Abstract

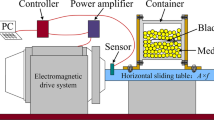

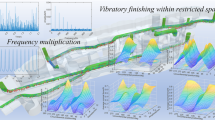

To explore the characteristics of the flow field and the movement of granular media in horizontal vibration, the motion behavior of granular media was studied based on the horizontal vibratory finishing blade process. The evolution of the fluidization process of granular media under different frequencies and amplitudes was analyzed. The relationship between granular media's long-term and short-term movements and their effects was clarified. And the results were verified by PIV technology. The results show that increasing the frequency and amplitude can improve the fluidization degree of the particle system. Moreover, increasing the amplitude is more effective than frequency. Due to the blade's obstruction, the flow field's characteristic is an asymmetric double rolls. Granular media's macro-movement is divided into long-term and short-term motion based on particles' movement characteristics. The short-term motion of granular media mainly realizes the polishing and finishing of the blade, while the long-term motion realizes the renewal and replacement of granular media. The long-term and short-term movements are positively correlated. This study provides a reference for selecting process parameters and regulating particle flow fields in horizontal vibration.

Graphical abstract

Similar content being viewed by others

References

Ahluwalia, K., Mediratta, R., Yeo, S.H.: A novel approach to vibratory finishing: double vibro-polishing. Mater. Manuf. Process. 32, 998–1003 (2017). https://doi.org/10.1080/10426914.2016.1232812

Shi, H., Liu, D., Pan, Y., Zhao, W., Zhang, X., Ma, A., Liu, B., Hu, Y., Wang, W.: Effect of shot peening and vibration finishing on the fatigue behavior of TC17 titanium alloy at room and high temperature. Int. J. Fatigue. 151, 106391 (2021). https://doi.org/10.1016/j.ijfatigue.2021.106391

Fleischhauer, E., Azimi, F., Tkacik, P., Keanini, R., Mullany, B.: Application of particle image velocimetry (PIV) to vibrational finishing. J. Mater. Process. Technol. 229, 322–328 (2016). https://doi.org/10.1016/j.jmatprotec.2015.09.017

Zhang, G., An, X., Zhao, B., Qian, Q., Zhao, H.: Discrete element method dynamic simulation of icosahedral particle packing under three-dimensional mechanical vibration. Particuology. 44, 117–125 (2019). https://doi.org/10.1016/j.partic.2018.03.004

da Silva Maciel, L., Spelt, J.K.: Comparison of DEM predictions and measured wall-media contact forces and work in a vibratory finisher. Powder Technol. 366, 434–447 (2020). https://doi.org/10.1016/j.powtec.2020.02.014

Kang, Y.S., Hashimoto, F., Johnson, S.P., Rhodes, J.P.: Discrete element modeling of 3D media motion in vibratory finishing process. CIRP Ann. 66, 313–316 (2017). https://doi.org/10.1016/j.cirp.2017.04.092

Hao, Y., Yang, S., Li, X., Li, W., Wang, X.: Analysis of contact force characteristics of vibratory finishing within pipe-cavity. Granul. Matter. 23, 32 (2021). https://doi.org/10.1007/s10035-021-01089-3

Li, X., Li, W., Yang, S., Hao, Z., Shi, H.: Study on polyurethane media for mass finishing process: dynamic characteristics and performance. Int. J. Mech. Sci. 138–139, 250–261 (2018). https://doi.org/10.1016/j.ijmecsci.2018.02.017

Li, W., Zhang, L., Li, X., Yang, S., Wu, F.: Theoretical and simulation analysis of abrasive particles in centrifugal barrel finishing: Kinematics mechanism and distribution characteristics. Powder Technol. 318, 518–527 (2017). https://doi.org/10.1016/j.powtec.2017.06.033

Hashemnia, K., Pourandi, S.: Study the effect of vibration frequency and amplitude on the quality of fluidization of a vibrated granular flow using discrete element method. Powder Technol. 327, 335–345 (2018). https://doi.org/10.1016/j.powtec.2017.12.097

Wang, C., Li, X., Li, W., Wang, N., Yang, S.: Analaysis on numerical simulation and mechanism of medium flow field in spindle barrel finishing process. Surf. Technol. 47, 251–258 (2018). https://doi.org/10.16490/j.cnki.issn.1001-3660.2018.11.036

Götzendorfer, A., Tai, C., Kruelle, C., Rehberg, I., Hsiau, S.: Fluidization of a vertically vibrated two-dimensional hard sphere packing: A granular meltdown. Phys. Rev. E 74, 011304 (2006). https://doi.org/10.1103/PhysRevE.74.011304

Li, L., Wu, P., Abdul, R., Wang, L., Zhang, S., Xie, Z.-A.: Energy-dissipation correlated size separation of granular matter under coupling vibration and airflow. Powder Technol. 307, 84–89 (2017). https://doi.org/10.1016/j.powtec.2016.11.022

Raihane, A., Bonnefoy, O., Gelet, J.-L., Chaix, J.-M., Thomas, G.: Experimental study of a 3D dry granular medium submitted to horizontal shaking. Powder Technol. 190, 252–257 (2009). https://doi.org/10.1016/j.powtec.2008.04.068

Gallas, J.A.C., Herrmann, H.J., Sokołowski, S.: Convection cells in vibrating granular media. Phys. Rev. Lett. 69, 1371–1374 (1992). https://doi.org/10.1103/PhysRevLett.69.1371

Pak, H.K., Behringer, R.P.: Surface waves in vertically vibrated granular materials. Phys. Rev. Lett. 71, 1832–1835 (1993). https://doi.org/10.1103/PhysRevLett.71.1832

Zhang, F., Wang, L., Liu, C., Wu, P., Zhan, S.: Patterns of convective flow in a vertically vibrated granular bed. Phys. Lett. A. 378, 1303–1308 (2014). https://doi.org/10.1016/j.physleta.2014.03.001

Chen, B., Wu, P., Xing, H., Liu, H., Li, L., Wang, L.: Convection behavior of ellipsoidal particles in a quasi-two-dimensional bed under vertical vibration. Powder Technol. 363, 575–583 (2020). https://doi.org/10.1016/j.powtec.2020.01.004

Chung, Y.C., Hsiau, S.S., Liao, H.H., Ooi, J.Y.: An improved PTV technique to evaluate the velocity field of non-spherical particles. Powder Technol. 202, 151–161 (2010). https://doi.org/10.1016/j.powtec.2010.04.032

Hsiau, S.S., Chen, C.H.: Granular convection cells in a vertical shaker. Powder Technol. 111, 210–217 (2000). https://doi.org/10.1016/S0032-5910(99)00287-9

Hsiau, S.-S., Ou, M.-Y., Tai, C.-H.: The flow behavior of granular material due to horizontal shaking. Adv. Powder Technol. 13, 167–180 (2002). https://doi.org/10.1163/156855202760166523

Majid, M., Walzel, P.: Convection and segregation in vertically vibrated granular beds. Powder Technol. 192, 311–317 (2009). https://doi.org/10.1016/j.powtec.2009.01.012

Shi, H., Yang, S., Li, X., Li, W., Zhang, H.: Material removal mechanism of aluminium alloy in barrel finishing under grinding fluid. Mater. Manuf. Process. 36, 1049–1059 (2021). https://doi.org/10.1080/10426914.2021.1885703

Li, X., Li, W., Yang, S.: Investigation of surface integrity and fatigue performance of TC4 titanium alloy in centrifugal barrel finishing. Mechanics 23, 916–922 (2018). https://doi.org/10.5755/j01.mech.23.6.19849

Alcaraz, J.Y., Zhang, J., Nagalingam, A.P., Gopasetty, S.K., Toh, B.L., Gopinath, A., Ahluwalia, K., Ang, M.G.W., Yeo, S.H.: Numerical modeling of residual stresses during vibratory peening of a 3-stage Blisk—a multi-scale discrete element and finite element approach. J. Mater. Process. Technol. 299, 117383 (2022). https://doi.org/10.1016/j.jmatprotec.2021.117383

Coetzee, C.: Calibration of the discrete element method: strategies for spherical and non-spherical particles. Powder Technol. 364, 851–878 (2020). https://doi.org/10.1016/j.powtec.2020.01.076

Wu, Y., Li, X., Wang, J., Li, W., Yang, S., Shi, S.: Flow field characteristics analysis of media for horizontal vibratory mass finishing. Surface Technol. 50, 329–338 (2021). https://doi.org/10.16490/j.cnki.issn.1001-3660.2021.11.035

Rehman, A., Wu, P., Li, L., Zhang, S., Wang, L.: Convection rolls and individual particles movements in horizontally vibrated granular particles system. Acta Phys. Pol. A. 130, 1336–1342 (2016). https://doi.org/10.12693/APhysPolA.130.1336

Hao, Z., Li, W., Li, X., Wu, F., Zhao, W.: Effect of media parameters on contact forces in centrifugal barrel finishing. China Sciencepaper. 23, 2756–2760 (2017)

Zhang, C., Liu, W., Wang, S., Liu, Z., Morgan, M., Liu, X.: Dynamic modeling and trajectory measurement on vibratory finishing. Int. J. Adv. Manuf. Technol. 106, 253–263 (2019). https://doi.org/10.1007/s00170-019-04644-8

Ciampini, D., Papini, M., Spelt, J.K.: Impact velocity measurement of media in a vibratory finisher. J. Mater. Process. Technol. 183, 347–357 (2007). https://doi.org/10.1016/j.jmatprotec.2006.10.024

Da Silva Maciel, L., Spelt, J.K.: Measurements of wall-media contact forces and work in a vibratory finisher. Powder Technol. 360, 911–920 (2020). https://doi.org/10.1016/j.powtec.2019.10.066

Da Silva Maciel, L., Spelt, J.K.: Bulk mass flow in a vibratory finisher: mechanisms and effect of process parameters. Granul. Matter. 20, 57 (2018). https://doi.org/10.1007/s10035-018-0830-1

AghlmandiHarzanagh, A., Orhan, E.C., Ergun, S.L.: Discrete element modelling of vibrating screens. Miner. Eng. 121, 107–121 (2018). https://doi.org/10.1016/j.mineng.2018.03.010

Meng, F., Liu, H., Hua, S., Pang, M.: Force chain characteristics of dense particles sheared between parallel-plate friction system. Results Phys. 25, 104328 (2021). https://doi.org/10.1016/j.rinp.2021.104328

Jiang, M., Wu, P., Liu, H., Li, L., Chen, S., Zhang, S., Wang, L.: Motion behaviour of ellipsoidal granular system under vertical vibration and airflow. Soft Matter 16, 9559–9567 (2020). https://doi.org/10.1039/D0SM01129K

An, X., Huang, F., Dong, K., Yang, X.: DEM simulation of binary 372522sphere packing densification under vertical vibration. Part. Sci. Technol. 36, 672–680 (2018). https://doi.org/10.1080/02726351.2017.1292335

Liyan, S., Depeng, R., Qing, Y., Guodong, L., Huilin, L., Wenhao, Y.: Predicted configurational and translational granular temperatures of particles for low-velocity intruder impacting on granular bed using DEM. Powder Technol. 297, 283–293 (2016). https://doi.org/10.1016/j.powtec.2016.04.031

Acknowledgements

The work was co-supported by the National Natural Science Foundation of China (Grant Nos. 51975399 and 52075362) and the Central Government Guides Local Foundation for Science and Technology Development (Grant Nos. YDZJSX2022A020 and YDZJSX2022B004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Li, X., Li, W. et al. Convection and motion characteristics of granular media in horizontal vibratory finishing. Granular Matter 25, 76 (2023). https://doi.org/10.1007/s10035-023-01366-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01366-3