Abstract

Current economic and environmental pressure encourages companies to invest and reform processes in a sustainable way. However, the decision on the best sustainable investment in a given industry may not be as straightforward as given by the independent economic and environmental indicators. Analyzing such indicators for investment in process alternatives is a complex multi-objective decision-making process. Many methods can help solve multi-objective problems, GREENSCOPE suggests using the Addictive Utility Method, which may have some shortcomings. In this work, the Analytic Hierarchy Process and the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) are applied to the indicator scores obtained with the GREENSCOPE methodology. The Analytical Hierarchy Process is applied with Marginal Rate of Substitution, to obtain the priority matrices. MATLAB was used to apply the methods and through an algorithm, to determine the adequate number of indicators to be used. Three cases were studied, namely a biorefinery plant, and two academic case studies on the production of acetaldehyde from ethanol and propylene glycol from glycerol. The two academic cases were modeled in Aspen Plus, to obtain process data, and linked to GREENSCOPE using MATLAB. The methodology was applied to some proposed alternatives where the sustainability improvement of energy integration and material recycling was tested. The new methodology was able to identify the more sustainable case among the alternatives. This methodology based on TOPSIS proved to be the best choice, avoiding the weighting of indicators, and providing an expected analytical decision among alternatives.

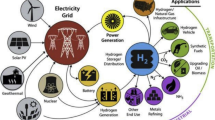

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Integrated solutions in Process System Engineering (PSE) are nowadays a must in any development, as better energy efficiency, lower environmental impact and better social integration are goals to be pursued. However, the decision-making between process innovations and alternatives is not trivial (Tang and You 2018), since an improvement in one area might mean a penalty in another one (Smith and Ruiz-Mercado 2014). Thus, any project development is a multi-objective decision-making (MODM) problem (Perez-Gallardo et al. 2018), that might benefit from a multidisciplinary team to consider all aspects, especially when there is variability in a process and control problems may arise (Li et al. 2020). Some methodologies may take a more straightforward approach, that allows smaller teams to solve such MODM problems, such as using only a selected set of sustainability indicators (Tzeng and Huang 2011; Smith et al. 2015).

One such approach is Life Cycle Assessment (LCA) which was introduced in the 1960s, with the increasing awareness of environmental and societal impacts of human activities (Guinée et al. 2011). In recent years, LCA has become essential in modern process design methodologies (Jacquemin et al. 2012). This means that, LCA is now a pivotal tool in PSE ensuring the sustainability analysis of a given project (Mimoso et al. 2015). Currently, LCA follows a strict set of rules, with ISO 14040 (The International Standards Organization 2006a) and ISO 14044 (The International Standards Organization 2006b) being the international standards.

An LCA study aims to analyze the entire life cycle of a given product, with a Cradle-to-Grave analysis, however, the analysis can be limited to any other mid-life point, which determines the scope of the analysis (Smith et al. 2015). It can also be extended to an Eco-LCA, where the natural resources are also taken into consideration as well as services and goods. If the scope of an analysis is to evaluate process changes, a Cradle-to-Grave analysis can be simplified to a Gate-to-Gate analysis, where process alternatives can be closely looked at. GREENSCOPE (Gauging Reaction Effectiveness for the Environmental Sustainability of Chemistries with a multi-Objective Process Evaluator), was first introduced in 2003 (Gonzalez and Smith 2003), and intends to make a sustainability analysis of a chemical process, considering not only the environmental impact of a process but also economic and, to some extent, societal aspects (Ruiz-Mercado et al. 2012a). The sustainability indicators are organized into four metrics: mass efficiency, environment, energy, and economy, with a total of 139 sustainability indicators.

The focus of this work is the interpretation of the sustainability indicator scoring obtained by GREENSCOPE (GRNS). An evaluation of the scoring was previously proposed using the Additive Utility Method (AUM) and the Marginal Rate of Substitution (MRS) (Ruiz-Mercado et al. 2013). These methods are used in this work and applied to a biodiesel plant as a case study, evaluated with GRNS and using AUM to decide between alternatives. Although, the indicator ponderation was still subjective, MRS already produces an interaction matrix that allows obtaining an objective ponderation vector. Other multi-objective decision-making (MODM) methodologies were found to be effective when used for sustainability analysis such as, Analytical Hierarchy Process (AHP) (Saaty 1977) and Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) (Gomes and Martins 2022). All these methods help decision-making between process routes and recommend the use of weights as a ponderation between indicators. Several works have been published in diverse fields of sciences, where AHP is used as decision-making tool (Saaty 1979; Vaidya and Kumar 2006).

This work introduces a new framework for sustainability analysis using GRNS methodology, to systematically compare and classify different process alternatives, to facilitate the decision-making process. The GRNS methodology is applied to three different case studies and a number of MODM methods are used to identify the best performing process alternatives.

Methodology

This section presents the theory which was used for the decision-making process between industrial processes. Firstly, the global score results are presented, which should translate into a rigorous decision on which alternative is more sustainable. Secondly, an analysis of the results obtained for each metric, defined as a group of indicators, is presented.

GREENSCOPE

GREENSCOPE (GRNS) is a sustainability analysis methodology, that sets the boundaries on the outer edges of the process being analyzed, a gate-to-gate analysis. This methodology uses a total of 139 indicators (\({I}_{i}\)) distributed in four metrics, as shown in Table 1.

The GRNS methodology represents the results obtained for each indicator in a normalized percentage scale (Gonzalez and Smith 2003). This way the performance of a given indicator is easily understandable, the closest to 100 % the better. The GRNS vector of scores (\(\%{G}_{k})\) is defined by Eq. (1).

where \({x}_{i}\) is the indicator value calculated based on process data, and \({x}_{i,worst}\) and \({x}_{i,best}\) are the worst and best values that the indicator could achieve. The denominator of the Eq. (1) is also referred as \({\Delta }_{i}\). Worth noting that every indicator has a specific equation, unit, and range. The range might be easy to determine for specific indicators, such as relative indicators (e.g., reaction yield); however, this might not be so straightforward for others. For mass intensity the units are \({kg}_{total in} . {{kg}_{desired prodct. out}}^{-1}\), which means it will depend on the total mass flown into the system, and the conversion to the desired product (Ruiz-Mercado et al. 2012b).

When changes are implemented to a complex system, such as a chemical plant, it can have repercussions in diverse parameters. For example, if the implemented modifications can improve energy consumption, it might come at an environmental or economic cost. Therefore, a method for comparison between alternatives is needed; one way of doing it is by directly analyzing the indicators scores and comparing them between versions. Although comparing the evolution of one indicator in multiple versions of a process might be feasible, comparing multiple indicators is not straightforward. The GRNS methodology proposes the representation of the indicator scores in a spider graph as shown in Fig. 1.

However, the analysis of Fig. 1 results is just qualitative, therefore a quantitative method is required to sort the different alternatives.

One way of solving this problem might be calculating the difference between indicators for every alternative (\({D}_{i}\), Eq. (2)), while aiming to maximize the sum of calculated differences, as shown in Table 2, as an illustrative example only with six indicators, four alternatives (V1 to V4) and one base case (V0).

The normalization built in the GRNS methodology (Eq. (1)), means that the scores between indicators are comparable, but the comparison between alternatives is nontrivial. The sum of the differences between alternatives is too simplistic, as shown in Table 2. Where V1 would be the best performing alternative, having the highest sum of differences, however, V4 has a total of 5 improved indicators from V0. This method does not consider the possibility that different indicators may have different levels of importance. This can be solved by introducing a factor, or weight (\({\omega }_{i}\)), to each indicator score in the equation of differences (Eq. (2)), defining \({D}_{ik}^{\prime}\) according to Eq. (3).

The weight introduced can take into consideration the different importance of each indicator for a given plant. However, the determination of such weights introduces another challenge into the complex task of identifying the best alternative from the sustainability analysis.

Additive utility method

The Additive Utility Method (AUM) is a widely used methodology that can be very straightforward, with an additive operation at its core. Smith applies AUM to the GRNS sustainability analysis, using the Marginal Rates of Substitution (MRS) as part of the ponderation step (Smith and Ruiz-Mercado 2014). Weights (\({\omega }_{i}\)) can also be added in this method, as represented in Eq. (4), where \({U}_{i}\) is the GRNS score of an indicator \({I}_{i}\), \({U}_{tot}\) the total utility and \(V\) the total number of alternatives considered for each case study.

MRS uses the partial derivative of each indicator score in order to the remaining indicator scores as entries to a matrix (\({M}_{ij}\)). This matrix is an interaction matrix, that as a diagonal of ones, and the upper triangle is the inverse of the lower triangle, Eq. (5) (Smith and Ruiz-Mercado 2014).

With the matrix \({M}_{ij}\) set, the goal of the evaluation must be defined, and an indicator must be chosen as the reference indicator. Based on the indicator chosen (\({I}_{\beta }\)), a column of the matrix \({M}_{ij}\) is selected and used for the ponderation of the utility. Combining Eq. (4) and column β of the \({M}_{ij}\) matrix, Eq. (6) is obtained, which represents the total utility, \({U}_{tot}\).

Analytic hierarchy process

Analytic Hierarchy Process (AHP) is a well-known Multi-Criteria Decision-Making (MCDM) method, introduced by (Saaty 1972), who proposed a systematic methodology to compare multiple possible choices. The problem is structured in four parts: goal, aspects, criteria (or indicators) and possible solutions (alternatives), as seen Fig. 2.

Graphical representation of AHP methodology, adapted from (Tzeng and Huang 2011)

This methodology allows for the consideration of many criteria, upon which a decision must be based. The decision is made using interaction matrices, \((A\) and \({M}_{k}\)), where each criterion is assigned a priority value (\({\rho }_{i}\)), between 1 and 9 (Saaty 1977). The priority attribution is made following the instructions in Table 3.

The pairwise comparisons, \({\alpha }_{ij}\), are obtained using Eq. (7) which are collected in matrix \(A\) defined by Eq. (8).

From matrix \(A\) a priority vector (\({P}^{{\prime}{\prime}}\)) of length n is obtained by calculating the geometric mean of each row and normalizing it, with a sum normalization, Eq. (9).

Again, for every criterion, an interaction matrix is obtained, where the entries are assigned a priority (\({\tau }_{i}\)) for each process alternative \(i\) over process alternative \(j\), as shown on Eq. (10).

As for the matrix \(A\), the geometric mean is calculated for these matrices as well as the \(n\) normalized priority vectors of means, \({p}_{k}^{{\prime}{\prime}}\):

Finally, the priority for each pair criteria-alternative is calculated as defined in Eq. (12). Table 4 shows these values.

Technique for order of preference by similarity to ideal solution

One other methodology for decision-making is the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), which consists in evaluating given alternatives based on its score deviation to the best score in each indicator. In this way, the best performing alternative for each indicator is identified and a compromise is created where the deviation from the best indicator score is minimized, by a sum of squared differences, as shown in Eqs. (13–20) (Gomes and Martins 2022).

First, a decision matrix \(F\) (with dimension \(V\times n\)) consisting of the GRNS scores obtained is created. This matrix contains the relative values, \({\%G}_{i}\), assigned to each criterion, \({C}_{k}\) and each alternative, \({V}_{i}\).

As the data from matrix \(F\) may have different sources, it is easier to compare normalized values. This normalization can be made using different approaches, depending on the objective and data in study, which will be further discussed in next section. The normalized matrix \(R=\left[{r}_{ij}\right]\), is obtained with Eq. (14), where a vectorial normalization technique is used.

With matrix \(R\) it is also possible to assign different levels of importance, i.e., weights, \({\omega }_{i}\), (where \(\sum {\omega }_{i}=1\) and \({\omega }_{i}\ge 0\)) to the scores, \({x}_{ij}\), obtained, as shown in Eq. (15).

The resulting normalized and weighted scores matrix \(G=[{v}_{ij}]\) is then used in TOPSIS algorithm. For each criterion, the best (\({A}^{+}\)) and worst (\({A}^{-}\)) performing alternatives are identified, as defined by eqs. (16) and (17).

These values are then used to calculate the Euclidean distances of each alternative to \({A}^{+}\) and \({A}^{-}\), \({S}_{i}^{+}\) and \({S}_{i}^{-}\), respectively.

As a final step in TOPSIS methodology, the relative closeness is calculated using Eq. (20), and used to determine the best overall alternative.

Equation (20) represents a trade-off that must be made in any decision-making process, where the best overall alternative may not be the best performing in all the criterion, but it is globally the closest to the best performing. Therefore, the highest values obtained in the \({\xi }^{+}\) vector, correspond to the best performing alternative.

Improving GREENSCOPE interpretation

Some adaptations were made to the methods previously described, so that it was possible to use them with the GRNS data obtained, as described below.

AUM-MRSmod

AUM was applied to the GRNS scores as described in additive utility method section, however, the indicator selection step was skipped, and every column of the \({M}_{ij}\) matrix multiplied by the GRNS vector of scores. The resulting vector was then summed to obtain a final value for decision-making.

AUM-AHP

A closer look at the units of Eq. (6) shows that it is not dimensionless. Therefore, the total utility evolution, from multiple indicators, throughout multiple changes in one process cannot be compared, and the main goal of the GRNS analysis is lost. GRNS has been proposed to provide a better understanding of the sustainability analysis of a process, generating scores between 0 % and 100 %, and with the use of AUM, will result in a set of incomparable results. However, if the indicator selection step were removed or skipped a dimensionless result would be obtained and the methodology would be improved. This adaptation (AUM-AHP) is tested in this paper instead of a straight application of the AUM method, as proposed by Smith & Ruiz-Mercado (2014).

When using GRNS, it is possible to consider the denominator of Eq. (1), (\(\left|{x}_{i,best}-{x}_{i,worst}\right|\), from now on represented as \({\Delta }_{i}\)) as an evaluation of priority. Even though \({\Delta }_{i}\), does not translate in a priority from an indicator over another, it can still be used to represent priority when calculating matrix \(A\). To this end, Eq. (8) is used with a redefined value of \({a}_{ij}=\frac{{\Delta }_{i}}{{\Delta }_{j}}\).

After the \(A\) matrix calculation, AHP method of priority is used, applying the geometric mean to each row of the matrix, and obtaining the priority vector \(P^{\prime}\). To obtain vector \({P}^{{\prime}{\prime}}\) a normalization method must be applied to \(P^{\prime}\). Table 5 shows different normalization techniques available (Vafaei et al. 2016).

Vector \({P}^{{\prime}{\prime}}\), obtained in the AHP methodology, was tested as a ponderation vector on the AUM methodology, instead of a column of matrix \({M}_{ij}\). This adaptation of the methodology was called AUM-MRSmod.

AHP-MRS

GRNS returns the score values of each indicator for every alternative, using Eq. (1). Therefore, for a given number of indicators (n), when applying AHP, there will be \(n+1\) comparison matrices (the + 1 accounts for matrix \(A\)). These comparison matrices (\({M}_{k}\)) were obtained with Eq. (21).

With matrices \({M}_{k}\) defined, it is possible to follow the AHP method, create the normalized vectors of means, \({P}^{{\prime}{\prime}}\) and \({p}_{k}^{{\prime}{\prime}}\), and combine them into a table, as illustrated in Table 4, to reach the final utility values.

AHP-MRSmod

A variation of the AHP method was also tested, where instead of calculating \(n\)+1 matrices, only \(k+1\) matrices were calculated, one per alternative, using Eq. (22) to obtain the \({M}_{k}\) matrices. Matrix \(A\) was also calculated, to obtain the vector \({P}^{{\prime}{\prime}}\) this vector and the \({p}_{k}^{{\prime}{\prime}}\) vectors are multiplied and summed, as in the original AHP method. The use of this new matrix is a modification of the AHP method (AHP-MRSmod).

Application

To carry out a sustainability analysis there must be a reference upon which the comparison can take place. The comparison between the alternatives involving different directions in process development, heat or mass integration, requires a robust methodology for comparison and decision making. The five methods (AUM-MRSmod, AUM-AHP, AHP-MRS, AHP-MRSmod and TOPSIS) will be studied in this work to find out which one is the more robust.

Case studies

To analyze the behavior of the different methodologies, three case studies were evaluated, namely a biodiesel refinery and two typical academic case studies, acetaldehyde production from ethanol and propylene glycol production from glycerol. For each case study, different alternatives were created, and the expected sustainability ranking defined as shown in Table 6 and explained in the next sections.

The four alternatives for the acetaldehyde and propylene glycol case studies were modeled using Aspen Plus and the obtained results used as inputs for GRNS.

Biodiesel production

An illustrative biodiesel case study is available within GRNS. Since it was a well-documented example, and contained all the required data for the analysis, it was used as a case study. Three new alternative cases with an expected order of sustainability were created by modifying the original data in GRNS. Alternative V0 suffered no changes and was determined to be the base case, for alternatives V1 and V2 the price of feed streams and product streams respectively were reduced. Alternative V3 suffered a 10 % reduction in the energy consumption of all equipment. The sustainability ranking of these alternatives was anticipated as shown in Table 6, as the lower price of the products is expected to be the worst performing alternative overall, so it was given an expected ranking of 4. Conversely, the lower price of the feed streams is expected to be the best performing alternative, with an expected ranking of 1. Since the energy reduction represents an improvement over the base case, this alternative (V3) must have a better expected ranking than the base case (V0), so V3 was given an expected ranking of 2 and V0 was given an expected ranking of 3.

Acetaldehyde production

Although the biodiesel case study was well established in GRNS, further proof of the DM process was needed. An academic case study that has been extensively studied by the authors in the past and modeled in Aspen Plus, was implemented in GRNS.

The process consists of feeding pure ethanol into a reactor operating at 280 ºC and 20 bar, where the reaction of dehydrogenation of ethanol takes place with a conversion of 60 %. The effluent is cooled, the gaseous phase removed, and the liquid stream is fed to a distillation column where the acetaldehyde is collected at the top and the ethanol is the residue. Four process alternatives have been established by considering material recirculation and energy integration. Alternative V1 considers only energy integration, alternative V2 includes recirculation of the residue of the distillation column and alternative V3 includes both energy integration and recirculation of the residue of the distillation column The four defined alternatives were modeled in Aspen Plus, and an expected ranking was determined, as shown in Table 6.

Propylene glycol production

Like the acetaldehyde case study, the propylene case study is a well-known academic example that has also been modeled in Aspen Plus. This case study takes glycerol, the residue from biodiesel refineries, and converts it into a valuable product, propylene glycol, through a hydrogenation reaction. This reaction requires large amounts of hydrogen, primarily due to the excess hydrogen required. This hydrogen can be returned to the reactor but requires two purification units. Therefore, alternatives V0 and V1 were modeled without hydrogen recirculation, and V2 and V3 with recirculation (and therefore with all the associated energy and capital penalties). As in the acetaldehyde case study, only V1 and V3 were modified to include energy integration.

Results display as rankings

The results obtained by the application of the MODM methods will have very diverse scales. Therefore, the use of a ranking scale will lead to a straightforward decision-making process on what is the best alternative. So, for every method and case study, the alternatives were ranked in descending order of sustainability, from position one to position four.

Sustainability indicators subset determination

In order to evaluate a given plant or an alternative using GRNS framework, it is possible to use the 139 sustainability indicators. However, some of these indicators may not be applicable, so it is necessary to define a set of indicators that best describe the system. One way of selecting the indicators is to reject the ones that GRNS does not calculate or returns error in the calculation. A methodology to determine the largest possible number of indicators was created, and the flowchart in Fig. 3 presents such methodology.

The vectors of indicator scores (%G) and deltas (Δ), obtained with GRNS for each alternative, are evaluated in the methodology to remove the indicators that were not calculated, either because there was a lack of information to calculate that indicator, or because it was no appropriate for that case study (Fig. 4).

Furthermore, small values of Δ (from Eq. (1)) will lead to large values on matrix \(A\) (Eq. (8)). To prevent this, a parameter \(a\) was introduced as a cut-off point and the values of Δ lower than \(a\) are removed, avoiding the generation of very large and meaningless values. This parameter is part of the elimination stages added to ensure that the MODM methods could be used.

In the cases studied, the minimum number of indicators obtained with this selection method was 55, which represents about 40 % of the total indicators available in GRNS. To ensure that a minimum of 20 % of the indicators is used, globally and for each individual metric, a minimum of 30 indicators with the following distribution was defined: mass efficiency 6, environment 14, energy 3, economy 7. The 20 % minimum is set using the Pareto’s 20/80 rule, which states that with 20 % knowledge about a system one can characterize as much as 80 % of such system (Brockhoff and Zitzler 2007).

The described methodology was developed and implemented using MATLAB. Firstly, all the GRNS data (%G and \(\Delta\)) is automatically collected from the Microsoft Excel file. The outlined restrictions are then applied and the indicators that fulfill the criteria are stored into a file. Finally, the MODM algorithms are used to find the best performing alternative.

Metric analysis

As mentioned previously and shown in Table 1, GRNS distributes the indicators by four metrics. Though each metric may be individually assessed, the methods available for this are diverse. In this work, two methods were used to evaluate the metrics. The first one splits the ponderation vectors previously determined, \({P}^{{\prime}{\prime}}\) and \({p}^{{\prime}{\prime}}\), depending on the method, and splits them according to the considered indicators in each metric. The second one applies the MODM methods to the indicators in each metric, treating each metric as an independent problem. Table 7 presents a brief description of the applied methods to each metric.

Results

This section presents the results obtained by applying the methodology previously described. Firstly, a subset of the GREENSCOPE indicators is obtained by discarding the indicators whose values would limit the application of the MODM methods. As described in the sustainability indicators subset determination section, the determination of parameter \(a\) is the first step of the methodology. Secondly the more appropriate normalization technique to use in the MODM methods is assessed, and finally the global and metric score results are presented.

Determination of parameter \({\varvec{a}}\)

The parameter \(a\) was introduced to avoid infeasible calculations, as previously stated. Since this parameter can have a significant impact on the total number of indicators used, a sensitivity analysis was performed to understand its impact on the total number of indicators.

The total number of indicators was obtained for a set of values of \(a\) (\(a\in \{\) 0.01, 0.1, 0.5, 0.8, 1\(\}\)) and the results are shown in Fig. 5. Since parameter \(a\) is used to discard indicators based on the \(\Delta\) value from GRNS, its maximum value was set to 1, because some indicators from GRNS vary between 0 and 1 and therefore have a \(\Delta\) value of 1 (e.g., reaction yield).

As seen in Fig. 5, a large amount of indicators is discarded for values of \(\Delta >0.1\) (cut-off point at \(a = 0.1\)), particularly for the biodiesel case study. For the other case studies, the larger reduction occurred for values of \(\Delta \le 0.01\).

Effectiveness of the elimination process

In order to select a proper value of \(a\), a balance between the total number of indicators considered in the analysis and their impact in the final decision-making process must be achieved. To this aim a comparison of the ranks obtained for each alternative was performed. Table 8 presents the absolute difference between the obtained rank of alternatives and the expected rank (previously presented in Table 6). The goal was to find the value of \(a\) that minimizes the difference between the expected and the obtained ranks in each case study for as many MODM methods as possible.

The results obtained for the different alternatives considered for the acetaldehyde and propylene glycol case studies reflect the impact that the total number of indicators can have in the final results. For AUM-MRSmod and AUM-AHP better results were found with a higher value of \(a\), so a smaller total number of indicators. This occurs since many indicators from GRNS have small values of Δ, which lead to high values on matrix \(A\), therefore high ponderation values on vector \(P^{^{\prime\prime}}\). In the end, assigning a high ponderation value to many indicators, that leads to rankings not correspondent to the expected ones.

AHP-MRS was not able to achieve the expected rankings, even for higher values of \(a\). This might come from the fact that matrix \(A\) was obtained from the MRS matrix, instead of the typical interaction matrix with values from 1 to 9. AHP-MRSmod accurately identified the rankings for the biodiesel case study, but it was not able to do so for the other two case studies, which may be due to the way this method was implemented.

Only TOPSIS was able to match the expected ranks, independently of the value of \(a.\) For this reason it was considered the most adequate method to further analyze the results obtained from GRNS. Since the results did not change for different values of \(a\), the method will be applied without the ponderation vector \(P^{^{\prime\prime}}\).

Elimination stages analysis

After defining the value of \(a\), the number of indicators eliminated in each stage of the methodology was analyzed. This is essential to understand which stage is the most influential in the indicator’s determination phases. The results of this analysis are found in Fig. 6.

Each elimination stage of the methodology leads to a reduction in the total number of indicators, with a different impact in each case study, since each one has its own specificities. With \(a\) equal to 0.05, it is possible to see that the first stage has a greater impact for the biodiesel case study than for the other two case studies. It is also possible to conclude that after stage 3 the total number of indicators does not change much, which was expected, since the first three stages were designed to ensure that matrices \(A\) and \(M\) have no infinite values. Stage 5 was introduced to ensure that the total number of indicators used is the same for each alternative of the case study. It was found that it further eliminates some indicators in all case studies.

Normalization technique analysis

To evaluate which of the normalization methods from Table 5 is the more suited to evaluate the GRNS indicator scores, the parameter \(a\) was fixed at 0.01, and the four different normalization techniques were applied to the MODM methods. These normalization techniques are expected to affect the results, since vectors \(P^{^{\prime\prime}}\) are used in all MODM methods as ponderation vector.

To compare the performance of the four normalization techniques, Pearson and Spearman correlations were calculated (Çelen 2014). These correlations compare the results of all the different methods being considered, using the values obtained in Pearson correlation and the results expressed as rankings in Spearmen correlation. The differences between the results for the normalization techniques were therefore quantified and the results can be found in Table 9.

The sum and vector normalization techniques are the best performing ones for the AHP-MRSmod and TOPSIS methodologies, as seen in Table 9. AUM-AHP was also evaluated, however, no differences were found in the use of the various normalization techniques (the value one was obtained for all the techniques). The normalization technique results were also evaluated using the same method applied to parameter \(a\) (effectiveness of the elimination process section), and the deviations obtained from the expected ranks are shown in Table 10.

The vectorial normalization technique has the smallest sum of deviations from the expected rank, and was therefore used in the methodologies presented in Table 10. Furthermore, it was found that the TOPSIS method can accurately identify the different alternatives without a ponderation vector, so it was used without ponderation.

Global scores

The global scores for the sustainability analysis were obtained using the MODM methods, with the aim of choosing which alternative is the more sustainable. When analyzing the results obtained, the alternative with the highest score is the one that should be chosen, independently of the methodology used. A methodology would be deemed good if it is able to rank the alternatives according to the expected ranks. However, if it is able to identify the alternatives with and without material recirculation (Table 6) within each case study, further investigation of the method could be justified. Table 11 presents the scores, the rankings generated and the sum of the differences to the expected rankings (\(\sum {\Delta }_{\mathrm{exp}})\) for all the case studies.

As shown in Table 11 the results obtained with the different methodologies have different scales, due to the different approaches used.

The results obtained for the biodiesel case study are based on changes made to the GRNS illustrative example, as described in the case studies section. Alternative V1 was expected to be the more sustainable, and it is in fact the best performing alternative in all methods but AHP-MRS.

The results obtained for the acetaldehyde case study were similar to those for biodiesel. AUM-MRSmod, AUM-AHP and TOPSIS were able to identify the two groups of alternatives (with and without material recirculation), but only TOPSIS ranked the four alternatives in the expected order. AHP-MRS and AHP-MRSmod do not lead to consistent results, with large \(\sum {\Delta }_{\mathrm{exp}}\) values.

The propylene glycol results show that AUM-MRSmod, AUM-AHP and TOPSIS accurately identify the alternative rankings in the expected order. TOPSIS provides the best overall results in the classification of alternatives, and will be used in the next section, where a closer look at the metrics evaluation will be carried out.

Metric analysis

Since GRNS divides the chosen sustainability indicators into four metrics, an analysis for each one was conducted. The number and percentage of total indicators used for each metric is presented in Table 12. As described in the metric analysis section, the metric scores can be obtained with various methods. However, since TOPSIS was found to be the best performing, only the results obtained with TOPSIS are presented (Table 13).

The results presented in Table 13 for the fragmentation and reset routes of metric analysis demonstrate that the analysis of only one metric cannot replace the overall sustainability analysis, since the ranking only corresponds to the expected for the economic metric in the biodiesel and propylene glycol case studies, and the energy metric in the propylene glycol case study. This means that the four metrics considered are indeed essential for the sustainability analysis, and that a process that has a very good economic score may not have the best environmental score. Only with an evaluation that considers all these factors is possible to have a clear understanding of the system.

Conclusions

Process design needs constant evaluation in pursuit of the required sustainable improvements. This can only be accomplished with a clear main goal, such as, to maximize short term profits, regardless of environmental impacts. Every project designer knows that mid to long term sustainability is necessary, and that sustainability is a wide term that should take into consideration not just the economic aspect, but also environmental and energy efficiency aspects. In this work, a sustainability evaluation method, with a gate-to-gate approach, GREENSCOPE, was used to evaluate the process design phase of a project. To overcome the difficulties of analyzing and using the large amount of data produced by GRNS, several MODM methods were used to systematically evaluate the sustainability indicator scores obtained from GRNS and create a ranking to facilitate the identification of the best alternatives.

It was found that the decision-making process can be very subjective and there is strong support for different approaches. AUM-MRSmod was implemented without the indicator selection process, considering all the sustainability indicators available. This method was found not to be consistent enough for a wider application, failing to correctly identify the expected order of sustainability for the various alternatives of the three case studies of this work. The AUM-AHP performed better in the identification of the acetaldehyde and propylene glycol case studies with material recirculation, indicating that it could be a good method when the alternatives are significantly different.

Even though AHP-MRS is a widely used MODM method, it failed to accurately rank the four alternatives in each case study. This may be inherent to the method, since interaction matrices are used based on a 1 to 9 priority scale, and the data originated from GRNS was subjected to the MRS interaction matrix. The resulting matrix contains very large and very small values, and therefore the ponderation vector disregards many indicators, even after normalization. AHP-MRSmod was also tested with a new interaction matrix based on the GRNS scoring, but it did not lead to better results for all the cases, failing to recognize the improved alternative designs with material recirculation for the acetaldehyde and propylene glycol case studies.

TOPSIS was found to be the most consistent MODM method. It was the only method that accurately ranked the four alternatives in all case studies, being able to detect less significative changes in the process design, such as energy integration in some cases.

It was also found that the methodology developed still uses a wide number of sustainability indicators, with as many as 92 out of 139, being considered for one case study. The restrictions implemented in the selection of indicators were introduced with the aim of allowing mathematical feasibility, and therefore a sensitivity analysis to the elimination parameters was carried out. This analysis concluded that the value of 0.01 for \(a\) is the best to allow the largest possible number of sustainability indicators to be considered and to achieve the correct ranking of the alternatives.

The decision-making process based on GRNS sustainability indicators was the main focus of this work, but this process is not straightforward without the use of decision-making methodologies. The results show that TOPSIS is the best MODM method for the evaluation of the different process alternatives and provides a clear ranking of the alternatives.

The innovative methodology presented in this work is intended to facilitate the evaluation of different alternatives of a project and to help in the decision-making process. Future work will pursue on further proof of concept with direct comparison with other sustainability evaluation programs, such as SimaPro.

Data availability

Enquiries about data availability should be directed to the authors.

References

Brockhoff D, Zitzler E (2007) Dimensionality reduction in multiobjective optimization: the minimum objective subset problem. In: operations research proceedings 2006

Gomes MI, Martins NC (2022) Mathematical models for decision-making with multiple perspectives: an introduction. CRC Press

Gonzalez MA, Smith RL (2003) A methodology to evaluate process sustainability. Environ Progress. https://doi.org/10.1002/ep.670220415

Guinée JB, Heijungs R, Huppes G et al (2011) Life cycle assessment: past, present, and future. Environ Sci Technol. https://doi.org/10.1021/es101316v

Jacquemin L, Pontalier PY, Sablayrolles C (2012) Life cycle assessment (LCA) applied to the process industry: a review. Int J Life Cycle Assess 17:1028–1041

Li S, Ruiz-Mercado GJ, Lima FV (2020) A visualization and control strategy for dynamic sustainability of chemical processes. Processes. https://doi.org/10.3390/pr8030310

Mimoso AF, Carvalho A, Mendes AN, Matos HA (2015) Roadmap for environmental impact retrofit in chemical processes through the application of life cycle assessment methods. J Clean Prod. https://doi.org/10.1016/j.jclepro.2014.11.057

Perez-Gallardo JR, Azzaro-Pantel C, Astier S (2018) Combining multi-objective optimization, principal component analysis and multiple criteria decision making for ecodesign of photovoltaic grid-connected systems. Sustain Energy Technol Assess 27:94–101. https://doi.org/10.1016/J.SETA.2018.03.008

Ruiz-Mercado GJ, Smith RL, Gonzalez MA (2012a) Sustainability indicators for chemical processes: I. taxonomy. Ind Eng Chem Res. https://doi.org/10.1021/ie102116e

Ruiz-Mercado GJ, Smith RL, Gonzalez MA (2012b) Sustainability indicators for chemical processes: II. data needs. Ind Eng Chem Res. https://doi.org/10.1021/ie200755k

Ruiz-Mercado GJ, Gonzalez MA, Smith RL (2013) Sustainability indicators for chemical processes: III. biodiesel case study. Ind Eng Chem Res. https://doi.org/10.1021/ie302804x

Saaty TL (1977) A scaling method for priorities in hierarchical structures. J Math Psychol. https://doi.org/10.1016/0022-2496(77)90033-5

Saaty TL (1979) Applications of analytical hierarchies. Math Comput Simul 21:1–20. https://doi.org/10.1016/0378-4754(79)90101-0

Saaty TL, Kearns KP (1985) CHAPTER 3 the analytic hierarchy process. In: SAATY TL, KEARNS KP (eds) analytical planning. Pergamon, pp 19–62

Saaty TL (1972) An eigenvalue allocation model for prioritization and planning. Energy management and policy center, University of Pennsylvania pp 28–31

Smith RL, Ruiz-Mercado GJ (2014) A method for decision making using sustainability indicators. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-013-0684-5

Smith RL, Ruiz-Mercado GJ, Gonzalez MA (2015) Using GREENSCOPE indicators for sustainable computer-aided process evaluation and design. Comput Chem Eng. https://doi.org/10.1016/j.compchemeng.2015.04.020

Tang Y, You F (2018) Life cycle environmental and economic analysis of pulverized coal oxy-fuel combustion combining with calcium looping process or chemical looping air separation. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.01.265

The International Standards Organisation (2006b) ISO 14044:2006. Environmental management—life cycle assessment—requirements and guidelines, ISO 14044, International Organization for Standardization 2006

The International Standards Organisation (2006a) ISO 14040:2006

Tzeng GH, Huang JJ (2011) Multiple attribute decision making: methods and applications

Vafaei N, Ribeiro RA, Camarinha-Matos LM (2016) Normalization techniques for multi-criteria decision making: analytical hierarchy process case study. In: IFIP advances in information and communication technology

Vaidya OS, Kumar S (2006) Analytic hierarchy process: an overview of applications. Eur J Oper Res 169:1–29. https://doi.org/10.1016/J.EJOR.2004.04.028

Funding

Open access funding provided by FCT|FCCN (b-on). The present work was financed by the Portuguese Foundation for Technology and Science (FCT) PTDC/EAM-PEC/32342/2017, CQE strategic project FCT-UIDB/00100/2020 and CERENA strategic project FCT-UIDB/04028/2020. This support is gratefully appreciated.

Author information

Authors and Affiliations

Contributions

Conceptualization was contributed by RD, RF and HM; methodology was contributed by RD, RF and HM; formal analysis was contributed by RD, RF and HM; writing—original draft, was contributed by RD; writing—review and editing, was contributed by RD, RF and HM; software was contributed by RD; visualization was contributed by RD, RF and HM; supervision was contributed by RF and HM; funding acquisition was contributed by RF and HM; project administration was contributed by HM. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dias, R.N., Filipe, R.M. & Matos, H.A. Decision-making based on sustainability analysis using GREENSCOPE. Clean Techn Environ Policy 26, 755–770 (2024). https://doi.org/10.1007/s10098-023-02647-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02647-4