Abstract

In Eswatini, 62.3% of households still rely on solid fuel for cooking, especially wood (61.8%). Smoke emissions during biomass burning remain the primary source of indoor air pollution, comprising pollutants detrimental to health. This study provides a quantitative exposure assessment of fuels used in the Shiselweni region with the objectives of monitoring the carbon monoxide (CO) and carbon dioxide (CO2) concentrations during cooking events and evaluating cancer and noncancer risks due to exposure to particulate-bound polycyclic aromatic hydrocarbons (PAHs) during cooking events among cooking personnel in households that cook indoors by burning biomass. Real-time CO, CO2, and particulate matter (PM) monitoring was performed in seventeen kitchens during cooking events across the Shiselweni region using different cooking methods: biomass in open fires and stoves, liquefied petroleum gas (LPG), and electric stoves. PM2.5, PM10, and CO exceeded indoor exposure guidelines for biomass fuel-related homesteads. Particulate PAH intake concentrations were evaluated, and biomass fuel users exhibited high cancer risks and low embryo survival chances due to particulate PAH exposure. The average total cost of reducing the incremental lifetime cancer risk (ILCR) and hazard quotient (HQ) to acceptable levels was lower when shifting from biomass to LPG stoves than when shifting to electric stoves.

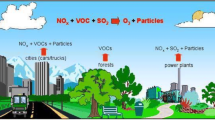

Graphical abstract

Similar content being viewed by others

Introduction

Indoor pollutant concentrations have been reported to be higher in developing countries than in developed countries due to the advanced technology and cleaner fuels utilized in developed countries for cooking and heating, such as liquefied petroleum gas (LPG), electricity, and natural gas (Abdullahi et al. 2013). In Eswatini, due to economic reasons, more than half of the population relies on biomass as a source of energy for cooking. It has been estimated that approximately 80% of households in rural Eswatini use unprocessed biomass fuels, mainly wood (79.4%), for daily cooking purposes (Simelane et al. 2020). In the energy sector, biomass is an inexpensive primitive fuel but is inefficient and more polluting than other highly ranked fuels that are less polluting in terms of pollutant mass per energy consumed, such as LPG and electricity (Van DerKroon et al. 2013). In developing countries, biomass combustion remains a significant source of indoor air pollution since most households using biomass fuels often cook indoors, using open fires in poorly ventilated houses (Bruce et al. 2000, Balmes 2019). In general, incomplete combustion of biomass fuels leads to the generation of particulate matter (PM) with aerodynamic diameters \(\le\) 10 µm (PM10) and 2.5 µm (PM2.5), carbon monoxide (CO) and aerosols that may contain carcinogenic and mutagenic toxins, such as polycyclic aromatic hydrocarbons (PAHs) (e.g., benzo[a]pyrene (BaP)) (Bruce et al. 2000, Kim et al. 2012, Du et al. 2020, Yu et al. 2020, Siregar et al. 2022).

Exposure to indoor biomass smoke has been associated with an increased risk of acute respiratory infection (ARI) occurrence among children, chronic obstructive pulmonary disease (COPD) among adults, lung cancer (Bruce et al. 2000, Fullerton et al. 2008, Pathak et al. 2020), cataracts (Pokhrel et al. 2005, Khanna 2020), and cardiovascular diseases (Kim et al. 2011, Mocumbi et al. 2019, Young et al. 2019). The risk due to exposure among women is higher than that among men because of their customary cooking responsibility (Bruce et al. 2000, Young et al. 2019, Mitra et al. 2022); therefore, it is unsurprising that the lung cancer risk of nonsmoking patients is higher among females (53%) than among males (15%) (Sun et al. 2007). The PAH concentration in the indoor environment has been reported to be the highest in kitchens where biomass fuels are used for cooking (Kim Oanh et al. 2002, Bhargava et al. 2004, Tiwari et al. 2015, Wolkoff 2018, Du et al. 2020). However, data on the indoor air concentration of PAHs are limited for the continent of Africa and nonexistent for Eswatini. Moreover, cooking using electric stoves is often excluded from research. Here, we report the distribution and health risk assessment results for 29 carcinogenic particulate-bound PAHs during indoor biomass burning via LPG and electricity stove employment for cooking.

Methodology

Study area

The study was conducted in the Shiselweni region of Eswatini, which is officially the Kingdom of Eswatini and the country formerly known as Swaziland. The Shiselweni region is positioned in the south of Eswatini, with an area of 3,786.71 km2, a population of 202,686, and a notably high portion of households relying on biomass fuels for cooking compared to the other three regions of Eswatini: Hhohho, Lubombo, and Manzini (Simelane et al. 2020). Approximately 84.1% of the Shiselweni region relies on biomass fuels as a source of energy for cooking, mainly wood (83.5%), and other fuel sources used for cooking in the region include electricity (19.9%) and LPG (10.8%) (Simelane et al. 2020).

Onsite sampling

Indoor air sampling was conducted in 17 kitchens using biomass fuels in open fires (n=6), biomass stoves (n=5), LPG stoves (n=3), and electric stoves (n=3) for cooking among three chiefdoms in the Shiselweni region. The chiefdoms selected were Mashobeni, Ekwendeni, and Nsingizini, as illustrated in Fig. 1. The selection criteria for the three chiefdoms and households were based on the following factors, including biomass fuel reliance, variation in cooking methods, geographical location, and household characteristics. (1) Biomass fuel reliance: these chiefdoms were chosen due to their significant dependence on biomass fuels for cooking, aligning with the primary focus of the study on households using these types of fuels; (2) Variation in cooking methods: The diversity in cooking methods observed across these chiefdoms, encompassing biomass stoves, open fires, LPG, and electric stoves, allowed for a comprehensive analysis of the impact of different cooking practices on indoor air quality; (3) Geographic location: The selected households were situated in rural areas away from major roads and industrial areas, ensuring a more controlled environment for sampling and minimizing external pollution sources; (4) Household characteristics: The households chosen comprised nonsmoking family members and predominantly used electricity for lighting, factors aimed at eliminating potential interference from other emission sources during the sampling process.

Stove characteristics

The biomass stoves used in Eswatini were typically constructed from black enamel cast iron and mostly consisted of four to six burners for cooking, an oven, and a chimney; while LPG, and electric stoves in the analyzed households were mainly made of aluminum. During open fire burning, biomass or unprocessed wood logs were typically burned on a metal sheet (Sites 1, 2, 7, and 12) or clay (Sites 3 and 16) on the kitchen floor without a chimney. In addition, a single three-legged cast iron pot was placed over a metal stand above an open fire when cooking. In biomass stoves, biomass or unprocessed wood logs were inserted by opening one of the burners so that the fuel could be manually ignited. LPG stoves were connected to an LPG cylinder and generally consisted of three or four hot burners, as observed at Sites 13 and 14, and two burners without an oven were observed at Site 17. Electric stoves were configured in the same way as LPG stoves; either three or four burners were configured with an oven (Sites 5 and 15) or two burners (Site 10).

Kitchens sampled

The characteristics of the sampled kitchens are summarized in Table 1. A separate house was employed for cooking using an open fire; while, electric stoves were used in the main house. The kitchen volume varied, ranging from 15.5 to 43.7 m3 with primarily one or two windows, except Site 3, where there was no window.

Wood was the main source of biomass fuel. During fire ignition among homesteads using biomass fuels, most homesteads used plastic material or candle wax to intensify the flaming stage, as indicated. Most homesteads cooked breakfast and lunch in the morning, and dinner was cooked after midday. Similar foods, including maize meal porridge, beans, vegetables, and meat, were routinely cooked and eaten in most homesteads.

Real-time monitoring

An indoor air quality (IAQ) monitor (HD21AB, Delta OHM, Italy) was used to monitor CO and carbon dioxide (CO2) in intervals of 1 min for at least 8 h starting at least 1 h before the onset of cooking. The IAQ monitor was located at a height of 1.5 m (the breathing zone of an adult with an average height of 1.59 m (Gbadamosi and Tlou 2020)) and situated 50–80 cm from the fire or stove.

PM sampling

PM samples were collected only during cooking events to focus on air pollution during these periods. Background samples were collected one hour before the onset of cooking in the surveyed kitchens. An SKC® three-stage personal modular impactor (PMI) supported with an SKC® pump at a flow rate of 3 L/min was selected to sample PM on glass fiber filter papers. The cutoff aerodynamic diameters for stages 1–3 of the PMI included <2.5 µm (PM2.5), 2.5–10 µm (PM2.5–10), and >10 µm (PM>10). The PMI was positioned at a height of 1.5 m and 50–80 cm from the fire or stove.

PM-bound PAH extraction, clean up, and analysis

The filters containing PM samples were extracted via ultrasonic-assisted extraction (ultrasonic unit: Elmasonic P60, Elma, Germany) with 20 mL dichloromethane for 30 min. The extraction process was repeated twice to reduce PAH attenuation and prevent light illumination. The obtained PAH extracts were vacuum concentrated to approximately 2 mL, purified via a column packed with silica gel and anhydrous sodium sulfate to remove any interfering substances in the samples, and ultrafiltered and concentrated to exactly 0.25 mL with pure nitrogen gas. The concentrated PAH extracts were then analyzed with a gas chromatography/mass spectrometry (GC/MS, Agilent 7890B/5977A MSD) instrument with an Agilent HP-5MS column (30 m × 0.25 mm i.d., DF=0.25 μm). The injection sample volume was 1 μL. The temperature program was as follows: the temperature was maintained at 40 °C for 1 min, increased at a rate of 15 °C/min to 100 °C, increased at a rate of 20 °C/min to 210° C and maintained for 10 min, and then increased at a rate of 5 °C/min to 290 °C and maintained for 10 min. The temperatures of the injector, ion trap mass analyzers, and transfer line were 300 °C, 250 °C, and 290 °C, respectively. The carrier gas was helium (purity: 99.995%), and the flow rate was 1.0 mL/min.

A total of 30 PAHs were determined, including the following 16 priority PAHs ranked by the U.S. Environmental Protection Agency (EPA): naphthalene (NAP); acenaphthylene (ACPy); acenaphthene (ACP); fluorene (FLU); anthracene (ANTHR); phenanthrene (PHE); fluoranthene (FLT); pyrene (PYR); BaP; benz[a]anthracene (BaA); chrysene (CHR); benz[b]fluoranthene (BbF); benz[k]fluoranthene (BkF); dibenz[a,h]anthracene (DBA); indeno[1,2,3-cd]pyrene (IND); benzo[ghi]perylene (BghiP) [23] and 14 other PAHs: 2-methylnaphthalene (2-MeNAP); 1-methylnaphthalene (1-MeNAP); 1-methyfluorene (1-MeFLU); 3-methylphenanthrene (3-MePHE); 2-methylphenanthrene (2-MePHE); 3,6-dimethylphenanthrene (3,6-DMP); benzo[c]phenanthrene (BcPH); benzo(b)napth(2,1-d)thiophene (BNT); cyclopenta[c,d]pyrene (CPP); benz[e]pyrene (BeP); perylene (PYL); anthanthrene (ANTHN); dibenzo[a,l]pyrene (DBalP); and coronene (COR).

Quality assurance and quality control

The recovery of the employed PAH standards ranged from 80.9 to 102.3%. The recovery of the surrogate compounds in each sample ranged from 75.1 to 110.1%. The method detection limits of the analyzed PAHs are listed as follows: Nap: 0.062 ng; 2-MeNAP: 0.058 ng; 1-MeNAP: 0.067 ng; ACPy: 0.359 ng; ACP: 0.581 ng; FLU: 0.124 ng; 1-MeFLU: 0.559 ng; PHE: 0.100 ng; ANTHR: 0.159 ng; 3-MePHE: 0.717 ng; 2-MePHE: 0.198 ng; 3,6-DMP: 0.088 ng; FLT: 0.117 ng; PYR: 0.075 ng; BcPH: 0.640 ng; BNT: 0.112 ng; CPP: 0.305 ng; BaA: 0.178 ng; CHR: 0.182 ng; BbF: 0.290 ng; BkF: 0.419 ng; BeP: 0.153 ng; BaP: 0.552 ng; PYL: 1.938 ng; INDY: 0.237 ng; DBA: 1.056 ng; BghiP: 0.157 ng; ANTHN: 0.284 ng; DbalP: 0.

Health risk assessment

BaP equivalent concentration

The PAH mixture toxicity risk was expressed by the BaP equivalent concentration (BaPeq). BaPeq can be estimated as the sum of the individual PAH concentrations multiplied by the toxic equivalency factor (TEF), where TEF denotes the relative potency of a given PAH compound, whereas BaP, a widely used marker for PAHs, serves as a reference (Nisbet and LaGoy 1992). The equation below was used to calculate BaPeq (Xia et al. 2013).

where Ci is the concentration of PAH congener i and TEFi is the TEF value for PAH congener i.

Cancer risk

The incremental lifetime cancer risk (ILCR) can be calculated to evaluate the cancer risk resulting from inhaling PM-bound PAHs among women using different cooking methods during cooking events. The following equation was used to calculate the ILCR (adapted from (Farland and Tuxen 1997, Qu et al. 2015, Yu et al. 2015)):

where C is the BaPeq derived from Eq. (1), IR is the inhalation rate (1.25 m3/h for females performing light work [International Commission on Radiological Protection (ICRP) model] (Hinds 1999) × the daily exposure to pollution resulting from cooking (6.61 h/day for open fires, 7.46 h/day for biomass stoves, 6.16 h/day for LPG stoves and 4.89 h/day for electric stoves based on our questionnaire study), EF is the exposure frequency (days/year) (365 days/year), ED is the exposure duration (60.3 years: 18–60 years (life expectancy in Eswatini)), CF is a conversion factor (10−6 mg/ng), BW is the body weight (kg) (69.4 kg for women between the ages of 15 and 69) \({\left(\frac{{\text{BW}}}{70}\right)}^{\left(\frac{1}{3}\right)}\) is a correction factor to modify integrated risk information system (IRIS) risk measures (USEPA 1997), AT is the average time for carcinogenic risk determination (25,567 days = 70 years, including 17 leap years) (USEPA 1997, Yu et al. 2015) and SFBaP is the slope factor (3.1 mg/kg/day−1) (Yu et al. 2015). The risk assessment formulas focused on adults because children have different exposure rates, behaviors, and physiological responses and cannot fit in the same risk assessment formulas. (Singh et al. 2023) Although children are not responsible for cooking, they are often present with their mothers or other female caregivers during cooking events. Therefore, excluding childhood in the risk assessment could lead to underestimation, which is a limitation of this study.

Noncancer risk

The hazard quotient (HQ) was calculated to evaluate the noncancer risk along the inhalation pathway among women exposed to PM-bound PAHs during cooking events. The following equation was used to calculate the HQ (US EPA and IRIS 2017):

where HQ is the hazard quotient, EC is the exposure concentration (mg/m3) derived from Eq. (4), CA is the BaPeq concentration (ng/m3), ET is the exposure time (6.61 h/day for open fires, 7.46 h/day for biomass stoves, 6.16 h/day for LPG stoves and 4.89 h/day for electric stoves), EF is the exposure frequency (365 days/year), ED is the exposure duration (43 years), CF is a conversion factor (ng/mg), AT is the average time (lifetime in years (61) × 365 days/year × 24 h/day = 534,360 h), and RfC is the reference concentration for the BaP developmental toxicity representing decreased embryo or fetal survival chances (2×10−6 mg/m3). However, there are limited studies to fully understand the precise susceptibility and duration of exposure required to develop toxicity (US EPA and IRIS 2017).

Monetary evaluation

The rand currency, which is the legal tender (official) in South Africa, Namibia, Lesotho and Eswatini, was employed in the economic assessment of this study. The cost of stoves widely varies across different brands and retailers. Table S1 (Supplementary Material) provides the average cost of stoves in Eswatini. The total annual cost (TC) is estimated as follows:

where ACcj is the annualized capital cost of stove type j and FCi represents the annual cost of fuel i. ACcj is calculated as follows:

where Ccj denotes the capital cost of stove type j and fi represents the annuity factor, which is estimated as follows:

where z denotes the discounted rate (assumed at 10%), and t denotes the stove lifetime (years). Ten years were selected as the stove lifetime of biomass, LPG, and electric stoves (Gujba et al. 2015).

The annual fuel consumption is estimated with the following equation:

where cooktj denotes the average daily cooking time for stove j (hrs/day), and fueltj represents the fuel quantity needed per unit cooking time for stove j [stove power (W, kJ hr−1) times the energy density (or calorific value) of the consumed fuel (ED, kJ kg–1)]. The fuel cost for electricity and LPG, which were assumed to be readily available, is expressed as follows:

where fueli is derived from Eq. (8), pi is the cost of LPG or electricity (E/kg or E/kW-hr, respectively), and X is the weighted fraction of stove operation and maintenance.

The switching unit cost of ILCR reduction from open fires to LPG stoves was calculated from the sum of the cost of LPG and LPG stoves divided by the quotient of ILCRopen fire and ILCRLPG. The same procedure was followed to calculate the cost per unit of ILCR reduction when switching from open fires to electric stoves and again when switching from biomass stoves to both LPG stoves and electric stoves. The acceptable ILCR was 10−6; while, the acceptable HQ was 1. The cost per unit of HQ reduction when switching from open fires to LPG stoves was calculated based on the sum of the cost of LPG and LPG stoves divided by the quotient of HQopen fire and HQLPG. A similar equation was applied to compute the cost per unit of HQ reduction when switching from open fires to electric stoves and when switching from biomass stoves to both LPG stoves and electric stoves (Gujba et al. 2015).

Results and discussion

PM, CO and CO2 concentrations

The concentrations of PM2.5, PM2.5–10, PM>10, CO, and CO2 throughout cooking events and during noncooking events are displayed in Table 2. The pollutants were observed to be lower during noncooking events and higher during cooking events. Some of the sites exhibited PM concentrations during noncooking events, which may be attributed to the short sampling time of 60 min. These findings concur with those in a study that monitored PM2.5 and CO in Indian kitchens, where it was also reported that PM2.5 and CO were significantly higher during cooking events than during noncooking events (Sidhu et al. 2017). However, in this study, PM was not monitored throughout the day; therefore, the distribution of PM2.5 and PM10 between the two periods was unknown. Outdoor activities at times might have influenced concentrations during noncooking events. For example, when sampling at Site 13, one of the family members was welding outside the premises, and for this reason, PM2.5 was observed to be higher before the initial cooking period than during the cooking event.

Cooking in open fires using biomass fuels was observed to yield the highest geographic mean (GM) concentrations of PM2.5, PM2.5–10, PM>10, CO2, and CO at 3554.50 µg/m3, 287.33 µg/m3, 267.30 µg/m3, 859.41 ppm, and 48.18 ppm, respectively. Findings by (Naeher 2000, Sidhu et al. 2017) have reported higher CO concentrations among kitchens using biomass fuels during cooking events than among kitchens using high-ranked fuels such as LPG. Site 11 in our study, where biomass fuels in a stove were used for cooking, showed the highest concentration levels of PM2.5 and CO (8001.10 µg/m3 and 229.03 ppm, respectively). The chimney at Site 11 horizontally protruded through the wall (Fig. 1), which caused poor ventilation efficiency, whereas at the other sites using biomass stoves, the chimney outlet vertically protruded from the roof of the house, which may explain why Site 11 was observed to exhibit higher emission concentrations. Site 3 attained the highest concentrations of PM2.5–10, PM>10, and CO2 during cooking events at 700.25 µg/m3, 408.02 µg/m3, and 1465.40 ppm, respectively. Site 3 exhibited the smallest kitchen volume and no windows, which could explain the high concentrations detected.

The Kruskal‒Wallis test method was selected to assess the significant differences in the emitted pollutants among the different cooking methods, as summarized in Table 2. There was a significant difference in the concentrations of PM2.5, PM2.5–10, PM>10, and CO among the different cooking methods during cooking events (p value < 0.05). However, there was no significant difference in the concentration of CO2 among the different cooking methods during cooking events. PM2.5, PM2.5–10, PM>10, CO2, and CO were not significantly different among the various cooking methods during noncooking events. Hence, this finding indicates that emissions from burning cooking fuel contributed to the observed concentration of pollutants during cooking events.

The GM PM2.5 and PM2.5–10 concentrations indicated that the order of air pollution was biomass in open fires > biomass stoves > electric stoves > LPG stoves. PM2.5 was reported to be primarily higher than PM2.5–10 among the sampled sites. In kitchens using biomass fuels in open fires, GM PM2.5 concentrations were 12-fold higher than the PM2.5–10 concentration but were 2-fold higher among sites using either LPG or electric stoves for cooking. PM2.5 is chiefly released during combustion, whereas PM2.5–10 mainly consists of larger particles, such as minerals and biological material (Adams et al. 2015), which may explain why cooking using biomass fuels resulted in higher concentrations of PM2.5. Similar studies also reported meaningfully higher PM2.5 (Titcombe and Simcik 2011, Sidhu et al. 2017) and PM10 (Naeher 2000, N. Mbanya and Sridhar 2017) levels among kitchens using biomass fuels for cooking than among kitchens using LPG.

The CO emissions monitored on site were expressed as an 8 h arithmetic mean concentration. PM2.5 and PM10 were normalized to 24 h, as shown in Fig. 2, under the assumption that PM2.5 and PM10 were zero when cooking was absent. Even under this assumption, kitchens using biomass fuels were observed to exceed the recommended indoor exposure limits for PM2.5 and PM10 at 25 µg/m3 and 50 µg/m3 (24 h arithmetic mean concentration), respectively. Kitchens using biomass fuel were also observed to exceed the indoor exposure limit of CO recommended by the World Health Organization (WHO) (1998) of 10 mg/m3 (9.0 ppm) for 8 h (arithmetic mean concentration). However, Sites 6 and 8 were exceptions, with 8 h CO levels of 0.32 and 3.61 ppm, respectively. This agrees with findings reported by (Pilishvili et al. 2016); they reported a significant reduction in mean CO when using an improved cooking stove compared to that during open fire burning. This finding suggests that improved biomass stoves could reduce indoor air pollution (Sharma and Jain 2019, Pratiti et al. 2020).

CO emissions were observed to be below the resolution of 1 ppm in homesteads using an electric stove for cooking; and thus, CO emissions were not detected. For a duration of 24 h, Site 11 displayed the highest levels of PM2.5 and PM10 (2878.17 µg/m3 and 3025.23 µg/m3, respectively). Site 11 also displayed the highest levels of CO (242.09 ppm) for 8 h. Site 10 showed the lowest concentrations of PM2.5 and PM10 (9.97 µg/m3 and 5.74 µg/m3, respectively), and the level of CO was undetectable when using the IAQ monitor selected in this study. Similar results for 24 h PM2.5 and PM10 levels exceeding WHO guidelines for open fires, biomass stoves, and LPG have been reported in Guatemala (Naeher 2000).

PM-bound PAHs

The total concentration of particulate PAHs in the sampled kitchens was found to be higher during cooking events than during times without cooking activities, as shown in Fig. 3. The total background PM-bound PAHs were below the detection limit at Sites 16 and 17; however, they reached 1324.05 ng/m3 at Site 11. At Site 13, the total particulate PAHs were higher when cooking activity was absent than when cooking occurred. The reason for this difference may be the welding activity, which was conducted by a family member during PM background sampling.

The total particulate PAHs during cooking events ranged from 3.58 to 28573.96 ng/m3. The order of the total PAH [GM (global standard deviation (GSD))] emissions among the different cooking methods was found to be open fires using biomass > biomass stoves > electric stoves > LPG stoves at concentrations of 2597.91 (2.15) ng/m3, 1646.48 (7.83) ng/m3, 76.28 (10.27) ng/m3 and 8.03 (2.01) ng/m3, respectively. Notably, Site 10, which used electricity for cooking, was reported to exhibit a higher total PM-bound PAH level of 685.02 ng/m3 during cooking events compared to Site 6, which used biomass stoves and was reported to have a total level of 109.58 ng/m3 PM-bound PAHs. The relatively high PM emission in Site 10 might been caused by emissions from frying eggs (see Table 1) rather than fuel combustion (Huang et al. 2023, Wei et al. 2023). However, Site 6 exhibited seventeen out of the thirty analyzed PAH species; whereas, Site 10 exhibited a total of seven, mainly coronene, at 613.14 ng/m3.

On the African continent, (Titcombe and Simcik 2011) also reported higher values of ∑PAHs among sites using biomass fuel than at a site using LPG for cooking; the sum of individual PAHs was calculated from 32 PAHs, including 15 priority PAHs regulated by the U.S. EPA. Slightly contrary to our study, (Titcombe and Simcik 2011) reported wood stoves with chimneys to yield the highest level of ∑PAHs mean±SD at 7966±760 ng/m3, followed by open fires (5113±609 ng/m3), charcoal stoves (763±76 ng/m3), fuel-efficient wood stoves (424 ng/m3), and LPG stoves (1±1 ng/m3).

In the Asian population, (Bhargava et al. 2004) reported 7 carcinogenic PAHs of 15.63±2.95 µg/m3 when cooking using wood and 7 carcinogenic PAHs of 4.18±1.06 µg/m3 when cooking using LPG during winter in India. In the current study, samples were also collected during the winter season; however, the total particulate PAHs were relatively lower than those reported in India. At the noncooking sites in India, the total PAHs were relatively high at 3.53±0.89 µg/m3, whereas the GM total PAH level during the noncooking event in the current study was 88.21 (4.6) ng/m3. In a study in Taiwan, the background concentration was relatively low at 2.29 ng/m3 for a total of 16 PAHs; however, the total PAH level ranged from 1440 to 56900 ng/m3 during cooking events using gas stoves for both particulate PAHs and gaseous PAHs (Yu et al. 2015), which was higher than the total PAH levels reported in this study when cooking using LPG. In Taiwan, the authors collected not only PM-bound PAHs using a ten-stage impactor supported by a high-volume pump collecting particulate sizes ranging from 0.056 to 18 µm in diameter but also PAHs in the gaseous phase, which may explain the higher sum of PAHs. The different cooking behaviors in these countries may also contribute to the difference in the total PAHs. In the current study, most families cooked maize meal and beans using water, salt, and vegetables with little to no oil and spices, whereas the cooking style in Taiwan involved high-temperature, deep frying, and stir-frying approaches (Zhong et al. 1999). When stir-frying meat, the BaP concentration has been documented to be four times higher than that when meat is boiled (Kurmi et al. 2012).

PM-bound PAHs were further categorized into three groups: low-molecular-weight PAHs (LM-PAHs, 2-/3-ring PAHs), medium-molecular weight PAHs (MM-PAHs, 4-ring PAHs) and high-molecular-weight PAHs (HM-PAHs, 5-/6-/7-ring PAHs) because the concentration and species of particulate PAHs widely diverged. During noncooking events, most of the sites emitted mainly LM-PAHS, except Sites 11 and 13, as illustrated in Fig. S1. Site 11 mainly emitted HM-PAHs at 904.15 ng/m3; whereas, Site 13 largely emitted MM-PAHs at 122.98 ng/m3 during noncooking events. HM-PAHs and MM-PAHs mainly dominated when cooking using indicating fuels (biomass, LPG, electric), as shown in Fig. S2. Kitchens using cleaner fuels did not yield a perfect trend of the emitted PAHs when categorized by their molecular weight. Sites 13 and 14 emitted mainly LM-PAHs, Sites 17 and 5 emitted MM-PAHs only, and Sites 10 and 15 emitted mostly HM-PAHs. These differences among kitchens using cleaner fuels for cooking may arise from the cooking ingredients and the cooking process, such as frying, as opposed to the consumed fuels (Huang et al. 2023). Sites 10 and 15, for example, used spices and sunflower cooking oil.

According to (Srogi 2007), LM PAHs predominantly occur in the vapor phase, which could explain why the levels of LM PAHs were lower than those of HM and LM PAHs among most of the sites. He further revealed that MM-PAHs occur in both the vapor and particle phases; whereas, HM-PAHs mainly occur in PAHs bound to particulates. Therefore, the PAH exposure level in the current study may be underestimated due to missed concentrations in the vapor phase. MM- and HM-PAHs, which were found to be higher among biomass fuel users, have been documented to be the most hazardous PAHs to human health since they have been reported to cause cancer among experimental animals.

An experimental study conducted by (Tiwari et al. 2015) in Mumbai also revealed that biomass fuel burning emitted more HM-PAHs; while, LPG burning emitted more LM-PAHs when PAHs bound in PM were analyzed; they were collected with an aerodynamic diameter ranging from 0.10 to 21.3 µm among different cooking fuels: firewood, coal, cow dung, LPG and kerosene.

Spearman’s rho correlation among BaPeq, PM, CO and CO2

Spearman’s rho correlation was applied to assess the carcinogenic potency of the PM-bound PAHs and the particulate size they bind to and was observed to be significantly and positively correlated with PM2.5 and PM2.5–10, as shown in Table 3. This finding suggests that most of the PAHs were bound to particles smaller than 10 µm in diameter. Previous studies have found that PM is deposited in the smallest region of the lungs, intensifying the health risk (Schwarze et al. 2006). Yu et al. also reported BaPeq to be significantly and positively correlated with PM3.2–5.6 and PM5.6–10 (Yu et al. 2015). However, they further reported BaPeq to be significantly and positively correlated with PM10–18; larger particles were not significantly correlated with BaPeq in the current study. Moreover, Yu et al. did not find BaPeq to be significantly correlated with PM smaller than 2.5 µm in aerodynamic diameter (Yu et al. 2015). They only included kitchens that cook using a gas stove; thus, the PAHs were mainly emitted from the food, not the fuel (Yu et al. 2015), which may explain this difference. Moreover, Titcombe and Simcik’s study included charcoal, open fire, kerosene, wood stove, and LPG, and found PM2.5 to be well correlated with ∑PAHs with an r2 of 0.76 (Titcombe and Simcik 2011). BaPeq also correlated with CO, as both are products of incomplete combustion.

Carcinogenic potency of particulate PAHs

The BaPeq GM values indicated the same order as that of the total PM-bound PAHs, namely, open fires using biomass stoves > biomass stoves > electric stoves > LPG stoves, as indicated in Table 4. The carcinogenic potency of PAHs ranged from 130.14 to 937.80 ng/m3 when cooking using biomass fuels in open fires and from 11.37 to 2995.32 ng/m3 when cooking using biomass stoves, whereas it was below 1 ng/m3 for kitchens using either LPG or electricity for cooking. Tiwari et al. also reported the highest BaPeq concentrations among biomass fuel users (327.15 µg/m3) and the lowest BaPeq concentrations among LPG stove users (69.99 µg/m3) (Tiwari et al. 2015). Their results indicated a similar trend for BaPeq; however, the BaPeq concentrations were higher than those reported in the current study. In addition, Titcombe and Simcik calculated the carcinogenic potency of 15 US EPA priority PAHs; they reported BaPeq concentrations in the following order: wood stoves (833.67 ng/m3) > open fires (391.77 ng/m3) > charcoal stoves (92.65 ng/m3) > efficient wood stoves (78.96 ng/m3) > LPG stoves (>0.01 ng/m3) (Titcombe and Simcik 2011). Moreover, Yu et al. reported BaPeq concentrations ranging from 40.8 to 233 ng/m3 in kitchens using LPG (Yu et al. 2015). The elevated BaPeq levels in the other studies may arise from the different PAH collection methods. The findings of (Titcombe and Simcik 2011) suggest that an effective stove could reduce exposure to PAHs; however, according to WHO guidelines for indoor exposure (1998), the unit risk of lung cancer for PAH mixtures is estimated at 8.7×10−5 per ng/m3, suggesting that even women using an effective stove or cleaner cooking fuel (LPG and electricity) without adequate ventilation are still at risk for lung cancer.

Health risk assessment

The ILCR and HQ values resulting from exposure to PM-bound PAHs are provided in Table 4. The ILCR was higher than the acceptable level of 10−6 suggested by the US EPA for carcinogenic chemicals for women using biomass fuels, with GM values of 7.72 × 10−5 and 6.85 × 10−5 for women exposed to emissions originating from open fire burning and biomass stoves, respectively. Women exposed to emissions originating from LPG and electric stoves attained ILCRs of 1.90 × 10−5 and 0.01, respectively. (Tiwari et al. 2015) reported the 50th percentile value of the ILCR among different cooking fuels in the order of dung cake (9.11 × 10−5) > firewood (6.26 × 10−5) > coal (2.99 × 10−5) > kerosene (1.14 × 10−5) > LPG (3.34 × 10−6). The ILCR of PAH exposure reported by Tiwari et al. (Tiwari et al. 2015) was lower for firewood and higher for LPG than that based on the findings in the current study. Tiwari et al. found the ILCR of exposure to emissions originating from LPG stoves to be one order of magnitude smaller than that of firewood, whereas in the current study, the ILCR of exposure to emissions originating from LPG stoves was four orders of magnitude smaller than that of biomass fuels (mainly wood), and the ILCR of exposure to emissions originating from electricity stoves was three orders of magnitude smaller than that of biomass fuels (Tiwari et al. 2015). In addition, Yu et al. reported a higher ILCR of PAH exposure due to LPG stove use during cooking events than that reported in the current study, with a range of 2.46 × 10−6 to 1.40 × 10−5 (Yu et al. 2015). The background ILCR in their study was 7.68 × 10−8 for females, which was still higher than the GM value of the ILCR of LPG exposure during cooking events reported in the current study (Yu et al. 2015).

The HQ, which is the ratio of the intake concentration to the reference concentration, was calculated to determine the non-carcinogenic toxicity of PM-bound PAHs representing embryo or fetal survival. An HQ higher than 1 indicates a significant adverse health effect [33]. Biomass fuel users were observed to exhibit HQ > 1; whereas, LPG and electric stove users were found to attain HQ < 1, as summarized in Table 4, indicating significantly decreased embryo and fetal survival chances among women exposed to biomass fuel-related emissions. Therefore, from the findings of this study, cooking using either LPG or electric stoves may reduce adverse health effects associated with exposure to PM-bound PAHs during cooking indoors. Furthermore, most of the households cooking using biomass fuels in the current study used plastic to initiate the burning process; some plastics have been documented to emit dioxins that are carcinogenic and mutagenic, cause neurological damage, and disrupt the respiratory and reproductive systems (Verma et al. 2016). This finding suggests that women may be exposed to more detrimental health pollutants than those presented in this study. Our results are supported by a previous study conducted by Feng et al., which reported that excessive use of solid fuels adversely affected inflammatory biomarkers in rural housewives (Feng et al. 2021).

Economic assessment

The average fuel consumption in kWh for each stove utilized is presented as follows: LPG 1-burner stoves = 0.88 kWh; LPG 2-burner stoves = 1.17 kWh; LPG 4-burner stoves = 1.76 kWh; electric 1-burner stoves =1 kWh; electric 2-burner stoves = 1.2 kWh; electric 4-burner stoves =1.5 KWh; biomass 1-burner stoves = 8.24 kWh; biomass 2-burner stoves = 20.04 kWh; and biomass 4-burner stoves =51.4 kWh. In regard to the average unit cost of wood per kg, people selling wood and their monthly earnings resulting from wood sales were considered. This cost was approximately 11 Rands (R11) for 100 kg of wood logs; while, some people may freely obtain wood by collecting their own firewood in forests instead of buying wood. Each kg of wood logs used as biomass fuel is known to produce approximately 5.14 kWh depending on other factors, such as the nature and humidity of the consumed wood. The consumption of wood in open fires requires approximately 7 kg per hour. The unit cost of LPG is approximately R18 per kg, while electricity costs approximately R180 for 100 kWh. The stove and fuel costs were determined as the sum of the annual fuel and stove costs. The cooking assessment results are shown in Fig. 4. A three-legged pot can be utilized without a cooking stand or stove; hence, it exhibits a stove cost of R0.00. The average stove cost shown in Fig. 4a is listed in descending order as follows: 4-burner biomass stoves (R7,500) > 4-burner electric stoves (R3,500) > 4-burner LPG stoves (R3,285) > 2-burner biomass stoves (R2,500) > 1-burner biomass stoves (R1,000) > 2-burner LPG stoves (R505) > 1-burner LPG stoves (R405) > 2-burner electric stoves (R200) > 1-burner electric stoves (R120) > open fires. The annual fuel cost was observed in the sequence of 4-burner LPG stoves (R5,076) > 4-burner electric stoves (R4,819) > 2-burner electric stoves (R3,855) > 2-burner LPG stoves (R3,384) > 1-burner electric stoves (R3,212) > 4-burner biomass stoves (R2,995) > 1-burner LPG stoves (R2,538) > open fires (R1,843) > 2-burner biomass stoves (R1,168) > 1-burner biomass stoves (R480). The average total cost of stoves combined with the annual fuel cost was in the order of 4-burner biomass stoves (R10,495) > 4-burner LPG stoves (R8,361) > 4-burner electric stoves (R8,319) > 2-burner electric stoves (R4,055) > 2-burner LPG stoves (R3,889) > 2-burner biomass stoves (R3,668) > 1-burner electric stoves (R3,333) > 1-burner LPG stoves (R2,943) > open fires (R1,843) > 1-burner biomass stoves (R1,480). The total average cost of cooking (1-, 2- and 4-burner stoves) was low for open wood fires (R5,530) and the highest for electric stoves (R15,707); while, the LPG stove total cost was R15,194 and the biomass stove total cost was R15,643.

The annual cost of reducing the ILCR to an acceptable level (10−6) is shown in Fig. 4b. Reducing pollution emitted during cooking when switching from biomass to cleaner fuels was the highest for 4-burner stoves, followed by 2- and 1-burner stoves. Among the 4-burner stoves, the reduction cost in descending order is biomass stoves ⇒ LPG stoves (R122) > biomass stoves ⇒ electric stoves (R121) > open fires ⇒ electric stoves (R108) = open fires ⇒ LPG stoves (R108); among the 2-burner stoves, the cost followed the order of biomass stoves ⇒ electric stoves (R59) > biomass stoves ⇒ LPG stoves (R57) > open fires ⇒ electric stoves (R53) > open fires ⇒ LPG (R50); and among the 1-burners stoves, the reduction cost followed the order of biomass stoves ⇒ electric stoves (R49) > open fires ⇒ electric stoves (R43) = biomass stoves ⇒ LPG (R43) > open fires ⇒ LPG stoves (R38). The cost of reducing the ILCR to an acceptable level was lower when shifting from open fires to cleaner fuels than when switching from cooking using biomass stoves. The total cost (1-, 2- and 4-burner stoves) of changing from open fires to LPG stoves was the lowest (R197), followed by changing from open fires to electric stoves (R203). The overall cost of shifting from biomass to LPG stoves was the lowest (R222), followed by shifting from biomass to electric stoves (R229).

Figure 4c shows the annual cost of reducing the HQ to an acceptable level among the different kinds of stoves and consumed fuels (1). In this study, 2-burner stoves reduced the HQ to an acceptable level at a lower cost than 4-burner stoves, and 1-burner stoves showed the lowest HQ reduction cost. The reduction cost of the HQ was lower for LPG stoves than for electric stoves when switching from both open fires and biomass stoves, except for the 4-burner stoves, where the cost of HQ reduced when switching from either open fires or biomass stoves to electric stoves was R1 lower than that for LPG stoves. The cost of reducing the HQ to an acceptable level when switching from open fires to LPG stoves was R12 lower than that when switching to electric stoves among the 1-burner stoves and R5 lower among the 2-burner stoves. Shifting from biomass to LPG stoves for the 1-burner stoves was R13 lower than that for the electric stoves and R6 lower for the 2-burner stoves than for the electric stoves.

Limitation

Rodes et al. reported that median personal exposure monitors to room-average exposure measurements for residential exposure settings range from approximately 1.5 to 2.0 (Rodes et al. 1991). Therefore, underestimating personal exposure could be a limitation of our study.

Conclusion and future research

Conclusion

This study investigates the PM2.5, PM10, and CO emitted during cooking using biomass fuels in the Kingdom of Eswatini (Swaziland). The TEF of BaP was found to be positively correlated with PM10; hence, PAHs were likely bound in smaller particles with a significant risk of deposition in the lungs. The ILCR of exposure to indoor air pollution resulting from cooking using biomass fuels exceeded the acceptable level of 10−6. Additionally, the HQ due to the inhalation of PM-bound PAHs exceeded 1 for biomass fuel users, thus suggesting a significant decrease in the embryo and fetal survival chances among exposed women. Therefore, using biomass fuels for cooking exposes the person responsible for cooking (mainly women) to high doses of pollutants. This study suggested that women using wood open fires and biomass fuel stoves should shift to LPG stoves to reduce their cancer risk and increase embryo or fetal survival chances. The study found that the concentrations of PM2.5 were significantly higher during cooking events, especially when using biomass fuels with open fires and biomass stoves. These cooking methods resulted in higher emissions of PM2.5 and PM-bound PAHs compared to LPG and electric stoves. Therefore, exposure to PAHs bound to PM2.5 showed a higher health risk than exposure to PAHs bound to PM10. The economic assessment indicated that the total cost of cooking involving open wood fires, determined to be detrimental to human health, was nearly 3 times lower than that of cooking involving other cooking techniques in the Shiselweni region. The total cost of reducing the ILCR to an acceptable level (10-6) was lower when shifting from open fires to cleaner fuels (LPG = R196.82 and electricity = R203.46) than when shifting from cooking using biomass stoves to cooking using cleaner fuels (LPG = R221.82 and electricity = R229.34). Overall, the reduction cost of the HQ was lower when shifting to LPG stoves than when shifting to electric stoves.

Future research

This study considered various kitchen characteristics, including the number of windows, kitchen volume, and stove types. However, the analysis did not explicitly evaluate the influence of these specific kitchen characteristics on exposure to air pollutants. The focus was primarily on assessing the impact of different cooking fuels and stove types on indoor air quality. While kitchen characteristics could potentially influence air pollution exposure, our study needed to thoroughly assess the direct correlation between these factors and pollutant levels. Further research that specifically investigates the relationship between kitchen features and indoor air quality could provide valuable insights into how these variables might affect pollutant exposure levels. Besides, investigating additional indoor burning practices like candle burning or incense use for different purposes would indeed be valuable for a more comprehensive understanding of indoor air quality across various contexts and regions.

Data availability

Data available within the article and its supplementary materials.

References

Abdullahi KL, Delgado-Saborit JM, Harrison RM (2013) Emissions and indoor concentrations of particulate matter and its specific chemical components from cooking: a review. Atmos Environ 71:260–294. https://doi.org/10.1016/j.atmosenv.2013.01.061

Adams K, Greenbaum DS, Shaikh R et al (2015) Particulate matter components, sources, and health: systematic approaches to testing effects. J Air Waste Manag Assoc 65:544–558. https://doi.org/10.1080/10962247.2014.1001884

Balmes JR (2019) Household air pollution from domestic combustion of solid fuels and health. J Allergy Clin Immunol 143:1979–1987. https://doi.org/10.1016/j.jaci.2019.04.016

Bhargava A, Khanna RN, Bhargava SK, Kumar S (2004) Exposure risk to carcinogenic PAHs in indoor-air during biomass combustion whilst cooking in rural India. Atmos Environ 38:4761–4767. https://doi.org/10.1016/j.atmosenv.2004.05.012

Bruce N, Perez-padilla R, Albalak R (2000) Indoor air pollution in developing countries a major environmental and public health challenge. Bull World Health Organ 78(9):1078–1092

Du W, Yun X, Chen Y et al (2020) PAHs emissions from residential biomass burning in real-world cooking stoves in rural China. Environ Pollut 267:115592. https://doi.org/10.1016/j.envpol.2020.115592

US EPA, IRIS2017 (2017) Toxicological review of Benzo [a] pyrene

Farland WH, Tuxen LC (1997) New directions in cancer risk assessment: accuracy, precision, credibility, and uncertainty. Hum Ecol Risk Assess An Int J 3:667–671. https://doi.org/10.1080/10807039709383726

Feng R, Xu H, He K et al (2021) Effects of domestic solid fuel combustion emissions on the biomarkers of homemakers in rural areas of the Fenwei Plain, China. Ecotoxicol Environ Saf 214:112104. https://doi.org/10.1016/j.ecoenv.2021.112104

Fullerton DG, Bruce N, Gordon SB (2008) Indoor air pollution from biomass fuel smoke is a major health concern in the developing world. Trans R Soc Trop Med Hyg 102:843–51. https://doi.org/10.1016/j.trstmh.2008.05.028

Gbadamosi MA, Tlou B (2020) Modifiable risk factors associated with non-communicable diseases among adult outpatients in Manzini, Swaziland: a cross-sectional study. BMC Public Health 20:1. https://doi.org/10.1186/s12889-020-08816-0

Gujba H, Mulugetta Y, Azapagic A (2015) The household cooking sector in Nigeria: environmental and economic sustainability assessment. Resources 4:412–433. https://doi.org/10.3390/resources4020412

Hinds WC (1999) Aerosol technology properties, behavior, and measurement of airborne particles, Second Edition

Huang WW, Sallah-Ud-Din R, Dlamini WN et al (2023) Effectiveness of a covered oil-free cooking process on the abatement of air pollutants from cooking meats. Heliyon 9:e19531. https://doi.org/10.1016/j.heliyon.2023.e19531

Jatmika SED, Maulana M (2018) Dental and oral health education for elemetary school students through patient hygiene performance index indicator. Int J Eval Res Educ 7:259. https://doi.org/10.11591/ijere.v7i4.14856

Khanna R (2020) Biomass fuel and cataract: an unrecognized epidemic. Indian J Ophthalmol 68:1500–1501. https://doi.org/10.4103/ijo.IJO_159_20

Kim KH, Jahan SA, Kabir E (2011) A review of diseases associated with household air pollution due to the use of biomass fuels. J Hazard Mater 192:425–431. https://doi.org/10.1016/j.jhazmat.2011.05.087

Kim KH, Jahan SA, Kabir E (2012) A review of breath analysis for diagnosis of human health. Trends Anal Chem 33:1–8. https://doi.org/10.1016/j.trac.2011.09.013

Kim Oanh NT, Nghiem LH, Phyu YL (2002) Emission of polycyclic aromatic hydrocarbons, toxicity, and mutagenicity from domestic cooking using sawdust briquettes, wood, and kerosene. Environ Sci Technol 36:833. https://doi.org/10.1021/es011060n

Kurmi OP, Lam KBH, Ayres JG (2012) Indoor air pollution and the lung in low- and medium-income countries. Eur Respir J 40:239–254. https://doi.org/10.1183/09031936.00190211

Mbanya VN, Sridhar MK (2017) PM 10 emissions from cooking fuels in Nigerian households and their impact on women and children. Health 9(13):1721. https://doi.org/10.4236/health.2017.913126

Mitra P, Chakraborty D, Mondal NK (2022) Assessment of household air pollution exposure of tribal women. Sci Total Environ 817:152869. https://doi.org/10.1016/j.scitotenv.2021.152869

Mocumbi AO, Stewart S, Patel S, Al-Delaimy WK (2019) Cardiovascular Effects of indoor air pollution from solid fuel: relevance to Sub-Saharan Africa. Curr Environ Heal Rep 6:116–126. https://doi.org/10.1007/s40572-019-00234-8

Naeher LP (2000) Particulate matter and carbon monoxide in highland Guatemala: indoor and outdoor levels from traditional and improved wood stoves and gas stoves. Indoor Air 10:200–205. https://doi.org/10.1034/j.1600-0668.2000.010003200.x

Nisbet ICT, LaGoy PK (1992) Toxic equivalency factors (TEFs) for polycyclic aromatic hydrocarbons (PAHs). Regul Toxicol Pharmacol 16:290–300. https://doi.org/10.1016/0273-2300(92)90009-X

Pathak U, Gupta NC, Suri JC (2020) Risk of COPD due to indoor air pollution from biomass cooking fuel: a systematic review and meta-analysis. Int J Environ Health Res 30:75. https://doi.org/10.1080/09603123.2019.1575951

Pilishvili T, Loo JD, Schrag S et al (2016) Effectiveness of six improved cookstoves in reducing household air pollution and their acceptability in rural western Kenya. PLoS One 11:e0165529. https://doi.org/10.1371/journal.pone.0165529

Pokhrel AK, Smith KR, Khalakdina A et al (2005) Case-control study of indoor cooking smoke exposure and cataract in Nepal and India. Int J Epidemiol 34:702–708. https://doi.org/10.1093/ije/dyi015

Pratiti R, Vadala D, Kalynych Z, Sud P (2020) Health effects of household air pollution related to biomass cook stoves in resource limited countries and its mitigation by improved cookstoves. Environ Res 186:109574

Qu C, Li B, Wu H et al (2015) Multi-pathway assessment of human health risk posed by polycyclic aromatic hydrocarbons. Environ Geochem Health 37:587–601. https://doi.org/10.1007/s10653-014-9675-7

Rodes CE, Kamens RM, Wiener RW (1991) The significance and characteristics of the personal activity cloud on exposure assessment measurements for indoor contaminants. Indoor Air 1:123–145. https://doi.org/10.1111/j.1600-0668.1991.03-12.x

Schwarze PE, Øvrevik J, Låg M et al (2006) Particulate matter properties and health effects: consistency of epidemiological and toxicological studies. Hum Exp Toxicol 25(10):559–79. https://doi.org/10.1177/096032706072520

Sharma D, Jain S (2019) Impact of intervention of biomass cookstove technologies and kitchen characteristics on indoor air quality and human exposure in rural settings of India. Environ Int 123:240–255. https://doi.org/10.1016/j.envint.2018.11.059

Sidhu MK, Ravindra K, MorS John S (2017) Household air pollution from various types of rural kitchens and its exposure assessment. Sci Total Environ 586:419–429. https://doi.org/10.1016/j.scitotenv.2017.01.051

Simelane MS, Chemhaka GB, Zwane E (2020) A multilevel analysis of individual, household and community level factors on stunting among children aged 6–59 months in Eswatini: a secondary analysis of the Eswatini 2010 and 2014 multiple indicator cluster surveys. PLoS One 15(10):e0241548. https://doi.org/10.1371/journal.pone.0241548

Singh A, Banerjee T, Latif MT et al (2023) Molecular distribution, sources and potential health risks of fine particulate-bound polycyclic aromatic hydrocarbons during high pollution episodes in a subtropical urban city. Chemosphere 340:139943. https://doi.org/10.1016/j.chemosphere.2023.139943

Siregar S, Idiawati N, Lestari P et al (2022) Chemical composition, source appointment and health risk of PM2.5 and PM2.5–10 during forest and peatland fires in Riau, Indonesia. Aerosol Air Qual Res 22:220015. https://doi.org/10.4209/aaqr.220015

Srogi K (2007) Monitoring of environmental exposure to polycyclic aromatic hydrocarbons: a review. Environ Chem Lett 5:169–195

Sun S, Schiller JH, Gazdar AF (2007) Lung cancer in never smokers: a different disease. Nat Rev Cancer 7:778–790. https://doi.org/10.1038/nrc2190

Titcombe ME, Simcik M (2011) Personal and indoor exposure to PM2.5 and polycyclic aromatic hydrocarbons in the southern highlands of Tanzania: a pilot-scale study. Environ Monit Assess 180:461–476. https://doi.org/10.1007/s10661-010-1799-3

Tiwari M, Sahu SK, Pandit GG (2015) Inhalation risk assessment of PAH exposure due to combustion aerosols generated from household fuels. Aerosol Air Qual Res 15(2):582–590. https://doi.org/10.4209/aaqr.2014.03.0061

USEPA (1997) Exposure factors handbook (1997 final report) EPA/600/P-95/002a-c. USEPA I:1193

Van Der Kroon B, Brouwer R, VanBeukering PJH (2013) The energy ladder: theoretical myth or empirical truth? Results from a meta-analysis. Renew Sustain Energy Rev 20:504–513. https://doi.org/10.1016/j.rser.2012.11.045

Verma R, Vinoda KS, Papireddy M, Gowda ANS (2016) Toxic pollutants from plastic waste: a review. Proc Environ Sci 35:701. https://doi.org/10.1016/j.proenv.2016.07.069

Wei H, Kerebo A, Siregar S, Yu K (2023) High-efficiency carbon-coated steel wool filter for controlling cooking-induced oil smoke ★. Environ Pollut 334:122144. https://doi.org/10.1016/j.envpol.2023.122144

Wolkoff P (2018) Indoor air humidity, air quality, and health–an overview. Int J Hyg Environ Health 221(3):376–390

Xia Z, Duan X, Tao S et al (2013) Pollution level, inhalation exposure and lung cancer risk of ambient atmospheric polycyclic aromatic hydrocarbons (PAHs) in Taiyuan, China. Environ Pollut 173:150–156. https://doi.org/10.1016/j.envpol.2012.10.009

Young BN, Clark ML, Rajkumar S et al (2019) Exposure to household air pollution from biomass cookstoves and blood pressure among women in rural Honduras: a cross-sectional study. Indoor Air 29:130. https://doi.org/10.1111/ina.12507

Yu KP, Yang KR, Chen YC et al (2015) Indoor air pollution from gas cooking in five Taiwanese families. Build Environ 93:258–266. https://doi.org/10.1016/j.buildenv.2015.06.024

Yu KP, Chen YC, Miao YJ et al (2020) Effects of oil drops and the charcoal’s proximate composition on the air pollution emitted from charcoal barbecues. Aerosol Air Qual Res 20:1480–1494. https://doi.org/10.4209/aaqr.2019.01.0042

Zhong L, Goldberg MS, Parent MÉ, Hanley JA (1999) Risk of developing lung cancer in relation to exposure to fumes from Chinese-style cooking. Scand J Work Environ Heal 25:309–316

Acknowledgements

This study is financially supported by the Ministry of Science and Technology of Taiwan (Grant No: MOST 110-2621-M-A49A-502-).

Funding

Open Access funding enabled and organized by National Yang Ming Chiao Tung University. This study is financially supported by the Ministry of Science and Technology of Taiwan (Grant No: MOST 110-2621-M-A49A-502-).

Author information

Authors and Affiliations

Contributions

Melinda Neumann contributed to data curation, formal analysis, investigation, methodology, and writing—original draft. Wonder Nathi Dlamini contributed to formal analysis and writing—original draft. Rasham Sallah-Ud-Din contributed to writing—review & editing. Abiyu Kerebo Berekute contributed to writing—review & editing. Wen-Chi Pan contributed to conceptualization and formal analysis. Shih Chun Candice Lung contributed to conceptualization, resources, and funding acquisition. Kuo-Pin Yu contributed to conceptualization, resources, writing—review & editing, supervision, and funding acquisition. Sepridawati Siregar contributed to writing—review & editing. Mastewal Endeshaw Getnet contributed to writing—review & editing. Muchsin Maulana, contributed to writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

There are no Competing Interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Neumann, M., Dlamini, W.N., Sallah-Ud-Din, R. et al. Assessment of air pollution emitted during cooking using biomass and cleaner fuels in the Shiselweni region of Eswatini (Swaziland). Clean Techn Environ Policy (2024). https://doi.org/10.1007/s10098-024-02786-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10098-024-02786-2