Abstract

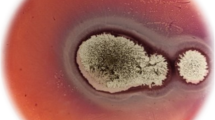

Use of 4 agro-industrial by products and organic materials as nitrogen sources for production of Aspergillus oryzae S2 α-amylase in liquid culture was investigated. The 2 agro-industrial byproducts maltose and saccharose, and also lactose and starch were individually evaluated for use as carbon sources. A Box-Behnken experimental design was used to determine optimal conditions for production of α-amylase. A maximum amylase activity of 750 U/mL was obtained at a temperature of 24°C, a urea concentration of 1 g/L, and a C/N ratio of 2. Laboratory scale application of optimal conditions in a 7 L fermentor produced a final α-amylase activity of 770 U/mL after 3 days of batch cultivation. Addition of 10% starch to the culture medium each 12 h immediately after the stationary phase of cell growth led to a production yield of 1,220 U/mL at the end of fed-batch cultivation.

Similar content being viewed by others

References

Goesaert H, Slade L, Levine H, Delcour JA. Amylases and bread firming-An integrated view. J. Cereal Sci. 50: 345–352 (2009)

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B. Microbial α-amylases: A biotechnological perspective. Process Biochem. 38: 1599–1616 (2003)

Chang PK, Ehrlich KC. What does genetic diversity of Aspergillus flavus tell us about Aspergillus oryzae. Int. J. Food Microbiol. 138: 189–199 (2010)

Gangadharan D, Sivaramakrishnan S, Nampoothiri KM, Sukumaran RK, Pandey A. Response surface methodology for the optimization of alphaamylase production by Bacillus amyloliquefaciens. Bioresource Technol. 99: 4597–4602 (2008)

Ravindar DJ, Elangovan N. Molecular identification of amylase producing Bacillus subtilis and detection of optimal conditions. J. Pharm. Res. 6: 426–430 (2013)

Hashemi M, Razavi SH, Shojaosadati SA, Mousavi SM. The potential of brewer’s spent grain to improve the production of alpha-amylase by Bacillus sp. KR-8104 in submerged fermentation system. New Biotechnol. 28: 165–172 (2011)

Haq IU, Hamad A, Qadeer MA, Iqbal J. Pearl millet, a source of alpha-amylase production by Bacillus licheniformis. Bioresource Technol. 96: 1201–1204 (2005)

Bennamoun L, Meraihi Z, Dakhmouche S. Use of experimental planning to optimize production of alpha amylase by Aspergillus oryzae Ahlburg (Cohen) 1042.72 cultivated on a basal medium make from orange waste. J. Food Eng. 64: 257–264 (2004)

Hashemi M, Mousavi SM, Razavi SH, Shojaosadati SA. Comparison of submerged and solid state fermentation systems effects on the catalytic activity of Bacillus sp KR-8104 α-amylase at different pH and temperatures. Ind. Crop Prod. 43: 661–667 (2013)

Pedersen H, Nielsen J. The influence of nitrogen sources on the alpha-amylase productivity of Aspergillus oryzae in continuous cultures. Appl. Microbiol. Biotech. 53: 278–281 (2000)

Kalishwaralal K, Gopalram S, Vaidyanathan R, Deepak V, Pandian SR, Gurunathan S. Optimization of α-amylase production for the green synthesis of gold nanoparticles. Colloid. Surface. 77: 174–180 (2010)

Spohr A, Carlsen M, Nielsen J, Villadsen J. α-Amylase production in recombinant Aspergillus oryzae during fed-batch and continuous cultivations. J. Ferment. Bioeng. 86: 49–56 (1998)

Imai Y, Suzuki M, Masamoto M, Nagayasu K. Amylase production by Aspergillus oryzae in a new kind of fermentor with a rotary draft tube. J. Ferment. Bioeng. 76: 459–464 (1993)

Aguilar G, Morlon-Guyot J, Trejo-Aguilar B, Guyot JP. Purification and characterization of an extracellular alpha-amylase produced by Lactobacillus manihotivorans LMG 1801 (T), an amylolytic lactic acid bacterium. Enzyme Microb. Tech. 27: 406–413 (2000)

Sahnoun M, Bejar S, Sayari A, Triki MA, Kriaa M, Kammoun R. Production purification and characterization of two α-amylase isoforms from a newly isolated Aspergillus oryzae strain S2. Process Biochem. 47: 18–25 (2011)

Kammoun R, Naili B, Bejar S. Application of a statistical design to the optimization of parameters and culture medium for α-amylase production by Aspergillus oryzae CBS 81972 grown on gruel (wheat grinding by-product). Bioresource Technol. 99: 1–8 (2008)

AACC. International Approved Methods of AACC. 10th ed. Methods 46-10A. American Association of Cereal Chemists, St. Paul, MN, USA (2000)

AOAC. Official Method of Analysis of AOAC Intl. 18th ed. Method 920.39. Association of Official Analytical Chemists, Gaithersburg, MD, USA (2005)

Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31: 426–428 (1959)

Sasaki H, Kurosawa K, Takao S. Screening of Microorganisms for raw starch saccharifying enzyme production. Agr. Biol. Chem. Toky. 50: 1661–1664 (1986)

Tanyildizi MS, Ozer D, Elibol M. Production of bacterial α-amylase by B amyloliquefaciens under solid substrate fermentation. Biochem. Eng. J. 37: 294–297 (2007)

Hashemi M, Razavi SH, Shojaosadati SA, Mousavi SM, Khajeh K, Safari M. Development of a solid-state fermentation process for production of an alpha-amylase with potentially interesting properties. J. Biosci. Bioeng. 110: 333–337 (2010)

Mørkeberg R, Carlsen MJ. Nielsen Induction and repression of amylase production in batch and continuous cultures of Aspergillus oryzae. Microbiolog. 141: 2449–2454 (1995)

Bhella RS, Altosaar I. Purification and some properties of the extracellular alpha-amylase from Aspergillus awamori. Can. J. Microbiol. 31: 149–153 (1985)

Møller K, Sharif MZ, Olsson L. Production of fungal α-amylase by Saccharomyces kluyveri in glucose-limited cultivations. J. Biotechnol. 111: 311–318 (2004)

Jin B, van Leeuwen HJ, Patel B, Yu Q. Utilisation of starch processing wastewater for production of microbial biomass protein and fungal α-amylase by Aspergillus oryzae. Bioresource Technol. 66: 201–206 (1998)

Hernandez MS, Rodrýguez MR, Guerra NP, Roses RP. Amylase production by Aspergillus niger in submerged cultivation on two wastes from food industries. J. Food Eng. 73: 93–100 (2006)

Sahnoun M, Naili B, Elgharbi F, Kammoun R, Gabsi K, Bejar S. Effect of Aspergillus oryzae CBS 81972 α-amylase on rheological dough properties and bread quality. Biologi. 68: 808–815 (2013)

Szijártó N, Faigl Z, Réczey K, Mézes M, Bersényi A. Cellulase fermentation on a novel substrate (waste cardboard) and subsequent utilization of homeproduced cellulase and commercial amylase in a rabbit feeding trial. Ind. Crop. Prod. 20: 49–57 (2004)

Kole MM, Gerson DF. Ammonium controlled fed-batch fermentation for amylase production. J. Ferment. Bioeng. 68: 423–427 (1989)

Nedovic V, Willaert R. Fundamentals of Cell Immobilisation Biotechnology. Springer, Berlin, Germany. pp. 60–75 (2004)

Choi DB, Park EY. Enhanced production of mouse α-amylase by feeding combined nitrogen and carbon sources in fed-batch culture of recombinant Pichia pastoris. Process Biochem. 41: 390–397 (2006)

Shiina S, Ohshima T, Sato M. Extracellular production of -amylase during fedbatch cultivation of recombinant Escherichia coli using pulsed electric field. J. Electrostat. 65: 30–36 (2007)

Schwab K, Johannes B, Brokamp C, Popoviæ MK, Bajpai R, Beroviè M. Dual feeding strategy for the production of α-amylase by Bacillus caldolyticus using complex media. New Biotechnol. 26: 68–74 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naili, B., Sahnoun, M., Bejar, S. et al. Optimization of submerged Aspergillus oryzae S2 α-amylase production. Food Sci Biotechnol 25, 185–192 (2016). https://doi.org/10.1007/s10068-016-0028-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-016-0028-4