Abstract

Wind turbines are a major source of renewable energy. Load monitoring is considered to improve reliability of the systems and to reduce the cost of operation. We propose a load monitoring system which consists of inertial measurement units. These track the movement of rotor blade, hub and tower top. In addition, wind turbine states, e.g. yaw angle, pitch angle and rotation speed, are recorded. By solving a navigation algorithm with a Kalman Filter approach, the raw sensor data is combined with an error model to reduce the tracking error. In total, five inertial measurement units are installed on the research wind energy converter AD 8–180 on the test site in Bremerhaven. Results show that tracking the blade movement in full operation is possible and that loads can be estimated with a model-based approach. In comparison to simulations, the blade deflections can be approximated by an aeroelastic model. The presented approach can be used as basis for comprehensive load monitoring and observer system with additional increase of system robustness by measurement redundancy.

Zusammenfassung

Windenergieanlagen sind eine wesentliche Grundlage erneuerbarer Energie. Um die Gestehungskosten noch weiter zu senken, müssen die Zuverlässigkeit weiter erhöht und die Betriebskosten weiter gesenkt werden. Dies wird durch eine Lastüberwachung ermöglicht. In dem vorliegenden Artikel wird ein derartiges System basierend auf inertialen Messeinheiten zur Erfassung von Bewegungen von Rotorblatt, Nabe und Turm vorgestellt. Zusätzlich werden weitere Betriebsgrößen wie z. B. Gierwinkel, Pitchwinkel und Drehzahl erfasst. Hierzu werden die Sensordaten basierend auf der Lösung eines Navigationsalgorithmus mittels Kalman-Filter-Ansatz verarbeitet, um Nachlauffehler durch ein entsprechendes Fehlermodell reduzieren zu können. Insgesamt sind fünf inertiale Messeinheiten in der Forschungs-Windenergieanlage AD 8-180 auf dem Testfeld in Bremerhaven installiert. Die Ergebnisse zeigen, dass eine Bestimmung der Blattbewegung im Volllastbetrieb möglich ist und dass die wirkenden Lasten mit einem modellbasierten Ansatz abgeschätzt werden können. Die gemessenen Blattauslenkungen stimmen mit Ergebnissen aus Vergleichssimulationen gut überein. Der vorgestellte Ansatz kann als Basis für ein umfassendes Lastüberwachungs- und Beobachtersystem verwendet werden. Die Systemrobustheit wird durch erhöhte Messredundanz gesteigert.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The increasing progress of digitalization in the industry offers the opportunity to develop more and more innovative and advanced monitoring concepts of plants. There is an urgent need for load monitoring methods because maintenance and spare parts costs should be reduced to a minimum and at the same time lifetime should be further optimized. In the area of the wind industry this is strongly linked to the reduction of specific electricity production costs to offer wind energy at competitive prices on the market [1]. With the help of advanced monitoring and analysis methods, damage of components can be detected reliably at an early stage, ideally before failure, or even be avoided [2]. Using sophisticated monitoring algorithms opens the possibility to determine and monitor the current health status of wind energy converters (WECs). Depending on the current health status, the load can be decreased or increased. Since the wind turbine is a dynamically complex coupled system, these algorithms must follow a holistic approach to obtain a reliable information for the entire plant.

Classical Condition Monitoring Systems (CMS) of WECs, however, still frequently follow a component-based approach only, as it has been observed for several years in the field of drivetrain monitoring [3] and in the meantime also for monitoring of rotor blades and tower vibrations with Structural Health Monitoring (SHM) techniques [4, 5]. With these systems, the measured values of the vibrations recorded in time domain are represented in the frequency domain. This way, possible damage can be detected based on certain characteristics of the frequency response. The time of damage-relevant events cannot be determined directly due to the loss of time information by transforming into the frequency domain. In addition, the impossibility to link this data directly to the turbine control system prevents a continuous automation of the analysis and adaption process. The final evaluation of the analyses and the resulting actions are often performed manually by employees of the responsible CMS centers.

With a load monitoring of all relevant components in the time domain, the operating loads could be reconstructed to determine the condition of the WEC. For load measurement, strain gauges are usually used, e.g. for rotor blade root loads. They can give a good load indication, but high accuracy, sensitivity and redundant systems are needed if high robustness is required. Today’s piezoelectric vibration sensors, however, have problems in resolving very low frequency ranges (≤ 0.1 Hz). Furthermore, most of the present vibration sensors are acceleration or strain sensors that only measure in two spatial directions (biaxial) (see also sensors for rotor blade monitoring in [4] and [5]). In this paper we discuss the installation (Chap. 2) and evaluation (Chap. 3 and 4) of distributed inertial measurement units (IMUs) for model-based load assessment in wind turbines. These IMUs can measure rotation rates as well as accelerations in three axes with high accuracy, in low frequency ranges and can give insight in the global dynamics of the WEC. A monitoring of torsional vibrations with angular rate sensors does normally not take place in the commercial WEC sector. Sensors that measure all 6 degrees of freedom are also not used commercially and are usually only part of scientific investigations as for example in [6] and [7] or like presented in this paper. Besides the various advantages of inertial sensors and inertial navigation, a major disadvantage is the fact that the calculated position “drifts” over time. However, these errors can be controlled and minimized significantly by suitable support algorithms and constraints like described in Chap. 3.1. Chap. 3.2 describes initialization routines for the sensor system and Chap. 3.3 presents a model-based approach which can be used to reconstruct the loads. In Chap. 4 results from measurements on IWES’s research WEC Adwen AD 8–180 are presented and discussed. These results were mainly obtained within the research projects MOD-CMS [8] and Testfeld BHV [9]. The theoretical application of IMUs in wind turbines for model-based fault detection is discussed in [10]. Chap. 5 completes the paper with a summary and an outlook on future research possibilities.

2 Measurement system and installation

The complete measurement system consists of the sensor system, a controller for recording and monitoring the measurement, power supply, a mobile GSM router for supervision and a high-precision GPS clock.

The main components of the sensor system are five IMUs. They are mounted in the wind turbine nacelle, rotor hub and inside one rotor blade at three different positions. The IMUs used here are LCI-100 [11] from Northrop Grumman LITEF GmbH. Each sensor consists of three fiber optic angular rate sensors (Sagnac interferometers) and an accelerometer triad. The rate sensor accuracy is specified with a bias of 0.1°/h and noise of 0.012°/h1/2 and accelerometers with a bias of 0.25 mg and a noise of 0.1 mg/Hz1/2.

The measuring system was designed and built in two parts, since no direct and real-time capable communication interface was available between rotor (rotating part) and nacelle (stationary part) of the AD 8–180 WEC, see Fig. 1. Beckhoff PLCs were used to acquire the measured values of the sensors, whereas the EtherCAT protocol, designed for hard real-time applications, was used for data transmission. A synchronous pulse was sent to all IMUs in a 1 kHz cycle to store and send the measured values. The synchronization of both measuring systems via the GPS signal, from which the time stamps for storing the measured data on both systems are derived, enables a subsequent merging of the data. The GSM modem is used for remote monitoring of the entire system, allowing code updates or restarts of individual components if required.

For the selection of optimal sensor positions, separation of eigenmodes from measured data is of prime importance. For this reason, the discrete measurement positions were assembled into a vector for each eigenmode, which is similar to the eigenvector of a discrete system, and the distance between all eigenvectors was maximized. This approach yields the following optimal positions along the blade centerline: 23 m, 40 m, 52 m. However, outward position was limited by accessibility of the blade interior, so the third blade IMU was installed at a position of 46 m. Two other sensors are located in the hub and the tower top. Fig. 2 shows the approximate mounting locations of all sensors on the turbine and exemplary pictures of the mounted sensors and PLCs.

Each IMU with EtherCAT interface, enclosure and mounting equipment has a weight of approximately 6 kg. Compared with other sensor solutions, they are quite large and heavy. However, inside the AD 8–180 blades, the additional mass is negligible. Commercial implementations could be based on smaller, lighter sensors which are also sufficiently accurate.

The installation of the system was performed by our Application Center for Wind Energy Field Measurements (AWF) team on several days in March 2019, whereas the biggest effort was linked to the sensor installation in the blade. Measurements were performed from April till the End of 2019 with some downtimes in-between due to low winds, turbine services and failure shutdowns.

3 Evaluation of measurement data

3.1 Navigation algorithm

The angular rate sensors measure the absolute rotation relative to the inertial system and the accelerometers measure the so called specific forces, which are an addition of the earth’s gravity and the acceleration of the IMU relative to the inertial system. The relationship between the IMU output and a navigation solution (position, velocity, and attitude) is given by the following differential equations formulated for Earth-Centered-Earth-Fixed (E-frame) coordinates as:

with

-

\(a^{B}\) specific force represented in B‑frame (body frame measured by IMU)

-

\(\omega _{IB}^{B}\) angular rate represented in B‑frame (body frame measured by IMU)

-

\(\omega _{IE}^{E}=\left(\begin{array}{c} 0\\ 0\\ \omega _{E} \end{array}\right)\) earth rate represented in E‑frame

-

\(v^{E}\) velocity of the B‑frame relative to E‑frame represented in E‑frame

-

\(g^{E}\)acceleration due to gravity represented in E‑frame

-

\(B\) Body frame (to which the IMU is fixed)

-

\(I\) Inertial frame

-

\(E\) Earth-Centered-Earth-Fixed frame

A navigation algorithm solves these equations numerically and provides a navigation solution. In the overall setup, each of the distributed IMUs feeds a navigation algorithm so that the position, velocity, and orientation of all measurement points are determined. The pure inertial navigation, as described above, exhibits growing errors, i.e. attitude, velocities and position are drifting over time. With additional information about system states, sensor data fusion is an optimal means to estimate and compensate these drifts. The data fusion is done with a Kalman filter (KF). A linear Error States KF is used, which estimates the state error of the inertial system and corrects the navigation solution, see [12].

The position of the IMUs is used as aiding information. It is based on the following approach: The wind turbine foundation has a known position in the E‑frame. According to this, the position of the IMU in the nacelle is determined by the rigid body geometry and the current nacelle angle. Since the rigid body geometry deviates from the actual geometry under the influence of external forces, there is a difference between the actual position of the nacelle and the rigid body approximation. This difference is modeled in the KF as measurement uncertainty and the rigid body approximation is used as virtual position measurement. Based on the nacelle IMU and its position and attitude estimation, a rigid body approximation of the next IMU position in the rotor hub is calculated and fed to it as virtual position measurement. The virtual position measurements for the next IMUs in rotor blades are obtained from the position and attitude estimation of the rotor hub and the rigid body approximation.

3.2 Initialization of analysis algorithm

The navigation algorithm requires position, velocity, and orientation of every single IMU for initialization. Exact measurement of these quantities is associated with a tremendous effort and therefore a combination of measurement and estimation is suggested.

In this study, the initialization is executed before wind turbine operation starts. Thereby, the velocity can be estimated to be zero and the position is determined by a combination of measurements and a rigid geometric model. Construction data from the turbine is used to estimate the positions of IMUs with respect to measurement points. This led to a parametric, geometric rigid model of the wind turbine, which yields the position data for the IMUs in the North-East-Down-frame (NED), which describes the local tangent plane coordinates in north, east and down direction. The down direction is oriented to the earth center. This parametric model considers operational parameters like yaw, azimuth, and pitch angle and constructional data like tower base coordinates, tower height, hub height, tilt angle, cone angle and prebend of the rotor blade. Operational parameters are obtained from SCADA data. In the end, the position vector is transformed from NED to E‑frame.

The orientation is estimated by evaluating the measurement of the gravity acceleration in a process called alignment. In this process the orientation of the IMU axes is determined with respect to a reference frame, for example the E‑ or NED-frame. We use a technique, outlined in [13], for alignment on a stationary platform. In the stationary case, the IMU measures the gravity and earth rotation rate vectors, which define the NED frame at a given location.

In the end, the displacement vectors between IMUs are calculated from the position vectors in the E frame and rotated into the corresponding IMU B‑frame.

3.3 Reconstruction of loads and load cases

The reconstruction of loads is achieved by comparing measured data to simulation results. Therefore, an accurate model of the real wind turbine is needed. The measured blade deflection from IMUs can be compared to blade deflection in the simulation. When all states of the wind turbine (yaw, azimuth, pitch, rotation speeds and generator torque) match between simulation and measured data, a model-based estimation of loads by simulation can be performed. An approach like this requires a calibrated model of the wind turbine. The manufacturer provided a model of the prototype WEC AD 8–180 in the Software BLADED. This model is converted to our self-developed aeroelastic load simulation tool called MoWiT [14]. MoWiT follows a similar approach but is based on Modelica/Dymola and thus allows for more options for cross-platform compilation and code generation for real-time simulations. It describes the dynamic interaction of the wind turbine with the surrounding wind and includes a controller. In this case, the original turbine controller is used in the simulation scenarios.

A correct description of the current wind field is essential for simulation of real scenarios. The AD 8–180 WEC is built in Bremerhaven and part of the Testfeld BHV [9]. Incoming wind is measured by a met mast on the test site. With 5 points of measurement, the data from the met mast gives a good starting point for an estimation of the incoming wind. The proposed procedure for generation of wind fields for a certain load case matches the mean value of turbulence intensity. Wind shear and mean wind direction are extracted from the measured data. The mean wind speed of the wind field was adjusted to match power output and pitch actuation characteristics to the actual wind turbine behavior. For the generation of turbulent wind field data, the stochastic inflow turbulence simulator TurbSim [15] was used.

The first load case consists of normal operation close to rated wind speed. In this case, the wind turbine starts from the idle position and immediately ramps up close to full load operation. For a comparison in this way, only characteristics of signal data, e.g. standard deviation, minimum and maximum deflection, can be compared. For a more detailed comparison in the time domain, a sophisticated measurement of the full incoming fields must be obtained. The second case is a special load scenario. On this event, the rotor of the WEC was locked, and high wind speed of 15 m/s occurred with a high yaw misalignment of 70 degree. All rotor blades were pitched to feather. This led to an excitation of synchronous blade oscillations. The rotor blades oscillated in phase and mainly in edgewise direction. This scenario is not relevant for real-world operation but allows for detailed validation of the IMU-based load measurement system.

4 Results

The analysis of measured IMU data showed that the sensor data can be used in multiple post processing, not only to evaluate loads, but also to estimate states of the WEC.

The evaluation algorithm from Sect. 3.1, provides time series data of position in the ECEF frame and orientation as quaternions. The orientation is converted to degrees. For ease of visualization, the results are transformed in other coordinate systems. Since the rotor is rotating in operation, the blade deflection measurement is presented in the pitched blade root frame, where the axes are aligned with the blade radius, flap- and edgewise direction, as shown in Fig. 3.

The virtual blade root is determined by translation and rotation of the calculated moving hub position. Translation and rotation are determined from construction data. In the following, the IMUs are numbered according to Fig. 3.

4.1 Subsystem evaluation for wind turbine states

First, the measurements from IMU can be used to track multiple states of the WEC like rotation speed, yaw- and pitch angle, as displayed in Fig. 4. Since all IMUs are needed for the reconstruction of the blade movement with the navigation algorithm, these redundant measurements can be obtained without significant effort by additional post processing of IMU data.

The plots illustrated above show a comparison of the SCADA data with the computed values from the IMUs. One measurement of the IMUs is the rotation, which can be used directly to calculate the rotation speed of the rotor from the hub IMU. Since the nacelle IMU is directly mounted to the yawing part of the WEC, the computed orientation can be connected to the yaw of the turbine. The pitch angle is determined by IMU 1 from the virtual blade root coordinate system of Fig. 3. The lower part of the rotor blade shows almost no twisting and therefore the rotation between the blade root and IMU 1 coordinate system can be computed to obtain the current pitch angle as additional measurement. The correlation coefficients between SCADA and IMU signals of yaw angle, pitch angle and rotation speed are 99.9%, 99.8% and 99.9%, respectively.

Additionally, the measured gravity force can be obtained to estimate the azimuth angle by evaluating the IMU orientation.

4.2 Complete system evaluation for blade deflection and loads

To determine the blade edgewise and flapwise deflections and loads, the whole systems needs to be evaluated. In the following, only evaluation regarding the rotor blades are shown.

Normal operation load case

This load case represents regular nominal operation of the WEC. Fig. 5 compares the evaluated measurement and simulation data in the blade root frame. The data is presented for a time span of 10 min, while the turbine controllers are not pitching or yawing. Finally, the comparison of the rotor speed yields for the SCADA data 8.43 ± 0.1 rpm and simulation 8.5 ± 0.07 rpm.

In general, the measurement and simulation data match quite well. The individual deflections for each measurement position show good agreement to simulation results for the edgewise deflection. All deflections are increasing with higher normalized radius. The flapwise direction is higher than the edgewise deflection, as can be observed in simulation and measurement. But the measurement differs from the simulation results, which are less fluctuating. Furthermore, the measurement shows higher deflections than the simulation model. The simulated blade loads show a range of 2.22 ± 6.6 MNm for the edgewise and 18.7 ± 1.8 MNm for the flapwise bending moment.

Blade oscillation at idle position

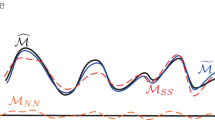

Since the rotor was locked in this scenario, we were able to measure only blade oscillation on the full-scale WEC without effects of rotation. The oscillation amplitudes are presented in Fig. 6.

These plots show the swept area of the rotor blade in a time window of 30 min. As shown before, the oscillation data shows increasing deflection with higher blade radius. In this special case, the edgewise deflection is larger than in flapwise direction by almost a factor of 2.

Additionally, we determined the frequency spectrum of the evaluated measurement data from the IMUs by Fast-Fourier-Transformation (FFT). The frequency spectrum for each blade measurement point deflection is shown in Fig. 7.

This special load case with locked rotor and high side winds caused high amplitudes for the edgewise direction. The IMUs capture the movement of the complete coupled system and therefore, eigenfrequencies of every component can be observed. The unusually high amplitude of the edgewise direction dominates in the edgewise plot while the amplitude in the flapwise direction is negligible. However, the edgewise frequency can clearly be identified in the flapwise motion spectrum. Furthermore, the characteristics show distinct peaks and a slightly different shape. Since the rotor was locked, the tower eigenfrequency is also visible in the blade movement. For this specific load case, the ratio between measured and data sheet specified eigenfrequencies of tower, flap- and edgewise first eigenmode are 1.006, 0.9401 and 1.004, respectively. Only the flapwise eigenfrequency is not matched exactly. Both peaks between 0.5 Hz and 0.8 Hz could not be identified as one of the known eigenfrequencies of the WEC. We assume that these frequencies belong to a coupled eigenmode specific to this load case, since the rotor was locked. Further research is needed in this case.

5 Discussion and conclusion

The estimation of loads is crucial for the development of load monitoring. In this paper, we proposed a holistic measurement system based on IMUs for oscillations of WECs. The highly accurate sensors combined with a navigation algorithm and a Kalman Filter provide a measurement of blade deflections in the WEC. Results show that the system states can be tracked and blade deflections at fixed positions are estimated. In comparison with coupled simulation, the loads at the blade root can be estimated. In addition, the proposed system shows redundancy with standard measurement equipment and thereby increases the robustness of WEC measurements.

Future research is focused on improvement of this system by calibrating the aero-elastic model of the AD 8–180 to the prototype in Bremerhaven and development of an estimator or observer algorithm for real-time computation of blade loads.

References

Bloomberg Q (2013) Clean energy policy & market briefing

BVG Associates (2012) Offshore wind cost reduction pathways—Technology work stream

Yang W et al (2014) Wind turbine condition monitoring: technical and commercial challanges. Wind Energy 17:673–693

Weidmüller GmbH & Co KG BLADEcontrol. https://www.weidmueller.de/de/unternehmen/maerkte_und_industrien/wind/bladecontrol/index.jsp. Accessed 31 Jan 2021

Bachmann electronic GmbH Cantilever-Sensor. https://www.bachmann.info/uploads/tx_sbdownloader/CLS_Cantilever_Sensor_de.pdf. Accessed 31 Jan 2021

Schulze A et al (2019) Verbundvorhaben: DynAWind – Leichtbauoptimierte Konstruktion von Windenergieanlagen: Schlussbericht: Berichtzeitraum: 01.12.2015 bis 31.05.2019 (Schlussbericht)

Universität Rostock, W2E Wind to Energy GmbH, WINDnovation Engineering Solutions GmbH (2021) Projekt DynAWind² – Modellgestützte, minimalsensorische strukturelle Überwachung von Windenergieanlagen (01185023/1)

Fraunhofer-Institut für Windenergiesysteme (IWES), Northrop Grumman LITEF GmbH (2019) Verbundvorhaben: MOD-CMS – Modellbasiertes und sensorgestütztes Condition Monito-ring System für Windenergieanlagen; Teilvorhaben: Überwachung von Windenergieanlagen mit einem modellbasierten und sensorgestützten Condition Monitoring System

Fraunhofer-Institut für Windenergiesysteme (IWES) (2021) Projekt Testfeld BHV – Kombination von Großprüfstands- und Freifeldtests zur Validierung von Windenergieanlagen der nächsten Generation. IWES, Bremerhaven

Meyer T et al (2018) Nutzung von Inertialmesstechnik zur Stützung modellbasierter Berechnungsalgorithmen von Windenergieanlagen. Schwingungen von Windenergieanlagen

Northrop Grumman LITEF (2013) https://northropgrumman.litef.com/fileadmin/downloads/Datenblaetter/Datenblatt_LCI-100.pdf. Accessed 6 Sept 2020

Grewal MS, Andrews AP (2001) Kalman filtering—theory and practice using Matlab. John Wiley & Sons,

Titterton D, Weston J (2004) Strapdown inertial navigation technology, 2nd edn.

Thomas P et al (2014) The onewind Modelica library for wind turbine simulation with flexible structure—modal reduction method in Modelica. Proceedings of the 10th International 2014, pp 939–948

Jonkman BJ (2009) TurbSim user’s guide: version 1.50. NREL.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wiens, M., Martin, T., Meyer, T. et al. Reconstruction of operating loads in wind turbines with inertial measurement units. Forsch Ingenieurwes 85, 181–188 (2021). https://doi.org/10.1007/s10010-021-00455-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-021-00455-0