Abstract

The electrodeposition of tantalum-titanium–based films using different tantalum and titanium halides was investigated in two ionic liquids, namely, 1-butyl-1-methylpyrrolidinium bis (trifluoromethyl-sulfonyl)imide ([BMP][TFSI]) and 1-butyl-1-methylpyrrolidinium trifluoromethanesulfonate ([BMP][OTf]). Cyclic voltammetry was used to analyse the electrochemistry of the electrolytes and potentiostatic deposition was performed to evaluate the feasibility of electrodepositing tantalum-titanium–based layers. Both the metal salts and the ionic liquid influenced the electrochemical reduction of the tantalum and titanium halides significantly. While titanium halides considerably retarded the reduction of tantalum pentahalides and inhibited electrodeposition in many electrolytes, an electrolyte composition from which tantalum and titanium-containing layers could be deposited was identified. Specifically, in TaBr5 and TiBr4 in [BMP][TFSI], TiBr4 did not inhibit the deposition of tantalum and titanium was co-deposited itself by a three-step reduction mechanism as confirmed by cyclic voltammetry and energy-dispersive X-ray spectroscopy. Furthermore, [BMP][TFSI] led to smoother and more compact deposits.

Similar content being viewed by others

Introduction

Refractory metals are a class of materials with extraordinary physical and chemical properties. The combination of high wear and corrosion resistance coupled with high temperature stability enables a versatile area of applications, e.g. protective coatings in chemically aggressive environments [1,2,3,4]. Tantalum is one of the most corrosion-resistant refractory metals and is particularly inert against corrosive attacks in acidic media [5]. In addition to its extreme chemical durability, tantalum has a good ductility (> 40%) but a relatively low hardness in the form of bulk coarse grains (1.17 GPa) [6]. The hardness of tantalum films can be significantly increased by modifying the grain size [6] or by alloying [7]. Its excellent biocompatibility makes tantalum an appealing choice as a material for medical implants [8, 9]. For instance, coating intervertebral discs with tantalum enhances their life span by several decades and thus can render it unnecessary to exchange them due to wear, helping patients to avoid the cost and pain of implant replacement operations [10]. While tantalum is almost completely immune to attacks by aggressive acidic media like aqua regia, it is less corrosion-resistant in alkaline environments than other refractory metals such as titanium [11]. Therefore, alloying tantalum with titanium increases the corrosion resistance against oxidizing agents, while reducing the specific weight and the elastic modulus of the material, thereby adjusting the mechanical properties to the human bone [12,13,14].

Tantalum-titanium alloys are usually manufactured through powder metallurgy or metal casting [15, 16]. Such methods require extensive maintenance of machinery and are operated at extremely high working temperatures above 1000 °C, consuming a significant amount of energy and rendering them economically unlucrative [8, 13, 15]. By contrast, electrochemical deposition of metals is a cost-effective and easy-to-maintain process that can coat substrates with complex geometries. While electrodeposition of refractory metals is often performed in high-temperature molten salts at temperatures above 400 °C, ionic liquids (ILs) have attracted much attention in the last two decades as alternative solvents owing to their unique physical and chemical properties [17,18,19]. Particularly, the combination of low melting points and electrochemical stability windows up to 6 V allows the electrodeposition of technologically important metals like aluminum, refractory metals or other industrially useful metals and alloys at room temperature [20,21,22,23,24,25,26,27,28,29,30,31]. Contrary to organic solvents, many ILs have a low vapor pressure and are considered green solvents due to their low toxicity [32].

Nevertheless, reports on the electrochemical deposition of tantalum-titanium alloys in molten salts are limited. The main reason for the lack of research on this issue is the reluctance of titanium to electrodeposit from molten salts as well as the complex behaviour of reactive intermediate titanium compounds that are formed during electrolysis [33,34,35,36]. Endres et al. investigated the electrodeposition of titanium from its halides (TiF4, TiCl4 and TiI4) in several bis (trifluoromethyl-sulfonyl)imide-based ILs. Their research showed that the electrodeposition of titanium in ILs from its halides mainly results in the deposition of intermediate species and insoluble non-stoichiometric titanium compounds. Despite the improved solubility of TiCl3 and TiCl2 when adding acetylacetone to the electrolyte, the amount of elemental titanium in the deposits remained negligible [37]. In contrast, El Abedin et al. reported the electrodeposition of elemental tantalum from TaF5 in 1-butyl-1-methylpyrrolidinium bis (trifluoromethyl-sulfonyl)imide, [BMP][TFSI], with LiF as additive [38]. While deposits with thicknesses in the micrometer range contained co-deposited impurities, deposits with a thickness of up to 300 nm were shown to be metallic by in situ current/voltage tunneling spectroscopy. Furthermore, Borisenko et al. reported that metallic tantalum can also be deposited at room temperature without LiF if electrodeposition is performed under potentiostatic square pulsed conditions [39]. While the electrodeposition of metallic titanium from ILs appears infeasible, induced co-deposition with more readily deposited metals is an effective solution to overcome the resistance of titanium to electrodeposit in ILs. Recently, we reported the electrodeposition of titanium-gallium alloys from bis(cyclopentadienyl)titanium(IV) bis(trifluoromethanesulfonate) and GaCl3 in 1-butyl-1-methylpyrrolidinium trifluoromethanesulfonate ([BMP][OTf]) [40]. While elemental titanium could not be deposited without additives, the addition of GaCl3 facilitated the reduction of the Ti (IV) species, enabling the deposition of metallic titanium-gallium alloys. Since tantalum deposits more readily from ILs, induced co-deposition could facilitate the reduction of titanium from ILs and yield electrodeposited tantalum-titanium alloys.

In the present work, we investigated the electrochemical reduction of various tantalum and titanium halides (TaF5, TaBr5, TiF4, TiCl4, TiBr4) in two ionic liquids ([BMP][TFSI] and [BMP][OTf]). The aim of this study was to evaluate the feasibility of electrodepositing tantalum-titanium alloys from ILs and to identify the required electrolyte characteristics. Firstly, we studied the electrochemical behaviour with cyclic voltammetry and assessed the electroactivity of titanium tetrahalides as well as their influence on the reduction of tantalum pentahalides. Afterwards, potentiostatic deposition experiments were carried out to analyse the morphology and elemental composition of deposits from electrolytes, in which the electrodeposition of layers was feasible.

Experimental

All electrolytes had a constant tantalum halide concentration of 0.25 M, while the concentration of the titanium halide was varied from 0.05 M to 0.25 M. TaF5, TaBr5, TiF4 and TiBr4 were purchased from Alfa Aesar in their anhydrous form at a purity ≥ 99.0%. TiCl4 was purchased from Fluka in its anhydrous form at a purity ≥ 99.0%. [BMP][TFSI] and [BMP][OTf] were purchased from Iolitec (Ionic Liquids Technology, Germany) at a purity ≥ 99.0%. The ILs were dried for 24 h at 100° C under vacuum in a Schlenk line to a remaining water content below 10 ppm (Karl Fischer titration). All chemicals and ILs were stored in a glove box (GS Mega 4 from GS Glovebox Systemtechnik, Germany) under nitrogen atmosphere with a water and oxygen trace content < 1 ppm. To prepare electrolytes, metal salts were added in the desired concentration to the IL and stirred on a magnetic heating plate at ~ 80° C until the salts were completely dissolved.

Cyclic voltammetry (CV) investigations were carried out inside the glove box at a temperature of 100 °C and a scan rate of 20 mV/s, using a SP-300 potentiostat from Biologic (France) controlled by EC-Lab software Version 11.02. During all cyclic voltammetry experiments, we observed the continuous formation of loosely adhering, insoluble black particles in the vicinity of the electrode, probably due to IL degradation. The extent of this occurrence varied depending on the electrolyte composition. Such perturbations of the electrode surface and the electrode-electrolyte interface were shown to introduce significant errors in ohmic potential drop determination [41, 42]. Consequently, we refrained from ohmic drop compensation and constructed the electrochemical cell with minimal distance (~ 1 cm) between the working electrode (WE) and reference electrode (RE) to mitigate its effect. All electrochemical experiments were conducted with a three-electrode-arrangement. Copper sheets with a surface area of 1.2 cm2 and a platinum rod were used as WE and counter electrodes, CE, respectively. Before the experiments, the surface of the copper electrode was polished with sandpaper (SiC with 4000 grit) and rinsed with isopropanol inside the glove box. The platinum rod was rinsed with acetone and then heated in a hydrogen flame to red glow for several minutes. A lab-made ferrocene-based electrode was used as reference electrode (RE). The RE consisted of a platinum wire immersed in 5 mM ferrocene in the corresponding IL and was separated from the electrolyte with a porous glass frit (CoralPor®, purchased from GAMEC – Analysentechnik, Germany) with an average pore diameter of 10 nm. The potential stability of the RE was examined in a three-electrode cell, utilizing a Pt disk electrode (surface area 1.25 cm2, maximum operating temperature 70 °C) without rotation and a Pt wire as WE and CE, respectively. The RE was found to reproduce redox potentials accurately up to 24 h and again after renewal of the solution inside the RE glass capillary, as is illustrated in Fig. S1 in the supplementary information. The tested Fc/Fc+-RE shows a stable half-wave potential of approximatively + 70 mV over 24 h, which increases to ca. + 90 mV after 48 h. Upon renewal of the electrolyte inside the glass capillary, the half-wave potential decreases again to 68–72 mV. One could approximate that the drift of the RE was around 54 µV/h for the 168-h duration investigated, if fresh solution was added in the capillary of the RE, and around 450 µV/h if the solution is not refreshed. In this work, the potential of the RE was checked every time at the beginning of a set of deposition experiments and if a strong drift in its potential was observed, the electrolyte inside the glass capillary of the RE was replaced. After the electrodeposition experiments, deposits were rinsed twice with isopropanol inside the glovebox. A scanning electron microscope (SEM) model S-4800 (Hitachi High-Technologies Corporation, Japan) equipped with an energy-dispersive X-ray (EDX) detector was used to analyse the morphology and the elemental composition of the electrodeposited layers.

Results and discussion

TaF5 and different titanium halides in [BMP][TFSI] and [BMP][OTf]

We first investigated the effect of the concentration of the titanium salt on the electrochemical behaviour of Ta-Ti reduction process by cyclic voltammetry, measurements at 100 °C and on Cu working electrodes in [BMP][TFSI] (Fig. 1) and [BMP][OTf] (Fig. 2), TiF4 was therefore added to 0.25 M TaF5 in the corresponding IL at concentrations of 0.1 M and 0.25 M, and an initial CV at a scanning rate of 20 mV/s was recorded (Figs. 1 and 2). In this work, only the second cycles of the CVs will be shown since there were only slight changes in the current response after this cycle.

Clearly, adding TiF4 to the electrolyte strongly inhibits the electroreduction of TaF5 on Cu electrodes in both ILs- fact proved by the decrease in the cathodic current density with increasing the concentration of Ti in the ILs (Figs. 1 and 2). For instance, in the case of an equimolar ratio of TiF4 and TaF5 in [BMP][TFSI], TiF4 seems to completely inhibit the reduction of TaF5 species on Cu electrodes (Fig. 1, red curve). The respective CV exhibits no distinct cathodic peak and the detected cathodic current was similar in absolute values to the current measured in neat [BMP][TFSI] (not shown). If 0.1 M TiF4 was added to the [BMP[[TFSI] IL containing 0.25 M TaF5 a very broad cathodic wave at − 2.6 V was observed (Peak C1 in Fig. 1, black curve). However, compared to the current density in this potential region of pure TaF5 in [BMP][TFSI] without TiF4 (Fig. 1, blue curve), the effect of TiF4 addition seems to be mainly inhibitive: smaller current densities were observed when TiF4 was added to the IL and the potential value where the electrochemical reduction set in is moved towards more cathodic values (peak C1 in the blue and black curves, respectively). Similarly, when using [BMP][OTf] as IL instead, an equimolar concentration of TaF5 and TiF4 results in a pronounced hindrance of the electroreduction of TaF5 (Fig. 2, red curve). While the CV exhibits one cathodic peak (C1 in Fig. 2, red curve) at around -0.85 V and a significant increase in the current density below -1.9 V in the forward scan, the respective current densities are low compared to the electrolyte without TiF4 (C1 in Fig. 2, blue curve). In the reverse scan of 0.25 M TaF5 and 0.25 M TiF4 in [BMP][OTf], the cathodic current continues to flow and crosses the forward scan at -2.15 V, indicating that a nucleation process takes place. Although there was no deposit on the substrate, solid particles in the solution could be observed after the experiment, suggesting that the deposit did not adhere to the substrate or a chemical reaction with intermediate species occurred. The poor adhesion during electrodeposition could also be related to the presence of TiF4 at the IL/cathode interface, preventing the reduced tantalum species from bonding to the substrate. In comparison to [BMP][TFSI], the presence of TiF4 is less inhibitive on the electroreduction of TaF5 in [BMP][OTf]. Accordingly, when the concentration of TiF4 is reduced to 0.1 M (Fig. 2, black curve), two peaks, C1 and C2, in the cathodic branch of the CV can be observed at approximately − 0.8 V and − 1.5 V respectively, which are close in peak potential to peaks observed in neat TaF5 in [BMP][OTf] (C1 and C2 Fig. 2, blue curve, at ca. − 1 V and − 1.7 V respectively), but, nevertheless, that are still shifted towards more negative potentials, proving that the reduction process in the presence of Ti-ions occurs at lower potentials. A third cathodic process arises below − 2.5 V in 0.1 M TiF4 with 0.25 M TaF5 [BMP][OTf] (Fig. 2, black curve), which could be due to the set in of decomposition of the IL. Although here the oxidation peak in the reverse scan at − 2.55 V suggests that the reduction is not entirely irreversible, it coincides with the decomposition of [BMP]+ cation which starts around -2.7 V. An anodic peak, A1, could be observed in the solution containing only TaF5 in [BMP][OTf] (Fig. 2, blue curve), which indicates the dissolution of the deposited film.

The reduced inhibitive effect of TiF4 in [BMP][OTf] could be a consequence of the smaller titanium [OTf] complexes, blocking less area of the electrode surface, thereby facilitating the diffusion of TaF5 species to the cathode. However, the inhibitive effect of TiF4 remains pronounced, and TiF4 itself seems electrochemically inert in large parts of the cathodic stability range of both ILs. Therefore, TiF4 and TaF5, despite the equal nature of their anion, do not appear a suitable choice of metal salts to electrodeposit tantalum-titanium containing layers on Cu electrodes.

Although the experiments mentioned above did not yield a deposit, two conclusions can be drawn from the results. Firstly, a molar ratio of Ti to Ta lower than unity is more suitable to electrodeposit tantalum-titanium containing layers, and secondly, both the metal salts and the IL significantly influence the electroreduction of Ta(V) and Ti (IV). Therefore, we kept the titanium salt concentration constant at 0.1 M and investigated electrolytes with TiCl4 and TiBr4 as titanium source. Since the latter two both adopt a monomeric structure, this might occupy less space at the IL/cathode interface than the polymeric TiF4. Figure 3 shows the CV of 0.25 M TaF5 and 0.1 M TiCl4/TiBr4 in [BMP][OTf] and 0.25 M TaF5 in [BMP][OTf].

Compared to TiF4, adding other titanium halides to TaF5 in [BMP][OTf] inhibits the reduction of TaF5 less significantly. For instance, the CV of 0.25 M TaF5 and 0.1 M TiCl4 in [BMP][OTf] displays three cathodic processes (Fig. 3, red curve). Firstly, two cathodic peaks at -0.6 V (C1) and -1.3 V (C2) not exhibited in the CV of 0.25 M TaF5 [BMP][OTf], suggest that TiCl4 is reduced to Ti (II) by a two-step reduction in this potential region. Furthermore, the current density from open circuit potential, OCP, to -1.45 V increases compared to TaF5 in [BMP][OTf], indicating that the reduction of TaF5 is not affected by the presence of TiCl4 in this potential region. However, at more cathodic potentials, the presence of Ti (II) in the solution appears to inhibit the further reduction of the tantalum species. Specifically, the onset of a broad wave can be observed at around -2.25 V (C3). The small slope of this wave could be associated with the poorly soluble TiCl2 precipitating at the cathode, which not only prevents its reduction to elemental titanium, as reported by Endres et al. but also passivates the electrode [37]. After potentiostatic deposition in the potential region of C2-C3 (Fig. 3, red curve), a very thin black deposit could be observed. However, EDX analysis detected no titanium in this deposit but indicated that the deposit consisted mainly of IL elements in addition to 22.0 wt.-% Ta (not shown). Therefore, it seems that the presence of TiCl2 at the IL/cathode interface induces the decomposition of the IL, which could be associated with the high reactivity of titanium (II) chloride [34]. The reverse scan shows an oxidation peak at -1.05 V (A2) and the anodic peak exhibited at around -0.45 V (A1) increased in current density compared to TaF5 in [BMP][OTf], supporting that the reduction processes at C1 and C2 are attributed to the reduction of Ti (IV). However, the current density ratio of A2 and C2 is much lower than unity, which is a piece of further evidence that the reduction of Ti (III) to Ti (II) is linked to an irreversible process which prevents its reduction to elemental titanium.

Changing the titanium source to TiBr4 results in a more pronounced inhibition on the electroreduction of TaF5, while TiBr4 appears to remain electro-inactive in large parts of the cathodic branch of the CV (Fig. 3, black curve). Specifically, the absence of a sharp peak-shaped wave in the potential region from OCP to around -2.25 V indicates that the current in this potential region is mainly capacitive. Nevertheless, some small cathodic waves could be seen around − 0.7 V (C1) and − 1.7 V (C2), but not so pronounced as in the case when TiCl4 has been used. In particular, the reduction peak at -1.7 V in the CV of 0.25 M TaF5 in [BMP][OTf] (Fig. 3, blue curve) shows the highest current density when no Ti- precursor was added to the IL, and the lowest current density when TiBr4 was added to the solution, indicating the fact that adding Ti-precursors to the IL will inhibit the reduction process of Ta, too. In the reverse scan of 0.25 M TaF5 with 0.1 M TiBr4 in [BMP][OTf], one additional oxidation peak A3, arises at -2.3 V, indicating that the cathodic process happening below -2.5 V can be attributed to the reduction of TiBr4. However, as will be discussed in the following, the interaction [OTf]/TiBr4 appears to result in particularly stable titanium complexes. While the successful electrochemical deposition of tantalum-containing layers from TaF5 in ILs was reported, the above results suggest that TaF5 is not an appropriate choice for the co-deposition of tantalum and titanium.

We investigated several additional combinations of tantalum and titanium halides in [BMP][TFSI] and [BMP][OTf]. The respective CVs showed similar inhibiting effects caused by the titanium salts, mainly leading to a reduction in current density of the Ta(V) reduction processes, while the titanium species showed negligible electrochemical activity. Consequently, potentiostatic electrodeposition experiments in electrolytes with this characteristic electrochemistry did not result in the deposition of a layer. A summary of the electrolyte compositions studied is presented in Table 1. While a wide separation of deposition potentials of the parent metals could prevent the deposition of tantalum-titanium containing films, the total hindrance of deposition indicates that the presence of titanium halides blocks the tantalum species from accessing the cathode. This blockage might be connected to the preferential adsorption of titanium species to the copper cathode, decreasing the accessible surface area. In addition, Endres et al. suggested the formation of bulky titanium clusters after initial reduction reactions, which would also explain the increased inhibitive effect at more cathodic potentials and the complete hindrance of deposition [37].

TaBr5 and TiBr4 in [BMP][TFSI] and [BMP][OTf]

As the above findings suggest that the electrodeposition of tantalum-titanium containing films in ILs from metal halides is not feasible with TaF5 as tantalum source, further experiments were carried out with TaBr5 and TiBr4 (CVs in Fig. 4).

As observed before for 0.25 M TaF5 and 0.1 M TiBr4 in [BMP][OTf] (black curve in Fig. 3), the addition of TiBr4 to 0.25 M TaBr5 in [BMP][OTf] causes a strong decrease in current density in the potential region from OCP to -1.50 V (Fig. 4, comparison of black and red curves). For instance, the broad wave with a peak potential at around -0.6 V (C1) in the electrolyte without TiBr4 (Fig. 4, black curve) is comparatively narrow and a decrease in current density can be observed when 0.1 M TiBr4 is added to the solution. In more cathodic potential regions, the CV in 0.25 M TaBr5 and 0.1 M TiBr4 in [BMP][OTf] (Fig. 4, red curve) exhibits two cathodic peaks at -2.05 V (C2) and -2.3 V (C3). The similar peak separation compared to the reduction processes of 0.25 M TaBr5 in [BMP][OTf] at -1.70 V and -1.95 V indicates that the reduction potentials shifted negatively due to an increased electrochemical stability in the presence of TiBr4 in solution. Furthermore, the addition of TiBr4 to 0.25 M TaBr5 in [BMP][OTf] does not appear to cause any new reduction reactions in the cathodic branch of the CV, suggesting that TiBr4 remains electro-inactive. To confirm this, further experiments with different TiBr4 concentrations were carried out, which will be discussed below. The reverse scan displays the onset of an anodic peak, A1, at -0.5 V, similar in potential to the electrolyte without TiBr4. Since after the potential scan a thin black deposit can be observed on the Cu substrate, this peak can be attributed to the partial dissolution of the deposit. The deposition occurs at C3 and therefore potentiostatic electrodeposition at -2.0 V was carried out for 30 min to investigate the composition and morphology of the deposit (Fig. 5).

The deposit shows a spongy morphology (Fig. 5) which is characteristic when deposition is under mass-transport limitation with a low nucleation rate [43]. This low nucleation rate could be caused by a decreased concentration of tantalum species at the IL/cathode interface due to TiBr4 preferentially adsorbing onto the cathode, which then blocks the tantalum species from the electrode surface. Although it was difficult from the CV results to prove that TiBr4 is reduced to elemental titanium (Fig. 4, red curve), EDX analysis detected titanium (2.9 wt.-%) along with tantalum (55 wt.-%) in the deposit presented in Fig. 5 (see also Table S1 (found in the supplementary information), EDX element analysis for other potentiostatic depositions). Other detected elements, such as C, N, O, F, S and Br can be attributed to the IL incorporated into the layer or co-deposited through decomposition. Furthermore, deposition experiments in the potential region from -1. to -2.0 V showed poor surface coverage with individual grains, again demonstrating that the deposition is associated with a low nucleation rate.

The Ta and Ti content of the potentiostatically deposited films obtained by the EDX analysis is given in Table S1 for the range of ILs and precursors investigated in this work. One can see in Table S1 that the amount of Ti in the films generally was constant or increased slightly with increasing the deposition potential towards more cathodic values independent of the IL and precursors used, while the content of Ta in the films seems to reach a maximum between − 1.8 and − 2.0 V and decreases at more negative potentials. More Ta than Ti was detected in the films, fact that confirms the reduction of Ta-ions is more favorable in the chosen ILs than the reduction of Ti-ions.

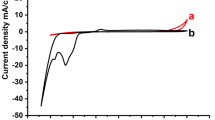

In contrast to TaBr5 and TiBr4 in [BMP][OTf], when using [BMP][TFSI] instead, TiBr4 appears to undergo electroreduction without negatively affecting the reduction of TaBr5. In particular, the addition of 0.1 M TiBr4 to the electrolyte leads to three additional cathodic peaks in the CV (Fig. 4, comparison between the green and blue curve). Firstly, a broad wave arises at the OCP with a peak potential at -0.4 V (C1). Secondly, another cathodic peak arises at − 0.9 V (C2) and finally, a third additional cathodic peak can be observed at -2.15 V (C3). Since only Ti (III) and Ti (II) are known to form stable compounds, the occurrence of three additional reduction processes, when adding TiBr4, indicates that a three-step reduction of Ti (IV) to Ti (0) occurs. Additionally, another cathodic wave appears at -2.45 V (C4) which are attributed to the reduction of the tantalum species (Fig. 4, blue curve). A black deposit on the substrate can be observed after the potential scan. The redissolution of the deposit seems to be kinetically impaired, as the reverse scan exhibits only one anodic peak, A1, at -0.35 V. To examine the morphology (Fig. 6) and composition of the deposit, potentiostatic deposition in the potential region of C3 was performed.

Contrary to deposits from 0.25 M TaBr5 and 0.1 M TiBr4 in [BMP][OTf] at -2.0 V, the deposit morphology from 0.25 M TaBr5 and 0.1 M TiBr4 in [BMP][TFSI] at -2.1 V is more compact and smoother (Fig. 6). Although the electrodeposition from [BMP][TFSI] seems to be accompanied by a higher tendency to form cracks, the surface coverage is significantly improved which could be attributed to TiBr4 complexes in [BMP][TFSI] blocking less cathode surface. As [TFSI]− is considerably larger than [OTf]−, this reduced blockage could be associated with a lower tendency to form titanium clusters when the titanium species is speciated with [TFSI]−. Accordingly, EDX analysis of the layer presented in Fig. 6 indicated a slightly increased amount of titanium (4.1 wt.-%) in the deposit, while other elements were tantalum (55 wt.-%) and IL components. The deposition of titanium seems to be located at around -2.1 V, since deposition at more positive potentials resulted in decreased Ti in the layer (1.8 to 2.3 wt.-%), while Ta remained around 55 wt.-%. Deposits at more negative potentials showed increased crack formation, were powdery and adhered poorly to the substrate, suggesting that both tantalum and titanium deposition potentials are closely located around C3-C4. The proximity of deposition potentials is an important condition for successfully electrodepositing alloys which appears to be satisfied in TaBr5 and TiBr4 in [BMP][TFSI].

Influence of TiBr4 concentration on the electrochemical reduction

To investigate the effect of TiBr4 concentration on the reduction processes in TaBr5 and TiBr4 in [BMP][OTf] and [BMP][TFSI] and on the deposit composition, the concentration of TiBr4 in both ILs was varied from 0.05 to 0.15 M and characterized with CV (Figs. 7 and 9, respectively).

As can be seen in the CVs of 0.25 M TaBr5 and TiBr4 [BMP][OTf] with TiBr4 concentration ranging from 0.05 to 0.15 M (Fig. 7), the addition of TiBr4 results in an increasingly pronounced inhibition of the cathodic reactions. At 0.15 M TiBr4 (Fig. 7, blue curve), the first reduction process at -0.6 V (Fig. 7, black curve) is completely suppressed and as in 0.25 M TaF5 with 0.1 M TiBr4 [BMP][OTf] (Fig. 3, black curve), only capacitive currents flow in this potential region. Additionally, the second and third cathodic peaks at -2.05 V and -2.35 V (Fig. 7, black curve) merge into a single broad wave, C1 in Fig. 7, blue curve, which indicates the reduction process at around -2.05 V exhibited at lower concentrations of TiBr4 is absent at 0.15 M. Since this pronounced inhibiting effect could be observed in all electrolyte compositions with [BMP][OTf], the speciation of TiBr4 with [BMP][OTf], must result in complexes that are electrochemically stable in the bulk of the cathodic stability limit of [BMP]+. As mentioned earlier, this stable TiBr4 complex seems to prevent the tantalum species from accessing the cathode which is also supported by the results of potentiostatic deposition experiments (Fig. 8).

When electrodeposition is carried out in 0.25 M TaBr5 and 0.05 M TiBr4 in [BMP][OTf] at -2.0 V (Fig. 8a, b), the deposit is visibly smoother and more compact than in 0.25 M TaBr5 and 0.10 M/0.15 M TiBr4 in [BMP][OTf] (Fig. 8c, d). The increased substrate coverage at lower concentrations of TiBr4 is further evidence that TiBr4 hinders the tantalum species from accessing the cathode. EDX analysis of the deposit detected 60.7 wt.-% Ta and 0.7 wt.-% Ti. The negative correlation of titanium and tantalum content also supports that the presence of TiBr4 in [BMP][OTf] inhibits the reduction of TaBr5. Consequently, the deposit obtained at -2.0 V in 0.25 M TaBr5 and 0.15 M TiBr4 in [BMP][OTf] showed a morphology consisting of individual islands and poor surface coverage. EDX analysis of this layer indicated a significantly lower amount of tantalum (46 wt.-%) but 1.3 wt.-% of titanium in the deposit whereas the deposit contained more elements attributed to [BMP][OTf]. Although EDX detected titanium in all deposits from TaBr5 and TiBr4 in [BMP][OTf], it is more plausible that titanium is co-deposited with tantalum as an inclusion of intermediate titanium compounds than as elemental titanium. This is supported by the absence of any new cathodic processes in the CV when TiBr4 is added to the electrolyte.

Adding TiBr4 in the [BMP][OTf] solution inhibits the reduction process of TaBr5 and TiBr4 appears to be electro-inactive in this IL However, TiBr4 is reduced in a three-step reduction process and significantly less inhibits the reduction of TaBr5 in [BMP][TFSI] (CVs in Fig. 9).

In particular, the current densities of C2 and C4 (Fig. 9, black curve vs blue curve) display a dependence on the concentration of TiBr4, which confirms that both cathodic processes can be attributed to the electroreduction of TiBr4 in the solution. While C3 in the CV of 0.25 M TaBr5 and 0.1 M TiBr4 in [BMP][TFSI] at -0.9 V could not be detected at 0.15 M TiBr4, the increased current density at -0.6 V indicates that the peak potential of this process is shifted anodically when the concentration of TiBr4 is set to 0.15 M. Similarly, C4 and C5 shifted in anodically, and the formation of a shoulder indicates that C4 can be attributed to titanium. Therefore, TiBr4 undergoes a three-step reduction which suggests the formation of elemental titanium in [BMP][TFSI]. The reverse scan exhibits one additional oxidation peak at -1.6 V, which might be associated with the re-oxidation of titanium species in the deposit. Additionally, the anodic peak, A1, at -0.5 V increases, however, the redissolution of the deposit appears to be kinetically impaired, as all ratios of anodic and cathodic peak current densities are significantly lower than unity. The difference in electrochemical reduction behavior of TaBr5 and TiBr4 in [BMP][TFSI] compared to [BMP][OTf] could be related to the lower viscosity of [BMP][TFSI] and [BMP][OTf], improving transport properties. While the viscosity of [BMP][OTf] at 100° C is 12.95 mPa·s, due to the delocalized charge distribution and thus weaker cation-anion interaction, the viscosity of [BMP][TFSI] at 100° C is only 8.45 mPa·s [44]. In addition to its lower viscosity, the weakly coordinating [TFSI]− might form less stable metal complexes which are reduced at less negative electrode potentials than [OTf]-metal complexes. Furthermore, the bulky [TFSI]− might sterically hinder the collision of metal centres and thus prevent the formation of metal clusters at the IL/cathode interface.

Influence of TiBr4 concentration and deposition potential on deposit morphology

To investigate the effect of TiBr4 concentration and the deposition potential on the morphology, potentiostatic experiments in the potential region from -2.0 to -2.4 V were conducted (Fig. 10a, b).

As can be seen, the deposit from 0.25 M TaBr5 and 0.05 M TiBr4 in [BMP][TFSI] at -2.0 V shows an increased occurrence of cracks compared to 0.10 M TiBr4. Additionally, the formation of coarse-grained structures and an increased surface roughness can be observed. Contrary to [BMP][OTf], decreased TiBr4 concentration leads to a rougher deposit morphology in [BMP][TFSI]. EDX analysis of deposits from 0.25 M TaBr5 and 0.05 M TiBr4 in [BMP][TFSI] found an average of 61.7 wt.-% Ta, while Ti decreased to about 1.2 wt.-%. Deposition at -2.4 V led mainly to a reduced Ta and Ti content, while more elements attributed to IL were detected in the layers, showing that IL components were decomposed at a higher rate at more negative deposition potentials. The roughness and, above all, the occurrence of cracks increase at more cathodic potentials, as can be seen in the SEM micrograph of the layer deposited at -2.4 V (Fig. 10c, d). As the increased roughness of the deposit from 0.25 M TaBr5 and 0.05 M TiBr4 in [BMP][TFSI] suggests, increasing the TiBr4 concentration to 0.15 M leads to a smoother surface morphology (Fig. 11).

Although deposits from this electrolyte appear rougher than deposits from the electrolyte with 0.10 M TiBr4, the addition of TiBr4 to the solution generally tends to level the surface morphology. The increased smoothness of the deposits obtained in electrolytes with TiBr4 shows that, in [BMP][TFSI], the presence of TiBr4 not only significantly less inhibits the tantalum reduction, but also contributes to the uniform growth of layers during electrodeposition. The deposit composition changed due to the increased TiBr4 concentration similar as in [BMP][OTf], however, the negative correlation of tantalum and titanium in the deposit is far less significant. EDX showed 58 wt.-% Ta and 4.7 wt.-% in the deposit presented in Fig. 11, demonstrating that increased TiBr4 concentration leads to higher Ti fraction in the deposit, while significantly less inhibiting the tantalum deposition. The reduction of TaBr5 in [BMP][TFSI], as in [BMP][OTf], appears to be kinetically favoured compared to the reduction of TiBr4, as indicated by the EDX results (Table S1).

Outlook

To study the chemical composition of electrodeposited layers from TaBr5 and TiBr4 in [BMP][TFSI] in detail, further investigations should be carried out, e.g. X-ray diffractometry (XRD) and X-ray photoelectron spectroscopy (XPS). Although EDX detected titanium and tantalum in all deposits from TaBr5 and TiBr4 in [BMP][TFSI] and [BMP][OTf], this technique cannot clarify the oxidation states of Ta and Ti in the layers. This study aimed to examine the electrochemical behavior of a range of different electrolyte compositions to evaluate the feasibility of electrodepositing tantalum-titanium films from ILs. Therefore, we refrained from a comprehensive study of the chemical layer composition. However, we want to address other possible mechanisms, such as homogeneous or heterogeneous chemical reactions, which could also lead to the deposition of titanium species onto the cathode. Nevertheless, even though further studies may be necessary, CV and potentiostatic deposition in TaBr5 and TiBr4 in [BMP][TFSI] showed promising results, indicating that the electrodeposition of tantalum-titanium containing layers from this electrolyte is feasible.

Conclusion

In this study, we investigated the electrochemical deposition of tantalum-titanium layers from two ionic liquids ([BMP][OTf] and [BMP][TFSI]) using different tantalum and titanium halides (TaF5, TaBr5, TiF4, TiCl4, TiBr4). While the addition of titanium halides strongly inhibited the electrochemical reduction of tantalum pentahalides in most systems, we could identify one electrolyte composition where the titanium species does not cause this result and is electroactive itself. Specifically, the CV of TaBr5 and TiBr4 in [BMP][TFSI] exhibited three additional cathodic peaks due to the presence of TiBr4 in the solution. As confirmed by CV at various TiBr4 concentrations, all three peaks can be attributed to the reduction of TiBr4 in [BMP][TFSI]. Since there are only two stable intermediate oxidation states of Ti, we attribute those cathodic processes to the three-step reduction of Ti (IV) to Ti (0). Furthermore, we could show that it is possible to electrodeposit tantalum- and titanium-containing layers from this electrolyte. EDX analysis confirmed that deposits not only contained around 60 wt.-% Ta, but also up to ca. 8 wt.-% Ti. The divergent electrochemical behaviour of TaBr5 and TiBr4 in [BMP][TFSI] compared to all other investigated electrolyte compositions must be linked to the chemical interaction of [BMP][TFSI] and TiBr4. While in [BMP][OTf], the addition of TiBr4 significantly inhibited the reduction, this was not the case in [BMP][TFSI]. The increased electroactivity of TiBr4 in [BMP][TFSI] can be explained by the weakly coordinating nature of [TFSI]−, resulting in electrochemically less stable metal complexes. Additionally, the bulkier [TFSI]− appears to minimize the possibility of titanium metal centres to collide with each other and react in the formation of bulky metal clusters, reducing the blockage of the cathode surface. However, further studies of the IL/cathode interface, e. g. using atomic force microscopy, are necessary to confirm this. Future investigations should also be aimed at the detailed analysis of the chemical layer composition, e.g. with XPS and XRD. Additionally, pulsed-current deposition could minimize the co-deposition of impurities and reduce the occurrence of cracks as well as increase the titanium content in electrodeposits.

References

Zhou YL, Niinomi M, Akahori T, Fukui H, Toda H (2005) Mater Sci Eng A 398:28–36. https://doi.org/10.1016/j.msea.2005.03.032

Gladczuk L, Patel A, Paur CS, Sosnowski M (2004) Thin Solid Films 467:150–157. https://doi.org/10.1016/j.tsf.2004.04.041

Xu C, Hua Y, Zhang Q, Li J, Lei Z, Lu D (2017) J Solid State Electrochem 21:1349–1356. https://doi.org/10.1007/s10008-016-3498-7

Bruchiel-Spanier N, Betsis S, Naim G, Mandler D (2022) J Solid State Electrochem 26:1871–1896. https://doi.org/10.1007/s10008-022-05235-6

Cardarelli F, Taxil P, Savall A (1996) Int J Refract Met Hard Mater 14:365–381. https://doi.org/10.1016/S0263-4368(96)00034-0

Zhang M, Yang B, Chu J, Nieh TG (2006) Scr Mater 54:1227–1230. https://doi.org/10.1016/j.scriptamat.2005.12.027

Bernoulli D, Müller U, Schwarzenberger M, Hauert R, Spolenak R (2013) Thin Solid Films 548:157–161. https://doi.org/10.1016/j.tsf.2013.09.055

Albrecht S, Cymorek C, Andersson K, Reichert K, Wolf R (2011) Tantalum and tantalum compounds, in Ullmann’s Encyclopedia of Industrial Chemistry. Wiley-VCH Verlag, Weinheim, p 6

Fathi MH, Mortazavi V (2007) Tantalum, niobium and titanium coatings for biocompatibility improvement of dental implants. Dent Res J 4(2):74–82, ISSN: 1735-3327 (Print)/ 2008-0255 (Online), Wolters Kluwer Medknow Publications

Thorwarth K, Thorwarth G, Figi R, Weisse B, Stiefel M, Hauert R (2014) Int J Mol Sci 15:10527–10540. https://doi.org/10.3390/ijms150610527

Prigent H, Cathelineau G (1998) J Biomed Mater Res A 39:200–206. https://doi.org/10.1002/(SICI)1097-4636(199802)39:2%3c200::AID-JBM5%3e3.0.CO;2-T

Song Y, Xu DS, Yang R, Li D, Wu WT, Guo ZX (1999) Mater Sci Eng A 260:269–274. https://doi.org/10.1016/S0921-5093(98)00886-

Zhao D, Han C, Li Y, Li J, Zhou K, Wei Q, Liu J, ShiY (2019) J Alloys Compd 804: 288–298. https://doi.org/10.1016/j.jallcom.2019.06.307

Mendis S, Xu W, Tang HP, Jones LA, Liang D, Thompson R, Choong P, Brandt M, Qian M (2020) Appl Surf Sci 506:145013. https://doi.org/10.1016/j.apsusc.2019.145013

Dercz G, Matuła I, Zubko M, Kazek-Kęsik A, Maszybrocka J, Simka W, Dercz J, Świec P, Jendrzejewska I (2018) Mater Charact 142:124–136. https://doi.org/10.1016/j.matchar.2018.05.033

Morita A, Fukui H, Tadano H, Hayashi S, Hasegawa J, Niinomi M (2000) Mater Sci Eng A 280:208–213. https://doi.org/10.1016/S0921-5093(99)00668-1

Endres F, MacFarlane D, Abbott A (2017) Electrodeposition from ionic liquids, 2nd edn. Wiley-VCH Verlag, Weinheim, p 105

Ohno H (2005) Electrochemical aspects of ionic liquids, 2nd edn. John Wiley & Sons, Hoboken, New Jersey, p 111

Zhang S, Sun N, He X, Lu X, Zhang X (2006) J Phys Chem Ref Data 35:1475–1517. https://doi.org/10.1063/1.2204959

Zein El Abedin S (2008) Trans Inst Met Finish 86: 220–226. https://doi.org/10.1179/174591908X327545

Krischok S, Ispas A, Zühlsdorff A, Ulbrich A, Bund A, Endres F (2012) ECS Trans 50:229–237. https://doi.org/10.1149/05011.0229ecst

Liu F, Deng Y, Han X, Hu W, Zhong C (2016) J Alloys Compd 654:163–170. https://doi.org/10.1016/j.jallcom.2015.09.137

Marciniak A (2010) Int J Mol Sci 11:1973–1990. https://doi.org/10.3390/ijms11051973

Melton TJ, Joyce J, Maloy JT, Boon JA, Wilkes JS (1990) J Electrochem Soc 137:3865–3869. https://doi.org/10.1149/1.2086315

Ispas A, Adolphi B, Bund A, Endres F (2010) Phys Chem Chem Phys 12:1793–1803. https://doi.org/10.1039/B922071M

Vacca A, Mascia M, Mais L, Rizzardini S, Delogu F, Palmas S (2014) Electrocatalysis 5:16–22. https://doi.org/10.1007/s12678-013-0168-8

Nahra M, Svecova L, Chaînet E (2015) Electrochim Acta 182:891–899. https://doi.org/10.1016/j.electacta.2015.09.106

Nahra M, Svecova L, Sergent N, Chaînet E (2021) J Electrochem Soc 168:082501. https://doi.org/10.1149/1945-7111/ac1697

Liu Z, Cheng J, Höfft O, Endres F (2023) J Solid State Electrochem 27:371–378. https://doi.org/10.1007/s10008-022-05321-9

Elbasiony AM, Prowald A, Zeil El Abedin, S, Endres F (2022) J Solid State Electrochem 26:783–789. https://doi.org/10.1007/s10008-021-05109-3

Liu Z, Borisenko N, Zein El Abedin S, Endres F (2014) J Solid State Electrochem 18:2581–2587. https://doi.org/10.1007/s10008-014-2516-x

Mallakpour S, Dinari M (2012) Ionic liquids as green solvents: progress and prospects. green solvents II: properties and applications of ionic liquids. Springer, Dordrecht, pp 1–32

Popov BN, Kimble MC, White RE, Wendt H (1991) J Appl Electrochem 21:351–357. https://doi.org/10.1007/BF01020221

Haarberg GM, Rolland W, Sterten A, Thonstad J (1993) J Appl Electrochem 23:217–224. https://doi.org/10.1007/BF00241912

Abbott AP, Bettley A, Schiffrin DJ (1993) J Electroanal Chem 347:153–164. https://doi.org/10.1016/0022-0728(93)80085-V

Nohira T (2020) Electrochemistry 88:477–488. https://doi.org/10.5796/electrochemistry.20-00098

Endres F, Zein El Abedin S, Saad AY, Moustafa EM, Borissenko N, Price WE, Wallace GG, MacFarlane DR, Newman PJ, Bund A (2008) Phys Chem Chem Phys 10:2189–2199. https://doi.org/10.1039/B800353J

Zein El Abedin S, Farag HK, Moustafa EM, Welz-Biermann U, Endres F (2005) Phys Chem Chem Phys 7:2333–2339, https://doi.org/10.1039/B502789F

Borisenko N, Ispas A, Zschippang E, Liu Q, Zein El Abedin S, Bund A, Endres F (2009) Electrochim Acta 54:1519–1528. https://doi.org/10.1016/j.electacta.2008.09.042

Borisenko N, Ispas A, Wu Q, Carstens T, Behrens N, Karg J, Engemann T, Endrikat A, Bund A, Endres F (2020) J Electrochem Soc 167:122512. https://doi.org/10.1149/1945-7111/abb27f

Ehrhardt WC (1990) IR Drop in Electrochemical Corrosion Studies— Part I: Basic Concepts and Estimates of Possible Measurement Errors. Nisancioglu K Theoretical Problems Related to Ohmic Resistance Compensation. In Scribner LL, Taylor SR (eds) The Measurement and Correction of Electrolyte Resistance in Electrochemical Tests, Astm Intl, Baltimore MD, p. 27–77. https://doi.org/10.1520/STP1056-EB. ISBN: 0-8031-1283-1, ISBN-EB: 978-0-8031-5118-5, ISBN-13: 978-0-8031-1283-4

Glass GK (1986) The effect of a change in surface conditions produced by anodic and cathodic reactions on the passivation of mild steel. Corros Sci 26:441–454. https://doi.org/10.1016/0010-938X(86)90139-3

Popov KI, Djokić SS, Nikolić ND, Jović VD (2016) Mechanisms of formation of some forms of electrodeposited pure metals. In: Morphology of electrochemically and chemically deposited metals. Springer, Cham. https://doi.org/10.1007/978-3-319-26073-0_2

Gacino FM, Regueira T, Lugo L, Comunas MJP, Fernandez J (2011) J Chem Eng Data 56:4984–4999. https://doi.org/10.1021/je200883w

Acknowledgements

The authors also would like to thank Dr. Michael Stich (TU Ilmenau) for performing Karl Fischer titration of all metal salts and ILs used in our experiments and Anna Endrikat (TU Ilmenau) for the many fruitful discussions.

Funding

Open Access funding enabled and organized by Projekt DEAL. The authors gratefully acknowledge the funding by BMBF (Bundesministerium für Bildung und Forschung, Germany) within the project GALACTIF under grant number 13XP5017F.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Engemann, T., Ispas, A. & Bund, A. Electrochemical reduction of tantalum and titanium halides in 1-butyl-1-methylpyrrolidinium bis (trifluoromethyl-sulfonyl)imide and 1-butyl-1-methylpyrrolidinium trifluoromethanesulfonate ionic liquids. J Solid State Electrochem 28, 1557–1570 (2024). https://doi.org/10.1007/s10008-023-05773-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05773-7