Abstract

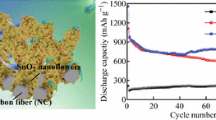

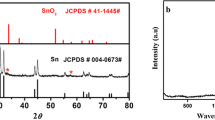

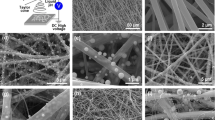

Obtaining a high specific capacity of Sn-Ti composite anode for lithium-ion batteries while maintaining stable cycle is a key issue to be solved. Research on using reasonable compensation treatment is of importance for solving the problem. In this work, the Sn-Ti-C nanofibers are prepared by electrospinning and using deep cryogenic treatment as supplementary treatment and then carbonization. After the deep cryogenic treatment, the abundant grain boundaries are introduced into Sn particles, which more easily combine with Ti to form Sn-Ti particles in the process of high-temperature carbonization. The Sn-Ti particles inside and outside the grooved nanofibers with low Ti content inhibits the volume expansion of Sn during the cycles and maintains the high specific capacity for Sn alloy. For the sample as the anode, the capacity can remain at 557 mAh g−1 and the capacity retention of 98.7% over 100 cycles. The improvement of electrochemical performance can be simply implemented by deep cryogenic treatment, which provides reliable theoretical and practical data for the preparation of Sn-Ti composite anode for lithium-ion batteries.

Similar content being viewed by others

References

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Wang H, Huang H, Niu C, Rogach AL (2015) Energy storage: ternary Sn-Ti-O based nanostructures as anodes for lithium ion batteries (small 12/2015). Small 11(12):1364–1383

Park M-G, Lee D-H, Jung H, Choi J-H, Park C-M (2018) A Sn-based nanocomposite for Li-ion battery anode with high energy density, rate capability, and reversibility. ACS Nano 12(3):2955–2967

Xue G, Zhong J, Cheng Y, Wang B (2016) Facile fabrication of cross-linked carbon nanofiber via directly carbonizing electrospun polyacrylonitrile nanofiber as high performance scaffold for supercapacitors. Electrochim Acta 215:29–35

Obrovac M, Chevrier V (2014) Alloy negative electrodes for Li-ion batteries. Chem Rev 114(23):11444–11502

Sun G, Sun L, Xie H, Liu J (2016) Electrospinning of Nanofibers for energy applications. Nanomaterials (Basel) 6(7):128

He X, Hu Y, Shen Z, Chen R, Wu K, Cheng Z, Zhang X, Pan P (2017) GeOx ultra-dispersed in microporous carbon nanofibers: a binder-free anode for high performance lithium-ion battery. Electrochim Acta 246:981–989

Luo L, Li D, Zang J, Chen C, Zhu J, Qiao H, Cai Y, Lu K, Zhang X, Wei Q (2017) Carbon-coated magnesium ferrite nanofibers for lithium-ion battery anodes with enhanced cycling performance. Energy Technol 5(8):1364–1372

Xia X, Wang X, Zhou H, Niu X, Xue L, Zhang X, Wei Q (2014) The effects of electrospinning parameters on coaxial Sn/C nanofibers: morphology and lithium storage performance. Electrochim Acta 121:345–351

Zhou H, Li Z, Qiu Y, Xia X (2016) The effects of carbon distribution and thickness on the lithium storage properties of carbon-coated SnO2 hollow nanofibers. J Alloys Compd 670:35–40

Jeun J-H, Park K-Y, Kim D-H, Kim W-S, Kim H-C, Lee B-S, Kim H, Yu W-R, Kang K, Hong S-H (2013) SnO2@TiO2 double-shell nanotubes for a lithium ion battery anode with excellent high rate cyclability. Nanoscale 5(18):8480–8483

Yi Z, Han Q, Zan P, Cheng Y, Wu Y, Wang L (2016) Facile fabrication of SnO2@TiO2 core–shell structures as anode materials for lithium-ion batteries. J Mater Chem A 4(33):12850–12857

Tran T, McCormac K, Li J, Bi Z, Wu J (2014) Electrospun SnO2 and TiO2 composite nanofibers for lithium ion batteries. Electrochim Acta 117:68–75

Niu J-L, Peng H-J, Zeng C-H, Lin X-M, Sathishkumar P, Cai Y-P, Xu A-W (2018) An efficient multidoped Cu0.39Zn0.14Co2.47O4-ZnO electrode attached on reduced graphene oxide and copper foam as superior lithium-ion battery anodes. Chem Eng J 336:510–517

Niu J-L, Zeng C-H, Peng H-J, Lin X-M, Sathishkumar P, Cai Y-P (2017) Formation of N-doped carbon-coated ZnO/ZnCo2O4/CuCo2O4 derived from a polymetallic metal-organic framework: toward high-rate and long-cycle-life lithium storage. Small 13(47):1702150

Lin X, Lin J, Niu J, Lan J, Reddy RCK, Cai Y, Liu J, Zhang G (2018) In situ synthesis of Cu2O-CuO-C supported on copper foam as a superior binder-free anode for long-cycle lithium-ion batteries. Mater Chem Front 2(12):2254–2262

Peng HJ, Hao GX, Chu ZH, Cui YL, Lin XM, Cai YP (2017) From metal-organic framework to porous carbon polyhedron: toward highly reversible Lithium storage. Inorg Chem 56(16):10007–10012

Niu J-L, Hao G-X, Lin J, He X-B, Sathishkumar P, Lin X-M, Cai Y-P (2017) Mesoporous MnO/C-N nanostructures derived from a metal-organic framework as high-performance anode for lithium-ion battery. Inorg Chem 56(16):9966–9972

Wang S, Yang Y, Dong Y, Zhang Z, Tang Z (2019) Recent progress in Ti-based nanocomposite anodes for lithium ion batteries. J Adv Ceram 8(1):1–18

Lin Y-X, Liu Z, Leung K, Chen L-Q, Lu P, Qi Y (2016) Connecting the irreversible capacity loss in Li-ion batteries with the electronic insulating properties of solid electrolyte interphase (SEI) components. J Power Sources 309:221–230

Slatter T, Thornton R (2017) Cryogenic treatment of engineering materials. Compr Mater Finish 2:421–454

Zhang Y, Xu F, Zhang C, Wang J, Jia Z, Hui D, Qiu Y (2016) Tensile and interfacial properties of polyacrylonitrile-based carbon fiber after different cryogenic treated condition. Compos Part B 99:358–365

Shao Y, Xu F, Liu W, Zhou M, Li W, Hui D, Qiu Y (2017) Influence of cryogenic treatment on mechanical and interfacial properties of carbon nanotube fiber/bisphenol-F epoxy composite. Compos Part B 125:195–202

Sun Y, Yu Z, Li T, Chen Y, Xia X (2019) Cryo-treatment in enhancing the electrochemical properties of SnSb/C nanofiber anodes for lithium ion batteries. Electrochim Acta 296:637–643

Xia X, Li Z, Zhou H, Qiu Y, Zhang C (2016) The effect of deep cryogenic treatment on SnSb/C nanofibers anodes for Li-ion battery. Electrochim Acta 222:765–772

Kim J-C, Kim D-W (2014) Synthesis of multiphase SnSb nanoparticles-on-SnO2/Sn/C nanofibers for use in Li and Na ion battery electrodes. Electrochem Commun 46:124–127

Jeong HY, Lee JH, Hayes KF (2008) Characterization of synthetic nanocrystalline mackinawite: crystal structure, particle size, and specific surface area. Geochim Cosmochim Acta 72(2):493–505

Bai Y, Pang C, Hu W, Wu F, Wu C, Yang L, Bao L-y (2013) High capacity cobalt boride prepared via vacuum freeze-drying method and used as anode material for alkaline secondary battery. J Renew Sustain Energy 5(2):2173–2176

Li Y, Yu Y, Liu Y, Lu C (2018) Interphase development in polyacrylonitrile/SWNT nanocomposite and its effect on cyclization and carbonization for tuning carbon structures. ACS Appl Nano Mater 1(7):3105–3113

Zhao R-X, P-f S, R-j L, Z-h D, X-s L, X-y L, X-d Z, Gao Z-m (2018) Influence of heating procedures on the surface structure of stabilized polyacrylonitrile fibers. Appl Surf Sci 433:321–328

Rosales A, Muñoz-Bascón J, López-Sánchez C, Álvarez-Corral M, Muñoz-Dorado M, Rodríguez-García I, Oltra JE (2012) Ti-catalyzed homolytic opening of ozonides: a sustainable C–C bond-forming reaction. J Org Chem 77(8):4171–4176

Dahbi M, Kiso M, Kubota K, Horiba T, Chafik T, Hida K, Matsuyama T, Komaba S (2017) Synthesis of hard carbon from argan shells for Na-ion batteries. J Mater Chem A 5(20):9917–9928

Yoon S, Manthiram A (2011) Nanostructured Sn-Ti-C composite anodes for lithium ion batteries. Electrochim Acta 56(8):3029–3035

Xu Y, Liu Q, Zhu Y, Liu Y, Langrock A, Zachariah MR, Wang C (2013) Uniform nano-Sn/C composite anodes for lithium ion batteries. Nano Lett 13(2):470–474

Soto FA, Yan P, Engelhard MH, Marzouk A, Wang C, Xu G, Chen Z, Amine K, Liu J, Sprenkle VL (2017) Tuning the solid electrolyte interphase for selective Li- and Na- ion storage in hard carbon. Adv Mater 29(18):1606860

Tang D, Yi R, Gordin ML, Melnyk M, Dai F, Chen S, Song J, Wang D (2014) Titanium nitride coating to enhance the performance of silicon nanoparticles as a lithium-ion battery anode. J Mater Chem A 2(27):10375–10378

Mei Y, Huang Y, Hu X (2016) Nanostructured Ti-based anode materials for Na-ion batteries. J Mater Chem A 4(31):12001–12013

Li R, Lin C, Wang N, Luo L, Chen Y, Li J, Guo Z (2018) Advanced composites of complex Ti-based oxides as anode materials for lithium-ion batteries. Adv Compos Hybrid Mater 1(3):440–459

Acknowledgments

We also would like to thank the Institute of Experimental Center of Xinjiang University for the help in SEM and XRD tests.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No.51763022), the Innovation Team of Development and Application Research of Characteristic Textile Materials in Xinjiang province (Grant No.201705151) and The Project of Xinjiang Graduate Research and Innovation (Grant No. XJ2019G073).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Ti-tiny Sn-Ti-C nanofibers were treated by DCT and then carbonization.

• Grain refinement was introduced by DCT, which promotes the formation of Sn-Ti particles.

• Ti-tiny particles inhibit the expansion of Sn and maintains a high specific capacity.

• Sn-Ti-C nanofibers with DCT show specific capacity of 557 mAh g−1 after 100 cycles.

• Sn-Ti-C nanofibers with DCT show 98.7% capacity retention after 100 cycles.

Rights and permissions

About this article

Cite this article

Li, T., Chen, Y., Wang, L. et al. Performance enhancement of Sn-Ti-C nanofibers anode for lithium-ion batteries via deep cryogenic treatment. J Solid State Electrochem 24, 781–793 (2020). https://doi.org/10.1007/s10008-020-04519-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04519-z