Abstract

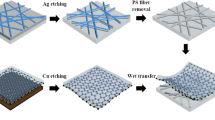

Ultraflexible, wearable, transparent, and conductive films have recently attracted increasing interest due to their applicability in various electronic devices. In this work, we report a facile, green, and inexpensive approach to preparing flexible hybrid films from graphene nanowalls (GNWs) and ethylene vinyl acetate (EVA) copolymer based on plasma-enhanced chemical vapor deposition (PECVD). PECVD at low temperature (~700 °C) on electrochemically polished Cu foil was found to be an effective method of preparing highly conductive and highly transparent GNWs. The resulting GNWs/EVA hybrid films can be randomly folded, bent, and tailored; they also have a low sheet resistance of ~2.09 kΩ sq−1, a high optical transparency of 67.58% in the UV region, and high wear resistance and ductility, all of which imply that these are highly promising films for use in flexible electronic applications.

Similar content being viewed by others

References

Granqvist CG (2007) Transparent conductors as solar energy materials: a panoramic review. Sol Energy Mater Sol Cells 91:1529–1598

Hu Z, Zhang J, Hao Z et al (2011) Highly efficient organic photovoltaic devices using F-doped SnO2 anodes. Appl Phys Lett 98:123302

Fu W, Liu L, Jiang K et al (2010) Super-aligned carbon nanotube films as aligning layers and transparent electrodes for liquid crystal displays. Carbon 48:1876–1879

Langley D, Giusti G, Mayousse C et al (2013) Flexible transparent conductive materials based on silver nanowire networks: a review. Nanotechnology 24:452001

Archambeau S, Séguy I, Jolinat P et al (2006) Stabilization of discotic liquid organic thin films by ITO surface treatment. Appl Surf Sci 253:2078–2086

Huang G-W, Xiao H-M, Fu S-Y (2015) Wearable electronics of silver-nanowire/poly(dimethylsiloxane) nanocomposite for smart clothing. Sci Rep 5:13971

Miyamoto A, Lee S, Cooray NF et al (2017) Inflammation-free, gas-permeable, lightweight, stretchable on-skin electronics with nanomeshes. Nat Nanotechnol 12:907–913

Dimitrakopoulos CD, Malenfant PRL (2002) Organic thin film transistors for large area electronics. Adv Mater 14:99–117

Trung TQ, Lee N-E (2016) Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoring and personal healthcare. Adv Mater 28:4338–4372

Roh E, Hwang B-U, Kim D et al (2015) Stretchable, transparent, ultrasensitive, and patchable strain sensor for human–machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano 9:6252–6261

Suo Z (2012) Mechanics of stretchable electronics and soft machines. MRS Bull 37:218–225

Choi TY, Hwang B-U, Kim B-Y et al (2017) Stretchable, transparent, and stretch-unresponsive capacitive touch sensor array with selectively patterned silver nanowires/reduced graphene oxide electrodes. ACS Appl Mater Interfaces 9:18022–18030

Yang J, Liu P, Wei X et al (2017) Surface engineering of graphene composite transparent electrodes for high-performance flexible triboelectric nanogenerators and self-powered sensors. ACS Appl Mater Interfaces 9:36017–36025

Saran N, Parikh K, Suh D-S et al (2004) Fabrication and characterization of thin films of single-walled carbon nanotube bundles on flexible plastic substrates. J Am Chem Soc 126:4462–4463

Oguntoye M, Johnson M, Pratt L, Pesika NS (2016) Triboelectricity generation from vertically aligned carbon nanotube arrays. ACS Appl Mater Interfaces 8:27454–27457

Zhang L, Yang R, Chen K et al (2017) The fabrication of Cu nanowire/graphene/Al doped ZnO transparent conductive film on PET substrate with high flexibility and air stability. Mater Lett 207:62–65

Mengistie DA, Ibrahem MA, Wang P-C, Chu C-W (2014) Highly conductive PEDOT:PSS treated with formic acid for ITO-free polymer solar cells. ACS Appl Mater Interfaces 6:2292–2299

Yao H-B, Ge J, Wang C-F et al (2013) A flexible and highly pressure-sensitive graphene-polyurethane sponge based on fractured microstructure design. Adv Mater 25:6692–6698

Bae S, Kim H, Lee Y et al (2010) Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotechnol 5:574–578

Chen Z, Guo X, Zhu L et al (2018) Direct growth of graphene on vertically standing glass by a metal-free chemical vapor deposition method. J Mater Sci Technol 34:1919–1924

Li X, Colombo L, Ruoff RS (2016) Synthesis of graphene films on copper foils by chemical vapor deposition. Adv Mater 28:6247–6252

Chen Z, Liu Y, Zhang W et al (2019) Growth of graphene/Ag nanowire/graphene sandwich films for transparent touch-sensitive electrodes. Mater Chem Phys 221:78–88

Shen C, Jia Y, Yan X et al (2018) Effects of Cu contamination on system reliability for graphene synthesis by chemical vapor deposition method. Carbon 127:676–680

Chen G, Liu Y, Liu F, Zhang X (2014) Fabrication of three-dimensional graphene foam with high electrical conductivity and large adsorption capability. Appl Surf Sci 311:808–815

Zhang LX, Sun Z, Qi JL et al (2016) Understanding the growth mechanism of vertically aligned graphene and control of its wettability. Carbon 103:339–345

Liu L, Cheng Y, Zhang X et al (2017) Graphene-based transparent conductive films with enhanced transmittance and conductivity by introducing antireflection nanostructure. Surf Coat Technol 325:611–616

Acknowledgements

The authors would like to thank the financial support provided by the Science and Technology Major Project of Shanxi Province (no. MC2016-06), the Project of Jiangsu Key Laboratory for Clad Materials, China (no. BM2014006), the National Natural Science Foundation of China (no. 21173041), and the Opening Project of Jiangsu Key Laboratory of Advanced Metallic Materials, China.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Z., Guo, X., Liu, Y. et al. Facile preparation of graphene nanowalls/EVA hybrid film for ultraflexible transparent electrodes. J Solid State Electrochem 23, 1473–1480 (2019). https://doi.org/10.1007/s10008-019-04231-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04231-7