation Seed Fund of Beijing University of Technology (Grant No. 2021A13).

Author information

Authors and Affiliations

Contributions

Conceptualization: JH; Methodology: JH and XW; Writing-original draft preparation: JH and XW; Writing-reviewing and editing: JH, XW, YW and YW; Supervision: FG. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, J., Wang, X., Wang, Y. et al. Copper recovery from leach solution of waste printed circuit boards by pulse current electrodeposition. J Mater Cycles Waste Manag 25, 1108–1119 (2023). https://doi.org/10.1007/s10163-023-01604-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01604-z