Abstract

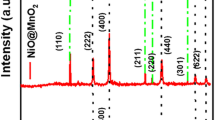

Graphene (G) and ternary nanocomposites of Mn3O4, TiO2, and reduced graphene oxide(rGO) electrodes have been prepared for supercapacitor applications. The as-synthesized samples were characterized using several techniques including XRD, SEM, TEM, XPS, and Raman spectroscopy. Electrochemical characterizations were studied via cyclic voltammetry (CV), galvanostatic charge–discharge (GCD), and electrochemical impedance spectroscopy (EIS). XRD patterns of TiO2 and Mn3O4 showed the formation of anatase and hausmannite tetragonal nanoparticles, respectively, whereas rGO and G showed an amorphous structure. The TEM analysis showed spherical shaped particles with less than 50 nm sizes for Mn3O4, nanotube for TiO2, fiber structure for rGO, and layered structure for graphene. The Mn3O4/TiO2/rGO ternary nanocomposite electrode presented a much higher specific capacitance than its single individual constituents. The ternary nanocomposite has a specific capacitance of 356 F g−1 in 6 M KOH aqueous electrolyte and respectable cycling performance, with 91% capacitance retained over 3000 cycles referring to its suitability for supercapacitor applications. An asymmetric supercapacitor (ASC) was constructed using a Mn3O4–TiO2–rGO (MTrGO) as a positive electrode and G as a negative electrode. The organized (ASC) works steadily under the potential window of 0–1.8 V and provides a high-energy density of 31.95 Wh kg−1 at a power density of 7188 W kg−1 complemented by satisfactory cycle stability with 87% capacitance retention over 1000 cycles.

Graphical Abstract

Similar content being viewed by others

References

Aray A, Sharma AL (2019) J Solid State Electrochem 23(4):997–1059

Kubota K, Kumakura S, Yoda Y, Kuroki K, Komab S (2017) Adv Energy Mater. https://doi.org/10.1002/aenm.201703415 Wiley on Line

Maile NC et al (2019) J Mater Sci Mater Electron 30:5555–5566

Libich J, Máca J, Vondrák J, Čech O, MSedlaříková M (2018) J Energy Storage 17:224–227

Ma Y, Zha M, Dong Y, Li L, Hu G (2019) Mater Res Expr 6(11):6. https://doi.org/10.1088/2053-1591/ab45bd

Najib S, Erdem E (2019) Nanoscale Adv 1(8):2817–2827

Yadav HM, Ghodake GS, Kim DY, Ramesh S, Maile NC, Lee DS, Shinde SK (2019) Colloids Surf 184 184:110500

Shinde SK, Jalak MB, Kim SY, Yadav HM, Ghodake GS, Kadam AA, Kim DY (2018) Ceram Int 44(18):23102–23108

Shinde SK, Mohite SM, Kadam AA, Yadav HM, Ghodake GS, Rajpure KY, Lee DS, Kim DY (2019) J Electroanalyt Chem 850:113433

Bryan AM, Santino LM, Lu Y, Acharya S, D’Arcy JM (2016) Chem Mater 28(17):5989–5998

Hao X, Zhao J, Li Y, Zhao Y, Ma D, Li L (2011) Colloid Surf Physicochem Eng Aspect 374(1-3):42–47

Zhou T, Mo S, Zhou S, Zou W, Liu Y, Yuan D (2011) J Mater Sci 46(10):3337–3342

Zhang X, Yu P, Zhang D, Zhang H, Sun X, Ma Y (2013) Mater Lett 92:401–404

Zhang X, Sun X, Chen Y, Zhang D, Ma Y (2012) Mater Lett 68:336–339

Sobaszek M, Siuzdak K, Sawczak M, Ryl J, Bogdanowicz R (2016) Thin Solid Films 601(Supplement C):35–40

Zhou M, Glushenkov AM, Kartachova O, Li Y, Chen Y (2015) J ElectrochemSoc 162(5):A5065–A5069

Salari M, Aboutalebi SH, Chidembo AT, Nevirkovets IP, Konstantinov K, Liu HK (2012) Phys Chem Chem Phys 14(14):4770–4779

Wang T, Peng Z, Wang Y, Tang J, Zheng G (2013) Sci Rep 3:1–9

Tang H, Sui Y, Zhu X, Bao Z (2015) Nanoscale Res Lett 10(1):260–270

Yan J, Fan Z, Sun W, Ning G, Wei T, Zhang Q, Zhang R, Zhi L, Wei F (2012) Adv Funct Mater 22(12):2632–2641

Hulicova J, Puziy A, Poddubnaya O, Suarez G, Juan M, Lu G (2009) J Am Chem Soc 131:5026–5027

Futaba D, Hata K, Yamada T, Hiraoka T, Hayamizu Y, Kakudate Y, Tanaike O, Hatori H, Yumura M, Iijima S (2006) Nat Mater 12:987–994

An Z (2020) Materials 13:716. https://doi.org/10.3390/ma13030716

Sing KSW et al (1985) Pure and Appl Chem 5:603–619

Kruk M, Jaroniec M (2001) Chem Mater 13(10):3169–3183

Wickramaratne NP (2014) Ph. D. Thesis, Kent State University, USA

Guerra E, Shanmugharaj A, Choi W, Ryu S (2013) Appl Catal A 468:467–474

Sheshmani S, Fashapoyeh M (2013) J Acta Chim Slov 60:813–822

Alam S, Sharma N, Kumar L (2017) Graphene 6(01):1–18

Perez A, Saja J, Manchado A (2008) J Mater Chem 18:2221–2226

Qiu S, Kalita S (2006) Mater Sci Engin A 435-436:327–332

Guo H, Wang X, Qian Q, Wang F, Xia X (2009) ACS Nano 3(9):2653–2659

Park S, An J, Potts JR, Velamakanni A, Murali S, Ruoff R (2011) Carbon 49(9):3019–3023

Jeong HK et al (2008) J Am Chem Soc 130:1362–1366

Wu Z, Ren W, Wen L, Gao L, Zhao J, Chen Z, Zhou G, Li F, Cheng H (2010) ACS Nano 4(6):3187–3194

Petit C, Seredych M, Bandosz TJ (2009) J Mater Chem 19(48):9176–9185

Fan X, Yu C, Yang J, Ling Z, Qiu J (2014) Carbon 70:130–141

Tiekun J, Fang F, Dongsheng Y, Jianliang C, Guang S (2018) Appl Surf Sci 430:438–447

Zhang W, Liu F, Li Q, Shou Q, Cheng J, Zhang L, Nelson BJ, Zhang X (2012) Phys Chem Chem Phys 14(47):16331–16337

Oku M, Hirokawa K, Ikeda S (1975) J Electron Spectrosc 7:465473

Li Y, Qu J, Gao F, Lv S, Lin S, He C, Sun J (2015) Appl Catal B 162:268–274

Sun H, Bai Y, Cheng Y, Jin W, Xu N (2006) Ind Eng Chem Res 45(14):4971–4976

Li W, Lei L, Zhao D (2016) Nature Rev Mater 1(6):16023

Tan YH (2012) J Mater Chem 22(14):6733–6745

Li H, Wang J, Chu Q, Wang Z, Zhang F, Wang S (2009) J Power Sources 190:578–586

Selvan R, Perelshtein I, Perkas N, Gedanken A (2008) J Phys Chem C 112(6):1825–1830

He L, Zhang G, Dong Y, Zhang Z, Xue S, Jiang X (2014) Nano- Micro Lett 6:38–45

Nagamuthu S, Vijayakumar S, Muralidharan G (2013) Energy and Fuels 27(6):3508–3515

Wang Y, Li H, Xia Y (2006) Adv Mater 18:2619–2623

Du X, Guo P, Song H, Chen X (2010) Electrochim Acta 55(16):4812–4819

Farma R, Deraman M, Awitdrus I, Talib I, Omar R, Manjunatha J, Ishak M, Basri N, Dolah B (2013) Int J Electrochem Sci 8:257–273

Jiang T, Chen H, Wan H, Miao L, Zhang L (2013) Electrochim Acta 114:674–680

Farsi H, Gobal F, Barzgari Z (2013) Ionics 19(2):287–294

Shah H et al (2016) Int J Electrochem Sci 11:8155–8162

Shaik D, Rosaiah P, Hussain O (2016) Mater Proceed 3:64–73

Mei BA, Munteshari O, Lau J, Dunn B, Pilon L (2018) J Phys Chem C 122(1):194–206

Choi W, Shin HC, Kim JM, Choi JY, Yoon WS (2020) J Electrochem Sci Technol 11(1):1–13

Wang W, Yao W, Chen W, Chen D, Ma Z, Lu Z (2020) Appl Sci 10(6):1907. https://doi.org/10.3390/app10061907

Bard AJ, Faulkner LR (2001) Electrochemical Methods, 2nd edn. Wiley, New Jersey, American

Lyu J et al (2019) ChemRxiv. https://doi.org/10.26434/chemrxiv.7637030.V1

Shasha J, Tiehu L, Xiong C, Tang C, Dang A, Li H, Zhao T (2019) Nanomaterials 9:1338–1350

Sun M, Tie J, Cheng G, Lin T, Peng S, Deng F, Ye F, Yu L (2015) Mater Chem A 3:1730–1736

Mousa M, Khairy M, Shehab M (2017) J Solid State Electrochem 21(4):995–1000

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The Mn3O4/TiO2/reduced graphene oxide nanocomposite was synthesized using a hydrothermal method.

• Nanotube TiO2 and spherical Mn3O4 nanoparticles were well-dispersed on reduced graphene oxide.

• The Mn3O4/TiO2/rGO ternary nanocomposite electrode showed a much higher specific capacitance than its single individual constituents.

• An asymmetric supercapacitor (ASC) constructed using a Mn3O4–TiO2–rGO (MTrGO) as a positive electrode and G as a negative electrode works steadily under a potential window of 0–1.8 V providing a high-energy density of 31.95 Wh kg−1 at a power density of 7188 W kg−1 in 6 M KOH aqueous electrolyte.

• The ASC exhibits satisfactory cycle stability with 87% capacitance retention over 1000 cycles.

Rights and permissions

About this article

Cite this article

El-Shahat, M., Mochtar, M., Rashad, M.M. et al. Single and ternary nanocomposite electrodes of Mn3O4/TiO2/rGO for supercapacitors. J Solid State Electrochem 25, 803–819 (2021). https://doi.org/10.1007/s10008-020-04837-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04837-2