Abstract

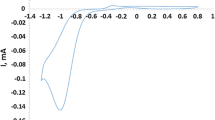

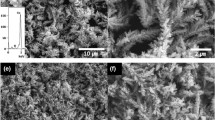

The influence of chronopotentiometry response on the morphology and structure of galvanostatically synthesized tin dendritic particles has been investigated. Sn dendrites were electrodeposited at the current density 1.5 times larger than the limiting diffusion current density (− 3 mA cm−2) with various amounts of the electricity (200 and 400 mC), and the obtained morphology and structure of the particles were characterized by SEM and XRD techniques, respectively. The strong effect of the amount of spent electricity on the morphology and structure of the particles was observed, and it is explained by morphological and structural analysis of Sn particles produced potentiostatically at various cathodic potentials selected to be in line with the recorded chronopotentiometry response. The strong correlation among chronopotentiometry response, morphology, and structure of the Sn dendrites was established. The spear-like and the dendrites with prismatic branches possessed the strong (200),(400) preferred orientation, and they were obtained with a chronopotentiometry response of about − 1200 mV vs. Ag/AgCl. The chronopotentiometry responses in the − 1210 ÷ − 1740 mV vs. Ag/AgCl range caused a formation of the fern-like dendrites with the strong (220),(440) preferred orientation. Based on the obtained results, it follows that the chronopotentiometry analysis represents good diagnostic criteria for obtaining Sn powder particles of desired morphology and structure.

Similar content being viewed by others

References

Tin powder – production and applications. https://nanografi.com/blog/tin-sn-powder/. Accessed 07 Oct 2022

Rudnik E (2013) Effect of anions on the electrodeposition of tin from acidic gluconate baths. Ionics 19:1047–1059. https://doi.org/10.1007/s11581-012-0819-4

Wang Z, Ru J, Hua Y, Bu J, Geng X, Zhang W (2021) Electrodeposition of Sn powders with pyramid chain and dendrite structures in deep eutectic solvent: roles of current density and SnCl2 concentration. J Solid State Electrochem 25:1111–1120. https://doi.org/10.1007/s10008-020-04894-7

Zhang LP, Zhao YY (2017) Particle size distribution of tin powder produced by centrifugal atomisation using rotating cups. Powder Technol 318:62–67. https://doi.org/10.1016/j.powtec.2017.05.038

Chee SS, Lee JH (2012) Reduction synthesis of tin nanoparticles using various precursors and melting behavior. Electron Mater Lett 8:587–593. https://doi.org/10.1007/s13391-012-2086-y

Zou CD, Gao YL, Yang B, Zhai QJ (2010) Size-dependent melting properties of Sn nanoparticles by chemical reduction synthesis. Trans Nonferrous Met Soc China 20:248–253. https://doi.org/10.1016/S1003-6326(09)60130-8

Chee SS, Lee JH (2012) Synthesis of tin nanoparticles through modified polyol process and effects of centrifuging and drying on nanoparticles. Trans Nonferrous Met Soc China 22:707–711. https://doi.org/10.1016/S1003-6326(12)61791-9

Qiu L, Pol VG, Calderon-Moreno J, Gedanken A (2005) Synthesis of tin nanorods via a sonochemical method combined with a polyol process. Ultrason Sonochem 12:243–247. https://doi.org/10.1016/j.ultsonch.2004.02.001

Dong J, Wu F, Han Q, Qi J, Gao W, Wang Y, Li T, Yang Y, Sun M (2020) Electrochemical synthesis of tin plasmonic dendritic nanostructures with SEF capability through in situ replacement. RSC Adv 10:36042–36050. https://doi.org/10.1039/D0RA06483A

Riviello AE Jr, Young D, Sebba F (1994) A novel method for production of finely divided tin metal powders. Powder Technol 78:19–24. https://doi.org/10.1016/0032-5910(93)02767-5

Amiri M, Nouhi S, Azizian-Kalandaragh Y (2015) Facile synthesis of silver nanostructures by using various deposition potential and time: a nonenzymetic sensor for hydrogen. Mater Chem Phys 155:129–135. https://doi.org/10.1016/j.matchemphys.2015.02.009

Popov KI, Djokić SS, Nikolić ND, Jović VD (2016) Morphology of electrochemically and chemically deposited metals. Springer New York USA 1–368. https://doi.org/10.1007/978-3-319-26073-0

Popov KI, Pavlović MG, Jovićević JN (1989) Morphology of tin powder particles obtained in electrodeposition on copper cathode by constant and square-wave pulsating overpotential from Sn(II) alkaline solution. Hydrometallurgy 23:127–137. https://doi.org/10.1016/0304-386X(89)90023-6

Kim TH, Hong KS, Sohn DR, Kim MJ, Nam DH, Cho EA, Kwon HS (2017) One-step synthesis of multilayered 2D Sn nanodendrites as a high-performance anode material for Na-ion batteries. J Mater Chem A 5:20304–20315. https://doi.org/10.1039/C7TA06469A

Rudnik E, Włoch G (2013) Studies on the electrodeposition of tin from acidic chloride–gluconate solutions. Appl Surf Sci 265:839–849. https://doi.org/10.1016/j.apsusc.2012.11.130

He A, Liu Q, Ivey DG (2008) Electrodeposition of tin: a simple approach. J Mater Sci: Mater Electron 19:553–562. https://doi.org/10.1007/s10854-007-9385-3

Shin HC, Dong J, Liu M (2003) Nanoporous structures prepared by an electrochemical deposition process. Adv Mater 15:1610–1614. https://doi.org/10.1002/adma.200305160

Khabazian S, Sanjabi S, Tonti D (2020) Electrochemical growth of two-dimensional tin nano-platelet as high-performance anode material in lithium-ion batteries. J Ind Eng Chem 84:120–130. https://doi.org/10.1016/j.jiec.2019.12.027

Azpeitia LA, Gervasi CA, Bolzan AE (2019) Electrochemical aspects of tin electrodeposition on copper in acid solutions. Electrochim Acta 298:400–412. https://doi.org/10.1016/j.electacta.2018.12.040

Low CTJ, Walsh FC (2008) The influence of a perfluorinated cationic surfactant on the electrodeposition of tin from a methanesulfonic acid bath. J Electroanal Chem 615:91–102. https://doi.org/10.1016/j.jelechem.2007.11.031

Nikolić ND, Lović JD, Maksimović VM, Živković PM (2022) Morphology and structure of electrolytically synthesized tin dendritic nanostructures. Metals 12:1201. https://doi.org/10.3390/met12071201

Wranglen G (1960) Dendrites and growth layers in the electrocrystallization of metals. Electrochim Acta 2:130–146. https://doi.org/10.1016/0013-4686(60)87010-7

Walsh FC, Low CTJ (2016) A review of developments in the electrodeposition of tin. Surf Coat Technol 288:79–94. https://doi.org/10.1016/j.surfcoat.2015.12.081

Lodge AW, Hasan MM, Bartlett PN, Beanland R, Hector AL, Kashtiban RJ, Levason W, Reid G, Sloan J, Smith DC, Zhang W (2018) Electrodeposition of tin nanowires from a dichloromethane based electrolyte. RSC Adv 8:24013–24020. https://doi.org/10.1039/C8RA03183E

Santato C, Lopez CM, Choi K-S (2007) Synthesis and characterization of polycrystalline Sn and SnO2 films with wire morphologies. Electrochem Commun 9:1519–1524. https://doi.org/10.1016/j.elecom.2007.02.006

Wang Z, Ru J, Hua Y, Wang D, Bu J (2020) Morphology-controlled preparation of Sn powders by electrodeposition in deep eutectic solvent as anodes for lithium ion batteries. J Electrochem Soc 167:082504. https://doi.org/10.1149/1945-7111/ab8824

Cao X, Xu L, Wang C, Li S, Wu D, Shi Y, Liu F, Xue X (2020) Electrochemical behavior and electrodeposition of Sn coating from choline chloride–urea deep eutectic solvents. Coatings 10:1154. https://doi.org/10.3390/coatings10121154

Liu D, Groult H, Gaillon L, Rizzi C, Soulmi N, Julien CM, Briot E, Krulic D (2015) Tunable electrodeposition of Sn and Sn-based alloys using ionic liquids. J Solid State Electrochem 19:2517–2532. https://doi.org/10.1007/s10008-015-2809-8

Hsu CH, Yang CH, Wang YC, Chang JK (2014) Nanostructured tin electrodeposited in ionic liquid for use as an anode for Li-ion batteries. J Mater Chem A 2:16547–16553. https://doi.org/10.1039/C4TA03709J

Elbasiony AMR, Zein El Abedin S, Endres F (2014) Electrochemical synthesis of freestanding tin nanowires from ionic liquids. J Solid State Electrochem 18:951–957. https://doi.org/10.1007/s10008-013-2340-8

Elbasiony AM, Prowald A, Abedin SZE, Endres F (2022) Electrochemical synthesis of nanowires and macroporous CuSn alloy from ionic liquids. J Solid State Electrochem 26:783–789. https://doi.org/10.1007/s10008-021-05109-3

Winand R (1994) Electrodeposition of metals and alloys–new results and perspectives. Electrochim Acta 39:1091–1105. https://doi.org/10.1016/0013-4686(94)E0023-S

Nikolić ND, Živković PM, Pavlović MG, Baščarević Z (2019) Overpotential controls a morphology of electrolytically produced copper dendritic forms. J Serb Chem Soc 84:1209–1220. https://doi.org/10.2298/JSC190522066N

Popov KI, Pavlović MG, Maksimović MD, Krstajić S (1978) The comparison of galvanostatic and potentiostatic copper powder deposition on platinum and aluminium electrodes. J Appl Electrochem 8:503–514. https://doi.org/10.1007/BF00610795

Lj A, Pavlović MM, Maksimović VM, Vuković M, Stevanović JS, Bugarin M, Nikolić ND (2017) Comparative morphological and crystallographic analysis of electrochemically- and chemically-produced silver powder particles. Metals 7:160. https://doi.org/10.3390/met7050160

Lj A, Maksimović VM, Baščarević Z, Ignjatović N, Bugarin M, Marković R, Nikolić ND (2019) Influence of the shape of copper powder particles on the crystal structure and some decisive characteristics of the metal powders. Metals 9:56. https://doi.org/10.3390/met9010056

Lj A, Ivanović ER, Maksimović VM, Pavlović MM, Vuković M, Stevanović JS, Nikolić ND (2018) Correlation between crystal structure and morphology of potentiostatically electrodeposited silver dendritic nanostructures. Trans Nonferrous Met Soc China 28:1903–1912. https://doi.org/10.1016/S1003-6326(18)64835-6

Nikolić ND, Lj A, Ivanović ER, Maksimović VM, Baščarević Z, Ignjatović N (2019) Comparative morphological and crystallographic analysis of copper powders obtained under different electrolysis conditions. Trans Nonferrous Met Soc China 29:1275–1284. https://doi.org/10.1016/S1003-6326(19)65034-X

Nikolić ND, Maksimović VM, Lj A (2021) Correlation of morphology and crystal structure of metal powders produced by electrolysis processes. Metals 11:859. https://doi.org/10.3390/met11060859

Berube LPh, Esperance GL (1989) A quantitative method of determining of the degree of texture of zinc electrodeposits. J Electrochem Soc 136:2314–2315. https://doi.org/10.1149/1.2097318

Bockris JOM, Reddy AKN, Gamboa-Aldeco ME (2000) Modern electrochemistry 2A: fundamentals of electrodics. Kluwer Academic/Plenum Publishers, New York, Boston, Dordrecht, London, Moscow

Wang SG, Tian EK, Lung CW (2000) Surface energy of arbitrary crystal plane of bcc and fcc metals. J Phys Chem Solids 61:1295–1300. https://doi.org/10.1016/S0022-3697(99)00415-1

Funding

This work was supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia (RS) (Grant Nos. 451–03-68/2022–14/200026 and 451–03-9/2022–14/200017) and Science Fund of RS (Grant No. AdCatFC: 7739802).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

Determination of the “Texture Coefficient” TC(hkl) and the “Relative Texture Coefficient” RTC(hkl) by analysis of the XRD data

The ratio of reflection intensity (hkl) to the sum of all intensities of the recorded reflections, R(hkl), (in %) is given by Eq. (1) [39]:

where I (hkl) is a reflection intensity (hkl) plane, in cps, and \(\sum_{i}^{16}I\left({h}_{i}{k}_{i}{l}_{i}\right)\) is the sum of all intensities of the recorded reflections, in cps, for the powder being considered (in the case of Sn, it is sixteen).

The “Texture Coefficient,” TC(hkl), for every (hkl) reflection is defined by Eq. (2):

where Rs(hkl) is defined in the same way as given by Eq. (2), but is related to the standard for metal under consideration. This coefficient gives the accurate quantitative information about the absolute reflection intensity.

Finally, the “Relative Texture Coefficient” RTC(hkl), (in %) is defined by Eq. (3):

The RTC (hkl) coefficient defines the reflection intensity (hkl) relative to the standard (included in the TC values).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nikolić, N.D., Lović, J.D. & Maksimović, V.M. The control of morphology and structure of galvanostatically produced tin dendrites by analysis of chronopotentiometry response. J Solid State Electrochem 27, 1889–1900 (2023). https://doi.org/10.1007/s10008-023-05380-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05380-6