Abstract

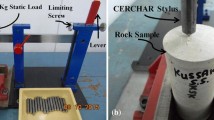

The rolling indentation abrasion test (RIAT) is a recently developed method for measuring rock abrasivity. In this study, RIAT tests were performed on 17 plutonic rock samples and the weight lost by the mini-disc cutter (mg) after testing (RIATa), the mean value of 10 evenly distributed measurements of the cutter penetration depth into the rock in 1/100 mm (RIATi), abrasion-penetration rate (APR), and penetration-time rate (PTR) values were determined for the samples. The Cerchar abrasivity index (CAI), LCPC abrasivity index (LAC), and equivalent quartz content (EQC%) values were determined for the samples. The relationship of APR and PTR to CAI, LAC, and EQC% was investigated using regression analysis, and the Fisher test and empirical equations between APR-EQC%, PTR-EQC%, APR-PTR, PTR-CAI, APR-LAC, and PTR-LAC are proposed. The proposed equations were validated on three control samples and were found to be valid for plutonic rock. The RIAT test was used at different rotations speeds to determine their effect on the samples, and an optimal rotation speed has been proposed for each sample using the APR parameter. Comparison of the current results and those of previous research on sandstone showed that the trends of PTR-EQC%, APR-PTR, and PTR-CAI were similar. An experimental relationship has been proposed for these types of rock for APR-EQC%. For hard and highly abrasive samples, the trends for PTR-EQC%, APR-PTR, and PTR-CAI were similar for plutonic rock and sandstone, but for medium-to-high abrasivity samples, the penetration rate of plutonic rock was less than for sandstone in terms of abrasivity.

Similar content being viewed by others

Change history

08 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10064-021-02356-6

Abbreviations

- RIAT:

-

Rolling indentation abrasion test

- RIATa:

-

Weight lost by the mini-disc cutter (mg) after RIAT test

- RIATi:

-

Mean value of 10 evenly distributed measurements of the cutter penetration depth into the rock in1/100 mm after RIAT test

- APR:

-

Abrasion-penetration rate

- PTR:

-

Penetration-time rate

- CAI:

-

Cerchar abrasivity index

- LAC:

-

LCPC abrasivity index

- EQC%:

-

Equivalent quartz content

- UCS:

-

Uniaxial compressive strength

- VHN:

-

Vicker’s hardness number

- NTNU:

-

Norwegian University of Science and Technology model

- TBM:

-

Tunnel boring machine

- IDT:

-

Indirect tensile strength

- AVS:

-

Abrasion value cutter steel

- AV:

-

Abrasion value

- SJ:

-

Sievers’ J-miniature

- S20:

-

Brittleness tests

- CLI:

-

Cutter-life index

- BWI:

-

Bit-wear index

- RSAI:

-

Rock and soil abrasivity index

References

Abu Bakar MA, Majeed Y, Rostami J (2016) Effects of rock water content on CERCHAR Abrasivity Index. Wear 368:132–145. https://doi.org/10.1016/j.wear.2016.09.007

AFNOR Association française de normalization (1990) AFNOR NF P18–579 : Granulats: Essai d’abrasivité et de broyabilité, Paris

AFNOR Association française de normalization (2000) AFNOR NF P94–430–1: Détermination du povoir abrasive d’une roche – Partie 1: Essai de rayure avec une pointe. (NF P 94–430 1), Paris

Altindag R, Sengun N, Sarac S, Mutluturk M, Guney A (2010) Evaluating the relations between brittleness and Cerchar abrasion index of rocks. In: Proceeding of the regional symposium of the international society for rock mechanics. EUROCK 2009

American Society for Testing and Materials (2010) ASTM D 7625–10: Standard test method for laboratory determination of abrasiveness of rock using the CERCHAR method. Designation

Aydın H (2019) Investigating the effects of various testing parameters on Cerchar abrasivity index and its repeatability. Wear 418:61–74. https://doi.org/10.1016/j.wear.2018.11.001

Bharti S, Deb D, Das P (2017) Abrasivity investigation by physic-mechanical parameters and microscopic analysis of rock samples. Int. Conf. on Deep Excavation, Energy Resources and Production. 24–26 January 2017, IIT Kharagpur, India DEEP16

Bieniawski ZT, Celada CB, Galera JM, Tardaguila IG (2009) Prediction of cutter wear using RME. ITA-AITES World Tunnel Congress. Budapest, Hungary

Bruland A (1998) Hard Rock Tunnel Boring. NTNU, Trondheim, Norway.8of 10, 22

Büchi E, Mathier JF, Wyss CH (1995) Gesteinsabrasivitat – ein bedeutender Kostenfaktor beim mechanischen Abbau von Fest- und Lockergestein. Tunnel 5:38–43

Capik M, Yilmaz AO (2017) Correlation between Cerchar abrasivity index, rock properties, and drill bit lifetime. Arab J Geosci 10(1):1–12. https://doi.org/10.1007/s12517-016-2798-7

Cheshomi A, Moradhaseli S (2017) Effect of petrographic characteristics on abrasive properties of granitic building stones. Q J Eng Geol Hydrogeol 50:347–353. https://doi.org/10.1144/qjegh2016-048

Cheshomi A, Mooradizadeh M, Fizollahi S (2020) Impact of petrography and hardness of sandstone minerals on the wear of mini disk cutters through rolling indentation abrasion test (RIAT). Rock Mech Rock Eng 53(3–4). https://doi.org/10.1007/s00603-020-02229-6

Dahl F, Grøv E, Breivik E (2007) Development of a new direct test method for estimating cutter life based on the Sievers’ J miniature drill test. Tunn Undergr Space Technol 22(1):106–116. https://doi.org/10.1016/j.tust.2006.03.001

Dahl F, Bruland A, Jakobsen P, Nilsen B, Gro E (2012) Classification of properties influencing the drillability of rocks, based on the NTNU/SINTEF test method. Tunn Undergr Space Technol 28:150–158. https://doi.org/10.1016/j.tust.2011.10.006Get

De Bono J, Li H, McDowell G (2020) A new abrasive wear model for railway ballast. Soils Found 60:714–721. https://doi.org/10.1016/j.sandf.2020.05.001

Deliormanlı AH (2012) Cerchar abrasivity index (CAI) and its relation to strength and abrasion test methods for marble stones. Constr Build Mater 30:16–21. https://doi.org/10.1016/j.conbuildmat.2011.11.023

Erarslan N, Ghamgosar M (2015) Viability assessment of cerchar abrasivity test for the anisotropic Brisbane rocks. 13th International Congress of Rock Mechanics. 10–13 May 2015, Montreal, Canada

Frenzel C (2011) Disc Cutter Wear Phenomenology and Their Implications on Disc Cutter Consumption for TBM. Proceedings of 45th US Rock Mechanics/Geomechanics Symposium. San Francisco. 26–29 June 2011, 1–7

Gehring K (1995) Prognosis of advance rates and wear for underground mechanized excavations (in German). Felsbau 13(9):439–448

Golovanevskiy VA, Bearman RA (2008) Gouging abrasion test for rock abrasiveness testing. Int J Miner Process 85:111–120. https://doi.org/10.1016/j.minpro.2007.08.004

Hamzaban MT, Hosseini Tavana N, Jakobsen PD (2019) The effect of the plastic behavior of clay particles on LCPC abrasive coefficient. Tunn Undergr Space Technol 92:15. https://doi.org/10.1016/j.tust.2019.103054

Hashemnejad H, Ghafoori M, Lashkaripour GR, Tarigh Azali S (2012) Effect of geological parameters on soil abrasivity using LCPC machine for predicting LAC. International Journal of Emerging Technology and Advanced Engineering 2:71–76

Hashemnejad H, Ghafoori M, Tarigh Azali S (2016) Utilizing water, mineralogy and sedimentary properties to predict LCPC abrasivity coefficient. Bull Eng Geol Environ 75:841–851. https://doi.org/10.1007/s10064-015-0779-9

Hassanpour J, Rostami J, Tarigh Azali S, Zhao J (2014) Introduction of an empirical TBM cutter wear prediction model for pyroclastic and mafic igneous rocks; a case history of Karaj water conveyance tunnel. Iran Tunnelling and Underground Space Technology 43:222–231. https://doi.org/10.1016/j.tust.2014.05.007

He J, Li S, Li X, Wang X, Guo J (2016) Study on the correlations between abrasiveness and mechanical properties of rocks combining with the microstructure characteristic. Rock Mech Rock Eng 49(7):2945–2951. https://doi.org/10.1007/s00603-015-0862-3

ISRM International Society for Rock Mechanics (1979) Suggested methods for determining water content, porosity, density, absorption and related properties and swelling and slake-durability index properties. 143–151

Kahraman S, Alber M, Fener M, Gunaydin O (2010) The usability of Cerchar Abrasivity index for the prediction of UCS and E of misis Fault Berccia: regression and artificial neural networks analysis. Expert Syst 37:8750–8756. https://doi.org/10.1016/j.eswa.2010.06.039

Kahraman S, Fener M, Käsling H, Thuro K (2016) The influences of textural parameters of grains on the LCPC abrasivity of coarse-grained igneous rocks. Tunn Undergr Space Technol 58:216–223. https://doi.org/10.1016/j.tust.2016.05.011

Kasling H, Thuro K (2010) Determining abrasivity of rock and soil in the laboratory. Geologically active. Taylor & Francis Group, London, 1973- 1980. ISBN 978–0–415–60034–7

Kasyap SS, Li S, Senetakis K (2021) Investigation of the mechanical properties and the influence of micro-structural characteristics of aggregates using micro-indentation and Weibull analysis. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.121509

Ko TY, Kim TK, Son Y, Jeon S (2016) Effect of geomechanical properties on Cerchar abrasivity index (CAI) and its application to TBM tunneling. Tunn Undergr Space Technol 57:99–111. https://doi.org/10.1016/j.tust.2016.02.006

Kohler M, Maidl U, Martak L (2011) Abrasiveness and tool wear in shield tunneling in soil. Geomechanic and Tunnelling 10:36–53. https://doi.org/10.1002/geot.201100002

Labas M, Krepelka F, Ivavicova L (2012) Assessment of abrasiveness for research of rock cutting. Acta Montan Slovaca 17:65–73

Larrea M, Martig S, Castro, S, Aliani P, Bjerg EA (2010) Rock. AR–A point counting application for petrographic thin sections. In 26th Spring Conference on Computer Graphics. Budmerice, Slovakia. 13–15

Lassnig K, Latal C, Klima K (2008) Impact of grain size on the Cerchar abrasiveness test. Geomechanik Und Tunnelbau 1(1):71–76. https://doi.org/10.1002/geot.200800008

Lislerud A (1997) Principles of mechanical excavation, Possiva report 97–12. Helsinki, Finland. ISBN 951–652–037–5

Macias FJ, Dahl F, Bruland A (2015) New rock abrasivity test method for tool life assessments on hard rock tunnel boring: The Rolling Indentation Abrasion Test (RIAT). Rock Mech Rock Eng 49:1679–1693. https://doi.org/10.1007/s00603-015-0854-3

Macias FJ, Dahl, F, Bruland A (2017) Applicability of the new rock abrasivity test method (RIAT) to cutter life assessments in hard rock tunnel boring. Proceedings of the World Tunnel Congress 2017. Surface challenges. Underground solutions. Bergen, Norway. 1–10

Maidl B, Schmid L, Ritz W, Herrenknecht M (2008) Hardrock tunnel boring machines, Ernst and Sone. A Wiley Company, Berlin. ISBN 978–3–433–01676–3

Majeed Y, Abu Bakar MA (2016) Statistical evaluation of CERCHAR Abrasivity Index (CAI) measurement methods and dependence on petrographic and mechanical properties of selected rocks of Pakistan. Bull Eng Geol Env 75(3):1341–1360. https://doi.org/10.1007/s10064-015-0799-5

Majeed Y, Abu Bakar MZ, Butt IA (2019) Abrasivity evaluation for wear prediction of button drill bits using geotechnical rock properties. Bull Eng Geol Env 79:767–787. https://doi.org/10.1007/s10064-019-01587-y

Mathier JF, Gisiger JP (2003) Abrasivity of Icelandic basalts. Proceeding of ISRM Technology Road Map for Rock Mechanics :809–811

McDowell GR, Lim WL, Collop AC, Armitage RN, Thom H (2005) Laboratory simulation of train loading and tamping on ballast. Proc Inst Civ Eng Transport 158(2):89–95. https://doi.org/10.1680/tran.2005.158.2.89

Moradizadeh M, Cheshomi A, Ghafoori M, TarighAzali S (2016) Correlation of equivalent quartz content, slak durability index and Is50 with Cerchar abrasiveness index for different types of rock. Int J Rock Mech Min Sci 86:42–47. https://doi.org/10.1016/j.ijrmms.2016.04.003

Mosleh M, Hu W, Rostami J (2019) Introduction to rock and soil abrasivity index (RSAI). Wear 432–433:10. https://doi.org/10.1016/j.wear.2019.202953

Piazzetta GR, Lagoeiro LE, Figueira IFR, Rabelo MAG, Pintaude G (2018) Identification of abrasion regimes based on mechanisms of wear on the steel stylus used in the Cerchar abrasiveness test. Wear 410:181–189. https://doi.org/10.1016/j.wear.2018.07.009

Plinninger RJ, Restner U (2008) Abrasiveness testing Quo vadis, a commentes over view of abrasiveness testing methods. GeoMechanic Und Tunnelbau 1:61–70. https://doi.org/10.1002/geot.200800007

Thuro K, Singer J, Kasling H, Bauer M (2007) Soil abrasivity assessment using the LCPC testing device. Proceedings of the 1st Canada–U.S. Rock Mechanics Symposium, Vancouver B.C

Thuro K, Singer J, Kasling H, Bauer M (2009) Determining abrasivity with LCPC test. Geomechanik und Tunnelbau:179–188

Torrijo FJ, Garzón-Roca J, Cobos G (2018) Estimation of Cerchar abrasivity index of andesitic rocks in Ecuador from chemical compounds and petrographical properties using regression analyses. Bull Eng Geol Environ 78(4):2331–2344. https://doi.org/10.1007/s10064-018-1306-6

Zhang G, Konietzky H, Fruhwirt T (2020a) Investigation of scratching specific energy in the Cerchar abrasivity test and its application for evaluating rock-tool interaction and efficiency of rock cutting. Wear 448–449:10. https://doi.org/10.1016/j.wear.2020.203218

Zhang G, Konietzky H, Song Z, Zhang M (2020b) Study of Cerchar abrasive parameters and their relations to intrinsic properties of rocks for construction. Constr Build Mater 448–449:15. https://doi.org/10.1016/j.conbuildmat.2020.118327

Author information

Authors and Affiliations

Corresponding author

Additional information

The original online version of this article was revised: The authors would like to correct Equation 11 which was written wrongly. This has been corrected.

Rights and permissions

About this article

Cite this article

Moradizadeh, M., Cheshomi, A. Results of Cerchar, LCPC, and equivalent quartz content from rolling indentation abrasion testing in plutonic rock. Bull Eng Geol Environ 80, 5979–6002 (2021). https://doi.org/10.1007/s10064-021-02335-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02335-x