Abstract

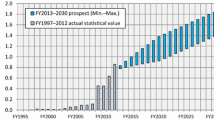

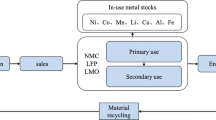

End-of-life vehicles (ELVs) are increasingly being recognized as a possible future resource pool for rare earth elements (REEs). This study provides the amount of REEs that can be recovered from ELVs in Japan based on dismantling survey, chemical identification and substance flow analysis. The REEs were quantified from common passenger vehicles and hybrid electric vehicles. We targeted 17 REEs in estimation of REE contents in ELVs. Four scenarios were developed to explore the recovery of REEs from ELVs. In these scenarios, NiMH batteries and motors containing NdFeB magnets were identified as target components due to they are main REEs carriers; we focused on interpretation of neodymium (Nd) and dysprosium (Dy) owing to they are two of the most critical REEs. The results suggest that 2700 (±500) tons of REEs can be recovered, of which 520 (±100) tons and 31 (±7) tons will be contributed by Nd and Dy in 2030. Meanwhile, the Dy recovered from ELVs can satisfy 23 % (±6 %) of the demand for NdFeB magnets and NiMH battery cells in automobile production of Japan; the Nd recovered from ELVs can satisfy 49 % (±9 %) of the production demands.

Similar content being viewed by others

References

Jody BJ, Daniels EJ, Duranceau CM, Pomykala Jr JA, Spangenberger JS (2010) End-of-life vehicle recycling: state of the art of resource recovery from shredder residue. Argonne Natl Lab ANL/ESD/10-8, p 164

Xiang W, Ming C (2011) Implementing extended producer responsibility: vehicle remanufacturing in China. J Clean Prod 19:680–686

Yoshida H, Hiratsuka J (2012) Overview and current status of ELV recycling in Japan. In: International workshop on 3R strategy and ELV recycling 2012, Nagoya, Japan, 19–21 September 2012

Eurostat website. http://ec.europa.eu/eurostat/web/waste/key-waste-streams/elvs. Accessed 1 Nov 2015

Binnemans K, Jones PT, Blanpain B, Van Gerven T, Yang Y, Walton A, Buchert M (2013) Recycling of rare earths: a critical review. J Clean Prod 51:1–22

Du X, Graedel TE (2013) Uncovering the end uses of the rare earth elements. Sci Total Environ 461–462:781–784

European Commission (2010) Critical raw materials for the EU, report of the Ad hoc Working Group on defining critical raw materials

US Department of Energy (2011) critical materials strategy

Alonso E, Wallington T, Sherman A, Everson M (2012) An assessment of the rare earth element content of conventional and electric vehicles. SAE Int J Mater Manf 5(2):473–477

Cullbrand K, Magnusson O (2011) The use of potentially critical materials in passenger cars. Master’s Thesis of Chalmers University of Technology, Sweden. http://studentarbeten.chalmers.se/publication/162842-the-use-of-potentially-critical-materials-in-passenger-cars. Accessed 9 July 2015

Yano J, Muroi T, Sakai S (2015) Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010–2030. J Mater Cycles Waste Manag (online available)

Seo Y, Morimoto S (2014) Comparison of dysprosium security strategies in Japan for 2010–2030. Resour Policy 39:15–20

US Geological Survey (2013) Mineral Commodity Summaries 2013

Sprecher B, Xiao Y, Walton A, Speight J, Harris R, Kleijn R, Visser G, Kramer GJ (2014) Life cycle inventory of the production of rare earths and the subsequent production of NdFeB rare earth permanent magnets. Environ Sci Technol 48(7):3951–3958

Pietrelli L, Bellomo B, Fontana D, Montereali MR (2002) Rare earth recovery from NiMH spent batteries. Hydrometallurgy 66:135–139

Saito T, Sato H, Motegi T (2006) Recovery of rare earths from sludges containing rare-earth elements. J Alloys Compd 425:145–147

Li L, Xu S, Ju Z, Wu F (2009) Recovery of Ni, Co and rare earths from spent Ni-metal hydride batteries and preparation of spherical Ni(OH)2. Hydrometallurgy 100:41–46

Tang K, Ciftja A, van der Eijk, Wilson S, Tranell G (2013) Recycling of the rare earth oxides from spent rechargeable batteries using waste metallurgical slags. J Min Metall Sect B 49:233–236

Müller T, Friedrich B (2006) Development of a recycling process for nickel-metal hydride batteries. J Power Sources 158:1498–1509

Innocenzi V, Vegliò F (2012) Recovery of rare earths and base metals from spent nickel-metal hydride batteries by sequential sulphuric acid and selective precipitations. J Power Sources 211:184–191

Luidold S, Antrekowitsch H (2012) Recovery of rare earth metals from waste material by leaching in non-oxidizing acid and by precipitating using sulphates. EP 2444507

Hoogerstraete TV, Wellens S, Verachtert K, Binnemans K (2013) Removal of transition metals from rare earths by solvent extraction with an undiluted phosphonium ionic liquid: separations relevant to rare-earth magnet recycling. Green Chem 15:919–927

Mochizuki Y, Tsubouchi N, Sugawara K (2013) Selective recovery of rare earth elements from Dy containing NdFeB magnets by chlorination. ACS Sustain Chem Eng 1:655–662

Solvay (2011) Press release: Umicore and Rhodia develop unique rare earth recycling process for rechargeable batteries. http://www.rhodia.com.cn/en/news_center/news_releases/Umicore_rare_earth_160611.tcm. Accessed 29 July 2015

Honda Motor Co., Ltd. (2012) Press release: Honda to reuse rare earth metals contained vehicles. http://www.greencarcongress.com/2013/03/hondanimh-20130303.html. Accessed 29 July 2015

Honda Motor Co., Ltd. (2012) Press release: Honda to begin reuse of rare earth metals extracted from used nickel-metal hydride batteries before the end of 2012. http://world.honda.com/news/2012/c120620Reuse-Rare-Earth-Metals/index.html. Accessed 29 July 2015

Honda Motor Co., Ltd. (2013) Press release: Honda to reuse rare earth metal extracted from nickel-metal hydride batteries in hybrid vehicles for the motors for hybrid vehicle motors. http://world.honda.com/news/2013/c130618Reuse-Rare-Earth-Metal/index.html. Accessed 29 July 2015

Toyota Motor Co., Ltd. (2013) Press release: Toyota honored for reducing, reusing, and recycling. http://www2.toyota.co.jp/en/news/13/10/1029.html. Accessed 29 July 2015

Alonso E, Sherman AM, Wallington TJ, Everson MP, Field F, Roth R, Kirchain RE (2012) Evaluating rare earth element availability: a case with revolutionary demand from clean technologies. Environ Sci Technol 46:3406–3414

Larsson K, Binnemans K (2014) Selective extraction of metals using ionic liquids for nickel metal hydride battery recycling. Green Chem 16:4595–4603

Kyoto University, National Institute for Environmental Studies, Ehime University, Japan Environmental Storage & Safety Corporation (2015) Report on end-of-life vehicles (ELV), their resource potential and environmental system analysis. The Environment Research and Technology Development Fund from the Ministry of the Environment, Japan (K123001) (in Japanese)

Sakai S (2015) End-of-life vehicles (ELVs) from the points of material cycles and final sinks. ISWA Beacon, 3rd International conference on Final Sinks, Taipei, Taiwan, August

Automobile Inspection and Registration Information Association (AIRIA) (2013) Vehicles in use of Japan based on the first-registered year, 41 (in Japanese)

Sougou Giken Co., Ltd. (2006) Current and future status of actuator for automobile (in Japanese)

Sougou Giken Co., Ltd. (2008) Current and future status of actuator for automobile (in Japanese)

Sougou Giken Co., Ltd. (2012) Current and future status of actuator for automobile (in Japanese)

Automobile Inspection and Registration Information Association (AIRIA) (2010) Vehicles in use of Japan based on some categorizations (in Japanese)

Ministry of Economy, Trade and Industry, Japan (METI) (2010) Next-generation vehicle strategy 2010 (in Japanese)

Oguchi M, Fuse M (2015) Regional and longitudinal estimation of product lifespan distribution: a Case study for automobiles and a simplified estimation method. Environ Sci Technol 49:1738–1743

Tang K, Ciftja A, Martinez A, Eijk C, Bian y, Guo S, Ding W (2007) Recycling the rare earth elements from waste NiMH batteries and magnet scraps by pyrometallurgical processes. Conference: the first international symposium on development of rare earths, Baotou, China

Morrice E, Shedd E S, Henrie T A (1968) Direct electrolysis of rare-earth oxides to metal and alloys in Fluorides melts. (No. CONF-670502). Bureau of Mines, Reno, Nev. Reno Metallurgy Research Center

Okamoto H (1991) Mg-Nd (magnesium–neodymium). J Phase Equilib 12:249–250

Koyama K, Kitajima A, Tanaka M (2009) Selective leaching of rare-earth elements from an Nd-Fe-B magnet. Kidorui 54:36–37

Voßenkaul D, Kruse S, Friedrich B (2013) Recovery of rare earth elements from small scale consumer scrap magnets. Proc EMC 2013:1–5

Hitachi Ltd. (2010) Hitachi develops recycling technologies for rare earth metals. http://www.hitachi.com/New/cnews/101206.html. Accessed 29 July 2015

Sakai S, Yoshida H, Hiratsuka J, Vandecasteele C, Kohlmeyer R, Rotter VS, Passarini F, Santini A, Peeler M, Li J, Oh G, Chi NK, Bastian L, Moore S, Kajiwara N, Takigami H, Itai T, Takahashi S, Tanabe S, Tomoda K, Hirakawa T, Hirai Y, Asari M, Yano J (2014) An international comparative study of end-of-life vehicle (ELV) recycling systems. J Mater Cycles Waste Manag 16(1):1–20

Dent PC (2012) Rare earth elements and permanent magnets (invited). J Appl Phys 111:07A721

Metal-page website. http://www.metal-pages.com/metalprices/rareearths/. Accessed 20 Jun 2015

Widmer R, Du X, Wager A (2015) Scarce metals in conventional passenger vehicles and end-of-life vehicle shredder output. Environ Sci Technol 49:4591–4599

Acknowledgments

This research was supported by the Environment Research and Technology Development Fund, Grant Number K123001 and 3K153001, from the Ministry of the Environment, Japan.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, G., Yano, J. & Sakai, Si. Scenario analysis for recovery of rare earth elements from end-of-life vehicles. J Mater Cycles Waste Manag 18, 469–482 (2016). https://doi.org/10.1007/s10163-016-0487-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0487-y