Abstract

Heat treatment improves the dimensional stability and hydrophobicity of wood, and heat-treated wood is currently attracting attention as a new interior material. However, there are few evaluations where the acoustic properties of heat-treated wood are reported when such wood is used as an interior material. In this study, Larix kaempferi wood, typically used as a building material, was heat-treated at 200, 220, and 240 °C for 9, 12, 15, and 18 h. The sound absorption coefficients of the treated wood samples were measured at 250, 500, 1000, 2000, and 4000 Hz in a reverberation room. The sound absorption coefficient increased with the treatment temperature and the treatment time. The results of this study showed that the high-frequency band range sound absorption coefficient of wood can be increased dramatically by heat treatment.

Similar content being viewed by others

Introduction

Wood has various colors and patterns, ease of processing, and high specific strength compared with other materials. Therefore, it has been used as an interior material since ancient times. Heat-treated wood, which is thermally modified at high temperatures, has increased hydrophobicity and improved dimensional stability [1]. Thus, heat-treated wood is attracting attention as a new interior material, and research on heat-treated wood is actively underway [2,3,4,5].

When heat-treated wood is used as an interior material, its sound absorption properties should be considered. Sound absorption, the process by which the energy of sound is reduced, shows a variety of mechanisms in accordance with the properties of the materials. The sound absorption coefficient is an indicator of the sound absorption. Various theories for evaluating the sound absorption coefficient have been studied [6,7,8,9,10]. However, these theories are too complex and can be applied to only limited samples. Thus, the empirical formulas obtained through a variety of experiments have been more useful [11,12,13,14,15]. The sound absorption coefficient of wood has been studied by many researchers [16,17,18,19,20], but there is limited research about the sound absorption coefficient of heat-treated wood. This study examined the sound absorption coefficient of heat-treated wood in accordance with treatment temperature and treatment time.

Materials and methods

Kiln-dried larch (Larix kaempferi) lumber (width 110 mm, thickness 30 mm, and length 2600 mm) was harvested from SK forest (Hwasun, Republic of Korea). The specimens for evaluating the sound absorption coefficient were made by attaching five heat-treated boards (width 105 mm, thickness 10 mm, and length 500 mm) in the width direction and the final size of specimens was 525 mm in width, 10 mm in thickness, and 500 mm length. The number of specimens was 13, depending on the number of heat treatment conditions.

Heat treatment equipment

The heat treatment equipment was designed and constructed (Fig. 1). The equipment consisted of a reactor (Hanwoul Engineering, Gunpo, Republic of Korea), a feed tank, a condenser, and a vacuum pump. The reactor was 640 mm in diameter, and 2200 mm in length. The capacity of the reactor was 0.7 m3, and the mantle-type heater was surrounding the reactor so that heat could be applied to the reactor. Additionally, insulating the outer surface of the reactor with glass wool minimized the heat loss to the outside. Sensors that could measure the temperature in the reactor and the temperature of the wood were attached to the reactor. The changes of temperature were measured in real time, and a computer saved these measured values. The temperature in the reactor was controlled by a computer program.

Wood heat treatment

The air heat treatment was performed with wood heat-treatment equipment. The kiln-dried larch (L. kaempferi) lumber was heat-treated in atmospheric pressure air at 200, 220, and 240 °C for 9, 12, 15, and 18 h. The initial moisture content (MC) of all the dried lumber was approximately 10–12%. Carbonization of specimen did not occur during heat treatment.

Sound absorption coefficient evaluation

To evaluate the sound absorption coefficient change in accordance with the heat treatment temperature and time, the sound absorption coefficients of specimens made with heat-treated panels were measured. Additionally, for comparison with the heat-treated specimens, the sound absorption coefficients of the specimens made with kiln-dried panels were measured.

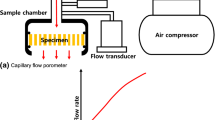

The sound absorption coefficients of specimens were measured by the reverberation room method. The reverberation room was made of cement with the dimensions of a 0.5 m3 cube. The internal surface of the reverberation room was covered with sound insulation material and sound absorption material to minimize the influence of external noise. When measuring the sound absorption coefficients, the reverberation room and specimen were bound tightly to minimize the diffractions of sound waves.

The acoustic property analysis system (Fig. 2) was used to measure the sound absorption coefficients of specimens. The acoustic property analysis system consisted of a function generator (SFG 2110, GW INSTEK, Taipei, Taiwan), a microphone set (Type 46AE, Brüel and Kjær, Copenhagen, Denmark), a data collection device (Apollo Box, SINUS, Leipzig, Germany), and analysis software (Amadeus 2ch SLM/Multi Analyzer, SINUS, Leipzig, Germany).

To calculate the sound absorption coefficients of specimens, the reverberation time when the reverberation room was covered with a lid (τ 1) and the reverberation time when the reverberation room was covered with a specimen (τ 2) were measured (Fig. 3). The frequency band was set to 250, 500, 1000, 2000, and 4000 Hz.

By substituting τ 1 and τ 2 in Sabine’s reverberation time formula, the equivalent sound absorption area could be calculated according to Eqs. (1) and (2),

where A 1 is the equivalent sound absorption area when the reverberation room is covered with a lid (m2), A 2 is the equivalent sound absorption area when the reverberation room is covered with a specimen (m2), c is the sound velocity (m/s), V is the volume of the reverberation room (m3), and m is the power attenuation coefficient.

The sound velocity (c) and power attenuation coefficient (m) were calculated by Eqs. (3) and (4), respectively,

where T is the internal temperature of the reverberation room (°C), and α air is the attenuation coefficient by the air.

From the difference between A 1 and A 2, the equivalent sound absorption area of the specimens was calculated according to Eq. (5):

where A T is the equivalent sound absorption area of the specimen.

Additionally, the sound absorption coefficients of specimens could be calculated according to Eq. (6):

where α S is the sound absorption coefficient of a specimen, and S is the area of a specimen.

Results

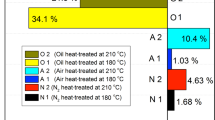

The measured sound absorption coefficients of each type of specimen are presented in Table 1. As shown in the table, the sound absorption coefficient increased with the treatment temperature and the treatment time. In particular, the increase rate of the sound absorption coefficient was dramatic in the high-frequency band range compared with the low-frequency band range. When the specimens that were heat-treated at 240 °C for 18 h and the control specimens were compared, the increase rate of the sound absorption coefficient was 16.67% at 250 Hz, 5.88% at 500 Hz, 41.67% at 1000 Hz, 191.67% at 2000 Hz, and 60.71% at 4000 Hz.

Discussion

The sound absorption coefficients of porous materials, such as wood, are proportional to the porosity and roughness of the internal pore wall. Researchers developed a theory for the propagation of stress waves in a porous elastic solid [7, 8]. The waves are propagated in two dilatational waves and one rotational wave when they propagate through the pore. In particular, in the low-frequency band range, the waves in porous materials are propagated in the form of Poiseuille flow. The Poiseuille flow is a pressure-induced channel flow in a long duct. It is distinguished from drag-induced flow, such as Couette flow. Friction between propagating wave and the internal pore wall critically influence the Poiseuille flow. Thus, in the low-frequency band range, the effect of the roughness of the internal pore wall is dominant because the sound wave propagates with the form of Poiseuille flow. In comparison, in the high-frequency band range, the effect of porosity is dominant because the form of Poiseuille flow is collapsed.

The increase of the sound absorption coefficient in a low-frequency band range is due to the increased roughness of the internal pore wall. During the heat treatment, as the components of wood (cellulose, hemicellulose, and lignin) were modified and relocated, the microstructure of the wood was changed, and the cell wall of the internal pores became rough (Fig. 4). However, it was determined that the heat treatment’s effect of increasing the roughness of the internal pore wall was slight because the increase rate of the sound absorption coefficient was low.

The increase of the sound absorption coefficient by heat treatment in the high-frequency band range is due to the increase of porosity. During heat treatment, the density of wood was reduced, and tylosoid and pit aspiration were removed. Additionally, due to the shrinkage of the cell wall, the intercellular layers were exposed. Thus, the porosity of the wood was increased (Fig. 5). Furthermore, the heat treatment’s effect of increasing porosity was great because the increase rate of the sound absorption coefficient was high.

Conclusion

-

1.

The sound absorption coefficient increased with the treatment temperature and the treatment time. The increased rate of the sound absorption coefficient was higher in the high-frequency band range than in the low-frequency band range.

-

2.

It was estimated that the increase of the sound absorption coefficient in the low-frequency band range was due to the increased roughness of the internal pore wall. In the high-frequency band range, it was due to the increased porosity of the wood.

-

3.

The effect of heat treatment on the sound absorption coefficients of L. kaempferi wood was analyzed, and the cause was determined. This study is expected to serve as a foundation for future research related to the acoustic properties of heat-treated wood.

References

Yoon K, Eom C, Park J, Kim H, Choi I, Lee J, Yeo H (2009) Color control and durability improvement of yellow poplar (Liriodendron tulipifera) by heat treatments. Mokchae Konghak 37(6):487–496

Militz H (2002) Heat treatment technologies in Europe: scientific background and technological state-of-art. In: Proceedings of conference on enhancing the durability of lumber and engineered wood products. Orlando, pp 11–13

Yildiz S, Yildiz C, Tomak D (2011) The effects of natural weathering on the properties of heat-treated alder wood. BioResour 6(3):2504–2521

Borůvka V, Zeidler A, Holeček T (2015) Comparison of stiffness and strength properties of untreated and heat-treated wood of Douglas fir and alder. BioResour 10(4):8281–8294

Wahyu H, Jang J, Park S, Qi Y, Febrianto F, Lee S, Kim N (2015) Effect of temperature and clamping during heat treatment on physical and mechanical properties of okan (Cylicodiscus gabunensis [Taub.] Harms) wood. BioResour 10(4):6961–6974

Zwikker C, Kosten W (1949) Sound absorbing materials. Elsevier, New York

Biot A (1956) Theory of elastic waves in a fluid saturated porous solid. I. Low-frequency range. J Acoust Soc Am 28(2):168–178

Biot A (1956) Theory of elastic waves in a fluid saturated porous solid. II. Higher frequency range. J Acoust Soc Am 28(2):179–191

Lambert F (1982) Propagation of sound in highly porous open-cell foams. J Acoust Soc Am 73(4):1131–1138

Allard F, Aknine A, Depollier C (1986) Acoustical properties of partially reticulated foams with high and medium flow resistance. J Acoust Soc Am 79(6):1734–1740

Delany E, Bazley N (1969) Acoustical characteristics of fibrous absorbent materials. Natl Phys Lab Aero Rep Ac 37:105–116

Miki Y (1990) Acoustical properties of porous materials-modification of Delany-Bazley model. J Acoust Soc Jpn 11(1):19–22

Allard F, Champoux Y (1992) New empirical equations for sound propagation in rigid frame fibrous materials. J Acoust Soc Am 91(6):3346–3353

Cummings A, Beadle P (1993) Acoustic properties of reticulated plastic foams. J Sound Vib 175(1):115–133

Wu Q (1988) Empirical relations between acoustical properties and flow resistivity of porous plastic open-cell foam. Appl Acoust 25:141–148

Obataya E, Umezawa T, Nakatsubo F, Norimoto M (1999) The effects of water soluble extractives on the acoustic properties of reed (Arundo donax L.). Holzforsch 53(1):63–67

Chang S, Chang H, Huang Y, Hsu F (2000) Effects of chemical modification reagents on acoustic properties of wood. Holzforsch 54(6):669–675

Jiang Z, Zhao R, Fei B (2004) Sound absorption property of wood for five eucalypt species. J Forest Res 15(3):207–210

Wang D, Peng L, Zhu G, Fu F, Zhou Y, Song B (2014) Improving the sound absorption capacity of wood by microwave treatment. BioResour 9(4):7504–7518

Zhu L, Liu Y, Liu Z (2016) Effect of high-temperature heat treatment on the acoustic-vibration performance of Picea jezoensis. BioResour 11(2):4921–4934

Acknowledgements

The authors are grateful for the Grant provided by the Korea Forest Service ‘Forest Science and Technology Projects (Project no. S121315L010100)’.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Chung, H., Park, Y., Yang, SY. et al. Effect of heat treatment temperature and time on sound absorption coefficient of Larix kaempferi wood. J Wood Sci 63, 575–579 (2017). https://doi.org/10.1007/s10086-017-1662-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-017-1662-z