Abstract

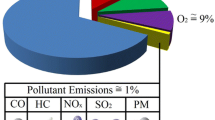

The rising costs of petroleum-based fuels for internal combustion engines and their detrimental environmental impacts have spurred the search for alternative fuels. This study explores minor modifications to a compression ignition engine, enabling it to operate in dual fuel mode using biofuels as a viable alternative to neat diesel. A novel biofuel was developed using cedar wood oil, and its performance was experimentally investigated in a single-cylinder diesel engine operating at a constant speed. Acetylene was continuously introduced to the engine at a flow rate of 6 L per minute, chosen for its optimal performance, yielding a brake thermal efficiency of over 30.7%. The engine was operated under constant conditions, including a compression ratio of 18, an ignition timing of 23°CA before top dead centre, and an injection pressure of 220 bar. Comparative evaluations were performed by analyzing the combustion characteristics and emission levels of diesel and cedar wood oil-based fuels with and without nanoadditive for diesel, B50 and B100 with a constant acetylene gas supply at 6 Lit/min. The primary objective was to reduce toxic emissions, including smoke, carbon monoxide, hydrocarbons, and nitrogen oxides, released during fuel combustion with the help nanoadditives in fuel. The effects of cerium nanoparticles as an additive were considered in this study due its thermal stability and activation energy which reduce CO and HC emission significantly.The smoke, CO and HC were decreased for B100 + 6L A + 50 ppm blend by 20.21%, 65.52% and 51.42% for 100% load. It is found that cedar wood oil oil with nanoparticle additives could effectively reduce smoke and hydrocarbon emissions while maintaining comparable efficiency to neat diesel and pure biodiesel modes.

Graphical abstract

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

Abbreviations

- IC:

-

Internal combustion

- ASTM:

-

American standard of testing materials

- CNG:

-

Compressed natural gas

- LPG:

-

Liquefied petroleum gas

- VCR:

-

Variable compression ratio

- CI:

-

Compression ignition

- N2 :

-

Nitrogen

- CO2 :

-

Carbon dioxide

- H2O:

-

Water vapour

- CO:

-

Carbon monoxide

- HC:

-

Hydrocarbon

- CR:

-

Compression ratio

- O2 :

-

Oxygen

- NOx :

-

Nitrogen oxide

- DI:

-

Direct injection

- CeO2 :

-

Cerium oxide

- A:

-

Acetylene

- cST:

-

Centistoke

- D:

-

Diesel

- B50:

-

50% Biodiesel + 50% diesel

- B75:

-

75% Biodiesel + 25% diesel

- B100:

-

100% Biodiesel

- FR:

-

Flow rate

- IP:

-

Injection pressure

- IT:

-

Injection timing

- CA:

-

Crank angle

- ppm:

-

Parts per million

- N:

-

Nanoparticle

- LPM:

-

Litre per minute

- RPM:

-

Revolution per minute

- bTDC:

-

Before top dead centre

- L:

-

Litre

References

Agarwal AK, Rajamanoharan K (2007) Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust Sci 33:233–271. https://doi.org/10.1016/j.pecs.2006.08.003

Ahmad AL, Yasin NHM, Derek CJC, Lim JK (2011) Microalgae as a sustainable energy source for biodiesel production: a review. Renew Sustain Energy Rev 15:584–593. https://doi.org/10.1016/j.rser.2010.09.018

Avinash A, Subramaniam D, Murugesan A (2014) Bio-diesel a global scenario. Renew Sustain Energy Rev 29:517–527. https://doi.org/10.1016/j.rser.2013.09.007

Chandrasekaran V, Arthanarisamy M, Nachiappan P, Dhanakotti S, Moorthy B (2016) The role of nano additives for biodiesel and diesel blended transportation fuels. Transp Res D Transp Environ 46:145–156

Das RK, Sharma SK (2018) Blend of jatropha biodiesel and tyre pyrolysis oil mixed with cerium oxide–an alternative to diesel fuel. Biofuels 9(6):739–744. https://doi.org/10.1080/17597269.2017.1316139

Dinesha P, Mohan S, Kumar S (2021) Impact of alumina and cerium oxide nanoparticles on tailpipe emissions of waste cooking oil biodiesel fuelled CI engine. Cogent Eng. https://doi.org/10.1080/23311916.2021.1902067

Dorado MP, Ballesteros E, Arnal JM, Gomez J, Lopez FJ (2003) Exhaust emissions from a diesel engine fueled with transesterified waste olive oil. J Fuel 82:1311–1315. https://doi.org/10.1016/S0016-2361(03)00034-6

Elkelawy M, Etaiw SEDH, Bastawissi HAE, Ayad MI, Radwan AM, Dawood MM (2021a) Diesel/biodiesel/silver thiocyanate nanoparticles/hydrogen peroxide blends as new fuel for enhancement of performance, combustion, and Emission characteristics of a diesel engine. Energy 216:119284. https://doi.org/10.1016/j.energy.2020.119284

Elkelawy M, El Shenawy EA, Khalaf-Almonem S, Nasef MH, Panchal H, Bastawissi HAE, Khalid M (2021b) Experimental study on combustion, performance, and emission behaviours of diesel/WCO biodiesel/Cyclohexane blends in DI-CI engine. Process Saf Environ Prot 149:684–697. https://doi.org/10.1016/j.psep.2021.03.028

Elkelawy M, Bastawissi H, Sekar SC, Karuppasamy K, Vedaraman N, Sathiyamoorthy K, Sathyamurthy R (2018) Numerical and experimental investigation of ethyl alcohol as oxygenator on the combustion, performance, and emission characteristics of diesel/cotton seed oil blends in homogenous charge compression ignition engine pp. 2018-01-1680. SAE Tech. Pap. https://doi.org/10.4271/2018-01-1680

EL-Seesy AI, Xuan T, He Z, Hassan H (2020) Enhancement the combustion aspects of a CI engine working with Jatropha biodiesel/decanol/propanol ternary combinations. Energy Conv Manag 226:113524. https://doi.org/10.1016/j.enconman.2020.113524

EL-Seesy AI, Waly MS, He Z, El-Batsh HM, Nasser A, El-Zoheiry RM (2022) Enhancement of the combustion and stability aspects of diesel-methanol-hydrous methanol blends utilizing n-octanol, diethyl ether, and nanoparticle additives. J Clean Prod 371:133673. https://doi.org/10.1016/j.jclepro.2022.133673

El-seesy AI, Waly MS, He Z, El-Batsh HM, Nasser A, El-Zoheiry RM (2021) Influence of quaternary combinations of biodiesel/methanol/n-octanol/diethyl ether from waste cooking oil on combustion, emission, and stability aspects of a diesel engine. Energy Conv Manag 240:114268. https://doi.org/10.1016/j.energy.2021.120543

El-Seesy AI, Waly MS, El-Batsh HM, El-Zoheiry RM (2023a) Enhancement of the diesel fuel characteristics by using nitrogen-doped multi-walled carbon nanotube additives. Process Saf Environ Prot 171:561–577. https://doi.org/10.1016/j.psep.2023.01.026

El-Seesy AI, Waly MS, El-Batsh HM, El-Zoheiry RM (2023b) Enhancement of the waste cooking oil biodiesel usability in the diesel engine by using n-decanol, nitrogen-doped, and amino-functionalized multi-walled carbon nanotube. Energy Conv Manag. 277:116646. https://doi.org/10.1016/j.enconman.2022.116646

El-Sheekh MM, Bedaiwy MY, El-Nagar AA, ElKelawy M, Bastawissi HAE (2022) Ethanol biofuel production and characteristics optimization from wheat straw hydrolysate: performance and emission study of DI-diesel engine fueled with diesel/biodiesel/ethanol blends. Renew Energ 191:591–607. https://doi.org/10.1016/j.renene.2022.04.076

El-Sheekh MM, El-Nagar AA, ElKelawy M, Bastawissi HAE (2023a) Bioethanol from wheat straw hydrolysate solubility and stability in waste cooking oil biodiesel/diesel and gasoline fuel at different blends ratio. Biotechnol Biofuels 16(1):1–11. https://doi.org/10.1186/s13068-023-02264-9

El-Sheekh MM, El-Nagar AA, ElKelawy M, Bastawissi HAE (2023b) Maximization of bioethanol productivity from wheat straw, performance and emission analysis of diesel engine running with a triple fuel blend through response surface methodology. Renew Energ 211:706–722. https://doi.org/10.1016/j.renene.2023.04.145

EL-Zohairy RM, Attia AS, Huzayyin AS, EL-Seesy AI (2023) Effect of diethyl ether addition to waste cooking oil biodiesel on the combustion and emission characteristics of a swirl-stabilized premixed flame. Energy Conv Manag 286:117052. https://doi.org/10.1016/j.enconman.2023.117052

Emiro AO, Mehmet S (2018) Combustion, performance and emission characteristics of various alcohol blends in a single cylinder diesel engine. 212:34–40

Ettefaghi E et al (2018) A novel bio-nano emulsion fuel based on biodegradable nanoparticles to improve diesel engines performance and reduce exhaust emissions. Renew Energy 125:64–72. https://doi.org/10.1016/j.renene.2018.01.086

Fu P, Bai X, Yi W, Li Z, Li Y, Wang L (2017) Assessment on performance, combustion and emission characteristics of diesel engine fuelled with corn stalk pyrolysis bio-oil/diesel emulsions with Ce0.7Zr0.3O2 nanoadditive. Fuel Process Technol 167:474–483. https://doi.org/10.1016/j.fuproc.2017.07.032

Gad MS, Abdel Aziz MM, Kayed H (2022) Impact of different nano additives on performance, combustion, emissions and exergetic analysis of a diesel engine using waste cooking oil biodiesel. Propuls Power Res 11(2):209–223. https://doi.org/10.1016/J.JPPR.2022.04.004

Gavaskar T, Arun K, Arivazhagan S (2023) The combined effect of green synthesized nitrogen-doped carbon quantum dots blended jackfruit seed biodiesel and acetylene gas tested on the dual fuel engine. Energy 275:127296. https://doi.org/10.1016/j.energy.2023.127296

Gharehghani A, Pourrahmani H (2019) Performance evaluation of diesel engines (PEDE) for a diesel-biodiesel fueled CI engine using nano-particles additive. Energy Convers Manag 198:111921. https://doi.org/10.1016/j.enconman.2019.111921

Gharehghani A, Asiaei S, Khalife E, Najafi B, Tabatabaei M (2019) Simultaneous reduction of CO and NOx emissions as well as fuel consumption by using water and nano particles in Diesel-Biodiesel blend. J Clean Prod 210:1164–1170. https://doi.org/10.1016/j.jclepro.2018.10.338

Hariram V, Seralathan S, Rajasekaran M, Kumar MD, Padmanabhan S (2017) Effect of metallic nano-additives on combustion performance and emissions of DI CI engine fuelled with palmkernel methyl ester. Int J Veh Struct Syst 9(2):103–109. https://doi.org/10.4273/ijvss.9.2.08

Heidari-Maleni A, Mesri Gundoshmian T, Jahanbakhshi A, Ghobadian B (2020) Performance improvement and exhaust emissions reduction in diesel engine through the use of graphene quantum dot (GQD) nanoparticles and ethanolbiodiesel blends. Fuel 267:117116. https://doi.org/10.1016/J.FUEL.2020.117116

Ilkilic C (2009) Emission characteristics of a diesel engine fueled with by 25% sunflower oil methyl ester and 75% diesel fuel blend. Energy Sources 31:480–491. https://doi.org/10.1080/15567030701531329

Jeyakumar N, Narayanasamy B, Venkatraman B (2019) Optimisation of biodiesel production from Jack fruit oil using response surface methodology. Int J Ambient Energy 1–12:1864–1875. https://doi.org/10.1080/01430750.2019.1621202

Jindal S, Nandwana BP, Rathore NS, Vashistha V (2010) Experimental investigation of the effect of compression ratio and injection pressure in a DI diesel engine running on Jatropha methyl ester. Appl Therm Eng 30:442–448. https://doi.org/10.1016/j.applthermaleng.2009.10.004

Kapilan N, Reddyand RP, Basavaraj T (2006) Effect of injection pressure on the performance and emission of diesel engine using blend of methyl esters of Karanja oil and diesel as fuel. SAE paper 2006-32-0025

Khan O, Mohd Zaheen Khan N, Ahmad et al (2021) Performance and emission analysis on palm oil derived biodiesel coupled with Aluminum oxide nanoparticles. Mater Today Proc 46(15):6781–6786. https://doi.org/10.1016/j.matpr.2021.04.338

Kumar D, Amirtham VA (2016) A review on preparation, characterization, properties and applications of nano fluids. Renew Sustain Energy Rev 60:21–40. https://doi.org/10.1016/j.rser.2016.01.055

Lakshmanan T, Nagarajan G (2010a) Experimental investigation of timed manifold injection of acetylene in direct injection diesel engine in dual fuel mode. Energy 35(8):3172–3178. https://doi.org/10.1016/j.energy.2010.03.055

Lakshmanan T, Nagarajan G (2010b) Experimental investigation on dual fuel operation of acetylene in a DI diesel engine. Fuel Process Technol 91:496–503. https://doi.org/10.1016/j.fuproc.2009.12.010

Lakshmanan T, Nagarajan G (2011a) Experimental investigation of port injection of acetylene in di diesel engine in dual fuel mode. Fuel 90:2571–2577. https://doi.org/10.1016/j.fuel.2011.03.039

Lakshmanan T, Nagarajan G (2011b) Study on using acetylene in dual fuel mode with exhaust gas recirculation. Energy 36(5):3547–3553. https://doi.org/10.1016/j.energy.2011.03.061

Lapuerta M, Armas O, Ballesteros R, Fernandez J (2005) Diesel emissions from biofuels derived from Spanish potential vegetable oils. Fuel 84:773–780. https://doi.org/10.1016/j.fuel.2004.11.010

Lapuerta M, Armas O, Rodríguez FJ (2008) Effect of biodiesel fuels on diesel engine emissions. Prog Energy Combust Sci 34:198–223. https://doi.org/10.1016/j.pecs.2007.07.001

Lawrence P, Mathews PK, Deepanraj B (2011) Experimental investigation on performance and emission characteristics of low heat rejection diesel engine with ethanol as fuel. Am J Appl Sci 8(4):348–354. https://doi.org/10.3844/ajassp.2011.348.354

Leo GL, Thodda G, Murugapoopathi S (2021) Experimental investigation on effects of gasoline premixed-Al2O3 additive blended fish oil biodiesel fuelled HCCI-DI engine. J Phys Conf Ser 2054(1):012040

Leo GL, Murugapoopathi S, Thodda G, Baligidad SM, Jayabal R, Nedunchezhiyan M, Devarajan Y (2023) Optimisation and environmental analysis of waste cashew nut shell oil biodiesel/cerium oxide nanoparticles blends and acetylene fumigation in agricultural diesel engine. Sustain Energy Technol Assess 58:103375. https://doi.org/10.1016/j.seta.2023.103375

Mohan S, Dinesha P (2022) Performance and emissions of biodiesel engine with hydrogen peroxide emulsification and cerium oxide (CeO2) nanoparticle additives. Fuel Jul 319:123872. https://doi.org/10.1016/J.FUEL.2022.123872

Montague X (1996) Introduction of rape methyl ester in Diesel fuel—the French National Program. SAE 962065

Muruganantham P, Pandiyan P, Sathyamurthy R (2021) Analysis on performance and emission characteristics of corn oil methyl ester blended with diesel and cerium oxide nanoparticle. Case Stud Therm Eng Aug 26:101077. https://doi.org/10.1016/J.CSITE.2021.101077

Murugapoopathi S, Vasudevan D (2019a) Performance, combustion and emission characteristics on VCR multi-fuel engine running on methyl esters of rubber seed oil. J Therm Anal Calorim 138(2):1329–1343. https://doi.org/10.1007/s10973-019-08281-x

Murugapoopathi S, Vasudevan D (2019b) Energy and exergy analysis on variable compression ratio multi-fuel engine. J Therm Anal Calorim 136(1):255–266. https://doi.org/10.1007/s10973-018-7761-2

Murugapoopathi S, Vasudevan D (2021) Experimental and numerical findings on VCR engine performance analysis on high FFA RSO biodiesel as fuel using RSM approach. Heat Mass Transf 57(3):495–513. https://doi.org/10.1007/s00231-020-02961-3

Murugapoopathi S, Ramachandran T, Rajaganapathy C (2022) Theoretical performance on energy and exergy analysis of methyl esters of rubber seed oil fuelled on supercharged VCR engine. Environ Dev Sustain. https://doi.org/10.1007/s10668-022-02642-7

Murugapoopathi S, Surendarnath S, Ramachandran T, Amesho KT, Senthil S (2023) Energy and exergy analysis of VCR engine fueled with rubber-seed oil methyl ester using response surface methodology. Energy. https://doi.org/10.1016/j.energy.2023.128238

Nour M, Sun Z, El-Seesy AI, Li X (2021) Experimental evaluation of the performance and emissions of a direct-injection compression-ignition engine fueled with n-hexanol–diesel blends. Fuel 302:121144. https://doi.org/10.1016/j.fuel.2021.121144

Nuriana W (2015) Ethanol synthesis from cedar wood (Artocarpus Heterophyllus Lam) stone waste as renewable energy source. Energy Procedia 65:372–377. https://doi.org/10.1016/j.egypro.2015.01.066

Poonia MP, Bhardwaj A, Jethoo AS, Pandel U (2011) Experimental investigations on engine performance and exhaust emissions in an LPG diesel dual fuel engine. Int J Environ Sci Develop. 2

Pramanik K (2003) Properties and use of Jatropha curcas oil and diesel fuel blends in CI engine. Renew Energy 28:239–248. https://doi.org/10.1016/S0960-1481(02)00027-7

Prasad CV, Krishna MM, Reddy CP, Mohan KR (2000) Performance evaluation of non-edible vegetable oils as substitute fuels in low heat rejection diesel engines. Proc Inst Mech Eng Part d J Automobile Eng 214(2):181–187

Raheman H, Ghade SV (2007) Performance of compression ignition engine with Mahua (Madhuca indica) biodiesel. Fuel 86:2568–2573. https://doi.org/10.1016/j.fuel.2007.02.019

Rajesh K, Sathiyamoorthi R, Senthil S, Murugapoopathi S, Damodharan D (2023) Analysis of performance and emission patterns of novel biofuel feedstock neat coconut fatty acid distillate (CFAD) fuelled single-cylinder diesel engine. Heat Transf 52(5):3732–3757. https://doi.org/10.1002/htj.22849

Ramadhas AS, Jayaraj S, Muraleedharan C (2004) Use of vegetable oils as IC engine fuels: a review. Renew Energy 29:727–742. https://doi.org/10.1016/j.renene.2003.09.008

Reddy CVS, Reddy CE, Reddy KH (2012) Effect of fuel injection pressures on the performance and emission characteristics of DI diesel engine with biodiesel blends cotton oil methyl ester. IJRRAS 13(1):139–140

Rengasamy M, Raj RV, Vedagiriswaran N (2017) Study on oil extraction from cedar wood and its application in biodiesel production. Elixir Renew Energy 102:44269–44272. https://doi.org/10.1063/5.0033994

Sai Kiran S, Madhu S, Bibin C, Woldegiorgis MM, Kumran P (2021) Effects of chrysopogon zizanioides nano additive with palm biodiesel on engine performance and exhaust emissions. Mater Today Proc Jan 45:6951–6957. https://doi.org/10.1016/J.MATPR.2021.01.416

Saravanamuthu M, Thulasiram R, Ramasamy D, Sundaramoorthy S (2023) Optimization of engine parameters using NSGA II for the comprehensive reduction of emissions from VCR engine fuelled with ROME biodiesel. Environ Sci Pollut Res 30(22):61162–61176. https://doi.org/10.1007/s11356-022-19752-4

Seela CR, Sankar BR, Kishore D, Babu MVS (2019) Experimental analysis on a DI diesel engine with cerium-oxide-added Mahua methyl ester blends. Int J Ambient Energy 40(1):49–53. https://doi.org/10.1080/01430750.2017.1360203

Shameer PM (2017) Study on clean technology-assisted combustion behavior and NOx emission using thermal imager for alternate fuel blends. Int J Environ Sci Technol 14(12):2759–2768. https://doi.org/10.1007/s13762-017-1353-8

Shehata MS, Ali Attia MA, Abdel Razek SM (2015) Corn and soybean biodiesel blends as alternative fuels for diesel engine at different injection pressures. Fuel 161:49–58. https://doi.org/10.1016/j.fuel.2015.08.037

Singh D, Sharma D, Soni SL, Sharma S, Sharma PK, Jhalani A (2020) A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 262:116553. https://doi.org/10.1016/j.fuel.2019.116553

Spataru A, Romig C (1995) Emissions and engine performance from blends of soya and canola methyl esters with ARB#2 diesel in a DCC 6V92 TA MUI engine. SAE Paper No. 952388

Thiruselvam K, Murugapoopathi S, Ramachandran T, Amesho KT (2023) Hydrogen-enriched palm biodiesel as a potential alternative fuel for diesel engines: investigating performance and emission characteristics and mitigation strategies for air pollutants. Int J Hydrog Energy. https://doi.org/10.1016/j.ijhydene.2023.04.256

Thodda G, Madhavan VR, Thangavelu L (2023a) Predictive modelling and optimization of performance and emissions of acetylene fuelled CI engine using ANN and RSM. Energy Sources A Recov Util Environ Eff 45(2):3544–3562. https://doi.org/10.1080/15567036.2020.1829191

Thodda G, Kathapillai A, Madhavan VR, Saravanamuthu M (2023b) Experimental analysis on the influence of compression ratio, flow rate, injection pressure, and injection timing on the acetylene—diesel aspirated dual fuel engine. Environ Sci Pollut Res 30(22):61217–61233. https://doi.org/10.1007/s11356-022-21483-5

Velmurugan A, Rajamurugan TV, Rajaganapathy C, Murugapoopathi S, Amesho KT (2023) Enhancing performance, reducing emissions, and optimizing combustion in compression ignition engines through hydrogen, nitrogen, and EGR addition: an experimental study. Int J Hydrog Energy. https://doi.org/10.1016/j.ijhydene.2023.09.115

Venu H, Raju VD, Subramani L (2019) Combined effect of in fluence of nano additives, combustion chamber geometry and injection timing in a DI diesel engine fuelled with ternary (diesel-biodiesel-ethanol) blends. Energy 174:386–406. https://doi.org/10.1016/j.energy.2019.02.163

Verma S, Upadhyay R, Shankar R, Pandey SP (2023) Performance and emission characteristics of micro-algae biodiesel with butanol and TiO2 nano-additive over diesel engine. Sustain Energy Technol Assessments 55:102975. https://doi.org/10.1016/J.SETA.2022.102975

Vijayabalan P, Nagarajan G (2009) Performance, emission and combustion of LPG diesel dual fuel engine using glow plug. Jordan J Mech Indust Eng 3:105–110

Wagner LE, Clark SJ, Schrock MD (1984) Effects of soybean oil esters on the performance, lubricating oil and water of diesel engines. SAE Paper No. 841385

Waly MS, El-Seesy AI, El-Batsh HM, Eoheiry RM (2023) Combustion and emissions characteristics of a diesel engine fuelled with diesel fuel and different concentrations of amino-functionalized multi-walled carbon nanotube. Atmosph Pollut Res 14(8):101831. https://doi.org/10.1016/j.apr.2023.101831

Wu Y, Zhang Y, Xia C, Chinnathambi A, Nasif O, Gavurova B et al (2023) Assessing the effects of ammonia (NH3) as the secondary fuel on the combustion and emission characteristics with nano-additives. Fuel 336:126831. https://doi.org/10.1016/j.fuel.2022.126831

Xuan T, Sun Z, Eeesy AI, Mi Y, Zhong W, He Z, Cao J (2021) An optical study on spray and combustion characteristics of ternary hydrogenated catalytic biodiesel/methanol/n-octanol blends; part П: liquid length and in-flame soot. Energy 227:120543. https://doi.org/10.1016/j.energy.2021.120543

Yu JZ, Yu-Sheng Z, Elkelawy M, Kui Q (2010) Spray and combustion characteristics of HCCI engine using DME/diesel blended fuel by port-injection pp.. 2010-01-1485. SAE Tech. Pap. https://doi.org/10.4271/2010-01-1485

Zhang X, Xia C, AlSalhi MS, Devanesan S, Sekar M, Jhanani GK et al (2023) Assessments of the power production, energy consumption and emission comparison of hydrogen feed vehicles. Fuel 334:126794. https://doi.org/10.1016/j.fuel.2022.126794

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Gavaskar Thodda contributed to conceptualization, data curation, formal analysis, investigation, methodology, software. S. Murugapoopathi contributed to methodology, software, validation, visualization, writing—original draft. D. Vasudevan contributed to validation, writing—original draft, writing—review and editing. Kassian T.T. Amesho contributed to formal analysis, supervision, validation, writing—original draft, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thodda, G., Murugapoopathi, S., Vasudevan, D. et al. Sustainable emission reduction in CI engines using cerium nanoparticles and acetylene-cedar wood oil biofuel. Clean Techn Environ Policy (2024). https://doi.org/10.1007/s10098-024-02768-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10098-024-02768-4