Abstract

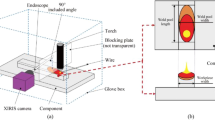

The optical three-dimensional (3D) measurement technique based on the laser stripe has become increasingly important in additive manufacturing, which is necessary to extract the laser stripe accurately. In welding, the wrong laser stripe centers due to the high-brightness noise are usually extracted, which causes serious measurement error. In this paper, a laser stripe extraction algorithm based on spatiotemporal noise regularization (SNR) is proposed, which calculates the noise weight of each pixel in time dimension and suppresses the high-brightness noise in space dimension. The proposed algorithm contains four novel steps to achieve accurate and fast laser stripe extraction when the laser stripe is influenced by the high-brightness noise. Meanwhile, an online welding 3D measurement system is constructed based on double-line structured light, which can achieve online 3D measurement in additive manufacturing. Experimental analysis verifies its effectiveness and accurateness.

Similar content being viewed by others

References

Wu, Q.Q., Lee, J.P., Park, M.H., et al.: A study on the modified Hough algorithm for image processing in weld seam tracking[J]. J. Mech. Sci. Technol. 29(11), 4859–4865 (2015)

Chen, H., Liu, W., Huang, L., et al.: The decoupling visual feature extraction of dynamic three-dimensional V-type seam for gantry welding robot[J]. Int. J. Adv. Manuf. Technol. 80(9–12), 1741–1749 (2015)

He, Y., Chen, Y., Xu, Y., et al.: Autonomous detection of weld seam profiles via a model of saliency-based visual attention for robotic arc welding[J]. J. Intell. Rob. Syst. 81(3–4), 395–406 (2016)

Wang, Z., Zhang, Y.M., Yang, R.: Analytical reconstruction of three-dimensional weld pool surface in GTAW[J]. J. Manuf. Processes. 15(1), 34–40 (2013)

Gong, Z., Sun, J., Zhang, G.: Dynamic structured-light measurement for wheel diameter based on the cycloid constraint[J]. Appl. Opt. 55(1), 198–207 (2016)

Fathi, H., Dai, F., Lourakis, M.: Automated as-built 3D reconstruction of civil infrastructure using computer vision: achievements, opportunities, and challenges[J]. Adv. Eng. Inform. 29(2), 149–161 (2015)

Yin, X.Q., Tao, W., Feng, Y.Y., et al.: Laser stripe extraction method in industrial environments utilizing self-adaptive convolution technique[J]. Appl. Opt. 56(10), 2653–2660 (2017)

El-Omari, S., Moselhi, O.: Integrating 3D laser scanning and photogrammetry for progress measurement of construction work[J]. Automat. Constr. 18(1), 1–9 (2008)

Zuo, C., Chen, Q., Qu, W., et al.: High-speed transport-of-intensity phase microscopy with an electrically tunable lens[J]. Opt. Express. 21(20), 24060–24075 (2013)

Hu, Y., Chen, Q., Tao, T., et al.: Absolute three-dimensional micro surface profile measurement based on a greenough-type stereomicroscope[J]. Meas. Sci. Technol. 28(4), 045004 (2017)

Ma, L., Li, J., Ma, J., et al. A modified census transform based on the neighborhood information for stereo matching algorithm[C]//2013 seventh international conference on image and graphics. IEEE 533–538 (2013)

Zuo, C., Feng, S., Huang, L., et al.: Phase shifting algorithms for fringe projection profilometry: a review[J]. Opt. Lasers. Eng. 109, 23–59 (2018)

Feng, S., Zhang, L., Zuo, C., et al.: High dynamic range 3d measurements with fringe projection profilometry: a review[J]. Meas. Sci. Technol. 29(12), 122001 (2018)

Lee, T.C., Kashyap, R.L., Chu, C.N.: Building skeleton models via 3-D medial surface axis thinning algorithms[J]. CVGIP. Graph. Mod. Image. Process. 56(6), 462–478 (1994)

Cornea, N.D., Silver, D., Yuan, X., et al.: Computing hierarchical curve-skeletons of 3D objects[J]. Vis. Comp. 21(11), 945–955 (2005)

Brandt, J.W., Algazi, V.R.: Continuous skeleton computation by Voronoi diagram[J]. CVGIP. Image. Underst. 55(3), 329–338 (1992)

Zhihua, L., Zhang, Z.: Build 3D scanner system based on binocular stereo vision [J]. J. Comp. 7, 2 (2012)

Du J, Xiong W, Chen W, et al. Robust laser stripe extraction using ridge segmentation and region ranking for 3D reconstruction of reflective and uneven surface[C]//2015 IEEE international conference on image processing (ICIP). IEEE 4912–4916 (2015)

Zhang L, Lin J, Sun J, et al. A robust stripe segmentation method for 3D measurement of structured light[C]//2015 IEEE international conference on mechatronics and automation (ICMA). IEEE 2431–2436 (2015)

Li C, Ye X, Gong Y, et al. A center-line extraction algorithm of laser stripes based on multi-Gaussian signals fitting[C]//2016 IEEE international conference on information and automation (ICIA). IEEE 189–194 (2016)

Steger, C.: Unbiased extraction of lines with parabolic and Gaussian profiles[J]. Comput. Vis. Image. Underst. 117(2), 97–112 (2013)

Steger, C.: An unbiased detector of curvilinear structures[J]. IEEE. Trans. Pattern. Anal. Mach. Intell. 20(2), 113–125 (1998)

Li, X., Li, X., Ge, S.S., et al.: Automatic welding seam tracking and identification[J]. IEEE. Trans. Industr. Electron. 64(9), 7261–7271 (2017)

Li, Y., Li, Y.F., Wang, Q.L., et al.: Measurement and defect detection of the weld bead based on online vision inspection[J]. IEEE. Trans. Instrum. Meas. 59(7), 1841–1849 (2009)

Pang, J., Hu, S., Shen, J., et al.: Arc characteristics and metal transfer behavior of CMT+ P welding process[J]. J. Mater. Process. Technol. 238, 212–217 (2016)

Ye, G., Guo, J., Sun, Z., et al.: Weld bead recognition using laser vision with model-based classification[J]. Robot. Comp. Integ. Manuf. 52, 9–16 (2018)

Fan, J., Deng, S., Jing, F., et al.: An initial point alignment and seam-tracking system for narrow weld[J]. IEEE. Trans. Industr. Inf. 16(2), 877–886 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant number 61727802.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, H., Peng, C., Zhao, Z. et al. Laser stripe extraction in additive manufacturing based on spatiotemporal noise regularization. Opt Rev 27, 521–529 (2020). https://doi.org/10.1007/s10043-020-00623-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10043-020-00623-7