Abstract

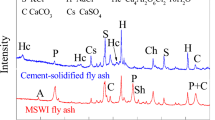

This study characterizes the leaching behavior of fuel raw boiler fly ash (BFA) and cement-solidified/stabilized raw boiler fly ash (SBFA). X-ray diffraction analysis shows that the mineral composition of BFA is made up of anhydrite, calcite, and calcium silicate, whereas the composition of SBFA consists of quartz, calcium aluminum silicate, gypsum, and calcite. To verify the environmental impact of utilizing the SBFA material as a road base aggregate, standardized regulatory batch leaching tests are conducted on the SBFA sample, and the results indicate that the concentrations of Cd, Pb, As, Cr, and Ni are below the limits of determination, respectively. The column leaching tests results suggest that mineral solubility is the main factor affecting the release of major elements. Results of pH-stat tests show a decrease in the released-heavy-metal concentration even in extreme acid conditions (pH < 4) for the SBFA sample. Geochemical speciation modelling is performed on the leachate analysis results of the column experiment with PHREEQC. The results indicate that the main mineral composition of the SBFA material under the experimental conditions might consist of calcium compounds such as ettringite, portlandite, gypsum, and anhydrite.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Zhang Y, Soleimanbeigi A, Likos JW, Edil TB (2016) Geotechnical and leaching properties of municipal solid waste incineration fly ash for use as embankment fill material. J Transp Res Board 2579:70–78. https://doi.org/10.3141/2F2579-08

Almahayni T, Vanhoudt N (2018) Does leaching of naturally occurring radionuclides from roadway pavements stabilized with coal fly ash have negative impacts on groundwater quality and human health. J Hazard Mater 349:128–134. https://doi.org/10.1016/j.jhazmat.2018.01.029

Choi MJ (2019) Performance evaluation of the use of tire-derived fuel fly ash as mineral filler in hot mix asphalt concrete. J Traffic Transp Eng (English Edition) 7(2):249–258. https://doi.org/10.1016/j.jtte.2019.05.004

Du B, Li J, Fang W, Liu J (2019) Comparison of long-term stability under natural aging between cement solidified and chelator stabilized MSWI fly ash. Environ Pollut 250:68–78. https://doi.org/10.1016/j.envpol.2019.03.124

Luo Z, Chen l, Zhang M, Zhao LL, Mu Y (2020) Analysis of melting reconstruction treatment and cement solidification on ultra-risk municipal solid waste incinerator fly ash-blast furnace slag mixtures. Environ Sci Pollut Res 27:32139–32151. https://doi.org/10.1007/s11356-020-09395-8

Hyks J, Astrup T, Christensen HT (2009) Long-term leaching from MSWI air-pollution-control residues: leaching characterization and modeling. J Hazard Mater 162:80–91. https://doi.org/10.1016/j.jhazmat.2008.05.011

Ludwig C, Johnson AC, Kappeli M, Ulrich A, Riediker S (2000) Hydrological and geochemical factors controlling the leaching of cemented MSWI air pollution control residues: a lysimeter field study. J Contam Hydrol 42:253–272. https://doi.org/10.1016/S0169-7722(99)00083-2

Hjelmar O, Holm J, Crillesen K (2006) Utilization of MSWI bottom ash as a sub-base in road construction: first results from a large-scale test site. J Hazard Mater A 139:471–480. https://doi.org/10.1016/j.jhazmat.2006.02.059

Dabo D, Badreddine R, De Windt L, Droudaine I (2009) Ten-year chemical evolution of leachate and municipal solid waste incineration bottom ash used in a test road site. J Hazard Mater 172:904–913. https://doi.org/10.1016/j.jhazmat.2009.07.083

Dijkstra J, Van der sloot HA, Comans RNJ (2006) The leaching of major and trace elements from MSWI bottom ash as a function of pH and time. Appl Chem 21:335–351. https://doi.org/10.1016/j.apgeochem.2005.11.003

Martinez JD, Fernandez JR, Sanchez-Valdepenas J, Murillo R, Garcia T (2014) Performance and emissions of an automotive diesel engine using a tire pyrolysis liquid blend. Fuel 115:490–499. https://doi.org/10.1016/j.fuel.2013.07.051

Uyumaz A, Aydogan B, Solmaz H, Yilmaz E, Hopa DY, Bahtli TA, Solmaz O, Aksoy F (2019) Production of waste tire oil and experimental investigation on combustion, engine performance, and exhaust emissions. J Energy Inst 92:1406–1418. https://doi.org/10.1016/j.joei.2018.09.001

JATMA 2020. Tire industry of Japan, 2020. The Japan Automobile Tire Manufacturers Association Inc. https://www.jatma.or.jp/media/pdf/tyre_industry_2020.pdf. Accessed 2 Feb 2022

Pan D, Jiang QW, Guo R, Huang Y, Pan W (2021) Thermogravimetric and kinetic analysis of co-combustion of waste tires and coal blends. ACS Omega 6:5479–5484. https://doi.org/10.1021/acsomega.0c05768

Hower JC, Robertson JD (2004) Chemistry and petrology of fly ash derived from the co-combustion of western United States coal and tire-derived fuel. Fuel Process Technol 85:359–377. https://doi.org/10.1016/j.fuproc.2003.05.003

Meima JA, Comans RNJ (1997) Geochemical modeling of weathering reactions in MSWI bottom ash. Environ Sci Technol 31:1269–1276. https://doi.org/10.1021/es9603158

Hareeparsad S, Tiruta-Barna L, Brouckaert CJ, Buckley CA (2011) Quantitative geochemical modeling using leaching tests: application for coal ashes produced by two South African thermal processes. J Hazard Mater 186:1163–1173. https://doi.org/10.1016/j.jhazmat.2010.11.127

Wang X, Lee H (2010) Simulation of a temperature in concrete incorporating fly ash or slag. Mater Struct 43:737–754. https://doi.org/10.1617/s11527-009-9525-8

Akinyemi S, Gitari W, Thobakgale R, Petrik L, Nyakuma B, Hower J, Ward C, Oliveira M, Silva L (2020) Geochemical fractionation of hazardous elements in fresh and drilled weatherd South African coal fly ashes. Environ Geochem Health 42:2771–2788. https://doi.org/10.1007/s10653-019-00511-3

Yakubu Y, Zhou J, Ping D, Shu Z, Chen Y (2018) Effects of pH dynamics on solidification/stabilization of municipal solid waste incineration fly ash. J Environ Manage 207:243–248. https://doi.org/10.1016/j.jenvman.2017.11.042

Li J, Zeng M, Ji W (2018) Characteristics of the cement-solidified municipal solid waste incineration fly ash. Environ Sci Pollut Res 25:36736–36744. https://doi.org/10.1007/s11356-018-3600-z

Du B, Li J, Fang W, Liu Y, Yu S, Li Yu, Liu J (2018) Characterization of naturally aged cement-solidified MSWI fly ash. Waste Manage 80:101–111. https://doi.org/10.1016/j.wasman.2018.08.053

Glasser FP (1997) Fundamental aspects of cement solidification and stabilization. J Hazard Mater 52:151–170. https://doi.org/10.1016/S0304-3894(96)01805-5

Fan C, Wang B, Zhang T (2018) Review on cement stabilization/solidification of municipal solid waste incineration fly ash. Advances Mater Sci Eng (Hindawi). https://doi.org/10.1155/2018/5120649

Bakhshi N, Sarrafi A, Ramezanianpour AA (2019) Immobilization of hexavalent chromium in cement mortar: leaching properties and microstructures. Environ Sci Pollut Res 26:20829–20838. https://doi.org/10.1007/s11356-019-05301-z

Yamaguchi O, Ida M, Uchiyama Y, Hanehara S (2005) A method for the determination of total Cr(VI) in cement. J Eur Ceram Soc 26:785–790. https://doi.org/10.1016/j.jeurceramsoc.2005.07.046

Li W, Sun Y, Xin M, Bian R, Wang H, Wang Y, Hu Z, Linh HN, Zhang D (2020) Municipal solid waste incineration fly ash exposed to carbonation and acid rain corrosion scenarios: release behavior, environmental risk, and dissolution mechanisms of toxic metals. Sci Total Environ 744:140857. https://doi.org/10.1016/j.scitotenv.2020.140857

Chen Q, Tyrer M, Hills C, Yang X, Carey P (2009) Immobilization of heavy metal in cement-based solidification/stabilization: a review. Waste Manage 29:390–403. https://doi.org/10.1016/j.wasman.2008.01.019

Van der Bruggen B, Vogels G, Van Herck P, Vandecasteele C (1998) Simulation of acid washing of municipal solid waste incineration fly ashes in order to remove heavy metals. J Hazard Mater 57:127–144. https://doi.org/10.1016/S0304-3894(97)00078-2

Li XD, Poon CS, Sun H, Lo IMC, Kirk DW (2001) Heavy metal speciation and leaching behaviors in cement-based solidified/stabilized waste materials. J Hazard Mater A82:215–230. https://doi.org/10.1016/S0304-3894(00)00360-5

Zhang Y, Cetin B, Likos WJ, Edil TB (2016) Impact of pH on leaching potential of elements from MSW incineration fly ash. Fuel 186:815–825. https://doi.org/10.1016/j.fuel.2016.07.089

Jiao F, Zhang L, Dong Z, Namioka T, Yamada N, Ninomiya Y (2016) Study on the species of heavy metals in MSW incineration fly ash and their leaching behavior. Fuel Process Technol 152:108–115. https://doi.org/10.1016/j.fuproc.2016.06.013

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Santiago, J.R., Sekito, T. & Dote, Y. Leaching behavior and mineral speciation of cement-solidified boiler fly ash from industrial waste incineration containing waste tires. J Mater Cycles Waste Manag 25, 910–919 (2023). https://doi.org/10.1007/s10163-022-01572-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01572-w