Abstract

In the present work, based on the Dugdale criterion, a closed-form theoretical crack tip driving force model of simple expressions was proposed for static and fatigue crack propagation along a linear yield strength gradient (YSG). Qualitative and quantitative analyses of the YSG effect on the crack tip driving force are given. The crack tip driving force depends on the yield strength at the crack tip, the YSG within the plastic zone and the applied load. A positive (or negative) YSG has a shielding (or amplifying) effect on the crack tip driving force. A difference of material-toughening mechanisms between smooth and sharp strength gradient was revealed both theoretically and numerically. In the linear YSG case, when a fatigue crack propagates along the YSG at a constant applied cyclic crack tip stress intensity factor, the cyclic crack tip opening displacement decreases (or increases) when the crack propagates towards a higher (or lower)-strength region; however, the cyclic crack tip stress intensity factor increases, no matter when the crack propagates towards a higher- or lower-strength region. This abnormal phenomenon causes theoretical and experimental challenges for characterizing the smooth strength gradient effect on the crack tip driving force.

Similar content being viewed by others

Abbreviations

- a :

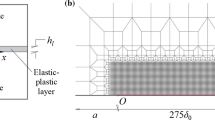

-

Distance between crack tip and interface

- \(C_{\mathrm{inh}}\) :

-

Additional material inhomogeneity term

- CPS8:

-

8-Node biquadratic plane stress quadrilateral element

- CT:

-

Compact tension

- CTOD:

-

Crack tip opening displacement

- DCB:

-

Double cantilever beam

- E :

-

Young’s modulus

- FCP:

-

Fatigue crack propagation

- FEM:

-

Finite element method

- \(G_{\mathrm{applied}}\) :

-

Applied energy release rate

- J :

-

J-integral

- \(J_{\mathrm{applied}}\) :

-

Applied J-integral

- \(J_{\mathrm{tip}}\) :

-

Crack tip J-integral

- k :

-

Yield strength gradient

- K :

-

Stress intensity factor

- \(K_{\mathrm{applied}}\) :

-

Applied stress intensity factor

- \(K_{\mathrm{cohesive}}\) :

-

Cohesive stress intensity factor

- \(K_{\mathrm{tip}}\) :

-

Crack tip stress intensity factor

- l :

-

Distance between interface and mathematical crack tip

- \(p_{\infty }\) :

-

Monotonic far field load

- \(P_{\mathrm{applied}}\) :

-

Applied load per thickness

- \(r_{\mathrm{hom}}\) :

-

Crack tip plastic zone size (or Dugdale cohesive zone size) in homogeneous material

- r :

-

Crack tip plastic zone size (or Dugdale cohesive zone size) in YSG case

- \(r^{\prime }\) :

-

Radius of crack tip circular plastic zone

- v :

-

Poisson’s ratio

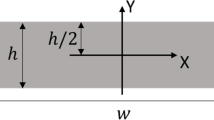

- W :

-

Specimen width

- YSG:

-

Yield strength gradient

- \(\alpha \) :

-

Ratio of crack length to specimen width

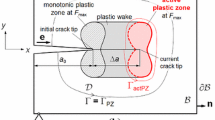

- \(\varGamma _{\mathrm{cz}}\) :

-

Integration contour for J-integral

- \(\delta \) :

-

Crack opening displacement

- \(\Delta \) :

-

Parameter under cyclic or fatigue load

- \(\varphi (z)\) :

-

Complex potential

- \({\sigma }^{\mathrm{A}}\) :

-

Yield stress of material A in plane stress condition

- \(\sigma ^{\mathrm{B}}\) :

-

Yield stress of material B in plane stress condition

- \(\sigma _{\mathrm{s}}\) :

-

Yield stress

- \(\sigma _{0}\) :

-

Cohesive stress at crack tip

- \(\upsilon \) :

-

Crack opening displacement in the y direction from the crack axis in the cohesive zone

References

Zhao, P., Guo, S., Liu, G., Chen, Y., Li, J.: Fast fabrication of W–Cu functionally graded material by high-gravity combustion synthesis and melt-infiltration. J. Nucl. Mater. 445(1), 26–29 (2014)

Liu, T.-J., Wang, Y.-S.: Axisymmetric frictionless contact problem of a functionally graded coating with exponentially varying modulus. Acta Mech. 199(1–4), 151–165 (2008)

Kapuria, S., Kumari, P., Nath, J.: Efficient modeling of smart piezoelectric composite laminates: a review. Acta Mech. 214(1–2), 31–48 (2010)

Bhattacharyya, A., Subhash, G., Arakere, N.: Evolution of subsurface plastic zone due to rolling contact fatigue of M-50 NiL case hardened bearing steel. Int. J. Fatigue 59, 102–113 (2014)

Trudel, A., Sabourin, M., Lévesque, M., Brochu, M.: Fatigue crack growth in the heat affected zone of a hydraulic turbine runner weld. Int. J. Fatigue 66, 39–46 (2014)

Suresh, S., Sugimura, Y., Tschegg, E.: The growth of a fatigue crack approaching a perpendicularly-oriented, bimaterial interface. Scr. Metall. Mater. 27(9), 1189–1194 (1992)

Sugimura, Y., Grondin, L., Suresh, S.: Fatigue crack growth at arbitrary angles to bimaterial interfaces. Scr. Metall. Mater. 33(12), 2007–2012 (1995)

Sugimura, Y., Lim, P., Shih, C., Suresh, S.: Fracture normal to a bimaterial interface: effects of plasticity on crack-tip shielding and amplification. Acta Metall. Mater. 43(3), 1157–1169 (1995)

Pippan, R., Flechsig, K., Riemelmoser, F.: Fatigue crack propagation behavior in the vicinity of an interface between materials with different yield stresses. Mater. Sci. Eng. A 283(1), 225–233 (2000)

Jiang, F., Deng, Z., Zhao, K., Sun, J.: Fatigue crack propagation normal to a plasticity mismatched bimaterial interface. Mater. Sci. Eng. A 356(1), 258–266 (2003)

He, J.-W., Jia, M., Wen, S.-P., Li, N.: Cracking in the soft interface layer of an Al-alloy laminate. Int. J. Fatigue 25(5), 421–426 (2003)

Ukadgaonker, V.G., Bhat, S., Jha, M., Desai, P.: Fatigue crack growth towards the weld interface of alloy and maraging steels. Int. J. Fatigue 30(4), 689–705 (2008)

Velu, M., Bhat, S.: Experimental investigations of fracture and fatigue crack growth of copper-steel joints arc welded using nickel-base filler. Mater. Des. 67, 244–260 (2015)

Kim, A., Suresh, S., Shih, C.: Plasticity effects on fracture normal to interfaces with homogeneous and graded compositions. Int. J. Solids Struct. 34(26), 3415–3432 (1997)

Kim, A., Besson, J., Pineau, A.: Global and local approaches to fracture normal to interfaces. Int. J. Solids Struct. 36(12), 1845–1864 (1999)

Kolednik, O., Predan, J., Fischer, F.D.: Reprint of “Cracks in inhomogeneous materials Comprehensive assessment using the configurational forces concept”. Eng. Fract. Mech. 77(18), 3611–3624 (2010)

Pippan, R., Riemelmoser, F.: Fatigue of bimaterials. Investigation of the plastic mismatch in case of cracks perpendicular to the interface. Comput. Mater. Sci. 13(1), 108–116 (1998)

Wäppling, D., Gunnars, J., Stahle, P.: Crack growth across a strength mismatched bimaterial interface. Int. J. Fract. 89(3), 223–243 (1998)

Riemelmoser, F.O., Pippan, R.: The J-integral at Dugdale cracks perpendicular to interfaces of materials with dissimilar yield stresses. Int. J. Fract. 103(4), 397–418 (2000)

Bhat, S., Ukadgaonker, V.G.: Dugdale cohesive zone modeling to evaluate J integral at the interface of strength mismatched steels: a simplified numerical approach. Finite Elem. Anal. Des. 46(7), 601–610 (2010)

Bhat, S., Narayanan, S.: A computational model and experimental validation of shielding and amplifying effects at a crack tip near perpendicular strength-mismatched interfaces. Acta Mech. 216(1–4), 259–279 (2011)

Bhat, S., Ukadgaonker, V.G.: Solution of singular integrals in mathematical model of mode I crack near strength mismatched interface. Am. J. Comput. Math. 2(02), 156 (2012)

Bhat, S., Ukadgaonker, V.G.: Finite element modeling of crack tip blunting for estimation of energy release rate component of mode I crack near a strength mismatched interface. Appl. Math. 4(05), 1 (2013)

Bhat, S.: Tip parameter approximation and fatigue growth of crack towards inclined weld interface between strength mismatched steels. Int. J. Damage Mech 20, 752–782 (2010)

Bhat, S., Ukadgaonker, V.G.: A refined theoretical model for mode I crack near the interface of strength and plasticity mismatched materials in K dominant regime. Int. J. Damage Mech 24(8), 1194–1213 (2015)

Simha, N., Fischer, F., Kolednik, O., Chen, C.: Inhomogeneity effects on the crack driving force in elastic and elastic–plastic materials. J. Mech. Phys. Solids 51(1), 209–240 (2003)

Simha, N., Fischer, F., Kolednik, O., Predan, J., Shan, G.: Crack tip shielding or anti-shielding due to smooth and discontinuous material inhomogeneities. Int. J. Fract. 135(1–4), 73–93 (2005)

Kolednik, O., Predan, J., Shan, G., Simha, N., Fischer, F.: On the fracture behavior of inhomogeneous materials—a case study for elastically inhomogeneous bimaterials. Int. J. Solids Struct. 42(2), 605–620 (2005)

Kahl, M., Reifsnider, K.: Influence of local variations of yield strength on plastic zones at crack tips. Eng. Fract. Mech. 4(4), 653–664 (1972)

Reifsnider, K., Kahl, M.: Effect of local yield strength gradients on fatigue crack propagation. Int. J. Mech. Sci. 16(2), 105–119 (1974)

Kermanidis, A., Pantelakis, S.: Fatigue crack growth analysis of 2024 T3 aluminium specimens under aircraft service spectra. Fatigue Fract. Eng. Mater. Struct. 24(10), 699–710 (2001)

Kermanidis, A., Pantelakis, S.G.: Prediction of crack growth following a single overload in aluminum alloy with sheet and plate microstructure. Eng. Fract. Mech. 78(11), 2325–2337 (2011)

Predan, J., Gubeljak, N., Kolednik, O.: On the local variation of the crack driving force in a double mismatched weld. Eng. Fract. Mech. 74(11), 1739–1757 (2007)

Kolednik, O., Predan, J., Gubeljak, N., Fischer, D.F.: Modeling fatigue crack growth in a bimaterial specimen with the configurational forces concept. Mater. Sci. Eng. A 519(1), 172–183 (2009)

Rakin, M., Kolednik, O., Medjo, B., Simha, N., Fischer, F.: A case study on the effect of thermal residual stresses on the crack-driving force in linear-elastic bimaterials. Int. J. Mech. Sci. 51(7), 531–540 (2009)

Sistaninia, M., Kolednik, O.: Effect of a single soft interlayer on the crack driving force. Eng. Fract. Mech. 130, 21–41 (2014)

Kolednik, O., Zechner, J., Predan, J.: Improvement of fatigue life by compliant and soft interlayers. Scr. Mater. 113, 1–5 (2016)

Kolednik, O., Suresh, S.: The influence of the yield strength gradient on the fracture resistance in FGMs. In: Materials science forum (1999), pp. 963–970. Trans Tech Publ

Kolednik, O.: The yield stress gradient effect in inhomogeneous materials. Int. J. Solids Struct. 37(5), 781–808 (2000)

Nazari, A., Mohandesi, J.A., Riahi, S.: Modeling fracture toughness of functionally graded steels in crack arrester configuration. Comput. Mater. Sci. 50(4), 1578–1586 (2011)

Nazari, A., Mohandesi, J.A., Riahi, S.: Fracture toughness of functionally graded steels. J. Mater. Eng. Perform. 21(4), 558–563 (2012)

Yang, B., Zhang, K., Chen, G., Luo, G., Xiao, J.: A quantitative analysis of the effect of laser transformation hardening on crack driving force in steels. Surf. Coat. Technol. 201(6), 2208–2216 (2006)

Yang, B.-Q., Zhang, K., Chen, G.-N., Luo, G.-X., Xiao, J.-H.: Effect of a laser pre-quenched steel substrate surface on the crack driving force in a coating-steel substrate system. Acta Mater. 55(13), 4349–4358 (2007)

Dugdale, D.: Yielding of steel sheets containing slits. J. Mech. Phys. Solids 8(2), 100–104 (1960)

Tada, H., Paris, P.C., Irwin, G.R.: The stress analysis of cracks handbook. Del Research Corporation, St. Louis (1985)

Rice, J.R.: A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 35(2), 379–386 (1968)

Rice, J.R.: Mechanics of crack tip deformation and extension by fatigue. ASTM STP 415, 247–309 (1967)

Suresh, S., Sugimura, Y., Tschegg, E.K.: The growth of a fatigue crack approaching a perpendicularly-oriented, bimaterial interface. Scr. Metall. Mater. 27(9), 1189–1194 (1992)

Siegmund, T., Bo, W.: Simulation of fatigue crack growth at plastically mismatched bi-material interfaces. Int. J. Plast. 22(9), 1586–1609 (2006)

ASTM Standard: E647-13a. Standard test method for measurement of fatigue crack growth rates (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shang, YB., Shi, HJ., Wang, ZX. et al. A crack tip driving force model for mode I crack propagation along linear strength gradient: comparison with the sharp strength gradient case. Acta Mech 227, 2683–2702 (2016). https://doi.org/10.1007/s00707-016-1628-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-016-1628-z