Abstract

This study presents a rate-independent constitutive model for granular materials which is based on the analysis of discrete element modelling (DEM) results. We examine the elastic and plastic strain rate at any state of shear, and explore how the plastic strain rate and the stress rate are related to some state variables (e.g. stress, void ratio, etc.). The elastic and plastic strain rate are evaluated by assuming that the rate of conservative energy defined in term of elastic strain rate equals the energy rate from work–energy analysis of granular assemblies. The verification of the theoretical work–energy analysis and the acquire of data regarding the mechanical rates at contacts between grains are done through DEM. It is shown that for a representative element volume of granular materials, the external work rate equals the sum of an elastic energy rate and a dissipation rate at contacts. The work rate is either the product of stress and strain rate or the sum of discrete work rate of external forces. Equations regarding the dilatancy, plastic deviatoric strain rate and stress rate are proposed. In the model, a yield surface is not explicitly defined and the deviatoric stress rate is related to not only the elastic deviatoric strain rate, but also a rate of dilatancy. Simulations show that the predictions match both virtual and Toyoura sand satisfactorily in various shear tests within a board range of densities. Additionally, the calibration of parameters is extremely simple. The treatment of cyclic loading condition is also presented.

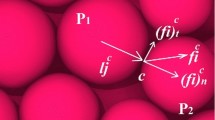

Graphic abstract

Similar content being viewed by others

Abbreviations

- C:

-

Model parameter for dilatancy

- d :

-

Dilatancy \( -\frac{{\dot{\varepsilon }}^p_{v}}{|\dot{{\varvec{\epsilon }}}^p|}\)

- \(d^\prime \) :

-

Modified dilatancy \( -\frac{{\dot{\varepsilon }}^p_{v}}{|\dot{{\varvec{\epsilon }}}|}\)

- D :

-

Diameter

- e :

-

Void ratio

- \(e_{max}\) :

-

Model parameter for critical state \(e{-}p\) relationship

- E :

-

Young’s modulus of the grains

- \(E^g_{kt}\) :

-

Transnational kinetic energy of a grain g

- \(E^g_{rt}\) :

-

Rotational kinetic energy of a grain g

- \({\varvec{f}}^{n,*}\) :

-

Normal contact force

- \({\varvec{f}}^{t,*}\) :

-

Tangential contact force

- \({{\mathbf {\mathsf{{I}}}}}\) :

-

Identity tensor

- I :

-

Inertia number

- \(K_0\) :

-

Elastic bulk modulus

- \(k_n\) :

-

Normal stiffness at contacts

- \(k_t\) :

-

Tangential stiffness at contacts

- \({\varvec{l}}^{gc}\) :

-

Vector from the centre of gravity g to contact point c

- m:

-

Model parameter for dilatancy

- \(m^g\) :

-

Mass of a grain g

- \({\varvec{M}}^{*}\) :

-

Contact moment

- \({\varvec{n}}^{*}\) :

-

Contact normal

- p :

-

Mean stress

- \(p_r\) :

-

Reference pressure (1 MPa)

- \(r^c\) :

-

Critical state stress ratio

- \({{\mathbf {\mathsf{{r}}}}}\) :

-

Stress ratio (\({{\mathbf {\mathsf{{s}}}}}/p\))

- \({{\mathbf {\mathsf{{s}}}}}\) :

-

Deviatoric stress tensor

- \({\varvec{v}}\) :

-

Velocity

- \({\widetilde{W}}^b\) :

-

Power density (i.e. unit volume work rate) from external agency

- \({\widetilde{W}}^c\) :

-

Power density at contacts

- \({\widetilde{W}}^\sigma \) :

-

Power density \( {\varvec{\sigma }}:\dot{{\varvec{\varepsilon }}}\)

- \({\varvec{x}}\) :

-

Position vector

- \(\alpha \) :

-

Parameter for critical state \(d^\prime = \alpha (|{{\mathbf {\mathsf{{r}}}}}| - r^c)\) relationship

- \(\beta \) :

-

Model parameter for dilatancy

- \(\beta _n\) :

-

Normal viscous damping constants

- \(\beta _s\) :

-

Tangential viscous damping constants

- \(\gamma \) :

-

Model parameter for deviatoric plastic strain rate

- \(\delta ^{c}\) :

-

Penetration depth at contacts

- \({\varvec{{\dot{\varepsilon }}}}\) :

-

Strain rate tensor

- \({\varvec{{\dot{\varepsilon }}}}^e\) :

-

Elastic strain rate tensor

- \({\varvec{{\dot{\varepsilon }}}}^p\) :

-

Plastic strain rate tensor

- \({\dot{\varepsilon }}^*_{v}\) :

-

Volumetric strain rate

- \(\dot{{\varvec{\epsilon }}}^*\) :

-

Deviatoric strain rate tensor

- \(\kappa \) :

-

\(k_n/k_t\)

- \(\lambda \) :

-

Model parameter for critical state \(e{-}p\) relationship

- \(\mu \) :

-

Friction coefficient at contacts

- \(\mu _r\) :

-

Rolling resistance coefficient at contacts

- \(\nu \) :

-

Poisson ratio

- \(\xi \) :

-

Model parameter for critical state \(e{-}p\) relationship

- \(\rho _{grain}\) :

-

Density of grains

- \({\varvec{\sigma }}\) :

-

Stress tensor

- \({\dot{\Phi }}^{fn}\) :

-

Power density of normal forces at contacts

- \({\dot{\Phi }}^{ftc}\) :

-

Conservative part of power density of shear forces at contacts

- \({\dot{\Phi }}^{mc}\) :

-

Conservative part of power density of contact moments at contacts

- \({\dot{\Phi }}^{e}\) :

-

\({\dot{\Phi }}^{ftc} + {\dot{\Phi }}^{mc}\)

- \({\widetilde{\Psi }}^{ftd}\) :

-

Dissipative part of power density of shear forces at contacts

- \({\widetilde{\Psi }}^{md}\) :

-

Dissipative part of power density of contact moments at contacts

- \({\widetilde{\Psi }}\) :

-

\({\widetilde{\Psi }}^{ftd} + {\widetilde{\Psi }}^{md}\)

- \(\psi \) :

-

State parameter [2]

- \({\varvec{\omega }}\) :

-

Angular velocity

- CV:

-

Constant volume (undrained) triaxial compression

- CR:

-

Constant radial stress (conventional drained) triaxial compression

- CP:

-

Constant mean stress triaxial compression

- DEM:

-

Discrete element model

- RVE:

-

Representative element volume

References

Ai, J., Chen, J.F., Rotter, J.M., Ooi, J.Y.: Assessment of rolling resistance models in discrete element simulations. Powder Technology 206(3), 269–282 (2011). https://doi.org/10.1016/j.powtec.2010.09.030. ISSN 00325910

Been, K., Jefferies, M.G.: A state parameter for sands. Géotechnique 35(2), 99–112 (2009). https://doi.org/10.1680/geot.1985.35.2.99. ISSN 0016-8505

da Cruz, F., Emam, S., Prochnow, M., Roux, J.N., Chevoir, F.: Rheophysics of dense granular materials: Discrete simulation of plane shear flows. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 72(2), 1–17 (2005). https://doi.org/10.1103/PhysRevE.72.021309. ISSN 15393755

Dafalias, Y.F., Taiebat, M.: SANISAND-Z: zero elastic range sand plasticity model. Géotechnique 66(12), 999–1013 (2016). https://doi.org/10.1680/jgeot.15.P.271. ISSN 0016-8505

Einav, I.: The unification of hypo-plastic and elasto-plastic theories. Int. J. Solids Struct. 49(11–12), 1305–1315 (2012). https://doi.org/10.1016/j.ijsolstr.2012.02.003. ISSN 00207683

He, X., Cai, G., Zhao, C., Sheng, D.: On the stress–force–fabric equation in triaxial compressions: some insights into the triaxial strength. Comput. Geotech. 85, 71–83 (2017). https://doi.org/10.1016/j.compgeo.2016.12.011. ISSN 0266352X

He, X., Liang, D., Wu, W., Cai, G., Zhao, C., Wang, S.: Study of the interaction between dry granular flows and rigid barriers with an SPH model. Int. J. Numer. Anal. Methods Geomech. (2018). https://doi.org/10.1002/nag.2782

He, X., Wu, W., Wang, S.: A constitutive model for granular materials with evolving contact structure and contact forces—part I: framework. Granul. Matter (2019). https://doi.org/10.1007/s10035-019-0868-8. ISSN 1434-5021

Jiang, M., Shen, Z., Wang, J.: A novel three-dimensional contact model for granulates incorporating rolling and twisting resistances. Comput. Geotech. 65, 147–163 (2015). https://doi.org/10.1016/j.compgeo.2014.12.011. ISSN 18737633

Kuhn, M.R., Sun, W.C., Wang, Q.: Stress-induced anisotropy in granular materials: fabric, stiffness, and permeability. Acta Geotech. 10(4), 399–419 (2015). https://doi.org/10.1007/s11440-015-0397-5. ISSN 18611133

Li, X.-S., Dafalias, Y.F.: Dilatancy for cohesionless soils. Geotechnique 50(4), 449–460 (2000). https://doi.org/10.1680/geot.2000.50.4.449. ISSN 0016-8505

Manzari, M.T., Dafalias, Y.F.: A critical state two-surface plasticity model for sands. Géotechnique 47(2), 255–272 (1997). https://doi.org/10.1680/geot.1997.47.2.255. ISSN 0016-8505

Nicot, F., Darve, F.: Describing failure in geomaterials using second-order work approach. Water Sci. Eng. 8(2), 89–95 (2015). https://doi.org/10.1016/j.wse.2015.05.001. ISSN 24058106

Richart, F.E.J., Hall, J.R.J., Woods, R.D.: Vibrations of soils and foundations. Can. Geotech. J. (1970). https://doi.org/10.1139/t71-033

Schofield, A., Wroth, P.: Critical State Soil Mechanics. McGraw Hill, New York (1968)

Thornton, C.: Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 50(1), 43–53 (2000)

Verdugo, R., Ishihara, K.: The steady state of sandy soils. Soils Found. 36(2), 81–91 (1996). https://doi.org/10.1248/cpb.37.3229. ISSN 09168451

Wu, W., Kolymbas, D.: Numerical testing of the stability criterion for hypoplastic constitutive equations. Mech. Mater. 9, 245–253 (1990). https://doi.org/10.1016/0167-6636(90)90006-2

Wu, W., Lin, J., Wang, X.: A basic hypoplastic constitutive model for sand. Acta Geotech. 12(6), 1373–1382 (2017). https://doi.org/10.1007/s11440-017-0550-4. ISSN 1861-1125

Acknowledgements

The first author acknowledges the financial support from the Otto Pregl Foundation for Geotechnical Fundamental Research, Vienna, Austria. The research is also partly funded by the project “GEORAMP” within the RISE programme of Horizon 2020 under Grant Number 645665.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, X., Wu, W., Cai, G. et al. Work–energy analysis of granular assemblies validates and calibrates a constitutive model. Granular Matter 22, 28 (2020). https://doi.org/10.1007/s10035-019-0990-7

Received:

Published:

DOI: https://doi.org/10.1007/s10035-019-0990-7