Abstract

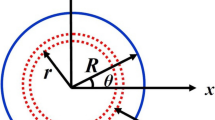

The mechanical properties of nanowires are significantly affected by surface effects. In this work, we investigate the potential mechanisms of surface residual stress and surface layer stiffness on the bending behavior of nanowires. The deflection equation of nanowires under pure bending is first derived from the Young–Laplace equation and the Euler–Bernoulli beam theory. Subsequently, a new finite element model based on Galerkin’s weighted residual method is developed to verify the accuracy of the theoretical solution. The theoretical and numerical solutions present the significant effects of surface residual stress and surface layer stiffness on the elastic properties of nanowires depending on the feature size, boundary conditions, and sectional geometry of the nanowires. Specifically, the surface residual stress makes the simply-supported and fixed–fixed nanobeams stiffer; however, it makes the cantilever nanobeam softer. Besides, the sectional geometry of the nanowires has a noticeable impact on their transverse deflection. If the size of circumscribed circle of the cross section remains constant, the nanowires become harder as the numbers of sectional sides increase for the specific feature size and boundary conditions. If the cross-sectional area remains unchanged, the deflection of the nanowires fluctuates as the number of cross-sectional side increases. We realize that the overall Young’s modulus of nanowires is closely related to the feature size. As the cross-sectional feature size is below a critical value, the surface residual stress dominates the bending behavior of the nanowire. As the sectional feature size exceeds the critical feature size that is correlated to the nanowire boundary conditions, the factor dominating the bending behavior gradually transforms from the surface residual stress to the surface layer stiffness. This study provides a theoretical framework for developing a design strategy that incorporates surface effects in the engineering of nano/microscale architected advanced materials.

Similar content being viewed by others

References

Maskery, I., Aboulkhair, N.T., Aremu, A.O., Tuck, C.J., Ashcroft, I.A.: Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Add. Manuf. 16, 24–29 (2017)

Mueller, J., Raney, J.R., Shea, K., Lewis, J.A.: Architected lattices with high stiffness and toughness via multicore-shell 3D printing. Adv. Mater. 30, e1705001 (2018)

Chen, Y., Li, T., Jia, Z., Scarpa, F., Yao, C.-W., Wang, L.: 3D printed hierarchical honeycombs with shape integrity under large compressive deformations. Mater. Des. 137, 226–234 (2018)

Kruk, S., Kivshar, Y.: Functional meta-optics and nanophotonics governed by mie resonances. ACS Photon. 4, 2638–2649 (2017)

Brunet, T., Leng, J., Mondain-Monval, O.: Materials science. Soft acoustic metamaterials. Science 342, 323–324 (2013)

Wang, Q., Jackson, J.A., Ge, Q., Hopkins, J.B., Spadaccini, C.M., Fang, N.X.: Lightweight mechanical metamaterials with tunable negative thermal expansion. Phys. Rev. Lett. 117, 175901 (2016)

Akselrod, G.M., Argyropoulos, C., Hoang, T.B., Ciracì, C., Fang, C., Huang, J., et al.: Probing the mechanisms of large Purcell enhancement in plasmonic nanoantennas. Nat. Photon. 8, 835–840 (2014)

Babaee, S., Shim, J., Weaver, J.C., Chen, E.R., Patel, N., Bertoldi, K.: 3D soft metamaterials with negative Poisson’s ratio. Adv. Mater. 25, 5044–5049 (2013)

Shi, J., Mofatteh, H., Mirabolghasemi, A., Desharnais, G., Akbarzadeh, A.: Programmable multistable perforated shellular. Adv. Mater. 33, e2102423 (2021)

Yuan, S., Chua, C.K., Zhou, K.: 3D-printed mechanical metamaterials with high energy absorption. Adv. Mater. Technol. 4, 1800419 (2019)

Shi, J., Akbarzadeh, A.H.: Hierarchical cellular ferroelectric metamaterials: A design motif to enhance multifunctional figures of merit. Comp. Struct. 250, 112395 (2020)

Cui, Y., Zhong, Z.H., Wang, D.L., Wang, W.U., Lieber, C.M.: High performance silicon nanowire field effect transistors. Nano Lett. 3, 149–152 (2003)

He, Z., Yang, Y., Liang, H.W., Liu, J.W., Yu, S.H.: Nanowire genome: a magic toolbox for 1D nanostructures. Adv. Mater. 31, 51 (2019)

Chen, W.S., Jiang, J.Y., Zhang, W.L., Wang, T., Zhou, J.F., Huang, C.H., et al.: Silver nanowire-modified filter with controllable silver ion release for point-of-use disinfection. Environ. Sci. Technol. 53, 7504–7512 (2019)

Meille, S., Lombardi, M., Chevalier, J., Montanaro, L.: Mechanical properties of porous ceramics in compression: on the transition between elastic, brittle, and cellular behavior. J. Eur. Ceram. Soc. 32, 3959–3967 (2012)

Fiedler, T., Ochsner, A., Gracio, J., Kuhn, G.: Structural modeling of the mechanical behavior of periodic cellular solids: open-cell structures. Mech. Compos. Mater. 41, 277–290 (2005)

Liu, L., Chen, Y.J., Liu, H.Z., Rehman, H.U., Chen, C., Kang, H.M., et al.: A graphene oxide and functionalized carbon nanotube based semi-open cellular network for sound absorption. Soft Matter 15, 2269–2276 (2019)

Zhang, C.Y., Akbarzadeh, A., Kang, W., Wang, J.X., Mirabolghasemi, A.: Nano-architected metamaterials: carbon nanotube-based nanotrusses. Carbon 131, 38–46 (2018)

Zhang, X., Vyatskikh, A., Gao, H.J., Greer, J.R., Li, X.Y.: Lightweight, flaw-tolerant, and ultrastrong nanoarchitected carbon. Proc. Natl. Acad. Sci. USA 116, 6665–6672 (2019)

Meza, L.R., Zelhofer, A.J., Clarke, N., Mateos, A.J., Kochmann, D.M., Greer, J.R.: Resilient 3D hierarchical architected metamaterials. Proc. Natl. Acad. Sci. USA 112, 11502–11507 (2015)

Kadic, M., Milton, G.W., van Hecke, M., Wegener, M.: 3D metamaterials. Nat. Rev. Phys. 1, 198–210 (2019)

Milton, G.W.: Complete characterization of the macroscopic deformations of periodic unimode metamaterials of rigid bars and pivots. J. Mech. Phys. Solids 61, 1543–1560 (2013)

Bauer, J., Meza, L.R., Schaedler, T.A., Schwaiger, R., Zheng, X.Y., Valdevit, L.: Nanolattices: an emerging class of mechanical metamaterials. Adv. Mater. 29, 40 (2017)

Bertoldi, K., Vitelli, V., Christensen, J., van Hecke, M.: Flexible mechanical metamaterials. Nat. Rev. Mater. 2, 17066 (2017)

Schaedler, T.A., Jacobsen, A.J., Torrents, A., Sorensen, A.E., Lian, J., Greer, J.R., et al.: Ultralight metallic microlattices. Science 334, 962–965 (2011)

Zheng, X.Y., Lee, H., Weisgraber, T.H., Shusteff, M., DeOtte, J., Duoss, E.B., et al.: Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014)

Bauer, J., Hengsbach, S., Tesari, I., Schwaiger, R., Kraft, O.: High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl. Acad. Sci. USA 111, 2453–2458 (2014)

Sarvestani, H.Y., Akbarzadeh, A.H., Mirbolghasemi, A., Hermenean, K.: 3D printed meta-sandwich structures: failure mechanism, energy absorption and multi-hit capability. Mater. Des. 160, 179–193 (2018)

Baughman, R.H.: Avoiding the shrink. Nature 425, 667 (2003)

Gibson, L.J., Ashby, M.F., Schajer, G.S., Robertson, C.I.: The mechanics of two-dimensional cellular materials. Proc. Roy. Soc. Lond. Mater. 382, 25–42 (1982)

Fang, X.Q., Zhu, C.S., Liu, J.X., Liu, X.L.: Surface energy effect on free vibration of nano-sized piezoelectric double-shell structures. Phys. B 529, 41–56 (2018)

Fan, T.: Nano porous piezoelectric energy harvester by surface effect model. Mech. Adv. Mater. Struct. 27, 754–760 (2020)

Xu, F.F., Fang, F.Z., Zhu, Y.Q., Zhang, X.D.: Study on crystallographic orientation effect on surface generation of aluminum in nano-cutting. Nanoscale Res. Lett. 12, 289 (2017)

Xia, W., Mahmood, A., Zou, R.Q., Xu, Q.: Metal-organic frameworks and their derived nanostructures for electrochemical energy storage and conversion. Energy Environ. Sci. 8, 1837–1866 (2015)

Kaneti, Y.V., Tang, J., Salunkhe, R.R., Jiang, X.C., Yu, A.B., Wu, K.C.W., et al.: Nanoarchitectured design of porous materials and nanocomposites from metal-organic frameworks. Adv. Mater. 29, 12 (2017)

Dickinson, M.: Animal locomotion: how to walk on water. Nature 424, 621–622 (2003)

Feng, L., Li, S.H., Li, Y.S., Li, H.J., Zhang, L.J., Zhai, J., et al.: Super-hydrophobic surfaces: from natural to artificial. Adv. Mater. 14, 1857–1860 (2002)

Roach, P., Shirtcliffe, N.J., Newton, M.I.: Progess in superhydrophobic surface development. Soft Matter 4, 224–240 (2008)

Arzt, E.: Overview no130: size effects in materials due to microstructural and dimensional constraints: a comparative review. Acta Mater. 46, 5611–5626 (1998)

Gao, H.J., Ji, B.H., Jager, I.L., Arzt, E., Fratzl, P.: Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc. Natl. Acad. Sci. USA 100, 5597–5600 (2003)

Kraft, O., Gruber, P.A., Monig, R., Weygand, D.: Plasticity in confined dimensions. Annu. Rev. Mater. Res. 40, 293–317 (2010)

Greer, J.R., De Hosson, J.T.M.: Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011)

Ban, Y.X., Mi, C.W.: Analytical solutions of a spherical nanoinhomogeneity under far-field unidirectional loading based on Steigmann-Ogden surface model. Math. Mech. Solids 25, 1904–1923 (2020)

Manoharan, M.P., Lee, H., Rajagopalan, R., Foley, H.C., Haque, M.A.: Elastic properties of 4–6 nm-thick glassy carbon thin films. Nanoscale Res. Lett. 5, 14–19 (2010)

Lee, C., Wei, X.D., Kysar, J.W., Hone, J.: Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008)

Mathur, A., Erlebacher, J.: Size dependence of effective Young’s modulus of nanoporous gold. Appl. Phys. Lett. 90, 061910 (2007)

Liu, J.L., Mei, Y., Xia, R., Zhu, W.L.: Large displacement of a static bending nanowire with surface effects. Phys. E 44, 2050–2055 (2012)

Biener, J., Hodge, A.M., Hamza, A.V., Hsiung, L.M., Satcher, J.H.: Nanoporous Au: a high yield strength material. J. Appl. Phys. 97, 024301 (2005)

Biener, J., Hodge, A.M., Hayes, J.R., Volkert, C.A., Zepeda-Ruiz, L.A., Hamza, A.V., et al.: Size effects on the mechanical behavior of nanoporous Au. Nano Lett. 6, 2379–2382 (2006)

Khorshidvand, A.R., Joubaneh, E.F., Jabbari, M., Eslami, M.R.: Buckling analysis of a porous circular plate with piezoelectric sensor-actuator layers under uniform radial compression. Acta Mech. 225, 179–193 (2014)

Huth, M., Kolb, F., Plank, H.: Dielectric sensing by charging energy modulation in a nano-granular metal. Appl. Phys. A Mater. 117, 1689–1696 (2014)

Mojahedin, A., Joubaneh, E.F., Jabbari, M.: Thermal and mechanical stability of a circular porous plate with piezoelectric actuators. Acta Mech. 225, 3437–3452 (2014)

Zhao, Q.S., Papadopoulos, P.: Continuum modeling and simulation of multiphase diffusion through a porous solid. Math. Mech. Solids 20, 251–267 (2015)

Gurtin, M.E., Murdoch, A.I.: Continuum theory of elastic-material surfaces. Arch. Ration Mech. An 57, 291–323 (1975)

Gurtin, M.E., Weissmuller, J., Larche, F.: A general theory of curved deformable interfaces in solids at equilibrium. Philos. Mag. A 78, 1093–1109 (1998)

Sun, K., Shi, J., Ma, L.: Atomistic insights into the effects of residual stress during nanoindentation. Curr. Comput.-Aided Drug Des. 7, 240 (2017)

Shenoy, V.B.: Atomistic calculations of elastic properties of metallic fcc crystal surfaces. Phys. Rev. B 71, 094104 (2005)

Gupta, R., Rai, B.: Effect of size and surface charge of gold nanoparticles on their skin permeability: a molecular dynamics study. Sci. Rep. UK 7, 45292 (2017)

Surblys, D., Kawagoe, Y., Shibahara, M., Ohara, T.: Molecular dynamics investigation of surface roughness scale effect on interfacial thermal conductance at solid-liquid interfaces. J. Chem. Phys. 150, 114705 (2019)

Chen, C.Q., Shi, Y., Zhang, Y.S., Zhu, J., Yan, Y.J.: Size dependence of Young's modulus in ZnO nanowires. Phys. Rev. Lett. 96 (2006)

He, J., Lilley, C.M.: Surface effect on the elastic behavior of static bending nanowires. Nano Lett. 8, 1798–1802 (2008)

Wang, Z.Q., Zhao, Y.P., Huang, Z.P.: The effects of surface tension on the elastic properties of nano structures. Int. J. Eng. Sci. 48, 140–150 (2010)

Feng, X.Q., Xia, R., Li, X., Li, B.: Surface effects on the elastic modulus of nanoporous materials. Appl. Phys. Lett. 94, 011916 (2009)

Fang, Q.H., Zhao, L., Li, J.: Surface effects on the elastic modulus of regular polygonal prism nanoporous materials. Acta Mech. 231, 3451–3460 (2020)

Xia, R., Li, X.D., Qin, Q.H., Liu, J.L., Feng, X.Q.: Surface effects on the mechanical properties of nanoporous materials. Nanotechnology 22, 265714 (2011)

Chen, Y., Liu, Y., Fang, Q., Li, J., Liu, Y., Liaw, P.K.: An unified model for dislocations interacting with complex-shape voids in irradiated metals. Int. J. Mech. Sci. 185, 105689 (2020)

Zhang, C., Lu, C., Michal, G., Li, J., Wang, R.: Strong strain hardening in graphene/nanotwinned metal composites revealed by molecular dynamics simulations. Int. J. Mech. Sci. 2021, 106460 (2021)

Zhang, R., Wen, L.H., Xiao, J.Y., Qian, D.: An efficient solution algorithm for space-time finite element method. Comput. Mech. 63, 455–470 (2019)

Niu, R.P., Liu, G.R., Yue, J.H.: Development of a software package of smoothed finite element method (S-FEM) for solid mechanics problems. Int. J. Comp. Meth-Sing. 17, 1845004 (2020)

Boso, D.P., Braga, T., Ravasini, S., Skrbic, T., Puglisi, A., Pinato, O., et al.: An integrated DEM–FEM approach to study breakage in packing of glass cartridges on a conveyor belt. Granul. Matter. 22, 73 (2020)

Vabishchevich, M.O., Solodei, I.I., Chepurnaya, E.A.: Determining the parameters of linear fracture mechanics in dynamic problems based on semianalytical finite-element method. Int. Appl. Mech. 54, 653–659 (2018)

Mi, C.: Surface mechanics induced stress disturbances in an elastic half-space subjected to tangential surface loads. Eur. J. Mech. A Solids 65, 59–69 (2017)

Mi, C.: Elastic behavior of a half-space with a Steigmann-Ogden boundary under nanoscale frictionless patch loads. Int. J. Eng. Sci. 129, 129–144 (2018)

Tian, L., Rajapakse, R.K.N.D.: Finite element modelling of nanoscale inhomogeneities in an elastic matrix. Comput. Mater. Sci. 41, 44–53 (2007)

He, J., Park, H.S.: A methodology for modeling surface effects on stiff and soft solids. Comput. Mech. 61, 687–697 (2018)

Zheng, X.P., Cao, Y.P., Li, B., Feng, X.Q., Wang, G.F.: Surface effects in various bending-based test methods for measuring the elastic property of nanowires. Nanotechnology 21, 205702 (2010)

Goudarzi, T., Avazmohammadi, R., Naghdabadi, R.: Surface energy effects on the yield strength of nanoporous materials containing nanoscale cylindrical voids. Mech. Mater. 42, 852–862 (2010)

Moshtaghin, A.F., Naghdabadi, R., Asghari, M.: Effects of surface residual stress and surface elasticity on the overall yield surfaces of nanoporous materials with cylindrical nanovoids. Mech. Mater. 51, 74–87 (2012)

Kim, G.T., Waizmann, U., Roth, S.: Simple efficient coordinate markers for investigating synthetic nanofibers. Appl. Phys. Lett. 79, 3497–3499 (2001)

Baron, T., Gordon, M., Dhalluin, F., Ternon, C., Ferret, P., Gentile, P.: Si nanowire growth and characterization using a microelectronics-compatible catalyst: PtSi. Appl. Phys. Lett. 89, 233111 (2006)

Sadeghian, H., Yang, C.K., Goosen, J.F.L., van der Drift, E., Bossche, A., French, P.J., et al.: Characterizing size-dependent effective elastic modulus of silicon nanocantilevers using electrostatic pull-in instability. Appl. Phys. Lett. 94, 221903 (2009)

Qiao, L., Zheng, X.J.: Effect of surface stress on the stiffness of micro/nanocantilevers: nanowire elastic modulus measured by nano-scale tensile and vibrational techniques. J. Appl. Phys. 113, 013508 (2013)

Fan, T., Yang, L.H.: Effective Young’s modulus of nanoporous materials with cuboid unit cells. Acta Mech. 228, 21–29 (2017)

Lu, Z.X., Xie, F., Liu, Q., Yang, Z.Y.: Surface effects on mechanical behavior of elastic nanoporous materials under high strain. Appl. Math. Mech. Engl. 36, 927–938 (2015)

Antonopoulos, D.C., Dougalis, V.A.: Galerkin-finite element methods for the shallow water equations with characteristic boundary conditions. Ima. J. Numer. Anal. 37, 266–295 (2017)

Singh, S.J., Harsha, S.P.: Thermo-mechanical analysis of porous sandwich S-FGM plate for different boundary conditions using Galerkin Vlasov’s method: a semi-analytical approach. Thin Wall Struct. 150, 106668 (2020)

Cuenot, S., Fretigny, C., Demoustier-Champagne, S., Nysten, B.: Surface tension effect on the mechanical properties of nanomaterials measured by atomic force microscopy. Phys. Rev. B 69 (2004)

Li, X.X., Ono, T., Wang, Y.L., Esashi, M.: Ultrathin single-crystalline-silicon cantilever resonators: fabrication technology and significant specimen size effect on Young’s modulus. Appl. Phys. Lett. 83, 3081–3083 (2003)

Nam, C.Y., Jaroenapibal, P., Tham, D., Luzzi, D.E., Evoy, S., Fischer, J.E.: Diameter-dependent electromechanical properties of GaN nanowires. Nano Lett. 6, 153–158 (2006)

Jing, G.Y., Duan, H.L., Sun, X.M., Zhang, Z.S., Xu, J., Li, Y.D., et al.: Surface effects on elastic properties of silver nanowires: contact atomic-force microscopy. Phys. Rev. B 73 (2006)

Acknowledgements

We acknowledge the support from the National Natural Science Foundation of China (Grant Numbers 11872149 and 12072072) and China Scholarship Council. A.H. Akbarzadeh acknowledges the financial support by Natural Sciences and Engineering Research Council of Canada through NSERC Discovery Grant (RGPIN-2016-0471) and Canada Research Chairs program in Multifunctional Metamaterials.

Funding

This study was funded by the National natural science foundation of China, 11872149, Changwen Mi, 12072072, Changwen Mi, China scholarship council, 202006090226, Yongchao Zhang, natural sciences and engineering research council of Canada, RGPIN-2016-0471, Abdolhamid Akbarzadeh, Canada research chairs, Multifunctional Metamaterials, Abdolhamid Akbarzadeh.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Cai, J., Mi, C. et al. Effect of surface residual stress and surface layer stiffness on mechanical properties of nanowires. Acta Mech 233, 233–257 (2022). https://doi.org/10.1007/s00707-021-03112-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03112-3