Abstract

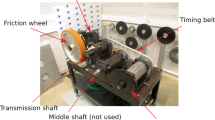

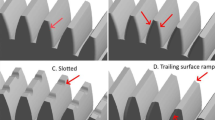

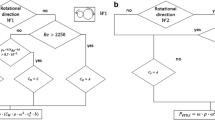

This paper deals with recent experimental and numerical research in the possible reduction of windage power losses (WPL). It is accepted that these load-independent losses become prominent over other sources in mechanical transmissions with peripheral speeds above 100 m/s as is the case in energy production, aeronautics and electric vehicles. So far, the majority of the experiments and models deal with WPL evaluation for one single rotating pinion. The unique test rig designed at INSA Lyon makes it possible to measure both the WPL of a single pinion or a non-meshing pinion-gear pair. A number of comparisons between experimental and numerical results are presented and commented upon. It is shown, that the gear environment changes the airflow and, in depending on the cases, it can either reduce or increase WPL. Finally, the influence of pinion-gear couplings on WPL is discussed as well as the interest of shrouds and deflectors.

Zusammenfassung

Dieser Artikel befasst sich mit neueren experimentellen und numerischen Untersuchungen zur möglichen Reduzierung von Luftwiderstandsverlusten (WPL). Es wird davon ausgegangen, dass diese lastunabhängigen Verluste bei mechanischen Getrieben mit Umfangsgeschwindigkeiten über 100 m/s gegenüber anderen Quellen eine herausragende Rolle spielen, wie dies bei der Energieerzeugung, in der Luftfahrt und bei Elektrofahrzeugen der Fall ist. Bisher befasst sich die Mehrzahl der Experimente und Modelle mit der WPL-Bewertung für ein einzelnes rotierendes Ritzel. Mit dem einzigartigen Prüfstand von INSA Lyon kann sowohl die WPL eines einzelnen Ritzels als auch eines nicht kämmenden Ritzelpaares gemessen werden. Eine Reihe von Vergleichen zwischen experimentellen und numerischen Ergebnissen wird vorgestellt und kommentiert. Es wird gezeigt, dass die Getriebeumgebung den Luftstrom verändert und in Abhängigkeit von den Fällen die WPL entweder verringern oder erhöhen kann. Abschließend wird der Einfluss von Ritzelkupplungen auf die WPL sowie das Interesse von Abdeckungen und Deflektoren erörtert.

Similar content being viewed by others

References

Dawson PH (1984) Windage loss in larger high-speed gears. Proc. I. Mech.E.Power and Process Eng, vol 198

Anderson NE, Lowenthal SH, Stuart H (1980) Spur gear systems efficiency at part and full load. NASA Technical Paper, vol 1622

Townsend D, Dudley DW (1992) Gear Handbook. McGraw-Hill, New York, p 1010

Lord AA (1998) An Experimental Investigation of Geometric and Oil Flow Effects on gear Windage and meshing Losses. PhD Thesis. Swansea: University of Wales

Diab Y, Ville F, Velex P, Changenet C (2004) Windage losses in hugh-speed gears—Preliminary experimental and theoretical results. J Mech Design. https://doi.org/10.1115/1.1767815

Voeltzel N, Marchesse Y, Changenet C, Ville F, Velex P (2016) On the influence of helix angle on gear windage losses. J Mech Eng Science 230:1101–1112

Johnson G, Simmons K, Foord C Experimetal investigation into windage power loss from a shrouded spiral bevel gear. Proceedings of ASME Turbo Expo 2007: Power for Land, Sea and Air, Montréal. https://doi.org/10.1115/GT2007-27885

Winfree DD (2000) Reducing gear windage losses from high speed gears. Proc ASME Power transmission and Gearing conference, Baltimore

Simmons K, Johnson G, Wiedemann N (2011) Effect of pressure and oil mist on windage power loss of a shrouded spiral bevel gear. Proc ASME Turbo Expo, Vancouver

Arisawa H, Nishimura M, Imai H, Goi T (2014) Computational fluid dynamics simulation and experiments for reduction of oil churning loss and windage loss in aeroengine tranmission gears. J Eng Gas Turbines Power. https://doi.org/10.1115/1.4026952

Al-Shibl K, Simmons H, Eastwick CN (2006) Modelling windage power loss from an enclosed spur gear. J Power Energy. https://doi.org/10.1243/09576509JPE344

Chaari F, Ben Romdhane M, Baccar W, Fakhfakh T, Haddar M (2012) Windage power loss in spur gear sets. Wseas Trans App Theo Mech 2:159–168

Pallas S, Marchesse Y, Changenet C, Ville F, Velex P (2013) Application and validation of a simplified numerical approach for the estimation of windage power losses in spur gears. Comput Fluids 84:39–45

Concli F, Gorla C, Della Torre A, Montenegro G (2014) Windage power losses of ordinary geras: different CFD approaches aimed to the reduction of the computational effort. Lubricants 2:162–176

Concli F, Gorla C (2016) Numerical modeling of the power losses in geared transmisions: windage, churning and cavitation simulations with a new intergrated approach thta drastically reduces the computational effort. Tribol Int 103:58–68

Burberi E, Fodelli T, Andreini A, Facchini B, Cipolla L (2016) CFD Simulations of a meshing gear pair. ASME Turbo expo: Power for Land, Sea and Air, Seoul

Massini D, Fondelli T, Andreini A, Facchini B, Tarchi L, Leonardi F (2018) Experimental and numerical investigation on windage power losses in high speed gears. J Eng Gas Turbines Power. https://doi.org/10.1115/1.4038471

Ruzek M, Ville F, Velex P, Boni J-B, Marchesse Y (2019) On windage losses in high-speed pinion-gear pairs. Mech Mach Theory 132:123–132

Menter FR (1994) Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J 32:1598–1605

Pallas S, Marchesse Y, Changenet C, Ville F, Velex P (2012) A windage power loss model based on CFD study about the volumetric flow rate expelled by spur gears. Mech Ind 13:317–323

Hill MJ, Kunz J, Noack RF, Long W, Morris PJ, Handschuh RF (2008) Application and validation of unstructured overset CFD technology for rotorcraft gearbox windage aerodynamics simulation. Proc. 64th American helicopter society annual forum, Montreal

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ruzek, M., Marchesse, Y., Ville, F. et al. Windage power loss reductions in high-speed gear pairs. Forsch Ingenieurwes 83, 387–392 (2019). https://doi.org/10.1007/s10010-019-00336-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-019-00336-7