Abstract

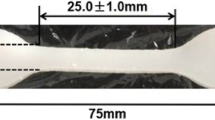

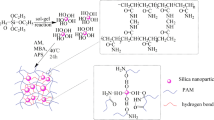

A facile method to fabricate tough and highly stretchable polyacrylamide (PAM) nanocomposite physical hydrogel (NCP gel) was proposed. The hydrogels are dually crosslinked single network with the PAM grafted vinyl hybrid silica nanoparticles (VSNPs) as the analogous covalent crosslinking points and the reversible hydrogen bonds among the PAM chains as the physical crosslinking points. In order to further elucidate the toughening mechanism of the PAM NCP gel, especially to understand the role of the dual crosslinking points, the PAM hybrid hydrogels (H gels) and a series of poly(acrylamide-co-dimethylacrylamide) (P(AM-co-DMAA)) NCP gels were designed and fabricated. Their mechanical properties were compared with those of the PAM NCP gels. The PAM H gels are prepared by simply mixing the PAM chains with bare silica nanoparticles (SNPs). Relative to the poor mechanical properties of the PAM H gel, the PAM NCP gel is remarkably tough and stretchable and also generates large number of micro-cracks to stop notch propagation, indicating the important role of PAM grafted VSNPs in toughening the NCP gel. In the P(AM-co-DMAA) NCP gels, the P(AM-co-DMAA) chains are grafted on VSNPs and the polydimethylacrylamide (PDMAA) only forms very weak hydrogen bonds between themselves. It is found that mechanical properties of the PAM NCP gel, such as the tensile strength and the elongation at break, are enhanced significantly, but those of the P(AM-co-DMAA) NCP gels decreased rapidly with decreasing AM content. This result reveals the role of the hydrogen bonds among the grafted polymer chains as the physical crosslinking points in toughening the NCP gel.

Similar content being viewed by others

References

Lee, K.Y. and Mooney, D.J., Chem. Rev., 2001, 101: 1869

Drury, J.L. and Mooney, D.J., Biomaterials, 2003, 24: 4337

Liu, Z.S. and Calvert, P., Adv. Mater., 2000, 12: 288

Bassil, M., Ibrahim, M. and El Tahchi, M., Soft Matter, 2011, 7: 4833

Saito, J., Furukawa, H., Kurokawa, T., Kuwabara, R., Kuroda, S., Hu, J.A., Tanaka, Y., Gong, J.P., Kitamura, N. and Yasuda, K., Polym. Chem., 2011, 2: 575

Yasuda, K., Kitamura, N., Gong, J.P., Arakaki, K., Kwon, H.J., Onodera, S., Chen, Y.M., Kurokawa, T., Kanaya, F., Ohmiya, Y. and Osada, Y., Macromol. Biosci., 2009, 9: 307

Nakajima, T., Takedomi, N., Kurokawa, T., Furukawa, H. and Gong, J.P., Polym. Chem., 2010, 1: 693

Huang, Y., Zhong, M., Huang, Y., Zhu, M., Pei, Z., Wang, Z., Xue, Q., Xie, X. and Zhi, C., Nat. Commun., 2015, 6: 10310

Huang, Y., Huang, Y., Zhu, M., Meng, W., Pei, Z., Liu, C., Hu, H. and Zhi, C., ACS Nano, 2015, 9: 6242

Hoffman, A.S., Adv. Drug Del. Rev., 2012, 64: 18

Haraguchi, K., Takehisa, T. and Fan, S., Macromolecules, 2002, 35: 10162

Barrett, D.G., Fullenkamp, D.E., He, L.H., Holten-Andersen, N., Lee, K.Y.C. and Messersmith, P.B., Adv. Funct. Mater., 2013, 23: 1111

Cui, J.X. and del Campo, A., Chem. Commun., 2012, 48: 9302

Tuncaboylu, D.C., Sari, M., Oppermann, W. and Okay, O., Macromolecules, 2011, 44: 4997

Kakuta, T., Takashima, Y., Nakahata, M., Otsubo, M., Yamaguchi, H. and Harada, A., Adv. Mater., 2013, 25: 2849

Sakai, T., Matsunaga, T., Yamamoto, Y., Ito, C., Yoshida, R., Suzuki, S., Sasaki, N., Shibayama, M. and Chung, U.I., Macromolecules, 2008, 41: 5379

Haraguchi, K. and Takehisa, T., Adv. Mater., 2002, 14: 1120

Zhao, X.H., Soft Matter, 2014, 10: 672

Sakai, T., Akagi, Y., Matsunaga, T., Kurakazu, M., Chung, U. and Shibayama, M., Macromol. Rapid Commun., 2010, 31: 1954

Okumura, Y. and Ito, K., Adv. Mater., 2001, 13: 485

Ito, K., Polym. J., 2007, 39: 489

Malkoch, M., Vestberg, R., Gupta, N., Mespouille, L., Dubois, P., Mason, A.F., Hedrick, J.L., Liao, Q., Frank, C.W., Kingsbury, K. and Hawker, C.J., Chem. Commun., 2006, 2774

Lin, P., Ma, S.H., Wang, X.L. and Zhou, F., Adv. Mater., 2015, 27: 2054

Gong, J.P., Soft Matter, 2010, 6: 2583

Gong, J.P., Katsuyama, Y., Kurokawa, T. and Osada, Y., Adv. Mater., 2003, 15: 1155

Tsukeshiba, H., Huang, M., Na, Y.H., Kurokawa, T., Kuwabara, R., Tanaka, Y., Furukawa, H., Osada, Y. and Gong, J.P., J. Phys. Chem. B, 2005, 109: 16304

Song, G.S., Zhang, L., He, C.C., Fang, D.C., Whitten, P.G. and Wang, H.L., Macromolecules, 2013, 46: 7423

Sun, T.L., Kurokawa, T., Kuroda, S., Bin Ihsan, A., Akasaki, T., Sato, K., Haque, M.A., Nakajima, T. and Gong, J.P., Nat. Mater., 2013, 12: 932

Hu, X., Vatankhah-Varnoosfaderani, M., Zhou, J., Li, Q. and Sheiko, S.S., Adv. Mater., 2015, 27: 6899

Yang, J., Wang, X.P. and Xie, X.M., Soft Matter, 2012, 8: 12133

Yang, J., Shi, F.K., Gong, C. and Xie, X.M., J. Colloid Interface Sci., 2012, 381: 107

Shi, F.K., Wang, X.P., Guo, R.H., Zhong, M. and Xie, X.M., J. Mater. Chem. B, 2015, 3: 1187

Zhong, M., Liu, X.Y., Shi, F.K., Zhang, L.Q., Wang, X.P., Cheetham, A.G., Cui, H.G. and Xie, X.M., Soft Matter, 2015, 11: 4235

Zhong, M., Liu, Y.T. and Xie, X.M., J. Mater. Chem. B, 2015, 3: 4001

Zhong, M., Shi, F.K., Liu, Y.T., Liu, X.Y. and Xie, X.M., Chin. Chem. Lett., 2016, 27: 312

Yang, J., Gong, C., Shi, F.K. and Xie, X.M., J. Phys. Chem. B, 2012, 116: 12038

Shi, F.K., Zhong, M., Zhang, L.Q., Liu, X.Y. and Xie, X.M., Acta Polymerica Sinica (in Chinese), DOI: 10.11777/j.issn1000-3304.2017.16162

Shi, F., Zhong, M., Zhang, L., Liu, X.Y. and Xie, X.M., J. Mater. Chem. B, 2016, 4: 6221

Zhang, L.Q., Chen, L.W., Zhong, M., Shi, F.K., Liu, X.Y. and Xie, X.M., Chinese J. Polym. Sci., 2016, 34: 1261

Zhong, M., Liu, Y.T., Liu, X.Y., Shi, F.K., Zhang, L.Q., Zhu, M.F. and Xie, X.M., Soft Matter, 2016, 12: 5420

Duan, Z.Q., Zhong, M., Shi, F.K. and Xie, X.M., Chin. Chem. Lett., 2016, DOI: 10.1016/j.cclet.2016.04.002

Lin, W.C., Marcellan, A., Hourdet, D. and Creton, C., Soft Matter, 2011, 7: 6578

Lin, W.C., Fan, W., Marcellan, A., Hourdet, D. and Creton, C., Macromolecules, 2010, 43: 2554

Na, Y.H., Tanaka, Y., Kawauchi, Y., Furukawa, H., Sumiyoshi, T., Gong, J.P. and Osada, Y., Macromolecules, 2006, 39: 4641

Zhao, Y., Nakajima, T., Yang, J. J., Kurokawa, T., Liu, J., Lu, J., Mizumoto, S., Sugahara, K., Kitamura, N., Yasuda, K., Daniels, A.U.D. and Gong, J.P., Adv. Mater., 2014, 26: 436

Baumberger, T., Caroli, C. and Martina, D., Eur. Phys. J. E, 2006, 21: 81

Rose, S., Dizeux, A., Narita, T., Hourdet, D. and Marcellan, A., Macromolecules, 2013, 46: 4095

Kong, H.J., Wong, E. and Mooney, D.J., Macromolecules, 2003, 36: 4582

Yang, J., Zhao, J.J., Han, C.R. and Duan, J.F., Compos. Sci. Technol., 2014, 95: 1

Zhou, T.H., Ruan, W.H., Rong, M.Z., Zhang, M.Q. and Mai, Y.L., Adv. Mater., 2007, 19: 2667

Dixon, D.A., Dobbs, K.D. and Valentini, J.J., J. Phys. Chem., 1994, 98: 13435

Sekine, Y., Takagi, H., Sudo, S., Kajiwara, Y., Fukazawa, H. and Ikeda-Fukazawa, T., Polymer, 2014, 55: 6320

Sekine, Y. and Ikeda-Fukazawa, T., J. Chem. Phys., 2009, 130: 034501

Monemian, S. and Korley, L.T.J., Macromolecules, 2015, 48: 7146

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (Nos. 21474058 and 51633003), State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University (No. LK1404), Tsinghua University Scientific Research Project (No. 2014Z22069), and State Key Laboratory of Organic-Inorganic Composites, Beijing University of Chemical Technology (No. OIC-201601006).

Electronic supplementary material

10118_2017_1869_MOESM1_ESM.pdf

Toughening Mechanism of Nanocomposite Physical Hydrogels Fabricated by a Single Gel Network with Dual Crosslinking — The Roles of the Dual Crosslinking Points

Rights and permissions

About this article

Cite this article

Shi, Fk., Zhong, M., Zhang, Lq. et al. Toughening mechanism of nanocomposite physical hydrogels fabricated by a single gel network with dual crosslinking — The roles of the dual crosslinking points. Chin J Polym Sci 35, 25–35 (2017). https://doi.org/10.1007/s10118-017-1869-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-017-1869-x